A FUZZY PARAMETRIC APPROACH FOR THE MODEL-BASED

DIAGNOSIS

F. Lafont

1

, N. Pessel

1

and J. F. Balmat

2

LSIS, UMR CNRS 6168, University of South-Toulon-Var

1

IUT of Toulon,

2

Faculty of Sciences and Techniques

B.P 20132, 83957 La Garde Cedex, France

Key

words: Adaptive model, fuzzy sy

stem models, diagnosis, Fault Detection and Isolation (FDI).

Abstract: This paper presents a new approach for the model-based diagnosis. The mode

l is based on an adaptation

with a variable forgetting factor. The variation of this factor is managed thanks to fuzzy logic. Thus, we

propose a design method of a diagnosis system for the sensors defaults. In this study, the adaptive model is

developed theoretically for the Multiple-Input Multiple-Output (MIMO) systems. We present the design

stages of the fuzzy adaptive model and we give details of the Fault Detection and Isolation (FDI) principle.

This approach is validated with a benchmark: a hydraulic process with three tanks. Different defaults

(sensors) are simulated with the fuzzy adaptive model and the fuzzy approach for the diagnosis is compared

with the residues method. The first results obtained are promising and seem applicable to a set of MIMO

systems.

1 INTRODUCTION

The automatic control of technical systems requires

a fault detection to improve reliability, safety and

economy. The diagnosis is the detection, the

isolation and the identification of the type as well as

the probable cause of a failure using a logical

reasoning based on a set of information coming from

an inspection, a control or a test (AFNOR, CEI)

(Noura, 2002 - Szederkényi, 1998). The model-

based diagnosis is largely studied in the literature

(Ripoll, 1999 – Maquin, 1997 – Isermann, 1997).

These methods are based on parameter estimation,

parity equations or state observers. (Ripoll, 1999 -

Maquin, 1997 – Isermann, 2005). The goal is to

generate the indicators of defaults through the

generation of residues (Isermann, 1984).

This paper deals with the problem of the model-

base

d di

agnosis by using a parametric estimation

method. We particularly focus our study on an

approach with an adaptive model. Many methods

exist which enable the design of these adaptive

models (Ripoll, 1999).

Many works tackle the model-based diagnosis

from a fuzzy m

odel of the processes (Querelle et al.,

1996 – Kroll, 1996 – Liu et al., 2005 – Evsukoff et

al., 2000 – Carrasco et al., 2004).

Sala et al. (Sala et al., 2005) notices that

“Hi

g

her decision levels in process control also use

rule bases for decision support. Supervision,

diagnosis and condition monitoring are examples of

successful application domains for fuzzy reasoning

strategies”.

In our work, unlike these approaches, fuzzy

logi

c is used to design the parametric model.

In all cases, for the model-based approaches,

the qu

ality of the fault detection and isolation

depends on the quality of the model.

It is possible to improve the model

id

entification by implementing an original method

based on a parameters adjustment by using a Fuzzy

Forgetting Factor (FFF) (Lafont et al., 2005).

The idea, in this study, is to use the variations

of

the fuzzy forgetting factors for the fault detection

and isolation.

Thus, we propose an original method based on

a fuzzy a

daptation of the parameter adjustments by

introducing a fuzzy forgetting factor.

From these factors (one by output), we can

generat

e residues for the fault detection and

isolation. A numerical example, with several types

of sensors defaults (the bias and the calibration

default), is presented to show the performances of

this method.

25

Lafont F., Pessel N. and F. Balmat J. (2007).

A FUZZY PARAMETRIC APPROACH FOR THE MODEL-BASED DIAGNOSIS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 25-31

Copyright

c

SciTePress

2 A NEW APPROACH: THE

“FUZZY FORGETTING

FACTOR” METHOD

In this section, after having presented the classical

approach for the on-line identification, we present a

new method of adaptation based on the fuzzy

forgetting factor variation.

We consider a non-linear and non-stationary

systems modeling. Consequently, an on-line

adaptation is necessary to obtain a valid model

capable of describing the process and allowing to

realize an adaptive command (Fink et al., 2000). A

common technique for estimating the unknown

parameters is the Recursive Least Squares algorithm

with forgetting factor (Campi, 1994 – Uhl, 2005 –

Trabelsi et al., 2004).

At each moment k, we obtain a model, such as:

( ) ()() ()()

kukBkykAky ..1 +=+

(1)

with the outputs vector and

u

the command

vector,

y

() ()

(

)()

T

kukyk =

ϕ

(2)

()

(

)()

kkky

T

ϕθ

.

ˆ

1

ˆ

=+

(3)

()()()()()(

1...1

ˆ

1

ˆ

+++=+ kkkPkmkk

T

εϕθθ

)

)

(4)

()()(

1

ˆ

11 +

−

+=+ kykyk

ε

(5)

()

()

()

()() ()()

() ()()()

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

+

−=+

kkPkk

kPkkkP

kP

k

kP

T

T

ϕϕλ

ϕϕ

λ

1

1

(6)

with the estimated parameters vector

(initialized with the least-squares algorithm),

()

k

θ

ˆ

()

k

ϕ

.

the regression vector,

(

1+k

)

ε

the a-posterior

error, the gain matrix of regular adaptation and

()

kP

()

k

λ

the forgetting factor.

If the process is slightly excited, the gain matrix

increases like an exponential (Slama-

Belkhodja and de Fornel, 1985). To avoid this

problem, and the drift of parameters, a measure

is introduced as:

()

kP

()

km

()

(

)()

u

S

u

kuku

ifkm >

−+

=+

max

1

11

(7)

or

( ) () ()

y

n

T

S

y

kkky

if >

−+

ϕθ

.

ˆ

1

(8)

()

(

)()

u

S

u

kuku

ifkm <

−+

=+

max

1

01

(9)

and

( ) () ()

y

n

T

S

y

kkky

if <

−+

ϕθ

.

ˆ

1

(10)

with the nominal value of

.

n

y

y

The adaptation is suspended as soon as the input

becomes practically constant and/or as soon as the

output reaches a predefined tolerance area from

the thresholds and/or . In the opposite case,

and/or when a disturbance is detected on the input,

the adaptation resumes with .

y

y

S

u

S

()

1=km

The adaptation gain can be interpreted like a

measurement of the parametric error. When an

initial estimation of the parameters is available, the

initial gain matrix is:

(

)

IGP .0

=

(11)

With

1

<

<G

or and

1<Trace

I

: identity

matrix.

We choose as initial values:

()

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

1.0000

01.000

001.00

0001.0

0P

(12)

and

(

)

96.00

=

λ

(13)

2.1 Methods of the Forgetting Factor

Variation

The considered class of the system imposes to use a

method with a variable forgetting factor in order to

take into account the non-stationarity of the process.

Generally, the adaptation of a model is obtained

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

26

by using a Recursive Least Squares algorithm with

forgetting factor. The forgetting factor can be

constant or variable.

There are different classical methods of the

forgetting factor variation as, for example, the

exponential forgetting factor. The variation of

λ

is

defined as:

() ()(

00

1.1

)

λ

λ

λ

λ

−+=+ kk

(14)

where

0 1

0

<<

λ

(15)

with the typical values:

()

99,0...95,00;99,0...95,0

0

==

λ

λ

(16)

This method consists in increasing

λ

to 1

rapidly.

Andersson proposes to modify the gain matrix

of the Recursive Least Squares algorithm to

improve the model (Andersson, 1985). This method

introduces an Adaptive forgetting Factor through

Multiple Models (AFMM) in considering the RLS

algorithm as a special case of the Kalman filter.

is approximated with a sum of many

Gaussian density functions. Moreover, when the

process is subjected to jumps, this method enables us

to reduce the importance of the gain matrix

(

1+kP

)

)(

1

ˆ

+k

θ

(

)

1

+

kP

in adjusting a parameter.

A new identification algorithm, inspired by these

two methods (exponential and Andersson), is

proposed. This approach presents a Fuzzy Forgetting

Factor (Lafont et al., 2005).

2.2 The Proposed Approach

We use fuzzy logic to modify the forgetting factor in

an automatic and optimal way (Jager, 1995). Thus,

we have defined a «fuzzy box» of Mamdani type by

using the following variables:

()

k

λ

and

(

)

k

ε

Δ

in

input and

(

1+k

)

λ

in output (Figure 1).

Figure 1: Fuzzy box.

()

k

ε

Δ

represents the variation of the mean error on

the N last samples:

() () ( )()

∑

+−=

−−=Δ

k

Nkj

jj

N

k

1

1

1

εεε

(17)

(

)

k

ε

Δ

had been defined with three membership

functions: one for the negative error, one for the null

error and one for the positive error (Figure 2). A

study of observed process allows to determine the

values:

{

}

maxminminmax

;;;

η

η

η

η

−

−

.

Negative PositiveNull

0

−η η−η η

1

0

min min maxmax

Figure 2: Fuzzyfication of the error variation.

The membership functions of the input

()

k

λ

and

the output

(

)

1

+

k

λ

are identical (Figure 3).

According to the application, the bounds [0.8 ; 1]

can be reduced.

Small GreatMean

0.90.8 10.85 0.95

1

0

Figure 3: Fuzzyfication of the lambda.

The inference rules are based on the variation

method of the exponential forgetting factor. In this

case, the forgetting factor must be maximum when

the modeling of the system is correct (small error

variation). Also, we have been inspired by

Andersson’s work. When there is an important non-

stationarity, the forgetting factor must decrease.

FUZZY MODIFICATION OF FORGETTING FACTOR

(k)

(k)

(k+1)

λ

λ

Δε

If

(

)

k

λ

is and

1

λ

n

F

()

k

ε

Δ

is then

2

ε

n

F

(

)

1

+

k

λ

is , where

3

'

λ

n

F

{

}

1

3

1

2

1

1

1

,, FFFF

n

∈

λ

is the set of

membership functions of the input variable

(

)

k

λ

,

{

}

2

3

2

2

2

1

2

,, FFFF

n

∈

ε

is the set of membership

A FUZZY PARAMETRIC APPROACH FOR THE MODEL-BASED DIAGNOSIS

27

functions of the input variable

(

)

k

ε

Δ

and

{

}

3

3

3

2

3

1

3

'

,, FFFF

n

∈

λ

is the set of membership

functions of

()

1+k

λ

.

The rules for the output

(

1+k

)

λ

are defined in

table 1.

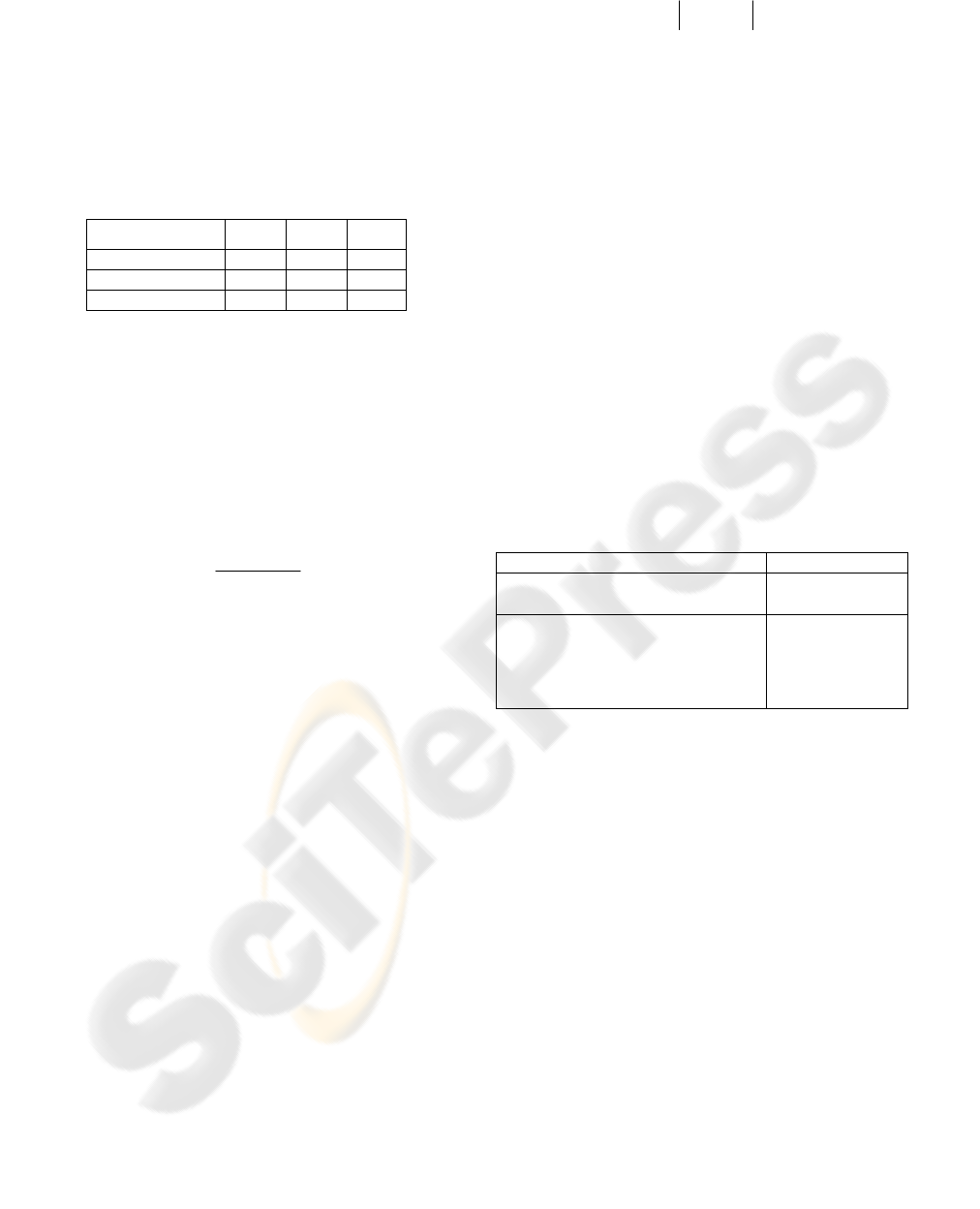

Table 1: Rules for the variation of the forgetting factor.

()

k

ε

Δ

\

()

k

λ

Small Mean Great

Negative Small Mean Great

Null Mean Great Great

Positive Small Small Mean

The inference method is based on the max-min

and the defuzzification is the centre of gravity.

() () () ()

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

⎟

⎠

⎞

⎜

⎝

⎛

= zz

nnn

FFF

3

'

21

,,minminmax

λελ

μνμυμμ

(18)

With to

3

, to and to .

1=

λ

n 1=

ε

n 3 1' =

λ

n 3

()

()

()

∫

∫

=+

dzz

dzzz

k

.

..

1

μ

μ

λ

(19)

The number of forgetting factors is equal to the

number of model outputs.

3 GENERATION OF RESIDUES

AND DECISION-MAKING

3.1 Classical Method

The residuals are analytical redundancy generated

measurements representing the difference between

the observed and the expected system behaviour.

When a fault occurs, the residual signal allows to

evaluate the difference with the normal operating

conditions.

The residuals are processed and examined under

certain decision rules to determine the change of the

system status. Thus, the fault is detected, isolated (to

distinguish the abnormal behaviours and determine

the faulty component) and identified (to characterize

the duration of the default and the amplitude in order

to deduce its severity).

A threshold between the outputs of the system

and the estimated outputs is chosen in order to

proceed to the decision-making.

The residues

(

)

jjj

yyr

ˆ

−=

are calculated to

estimate the case where there is no failure and the

case of sensor default. A threshold is taken: if

t

0

=

≤

jj

rthentr

.

At each instant

k

, the different are checked

in order to establish a diagnosis.

j

r

3.2 Approach with Fuzzy Lambda

Our method uses the fuzzy lambda to detect and

isolate a default on a sensor. For the MIMO system,

the algorithm generates one lambda for each output.

Let

j

λ

, with

1

=

j

to

n

, : number of outputs.

n

The residues

jj

r

λ

−

=

1'

are calculated to

estimate the case where there is no failure and the

case of sensor default. A threshold is taken: if

't

0'''

=

≤

jj

rthentr

.

At each instant , the different are checked

in order to establish a diagnosis as shown in table 2.

k

j

r'

Table 2: Analysis of residues.

Analysis of residues Diagnosis

0',

=

∀

j

rj

No failure

{}

0',''

,0'

≠=

≠

∃

j

j

rrindext

r

oneonlyandoneIf

Sensor default

4 APPLICATION

4.1 Benchmark Example: A Hydraulic

Process (Jamouli, 2003)

The approach proposed previously has been

validated on a benchmark: a hydraulic process. This

system is a hydraulic process composed of three

tanks (Figure 4). The objective of the regulation is to

be able to have a constant volume of the fluid. The

three tanks have the same section: .

S

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

28

() () () ()

()

∑

=

+=

N

k

TT

kuRkukxQkxJ

0

.....

2

1

(23)

Figure 4: A hydraulic process.

(

)

(

)

kxKku .

−

=

(24)

As shown in section 2, for each output, a

forgetting factor is assigned.

1

λ

,

2

λ

and

3

λ

vary

independently in function of the error between the

process outputs and the model outputs.

For this application, the values

min

η

and

max

η

,

described in section 2.2, are respectively 1.25 and

10. The model is adapted to follow the process

behaviour.

The physical model of this system is obtained

with the difference between the entering and

outgoing flows which make evolve the level of each

tank.

4.2 Sensors Defaults

For the sensors, two types of defaults have been

tested: the bias and the calibration default. The

simulation of the bias default has been carried out by

substracting a constant value

β

from the real value:

for example

β

−

=

sensorreal

hh

11

.

The state model is described by:

UDXCY

UBXAX

..

..

+=

+=

(20)

The simulation of the calibration default is

obtained by multiplying the real value by a

coefficient

γ

: for example

γ

*

11 sensorreal

hh =

.

[][

XYand

qqUhhhX

TT

=

==

21321

,

]

(21)

The environment of the supervision enables to

see the good detection of defaults. As soon as a

failure is detected, the algorithm stops and indicates

which sensor has a default (Figure 5). The physical

model is represented by the dotted line curve and the

parametric model by the solid line curve. For this

example, the default is simulated, at sample 10, on

the sensor h

1

. The diagnosis is depicted by a circle

on figure 5. The algorithm has detected the default at

sample 12.

The vector of outputs is the same as the state

vector and, thus, the observation matrix

C

is an

identity matrix with a size 3x3.

This system, considered as linear around a

running point, has been identified in using an ARX

structure. The discrete model is obtained by using a

sample period equal to 0.68 seconds.

The model describes the dynamical behaviour of

the system in terms of inputs/outputs variations

around the running point

(

)

00

YU

.

We have simulated the classical method and our

approach with the bias default and the calibration

default for the three sensors (h

1

, h

2

, h

3

). To compare

these two methods, we vary the values

β

and

γ

.

() ( )

TT

YU 20030040018.0

00

==

( ) () ()

() () () ()

knokuDkxCky

kuBkxAkx

dd

dd

++=

+=+

..

..1

(22)

4.3 Results

In table 3 and table 4, we show the performances of

the two methods. For this, we define a rate which is

the percentage of detection on 100 tests.

The sensors noise

(

)

kno

considered is a normal

distribution with mean zero and variance one.

This system is completely observable and

controllable.

A quadratic linear control, associated to an

integrator, enables to calculate the feedback gain

matrix

K

from the minimization of the following

cost function:

A FUZZY PARAMETRIC APPROACH FOR THE MODEL-BASED DIAGNOSIS

29

Figure 5: Supervision.

We can note that the fuzzy method gives better

results. Indeed, when the default is weak (

β

<7 or

γ

>0.97), the rate of detection is more important.

On the other hand, the results are similar. To

improve the detection with the classical method, the

threshold t could be decreased but that implies an

important rate of false alarm. Indeed, if the threshold

is weaker than the importance of the noise, the

algorithm stops in an inopportune way.

Table 3: Rate of detection for the bias default.

β

Bias default

Rate of detection in

percentage

4 5 6 7 8

Classical

method

Threshold:

t= 5.

5

h

1

h

2

h

3

6

6

22

42

42

42

88

80

80

98

100

90

100

100

100

Fuzzy method

Threshold:

t'= 0.1

h

1

h

2

h

3

64

76

86

84

92

92

100

98

98

100

100

100

100

100

100

Table 4: Rate of detection for the calibration default.

γ

Calibration default

Rate of detection in

percentage

0.99 0.98 0.97 0.96

Classical

method

Threshold:

t= 5.

5

h

1

h

2

h

3

24

2

0

100

84

8

100

100

80

100

100

98

Fuzzy method

Threshold:

t'= 0.1

h

1

h

2

h

3

70

48

36

100

100

68

100

100

92

100

100

100

4.4 Sensitivity to the Measure Noise

The measure noise has a great significance on the

fault detection. The presented values are the minimal

values which the method can detect.

In the case where the measure noise is more

important, these results can be upgraded by

modifying the values

min

η

and

max

η

defined in

section 2.2. If the measure noise is very large, it is

necessary to increase these initial values. By doing

that, a tolerance compared with the noise is

admitted. A compromise should be found between

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

30

the noise level and the variation of

min

η

and

max

η

.

Indeed, the algorithm can detect a false alarm.

5 CONCLUSIONS

This paper presents an original method of model-

based diagnosis with a fuzzy parametric approach.

This method is applicable to all non-linear MIMO

systems for which the knowledge of the physical

model is not required. We define a Fuzzy Forgetting

Factor which allows to improve the estimation of

model parameters, and to detect and isolate several

types of faults. Thus, the fuzzy adaptation of the

forgetting factors is used to detect and isolate the

sensor fault. The results are illustrated by a

benchmark system (a hydraulic process) and

comparisons between the classical method and this

method is depicted in table 3 and table 4.

The method is efficient to detect and isolate only

one sensor default at the same moment. The

proposed approach is able to detect faults which

correspond to a bias and a calibration default for a

sensor.

A possible extension would be to determine the

values

min

η

and

max

η

, described in section 2.2, in

an automatic way according to the sensor noise.

Moreover, it would be interesting to develop the

FFF method for the actuator defaults.

REFERENCES

Andersson, P., 1985. Adaptive forgetting in recursive

identification through multiple. In. Proc. Int. J.

Control, pp. 1175-1193.

Campi, M., 1994. Performance of RLS Identification

Algorithms with Forgetting Factor: A Φ-Mixing

Approach, Journal of Mathematical Systems,

Estimation, and Control, Vol. 4, N° 3, pp. 1-25.

Carrasco, E. F., Rodriguez, J., Punal, A., Roca, E., Lema,

J. M., 2004. Diagnosis of acidification states in an

anaerobic wastewater treatment plant using a fuzzy-

based expert system, Control Engineering Practice,

12, pp. 59-64.

Evsukoff, A., Gentil, S., Montmain, J., 2000. Fuzzy

reasoning in co-operative supervision systems,

Control Engineering Practice, 8, pp. 389-407.

Fink, A., Fischer, M., Nelles, O., 2000. Supervision of

Non-linear Adaptive Controllers Based on Fuzzy

Models, Control Engineering Practice, 8(10), pp.

1093-1105.

Isermann, R., 1984. Process fault detection based on

modelling and estimation methods – A survey,

Automatica,vol. 20, n°4, pp. 387-404.

Isermann, R., 1997. Supervision, fault-detection and fault-

diagnosis methods-Advanced methods and

applications, Proc. Of the IMEKO world congress,

New Measurements – Challenges and Visions,

Tampere, Finland, vol. 1, n°4, pp. 1-28.

Isermann, R., 2005. Model-based fault detection and

diagnosis - Status and applications, Annual Reviews in

Control, Elsevier Ltd., pp. 71-85, Vol. 28, No. 1.

Jager, R., 1995. Fuzzy Logic in Control, Thesis

Technische Universiteit Delft, ISBN 90-9008318-9.

Jamouli, H., 2003. Génération de résidus directionnels

pour le diagnostic des systèmes linéaires stochastiques

et la commande tolérante aux fautes, Thesis,

University Henri Poincaré, Nancy 1.

Kroll, A., 1996. Identification of functional fuzzy models

using multidimensional reference fuzzy sets, Fuzzy

Sets & Systems, vol. 8, pp. 149-158.

Lafont, F., Balmat, J. F., Taurines, M., 2005. Fuzzy

forgetting factor for system identification, Third

International Conference on Systems, Signals &

Devices, Volume 1, Systems analysis & Automatic

Control, Sousse, Tunisia, March 21-24.

Liu, G., Toncich, D. J., Harvey, E. C., Yuan, F., 2005.

Diagnostic technique for laser micromachining of

multi-layer thin films, International Journal of

Machine Tools & Manufacture, 45, pp. 583-589.

Maquin, D., 1997. Diagnostic à base de modèles des

systèmes technologiques, Mémoire d’Habilitation à

Diriger des Recherches, Institut National

Polytechnique de Lorraine.

Noura, H., 2002. Méthodes d’accommodation aux défauts:

théorie et application, Mémoire d’Habilitation à

Diriger des Recherches, University Henri Poincaré,

Nancy 1.

Querelle, R., Mary, R., Kiupel, N., Frank, P. M., 1996.

Use of qualitative modelling and fuzzy clustering for

fault diagnosis, Proc. of world Automation Congress

WAC’96, Montpellier, France, vol. 5, n°4, pp. 527-

532.

Ripoll, P., 1999. Conception d’un système de diagnostic

flou appliqué au moteur automobile, Thesis, the

University of Savoie.

Sala, A., Guerra, T. M., Babuska, R., 2005. Perspectives

of fuzzy systems and control, Fuzzy Sets & Systems,

156, pp. 432-444.

Slama-Belkhodja, I., de Fornel, B., 1996. Commande

adaptative d'une machine asynchrone, J. Phys. III, Vol.

6, pp. 779-796.

Szederkényi, G., 1998. Model-Based Fault Detection of

Heat Exchangers, department of Applied Computer

Science University of Veszprém.

Trabelsi, A., Lafont, F., Kamoun, M., Enéa, G., 2004.

Identification of non-linear multi-variable systems by

adaptive Fuzzy Takagi-Sugeno model, International

Journal of Computational Cognition, ISBN 1542-

5908, vol. 2, n° 3, pp. 137-153.

Uhl, T., 2005. Identification of modal parameters for non-

stationary mechanical systems, Arch Appl Mech, 74,

pp. 878-889.

A FUZZY PARAMETRIC APPROACH FOR THE MODEL-BASED DIAGNOSIS

31