PRESSURE BASED INK DIFFUSION MODEL FOR REAL-TIME

SIMULATION OF CHINESE CALLIGRAPHY

Ye Wang and Jon Rokne

Department of Computer Science, University of Calgary, Canada

Keywords:

Non-Photorealistic Rendering, Chinese Calligraphy and Ink Painting, Simulation of Ink Diffusion, Pressure

Based Modeling.

Abstract:

This paper describes a novel approach to simulating Chinese calligraphy for digital image purposes. The

approach includes an ink diffusion model, a multi-layer paper model, a brush model, and the simulation

of special effects. Special attention is given to the ink diffusion effect which is of importance in Chinese

calligraphy. When the ink is deposited onto absorbent paper, it spreads outside the original border of a stroke

since the flow of water will transport carbon particles along the capillary tubes found in the paper. The ink flow

model is based on a new algorithm simulating dynamic ink diffusion into absorbent paper. In this capillary

network based paper model, the pressure at each node can be obtained from Darcy’s law applied to the ink

used in the calligraphy on each edge and it is proportional to the density of capillaries. The deposition layer of

the paper is furthermore used to simulate the deposition of carbon particles into the paper and it is also used to

simulate the washing out effects. Ink effects such as irregular edges and back run effect can also be simulated.

The system is efficient and can create realistic Chinese calligraphy in real-time.

1 INTRODUCTION

Chinese calligraphy and Chinese painting have been

refined over thousands of years into distinctly Orien-

tal artforms. In the past, these artforms could only

be practiced using traditional tools and instruments.

With the advent of the computer, a powerful tool

that can be adapted to a variety of simulation tasks,

these artistic expressions can be simulated in a very

realistic manner. Since these artforms are artistic

expressions of reality they can be considered to be

non-photorealistic expressions, although calligraphy

might also be considered to be a photorealistic expres-

sion since the desired results shown should be as close

to the real ones as possible.

In this paper, an efficient novel approach to simu-

late ink diffusion and percolation based on the phys-

ical mechanism of ink diffusion in rice paper is pre-

sented. Together with simulation of ink dispersion,

paper and ink interaction and Chinese calligraphy

brush techniques, this forms a complete system con-

sisting of four main parts: the brush model, the ink

and water transfer model, the virtual paper simulation

and special effects simulation.

2 RELATED WORK

Simulating Chinese calligraphy and Chinese painting

on a computer is an interesting topic which has at-

tracted a number of researchers. One of the earliest

attempts is that of Strassmanns (Strassmann, 1986)

who simulated the calligraphy brush as a 1D array of

bristles. Following this Guo and Kunii (Guo and Ku-

nii, 1991) proposed a model to simulate rice paper

which consisted of a mesh with randomly distributed

fibers. They divided the simulation into small regions

and distributed the fibers so that the local fiber dis-

tribution was random and the global distribution uni-

form. However, the complex mechanisms of ink dif-

fusion and water percolation were not simulated ad-

equately. This meant that the characteristics of the

calligraphic brush interaction with the paper through

diffusion of the ink could not be simulated sufficiently

realistically.

Kunii et al. (Kunii et al., 1995) later proposed a

multidimensional diffusion model including three dis-

tinct zones (initial zone, black border, and gray zone).

Their model simulated ink diffusion, and it can also

be applied to black ink rendering. However, the dif-

271

Wang Y. and Rokne J. (2007).

PRESSURE BASED INK DIFFUSION MODEL FOR REAL-TIME SIMULATION OF CHINESE CALLIGRAPHY.

In Proceedings of the Second International Conference on Computer Graphics Theory and Applications - GM/R, pages 271-276

DOI: 10.5220/0002071902710276

Copyright

c

SciTePress

fusion rate was a constant in his model, which is not

realistic when ink is deposited on the highly absorbent

rice paper.

A paper model consisting of three layers was in-

troduced by Curtis et al. (Curtis et al., 1997). They

use a cellular automaton to simulate fluid flow and

pigment dispersion and the layering to simulate vari-

ous watercolor effects, such as edge-darking, granula-

tion, back runs, separation of pigments, and glazing.

Their approach did not include the permeability ef-

fect, which means that the subtle ink patterns of Chi-

nese calligraphy and painting can not be simulated by

their model. Lee (Lee, 2001) improved Kunii’s (Ku-

nii et al., 1995) model by using a two perpendicular

directions model that includes a texture structure and

sinusoidal variations to simulate rice paper. In this

paper model, the paper is divided into square regions

called ”papels”. They developed the sinusoidal wave

schema for representing the flow of ink through a fiber

mesh. However, the fiber mesh model used in the pa-

per is quite different from the fiber structure in real pa-

per and the wave algorithm for the diffusion process

is different from the real physical diffusion process.

This means that the model only simulates processes

of this kind which do not conform closely to the phys-

ical processes for ink flow in paper. Based on Lee’s

(Lee, 2001) fiber mesh structure and layer structure

for each paper cell, Yu et al. (Yu et al., 2003) pre-

sented a local equilibrium model (LEM) which sim-

ulated the movement of water and ink on and in pa-

per. Their modified layer model simulated overlapped

strokes successfully. However, without the physical

process based simulation, the simulation of the ink

diffusion phenomenon was not realistic. Xiaofeng

(Xiaofeng Mi, 2004) used different droplet models

to simulate the tangent area between brush and pa-

per and based on these models they developed a vir-

tual brush model which is inspired by calligraphy and

painting experience. Their models were able to create

realistic looking results in real time.

Huang et al. (Huang et al., 2003) presented a

method which can simulate a variety of tones on dif-

ferent types of paper. Both a regular fiber mesh whose

fibers are uniformly aligned and an irregularly dis-

tributed fiber mesh consisting of randomly positioned

fibers were simulated in this paper. The diffusion of

brush strokes can be easily controlled, according to

experimental data and users can specify parameters

to get the desired effects. Van et al. (T. V. Laer-

hoven, 2004) developed a layered paper model which

divides the paper into a grid of small subpapers. Each

layer is implemented as a two-dimensional grid of

cells that exchange certain amounts of water with ink.

It updates all cell values according to their neighbor-

ing cell values in the same layer, and possibly in a

layer above and below. They have to distribute the

system by breaking up the whole grid in smaller sub-

grids that are simulated on separate processing units.

The results are sent back to the parent application and

combined with the results of other subpapers to pro-

duce the final image. Tsai et al. (Tsai et al., 2005)

discussed diffusion rendering of ink painting and fo-

cussed on synthesizing artistic effects of ink-refusal

and stroke-trace-reservation. This was the first paper

to take the quantity of glue in the paper as one im-

portant parameters of the structure of paper in the ink

diffusion simulation.

Chu and Tai (Chu and Tai, 2005) presented a fluid

flow model based on the lattice Boltzmann equation

(LBE) (Succi, 2001) for simulating percolation in ab-

sorbent paper. Instead of starting with a macroscopic

description of the fluid, the LBE modeled the physics

of fluid particles at a macroscopic level. They adapted

the basic LBE method to incorporate various features

needed for the special case of percolation. The pa-

per thickness patterns obtained by scanning the paper

against a dark background were stored aa a texture

map.

3 CHINESE INK AND PAPER

Chinese ink is a mixture of soot and glue which is

ground together with water to get black liquid ink.

The soot is composed of carbon particles which are

easily dissolved in water. The dimension of a carbon

particle is in the range of 10-150 nm, thus it can seep

into the paper easily and produce the extraordinary

rendering effects of the Chinese calligraphy.

Rice paper is often used in Chinese calligraphy. It

is highly absorbent because of the special materials

used and the very thin fiber structures. To reduce its

absorbency, the paper can be soaked with alum water.

The higher the density of the alum water, the lower

the absorbency of the paper will be. So the rendering

effect is mainly determined by paper absorbency and

fiber structure.

The simulation of Chinese calligraphy includes

three parts:

1) Paper model: The paper consists of a mesh with

randomly distributed fibers. To model this fiber

structure, the paper is divided into small square

cells. Each cell has four neighbors which are con-

nected with fibers and each cell of the paper is

simulated as a network flow model with a node

and four edges. Each edge represents a bundle of

capillaries and the node acts as a reservoir which

stores the water flowing into it. The water will

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

272

flow out the cell along the edges only when it is

full of water.

2) Ink flow model: The two layer model, a diffu-

sion layer and a deposition layer, will be used to

simulate the ink flow on the rice paper. The net-

work based flow model will be used in the diffu-

sion layer to model the water flow in the paper and

also to determine the final region of the ink marks.

The deposition layer can model the carbon parti-

cles deposited into the paper. It is also used to

simulate the washing out effects when the area is

painted later.

3) Absorption: As the ink flows in the paper, the

carbon particles will be absorbed by the fibers and

deposited into the paper. Thus the density of the

ink changes as it flows along the fiber network.

These effects are considered in our simulation as

they affect the final rendering result.

4 PAPER MODEL

To simulate the texture of the paper, we add a uni-

formly distributed random number for modeling the

fiber density of each edge.

If the average fiber density is Den

ave

, the standard

deviation of the uniform distribution is Std

dev

, then

the fiber density of each edge will be:

Den

edge

= Den

ave

+2∗Xtd

dev

∗[rand(X

p

,X

p−1

− 0.5]

(1)

where Y

p

and X

p

is the size of the fiber mesh of the

paper. rand(M, N) is an M × N matrix with random

entries chosen from a uniform distribution on the in-

terval (0.0, 1.0).

After the fiber densities of all edges of each node

were generated, the fiber density of each cell, Den

cell

,

could be obtained by averaging the densities of all

edges:

Den

cell

= (Den

edge1

+ Den

edge2

+ · · ·)/n.

where n is the number of edge connected with this

cell.

In our programme, Den

ave

= 1Std

dev

= 0.2

- The edge is modeled as a pipe which consists of

a bundle of capillaries. The cross section area S

and the diffusion coefficient K of each of the four

edges is a function of the local fiber density ρ

e

. It

is assumed that K and S are linear with ρ

e

.

- All cells have the same volume and the fiber den-

sity ρ

c

m,n

of the cell (m,n) is random. The fiber

density of each cell is obtained by using the aver-

age value of the four edges.

5 INK FLOW MODEL

A network based flow model can be used in the diffu-

sion layer.

5.1 Darcy’s law

Darcy’s law is commonly used to study the flow in

porous media in groundwater hydrology. As a macro-

scopic law, it doesn’t tell us about the flow through

individual pores. Since paper is a typical porous

medium, the water diffusion in it can also be mod-

eled by Darcy’s law. As the flow through the indi-

vidual pores formed by the fibers of the paper is not

important, we mainly consider the flow through the

capillary bundles from one cell to another. According

to Darcy’s law, the flow through the pipe composed of

capillary bundle is

Q = KJS (2)

where Q(m

3

/s) is the flux of the diffusion, S(m

2

) is

the area of the cross section of the pipe which is con-

sist of a bundle of capillaries, J is the gradient of the

pressure of the flow(the pressure on unit length of the

pipe along the flow direction), and K(m/s)is the dif-

fusion coefficient of the pipe.

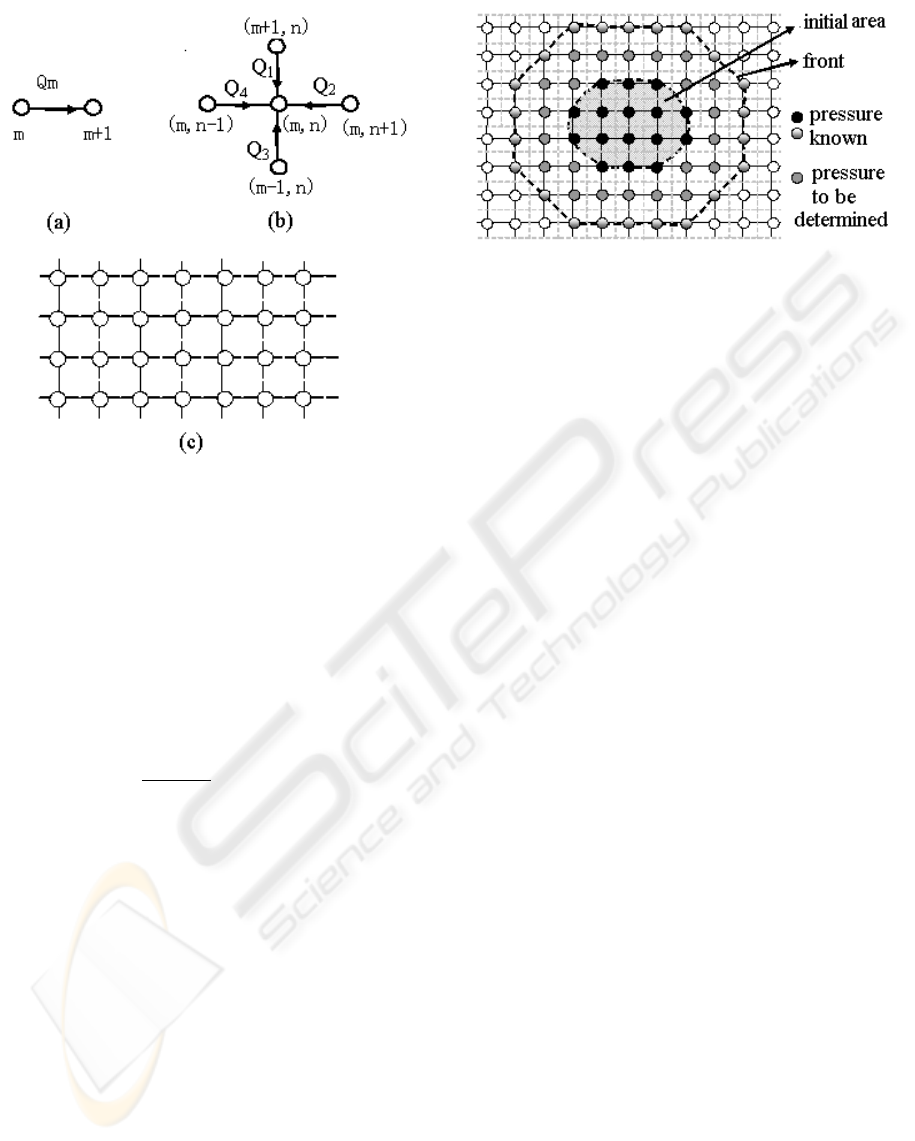

5.2 Flow in Capillary Networks

For two nodes connected with capillaries as shown

in Figure 1(a), if the pressure at nodes m and m + 1

are p

m

and p

m+1

, the length of the edge is L

m

, the

diffusion coefficient is K

m

and the cross-section is S

m

,

then, the flux will be

Q

m

= K

m

S

m

p

m

− p

m+1

L

m

(3)

according to Darcy’s law, so the flux can be derived if

the pressure at each node is known.

For the capillary network with nodes M × N as

shown in Figure 1(c), the pressure at each node can

be obtained by applying Darcy’s law on each edge.

For one node (m,n) in the network, if the pressure at

this node is p

m,n

, and the pressures at the four neigh-

boring nodes are p

m+1,n

, p

m,n−1

, p

m−1,n

and p

m,n+1

,

then the flux on the four edges are Q

1

,Q

2

,Q

3

and Q

4

,

and

Q

i

m,n

= K

i

m,n

S

i

m,n

ˆp

i

L

i

m,n

; i = 1,...,4 (4)

where ˆp

i

is the difference of the pressure on the edge,

ˆp

1

= p

m+1,n

− p

m,n

(5)

ˆp

2

= p

m,n+1

− p

m,n

(6)

PRESSURE BASED INK DIFFUSION MODEL FOR REAL-TIME SIMULATION OF CHINESE CALLIGRAPHY

273

Figure 1: Nodes and edges in the networks.

ˆp

3

= p

m−1,n

− p

m,n

(7)

ˆp

4

= p

m,n−1

− p

m,n

(8)

Since the flux is conservative, the flux flow into node

(m,n) is zero, that is

∑

i

Q

i

m,n

= 0 (9)

Let

c

i

m,n

=

K

i

m,n

S

i

m,n

L

i

m,n

; i = 1,...,4 (10)

Then

c

1

m,n

p

m+1,n

+ c

2

m,n

p

m,n+1

+ c

3

m,n

p

m−1,n

+c

4

m,n

p

m,n−1

−

∑

i

c

i

m,n

p

m,n

= 0 (11)

The same equation can be derived for each node,

and the following equation can be obtained

A

MN×MN

P

MN×1

= 0 (12)

where P

MN×1

is the pressure vector

P

MN×1

=

p

1,1

.

.

.

p

M,1

.

.

.

p

1,N

.

.

.

p

M,N

(13)

Figure 2: Diagram of the diffusion.

and A

MN×MN

is a coefficient matrix which is deter-

mined only by the properties of the paper.

The initial region of the ink is simulated as a reser-

voir, and for those nodes within this region, the pres-

sures can be assumed to be zero. Since the flow is

caused by the capillary attraction, it is also assumed

that the flow is driven by pressures on the front (the

boundary of the diffused area) nodes. The pressure at

the nodes on the front can be assumed to be a constant

p

0

.

When the ink is diffusing, the front is moving out-

wards. Therefore, at each step of the diffusion, only

pressures of the nodes in the diffused region have to

be calculated because pressures of the nodes in the

initial region and at the front are already given as

shown in Figure 2. Furthermore, pressures of the

nodes outside the diffusion region are not needed as

there is no ink there, and the matrix A can be sim-

plified when the corresponding components in P are

deleted from the equation. Now by replacing the com-

ponents corresponding to the pressures at the nodes in

the initial region and at the front in P with their val-

ues, eq. (12) can be written as

ˆ

A

ˆ

P = B (14)

where

ˆ

P is the pressures of the nodes within the dif-

fused region.

Since the pressure at nodes within the diffusion

region is varying as the ink is diffusing,

ˆ

A and

ˆ

P are

varying with time. However, at each time step, the

pressure

ˆ

P can be obtained by eq. (14). With the

pressure at each node, the flux can be then derived

with eq. (4) .

In this model, fiber texture is denoted by param-

eters K

m,n

and S

m,n

, which will affect the percolation

effect of the final rendering result. If the average val-

ues of K

m,n

and S

m,n

are K

0

and S

0

. So the three factors

K

0

, S

0

and the pressure p

0

at the front will determine

the diffusion speed. So in order to simulate the phys-

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

274

ical process of the ink diffusion in a paper, K

0

, S

0

and

p

0

are determined by experiments.

5.3 Algorithm

- Step 1: find the source region of the ink. The pres-

sure of the nodes in this region can be assumed to

be zero or a function of the amount of ink remain-

ing in this area.

- Step 2: find the front nodes. The pressure of the

node on the front is a function of the fiber density

of the cell. For simplicity, a constant pressure of

the node in the front can also be assumed.

- Step 3: find the mid-nodes of the diffusion net-

work and form the coefficient matrix A to obtain

pressures of these nodes.

- Step 4: solve the linear equation

ˆ

A

ˆ

P = B to get the

pressures.

- Step 5: calculate the flux of each edge. The evap-

oration of water can be considered in this step by

subtracting it from the flux of each edge.

- Step 6: calculate the time when a front cell is full

of ink and the amount of ink flows into each cell

on the front.

- Step 7: calculate the amount of the carbon parti-

cles deposited in the deposition layer.

- Step 8: update the amount of ink in the source re-

gion. If there is no ink left then stop the diffusion,

else go to step 2.

6 ABSORPTION

The size of the carbon particles in the ink is random

with a probability distribution. However, in order to

simplify the calculation, it is assumed that the carbon

particles all have the same size and all have the mean

dimension value. Thus the density of the ink is only

determined by the number of the particles in it.

The rendering effect can be calculated directly

from the carbon particles deposited in the paper. It is

assumed that the absorption rate is independent of the

velocity of the flow and only related to the local fiber

density of the paper and the diameters of the particles.

As the ink flows in the paper, the carbon particles will

be absorbed by the fibers and deposited into the paper.

Thus the density of the ink changes as it flows along

the fiber network. At the end of the diffusion, all par-

ticles in the ink remaining in each cell will deposit on

the paper after the water is evaporated. Furthermore,

following assumptions are made in our simulaition:

- The absorption rate of the paper is proportional to

the local fiber density of each cell.

- The color intensity of the image is a proportional

to the carbon density at each cell.

Since the source region is modeled as a reservoir,

the ink is uniformly distributed in this region and flow

out from its boundary. As the ink flows out and the

carbon particles deposit in the paper, there will be

a deep dark edge at the initial boundary if the ab-

sorbency of the paper is high. This is because the

ink flow in the initial region is ignored. In order to

avoid this unrealistic phenomena, the carbon particles

deposited in the diffusion region is re-distributed by

subtracting parts of the particles proportionally from

each cell and averagely putting them into the source

region to make the density of the deposited particles

continuous in the initial boundary.

If the density of the deposited carbon particles in

the diffusion region is d

m,n

and the average value at

the initial boundary is d

0

, the number of cells and the

average density in the source region are N

s

and d

s

.

Then

d

0

β = d

s

+ (1− β)

1

N

s

∑

m,n

d

m,n

(15)

where

β =

d

s

+

1

N

s

∑

m,n

d

m,n

d

0

+

1

N

s

∑

m,n

d

m,n

(16)

is the coefficient to balance the dark edge,

Therefore, the carbon density at each cell in the

diffusion region can be balanced by multiplying β to

correct the dark edge problems.

7 EXPERIMENTS

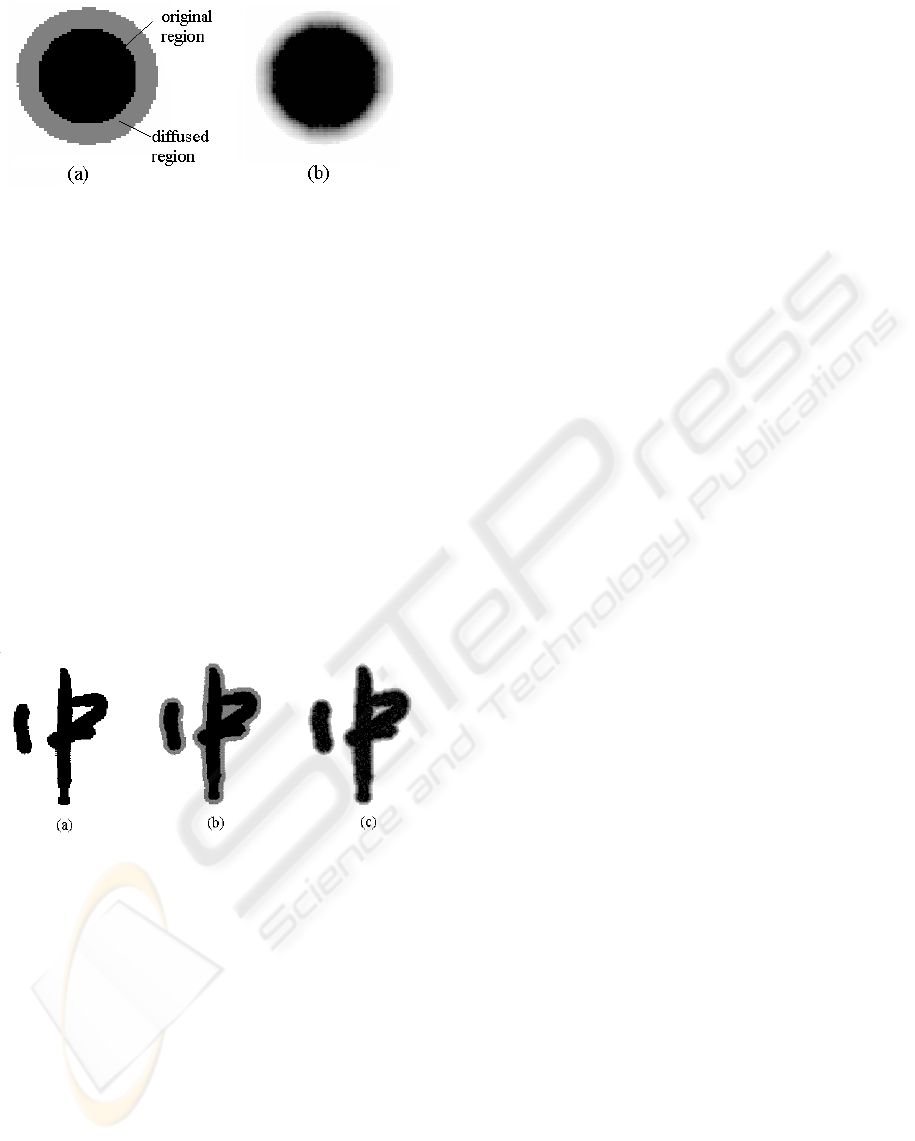

7.1 Rendering of a Circular Region

For a drop of ink diffusing in a paper, the image is a

circle. The result is shown in Figure 3.

Paper size: 100 by 100 cells

Paper texture: Uniform distribution on

the interval (0.8,1.2)

Original region: a circle at the center,

diameter 40

Amount of ink: 1200

Ink density: 1

Brightness of the ink: 0.8(Maximum:1)

Average absorption rate: 0.2

PRESSURE BASED INK DIFFUSION MODEL FOR REAL-TIME SIMULATION OF CHINESE CALLIGRAPHY

275

Figure 3: Diffusion from a circular region (a) region

diffused; (b) rendering effect.

7.2 Rendering of a Chinese Character

Using the Chinese character ”ZHONG” as a sample to

show the rendering effect of our method. The result is

shown in Figure 4.

Paper size: 150 by 150 cells

Paper texture: Uniform distribution

interval (0.8,1.2)

Original region: Chinese character

"ZHONG"

Amount of ink: 2000

Ink density: 1

Brightness of the ink: 0.8(Max:1)

Average absorption rate: 0.2

Figure 4: Diffusion of a Chinese character ”Zhong”

(a) original character; (b) region diffused; (c) render-

ing effect.

The results of the two case studies showed that our

method can simulate the ink diffusion in the rice pa-

per very well. The effect of the paper texture on the

diffusion can be considered by randomized fiber den-

sity. The percolation effect can also be modeled in our

model by the randomized fiber density and absorption

rate of the paper.

8 CONCLUSION

Our ink flow model is based on the Darcy’s law. By

calculating the pressure of each node on the paper

we can simulate the physical process of ink diffusion

and percolation unlike many other methods which can

only simulate the effect of the diffusion but can not

simulate the physical process. The experiments show

that our new method can give very satisfied result in-

cluding to simulate the irregular edge and fiber struc-

ture in a realistic way. In addition, compared to the

fluid model, there is no need to solve the partial dif-

ferential equations. This means that the calculations

are fast. There are some other effects like wash out,

ink draw back which will be added into our model

later.

REFERENCES

Chu, N. S.-H. and Tai, C.-L. (2005). MoXi: Real-Time

Ink Dispersion in Absorbent Paper. SIGGRAPH 2005,

24(3):504–511.

Curtis, C. J., Anderson, S. E., Seims, J. E., Fleischer, K. W.,

and Salesin, D. H. (1997). Computer-Generated Wa-

tercolor. In Whitted, T., editor, SIGGRAPH97, CG-

PACS, pages 421–430, New York.

Guo, Q. and Kunii, T. L. (1991). Modeling the diffuse paint-

ing of sumie. IFIP Modeling in Computer Graphics,

pages 329–338.

Huang, S., Way, D., and Shih, Z. C. (2003). Physical-Based

Model of Ink Diffusion in Chinese Ink Paintings. In

Proceedings of WSCG 2003, volume 10, pages 520–

527.

Kunii, T. L., Nosovskij, G. V., and Hayashi, T. (1995). A

diffusion model for computer animation of diffuse ink

painting. pages 98–102, Geneva, Switzerland.

Lee, J. (2001). Diffusion Rendering of Black Ink Paintings

Using New Paper and Ink Models. j-CAG, 25(2):295–

308.

Strassmann, S. (1986). Hairy brush. Proc. of SIGGRAPH

’86, pages 225–232.

Succi, S. (2001). Lattice Boltzmann equation for fluid dy-

namics and beyond. Oxford University Press.

T. V. Laerhoven, J.Liesenborgs, F. R. (2004). Real-time wa-

tercolor painting on a distributed paper model. pages

640–643, Crete, Greece.

Tsai, C., Liaw, C., Huang, C., and Lee, J. (2005). Syn-

thesizing the artistic effects of ink painting. Optical

engineering, pages 359–368.

Xiaofeng Mi, Min Tang, J. D. (2004). Droplet: A virtual

brush model to simulate chinese calligraphy and paint-

ing. Journal of Computer Science and Technology,

19(3):393–404.

Yu, Y. J., Lee, D. H., Lee, Y. B., and Cho, H. G. (2003). In-

teractive Rendering Technique for Realistic Oriental

Painting. Journal of WSCG, 11:538–545.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

276