E-ENTERPRISE: AWARENESS AND IMPLEMENTATION OF

TRANSPARENT FACTO

RY IN SOUTH EAST ASIA

Gobbi.R

1

, Abu Hassan

2

, Manimaran.B

3

, S. H. Chua

3

, Shanmugavel.S

3

, Josia.A

4

1

Faculty of Engineering, Multimedia University, Jalan Multimedia, 63100, Cyberjaya,Malaysia

2

University of Kuala Lumpur, Kuala Lumpur, Malaysia

3

Schneider Electric Industries (M) S.B. 11, Jalan U1/19, Seksyen U1, Hicom-Glenmarie Ind. Park, Shah Alam, Malaysia

4

Schneider Electric (Industries). Plot 4B no.1-2, Lemah Abang, Bekasi 17550, Jawa Barat, Indonesia

Keywords: E-business solution, Programmable logic

controller, TCP/IP, Transparent Factory.

Abstract: Three strategies, which denoted as M

3

A, Management Automation, Marketing Automation and

Manufacturing Automation have to be jointly incorporated to confront the more competitive market. An

answer to these needs, transparent factory (TF), which is an open automation framework, based on internet

technologies that provide seamless communication between plant floor and business system has been

introduced by Schneider Electric. Despite the good work and technology introduced, the acceptance is only

significant in United States, Europe and Africa. Hence, this paper is to look into the awareness of the TF in

South East Asia (SEA) in particular. A particular reference to oil & gas plant in Indonesia, which had the

system implemented recently, and a waste treatment plant in Malaysia will be highlighted in this paper.

1 INTRODUCTION

Business goes borderless as every entity within the

business units such as production line, management

system, information system etc. are forced to

integrate for effective agile manufacturing system.

The needs for flexibility due to demand, supply,

product, process and workforce and equipment

variability forces companies to transform their

current manufacturing system into more lean

production system or Big just in time (JIT).Two case

studies are presented here and they are divided into

three, namely pre-implementation, during

implementation and post-implementation. Some of

the points to be mentioned are the problems faced

which drive the company to implement the

transparent factory (TF).

As for the implementation stage, both case

stu

dies will focus on the local standards, which were

taken into consideration during design. The details

of the local standard specification or common

practices in oil and gas industries in Indonesia will

be elaborated. As a final point, the post

implementation especially on the cost reduction is to

be explained

2 TRANSPARENT FACTORY

Schneider Electric introduces its TF as an open

automation framework based on Internet and

Ethernet technologies that provides seamless

communication between plant floor and business

systems. This new automation system architecture

support enterprise-wide operations, enable

collaboration, and capture and dispense process

knowledge wherever it is required throughout the

enterprise. Adding to this the information and real

time data can easily be accessed from anywhere, at

anytime by authorized users. Another unique aspect

of this factory is the fact that production can be

followed live by the customer. It allows customers to

directly access the wealth of information within the

enterprise that is normally “buried” on the factory

floor in proprietary systems, communications

networks and workstations.

463

R G., Hassan A., B M., H. Chua S., S S. and A. J. (2004).

E-ENTERPRISE: AWARENESS AND IMPLEMENTATION OF TRANSPARENT FACTORY IN SOUTH EAST ASIA.

In Proceedings of the Sixth International Conference on Enterprise Information Systems, pages 463-466

DOI: 10.5220/0002594404630466

Copyright

c

SciTePress

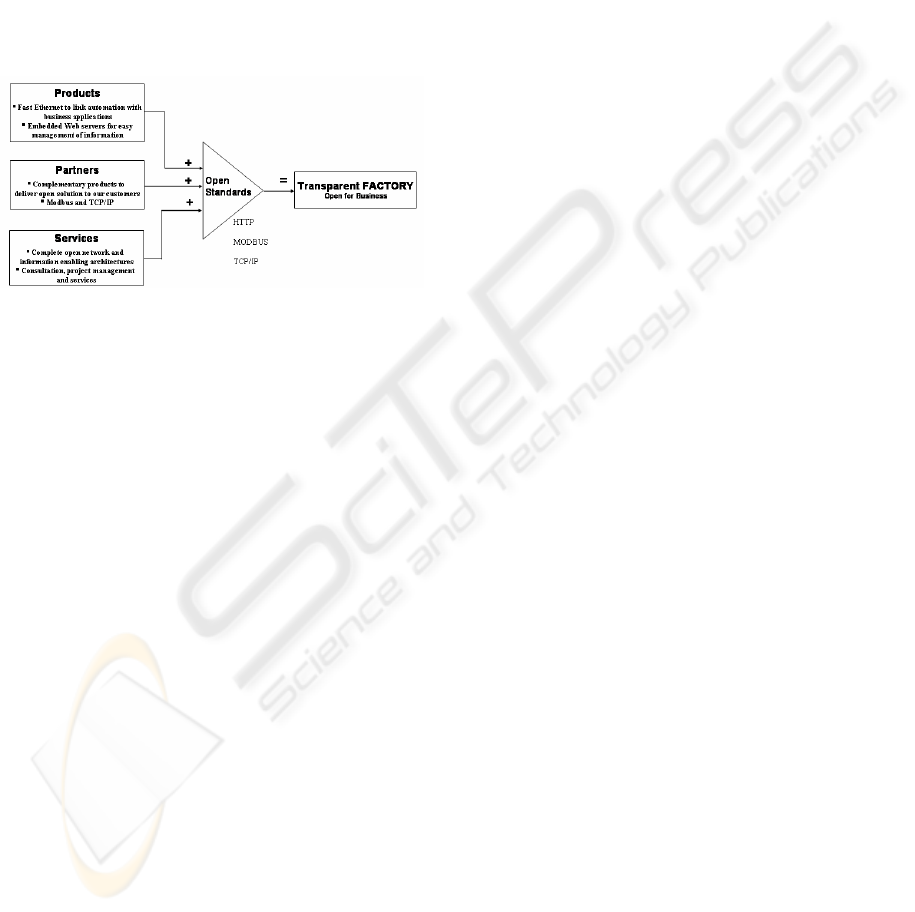

TF solves these issues by developing a three-

stage strategy. There are; Expose programmable

logic controller (PLC) information using open

standards, Interface/integrate automation systems

with business applications such as Enterprise

Requirement Planning (ERP), Develop an open

infrastructure that supports real-time and

determinism behaviors. Figure 1 illustrates the basic

components involved in the TF concept

The benefits of the TF among others are reduced

energy cost by 2-4%, saving on operation coast by

2-5% by avoiding purchase of unnecessary

equipment, reduced downtime by 10% via remote

monitoring and troubleshooting.

Figure 1: TF Concept (Schneider Electric, 2002)

3 AWARENESS

There is a need to move away from hierarchical

organizational structure and functional management

towards a horizontal cellular structure for people to

work effectively, especially in a dynamic

environment with cultural diversity.

Given the intense competition in the world

market today, a greater degree of specialization

among countries seems to be the trend in order to

gain comparative advantage. This in turn leads to

more and larger firms investing in countries where

technical expertise is found. This new trend almost

invariably means companies will increasingly have

to face cross-cultural management. The cellular

structure with its flexibility offers a good way for

such firms to meet this new challenge.

One of the global e-business solution provider

reports that 63% of memberships are owned by Asia

region and 37% represented by the America and

Europe. As Intel implemented the solution, Asia tops

the list among Intel plants for about 65% compare to

North America and Europe about 27% and 8%

respectively (Annual Summary, 2003). Also

mentioned that Asia-based government agencies

have committed funds for implementation

assistance, over US$51 Million through 2003.

Looking at SEA, Malaysia’s government allocated a

US$1.4 Million for the said solution grant, whereas

in Singapore, an authority has approved US$240,000

in funding for the development of the e-learning

center for the e-business solution.

In general, trend in information technology (IT)

usage over the last two years has shown significant

improvement both for primary and support activities.

Significant increase in usage is noted for the

procurement/purchasing activity, after sales service

and inbound logistics. It is observed that companies

are increasingly using IT for both operational as well

as strategic purposes. The application of IT has

clearly shown its effectiveness. IT has enable

companies to provide better services, promote

revenue growth, innovate new products and

processes, and form strategic alliances. The

diffusion of IT across all industries ought to

continue as the nation geared towards the

knowledge-based economy.

It is a huge market in SEA as far as electronic

business is concern. Governments in this region are

putting great effort and to some extend create

competition among them to attract investors into

their country. They believe that electronics related

businesses and manufacturing would capture the

current business world in very near future.

4 CASE STUDY 1

The plant was incorporated on 9

th

December 1991,

operates Malaysia's first integrated scheduled waste

management system. The system constitutes

complete management of scheduled waste from

collection at the waste generator's premises to

transportation, treatment and final disposal.

In line with the implementation of OHSAS

18001, the management has targeted two main

objectives. There are to achieve zero Loss Time

Injury (LTI) and to ensure legal compliance to

related legal and other requirement.

One of the programmes arranged to achieve zero

LTI is Monitoring program for potentially exposed

personnel to radiation. This was found as a

significant hazard and to minimize time spend by

their employees for activities like monitoring,

troubleshooting, data collections etc, TF has been

identified as the best solution by providing remote

access to their monitoring and control devices.

Breakdown minimization has seriously

encouraged the company to implement TF. It is

estimated that for every 1 hour of downtime, the

company has to bear lost of approximately

US$52.6K. With the system installed,

instrumentation staff that takes about 5 hours drive

from hometown in the case of urgent situation, can

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

464

actually rectify the problem from his hometown

while happily spend time with family. The total cost

to implement the system is insignificant compare to

the total maintenance budget the company spends

annually which is about US$2.63 million.

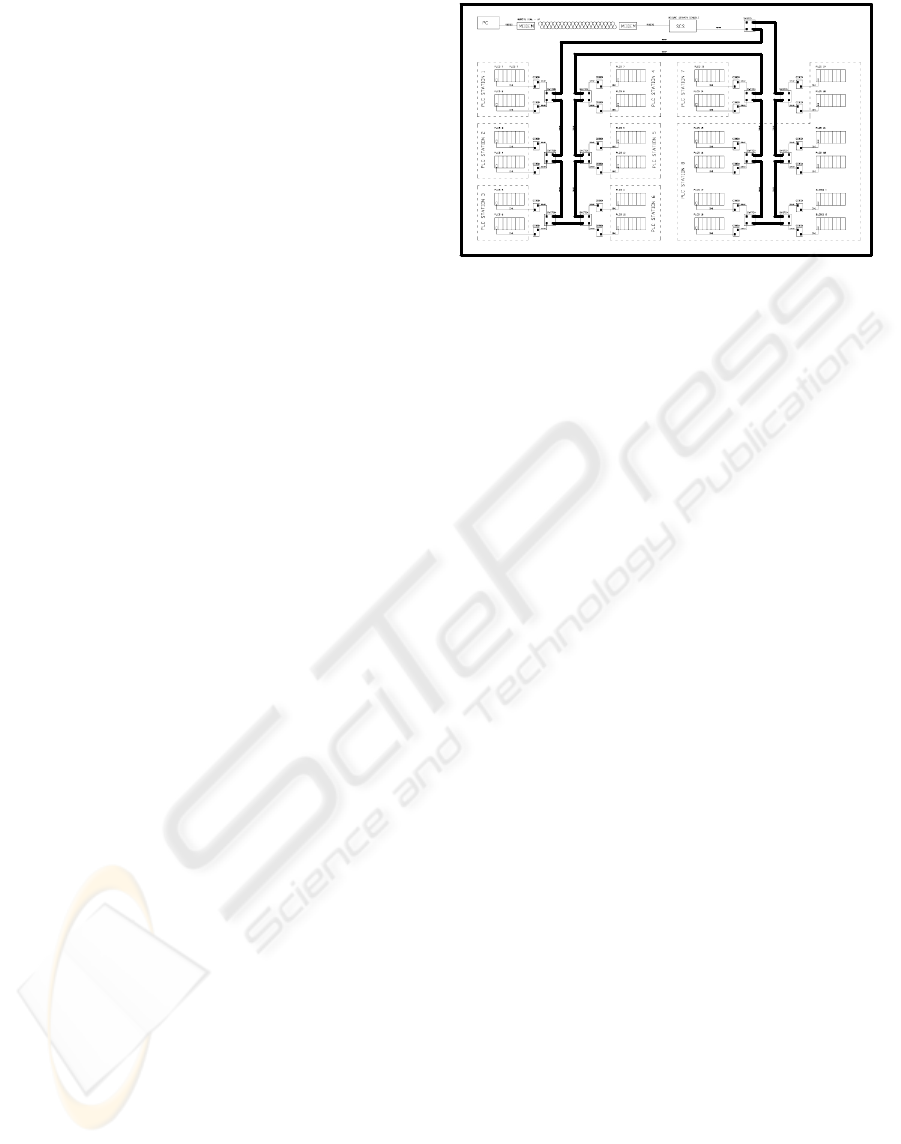

The system consists of a single master radio

modem connected to Human Machine Interaction

(HMI) workstations with PLCs and modems. The

PLCs serve eight stations scatter-ed throughout the

factory limits as shown in figure 2.In the master

station sites' configuration, the Master modem

communicates via remote access server, which in

turn communicates with the 24 PLCs over a 2.5km

fiber optic network. All stations use Schneider’s

Connexium Switches connected directly to PLCs via

a RS232 to Ethernet converter. The system runs at

19,200-baud rate via RS232 and 10Mega-baud rate

via Ethernet TCP/IP. The HMI system provides

monitoring and control of all stations to operators at

a Central Control Center.

Plans include connecting the current system to a

Wide Area Network (WAN) to further extend access

to the remote sites. One of the features that is most

useful is the ability to remotely monitor any of the

PLCs over a web browser via a Schneider’s

Embedded web-server from the host workstation.

This SCADA (Supervisory Control and Data

Acquisition) succeeds two previously installed radio

systems, neither of which operated acceptably.

Schneider Automation's TF’s architecture

provides seamless communication between Ethernet

and Control network. Now with Schneider Electric’s

embedded web servers, industrial plants may gain

the benefits of TF without additional cable

installation. Designed for control, configuration and

data collection applications, the TF architecture adds

broad capability to Ethernet in PLC systems. By

providing a highly reliable Ethernet connection,

peripherals may communicate on the plant network

without the expense and delay of cable installation.

The wireless connectivity also solves the

problem of communicating to devices where cable

workstations and devices installed on moving

platforms. In the past, these devices would be

isolated from the plant network. For example, a

portable PC may now connect to the network

virtually anywhere in the plant. This permits plant

engineers to work at the problem location while

having full access to the network

Figure 2: The Plant Remote Access System

5 CASE STUDY 2

In line with the end user’s initiative to achieve

operational excellence, they have chosen the TF

concept for the following reasons. First, Global data

access, as data is made available at any time and

able to be assessed from anywhere through internet,

it minimizes unnecessary travel to remote site. It

also improves quality management as the plant is

controlled in every aspect including the production

and productivity.

As the site is located about 150 km from the

office and the journey to the field is not comfortable.

It is a good idea to monitor, maintain the system

remotely from the office, and reduces the trips to the

field. Secondly, Standard based architecture which

obviously reliable and it enables collaboration,

lowers total cost of ownership, reduce training cost,

and widely applicable skill sets. The end users are

able to bring application online faster hence

maximize Return of Investment.

Third, Scalable, Publish-subscribe technology

that supports deterministic many-to-many

communications and synchronization of distributed

application. It allows efficient utilization of available

bandwidth. Fourth, Seamless Integration with

existing system without significant additional cost

contributes towards efficient utilization of

communication networks. The existing Area-1

system is using Modbus and Modbus Plus Network.

Area 2 & area 3 are using Modbus TCP/IP through

embedded web server module (NOE), complete with

web support. Area 2 consists of the following

system: Water injection system PLC, MCC for water

injection system and Vibration Monitor systems.

Whereas, Area 3 consists of the following system;

Oil shipping system PLC and MCC for Oil shipping

system. The detail layout is as shown in figure 3.

Remote monitoring through close circuit TV

(CCTV) in remote area 2 &3 is achieved over the

coaxial link into the multiplexer to be displayed on

E-ENTERPRISE: AWARENESS AND IMPLEMENTATION OF TRANSPARENT FACTORY IN SOUTH EAST ASIA

465

the surveying monitor in KB control room. These

signals are also being conveyed onto the local LAN.

The seamless integration of Area-2 &3 with

Area-1 through Modbus TCP/IP, Modbus plus and

Modbus network allows the information flows freely

anywhere in the system. SCADA for Water Source

Well & Production Well is using Serial Radio

Communication. There are about 60 wells are

monitored and controlled. These wells are spread

around the site for about 20 km in radius.

Fifth, Maintainable; Internet remote access

offers remote support capabilities including

diagnostics, trouble-shooting, remote alarming,

predictive maintenance , download program or

parameters updates, automatic node recovery,

reconfiguration capability and faulty device

replacement. Poll of support personal located at

centre office can directly access to plant control

system during breakdown to troubleshoot.

Since TCP/IP technology is used in TF, the

system also integrate the existing human machine

interface (HMI) and CCTV through TCP/IP

network. Therefore, user can access the site remotely

using the existing intranet.

Generally, the system consists of two main

SCADA system that are SCADA for Water Source

Well & Production Well and SCADA for Gathering

Station. Both SCADA systems are integrated in one

Server. All data in the server can be accessed

remotely, depends on the user’s password. SCADA

for Gathering Station is based on Modicon Quantum

PLC with TF, enhanced with HMI, Vibration

Monitor, CCTV Monitor, etc.

6 CONCLUSION

In this paper, the concept of TF has been explained

in simple manner with typical application examples.

The initial cost has not been mentioned in this paper

even though it is the main criterion for any

organization to decide on the possible imple-

mentation, of TF. Notwithstanding an obvious high

preliminary cost the concept has been proven of its

competence on providing complete solution to the

entire enterprise’s efficiency in a long run. Also

presented that in order to implement more flexible

and effective business, government in SEA is

pumping millions of money in for the past few

years. Two case studies presented clearly show that

TF will be accepted gradually in South East Asia. As

business gets borderless, TF will indeed the best

solution for productivity, safety & health and

ultimately for the overall enterprise’s efficiency.

Figure 3 : Detail Layout

REFERENCES

Annual Summary Report 2203/2003. Rosettanet.

http://www.resettnet.com/

John. F. V and Steven Floyd., 2001. Towards Modeling

the effect of national culture on IT implementation and

acceptance. Journal of Information Tech. 2001,16,

pp145-158. 2001

Karin Brue, C.J.Hemingway and

M.Strathern.,2001.Workforce agility: the new

employee strategy for the knowledge economy.

Journal of Info. Tech.. 2001,17, pp21-31.2001

Lee Peng, Tan & John. K.C. Tan. 2002. Organizing For

Cross-Cultural Project Mgmt in a Globalized

Economy. Journal of the Malaysia Institute of Mgmt.

Dec. 2002. Vol. 37. No. 2 pp 70-77

Schneider Electric. TF : Internet-based Technologies for

the Factory Floor. Product Catalogue. April 2002..

Smith.B.L., Miller.,2002. Software Development Cost

Estimation for Infrastructure Systems. Journal of

Mgmt in Eng. July 2002. pp 104-109.

Sou Khong, Yow.,2000. Survey Report on Information

Tech. (IT) Applications In The Service Sector. Journal

Productivity. Dec. 2000, pp 55-6

ICEIS 2004 - SOFTWARE AGENTS AND INTERNET COMPUTING

466