SOLVING THE MULTI-OBJECTIVE MIXED MODEL

ASSEMBLY LINE PROBLEM USING A FUZZY

MULTI-OBJECTIVE LINEAR PROGRAM

Iraj Mahdavi, Babak. Javadi and S. S. Sabet

Mazandaran University of Science and Technology, Babol, Iran

Keywords: Mixed model assembly line, Multi-objective linear program, Fuzzy multi-objective decision-making.

Abstract: This paper develops a fuzzy multi-objective linear program (FMOLP) model for solving the multi-objective

mixed model assembly line problem. In practice, vagueness and imprecision of the goals, constraints and

parameters in this problem make the decision-making complicated. The proposed model attempts to

simultaneously minimize total utility work cost, total production rate variation cost, and total setup cost. In

this paper, an asymmetric fuzzy-decision making technique is applied to enable the decision-maker to assign

different weights to various criteria in a real industrial environment. The model is explained by an

illustrative example.

1 INTRODUCTION

Mixed model assembly lines are a type of

production line where a variety of product models

similar in product characteristics are assembled.

The effective utilization of a mixed-model assembly

line requires solving two problems in a sequential

manner as follows: 1) line design and balancing and

2) determination of the production sequence for

different models. In this paper, we assume that the

line has already been balanced and sequencing

problem is only considered.

Korkmazel and Meral (2001) consider two major

goals in the mixed model sequencing problems: (1)

smoothing the workload on each workstation on the

assembly line, and (2) keeping a constant rate of

usage of all parts used on the assembly line. In their

study, first, some well-known solution approaches

with goal (2) are analyzed through minimizing the

sum-of-deviations of actual production from the

desired amount. The approaches that are found to be

performing better than the others are extended for

the bi-criteria problem considering both goals,

simultaneously.

Ponnambalam et al. (2003) investigate the

performance of genetic algorithms for sequencing

problems in mixed model assembly lines.

Mansouri (2005) presents a Multi-Objective

Genetic Algorithm (MOGA) approach to a Just-In-

Time (JIT) sequencing problem where variation of

production rates and number of setups are to be

optimized simultaneously.

Ding et al. (2006) compares two weighted

approaches in sequencing mixed model assembly

lines for a joint objective of multiple objectives.

Minimizing the weighted sum of percentage

differences from the best solution values of the

respective objectives is considered as the joint

objective.

Mixed model assembly line is a multi-objective

decision-making problem, in which criteria should

have different weightes. Vagueness of the

information in this problem, make the decision-

making complicated. In this paper, a fuzzy multi-

objective model developed to assign different

weights to the various criteria.

2 THE MULTI-OBJECTIVE

MIXED MODEL ASSEMBLY

LINE (MMAL) MODEL

2.1 Mixed-model Assembly Line

The design of the MMAL involves several issues

such as determining operator schedules, product

mix, and launch intervals. Two types of operator

schedules early start schedule and late start schedule,

are found in Bard et al. (1994). An early start

370

Mahdavi I., Javadi B. and S. Sabet S. (2007).

SOLVING THE MULTI-OBJECTIVE MIXED MODEL ASSEMBLY LINE PROBLEM USING A FUZZY MULTI-OBJECTIVE LINEAR PROGRAM.

In Proceedings of the Ninth International Conference on Enterprise Information Systems - AIDSS, pages 370-373

DOI: 10.5220/0002353003700373

Copyright

c

SciTePress

schedule is more common in practice and is used in

this paper (Chul et al. (1998)). Second, the master

production schedule (MPS) production, which this

strategy is widely accepted in mixed model

assembly lines, is also used in this paper. MPS is a

vector representing a product mix, such that

(d

1

,…,d

M

)=(D

1

/h,…,D

M

/h); where M is the total

number of models, D

m

is the number of products of

model type m which needs to be assembled during

the entire planning horizon and h is the greatest

common divisor or highest common factor of

D

1

,D

2

,…,D

M

. This strategy operates in a cyclical

manner. The number of products produced in one

cycle is given by

∑

=

=

M

i

i

dI

1

. Obviously, h times

the repetition of producing the MPS products can

meet the total demand in the planning horizon.

Third, the launch interval

)(

γ

is set to

()TIJ

×

, in

which T is the total operation time required to

produce one cycle of MPS products (Chul et al.

(1998)).

2.2 Objective Function

2.2.1 Minimizing Total Utility Work Cost

The utility work is typically handled by the use of

utility workers assisting the regular workers during

the work overload. Let L

j

be the fixed line length of

station j and U

ij

be the amount of the utility work

required for product i in a sequence at station j. The

following model is presented by Chul et al. (1998).

Minimize

)]/(

)1(

11

cji

I

i

ij

J

j

vZU

+

==

+

∑∑

(1)

s.t.

1

1

=

∑

=

M

m

im

x

i∀

(2)

m

I

i

im

dx =

∑

=1

m∀

(3)

=

+ ji

Z

)1(

max (4)

ji

vLvtxvZ

cjcjm

M

m

imcij

,

))](),(min(,0[

1

∀

×−×−

∑

+

=

γγ

=

ij

U

max

jivLtxvZ

c

j

M

m

jmimcij

,]/)(,0[

1

∀−

∑

+

=

(5)

0=

im

x

or 1

mi,∀

(6)

0

1

=

j

Z

,

jiZ

ij

,0∀≥

(7)

jiU

ij

,0

∀

≥

(8)

ij

Z is the starting position of the work on product i

in a sequence at station j, and

im

x is 1 if product i in

a sequence is the m

th

model; otherwise

im

x is 0. The

second term in the objective function takes into

account for the utility work that may be required at

the end of a cycle. Eq. (2) ensures that exactly one

product is assigned to each position in a sequence.

Eq. (3) guarantees that demand for each model is

satisfied. Eq. (4) indicates the starting position of the

worker at each station j on product i+1 in a

sequence. Utility work

ij

U for product i in a

sequence at station j is determined by Eq. (5).

2.2.2 Minimizing Total Production Rate

Variation Cost

One basic requirement of JIT systems is continual

and stable part supply. Since this can be realized

when the demand rate of parts is constant over time,

the objective is important to a successful operation

of the system. Thus, the objective can be achieved

by matching demand with actual production. The

following model is suggested by Miltenberg (1989).

Minimize

)(

111

∑∑∑

===

−

i

l

mlm

I

i

M

m

I

d

i

x

(9)

s.t.

Constraints (2), (3), and (6).

The first term in the objective function is the

production ratio of model m until product i is

produced. The second term is the demand ratio of

model m.

2.2.3 Minimizing Total Setup Cost

In many industries, sequence-dependent setups are

considered as an important item in assembly

operations. The model considering sequence-

dependent setups developed by Chul et al. (1998) is

considered in this paper.

Minimize

jmr

J

j

I

i

M

m

M

r

imr

cx

∑∑∑∑

== ==11 11

(10)

s.t.

1

11

=

∑∑

==

M

m

M

r

imr

x

i∀

(11)

∑∑

=

+

=

=

M

p

rpi

M

m

imr

xx

1

)1(

1

rIi ∀−= ,1,...,1

(12)

∑∑

==

=

M

p

rp

M

m

r

xx

1

1

1

Im

r

∀

(13)

m

I

i

M

r

imr

dx =

∑∑

==11

m∀

(14)

SOLVING THE MULTI-OBJECTIVE MIXED MODEL ASSEMBLY LINE PROBLEM USING A FUZZY

MULTI-OBJECTIVE LINEAR PROGRAM

371

imr

x =0 or 1

rmi ,,∀

(15)

where

jmr

c

is the setup cost required when the

model type is changed from m to r at station j.

imr

x

is 1 if model type m and r are assigned respectively

at position i and i+1 in a sequence; otherwise

imr

x is

0. Eq. (11) is a set of position constraints indicating

that every position in a sequence is occupied by

exactly one product. Eqs. (12) and (13) ensure that

the sequence of products is maintained while

repeating the cyclic production. Eq. (14) imposes the

restriction that all the demands should be satisfied in

terms of MPS.

In a real case, DMs do not have exact and

complete information related to decision criteria and

constraints. For mixed model assembly line

problems the collected data does not behave crisply

and they are typically fuzzy in nature.

2.3 The Fuzzy Mixed Model Assembly

Line Model

In this section, first the general multi-objective

model for mixed model assembly line is presented

and then appropriate operators for this decision-

making problem are discussed.

A general linear multi-objective model can be

presented as:

Find a vector x written in the transformed x

T

=

[x

1

, x

2

,…, x

n

] which minimizes objective function Z

k

with

.1,2,...,

1

pkxcZ

n

i

ikik

=

∑

=

=

(16)

and constraints:

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

≥=≤==∈

∑

=

0 ,,...,2,1 ,)(/ ,

1

xmrbxaxgxXXx

r

n

i

iridd

(17)

where c

ki,

a

ri

and b

r

are crisp or fuzzy values.

Zimmermann (1978) has solved problems (16-

17) by using fuzzy linear programming. He

formulated the fuzzy linear program by separating

every objective function Z

j

into its maximum Z

j

+

and

minimum Z

j

–

value by solving:

dk

-

kak

k

XxZZXxZZ ∈=∈=

+

,min , ,max

(18)

−

k

Z is obtained through solving the multi-objective

problem as a single objective using, each time, only

one objective and

d

Xx ∈ means that solutions

must satisfy constraints.

Since for every objective function Z

j

, its value

changes linearly from

−

j

Z

to Z

j

+

, it may be

considered as a fuzzy number with the linear

membership function

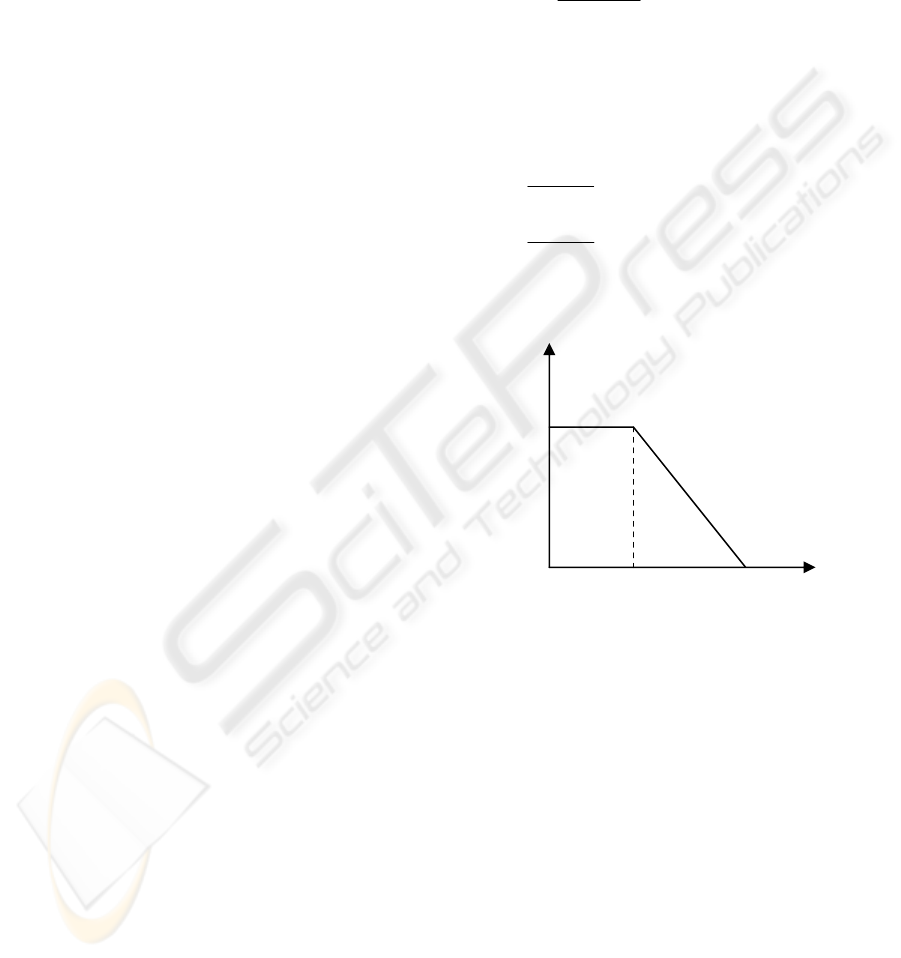

(

)

x

j

Z

μ

as shown in Fig.1.

Assuming that membership function, based on

preference or satisfaction is the linear membership

for minimization goals (Z

k

) is given as follows:

()

()

(

)

()

()

⎪

⎪

⎪

⎩

⎪

⎪

⎪

⎨

⎧

≥

≤≤

−

−

≤

=

+

+−

−+

+

−

.for 0

,for

,for 1

k

k

k

kk

k

k

k

k

kk

Z

ZZ

ZxZZ

ZZ

xZZ

ZZ

x

k

μ

for

,, ... , 2 , 1 pk

=

(19)

The linear membership function for the fuzzy

constraints is given as

()

()

()

()

()

() ()

⎪

⎪

⎪

⎪

⎩

⎪

⎪

⎪

⎪

⎨

⎧

≥≤

<<

−

<<

−

−

=

+−

+

+

−

−

−

. and for 0

,for

,for

bxgbxg

bxgb

b

xgb

bxgb

bb

bxg

x

rrrr

rrr

r

rr

rrr

rr

rr

g

r

μ

(20)

Figure 1: Objective function as fuzzy number for

minimizing objective function.

Z

k

.

+−

rr

bb , are the subjectively chosen constants

expressing the limit of the admissible violation of

the rth inequalities constraints.

In order to find optimal solution (x

*

) in the above

fuzzy model, it is equivalent to solve the following

crisp model (Zimmermann, 1978):

Maximize

α

(21)

s.t.

(

)

pjx

j

Z

,..., 2 , 1 =

≤

μ

α

(for all objective functions), (22)

(

)

,..., h , rx

r

g

21 =

≤

μ

α

(for fuzzy constraints), (23)

(

)

, ... , m hpbxg

pp

1 +

=

≤

(for deterministic constraints), (24)

Z

k

-

Z

k

+

0

1

(

)

x

k

Z

μ

Z

k

ICEIS 2007 - International Conference on Enterprise Information Systems

372

[

]

0,1 and 21 0 ∈=≥

α

, ... ,n, ix

i

(25)

where

() () ()

xxx

rj

gZD

μ

μ

μ

and ,

represent the

membership function of solution, objective functions

and constraints.

In this solution the relationship between

constraints and objective functions in a fuzzy

environment is fully symmetric (Zimmermann,

1978). In other words, in this definition of fuzzy

decision, there is no difference between the fuzzy

goals and fuzzy constraints. Therefore, depending on

the mixed model assembly line problem, situations

in which fuzzy goals and fuzzy constraints have

unequal importance to DM and other patterns, as the

confluence of objectives and constraints, should be

considered.

The convex fuzzy model proposed by Bellman

and Zadeh (1970) and the weighted additive model,

is given in equations (26) and (27)

() () ()

xxwx

rj

g

h

r

rZ

p

j

jD

μβμμ

∑

+

∑

=

== 11

(26)

0, 1

11

≥=

∑

+

∑

==

rj

h

r

r

p

j

j

ww

ββ

(27)

where w

j

and

j

β

are the weighting coefficients that

present the relative importance among the fuzzy

goals and fuzzy constraints. The following crisp

single objective programming is equivalent to the

above fuzzy model:

∑∑

==

+

h

r

rrj

p

j

j

w

11

max

γβα

(28)

s.t.

()

,, ... , 2 , 1 pjx

j

Zj

=≤

μ

α

(29)

()

, , ... , 2 , 1 hrx

r

gr

=≤

μ

γ

(30)

()

,, ... , 1 mhpbxg

pp

+=≤

(31)

[]

, ..., , 2 , 1 and ..., , 2 , 1 1,0, hrpj

rj

==∈

γ

α

(32)

,0, 1

11

≥=

∑

+

∑

==

rj

h

r

r

p

j

j

ww

ββ

(33)

nix

i

,..., 2 , 1 ,0 =≥

(34)

3 CONCLUSIONS

Mixed model assembly line is a multiple criteria

decision-making problem in which the objectives are

not equally important. In real cases, many input data

are not known precisely for decision-making. In this

paper, a fuzzy multi-objective model is developed

for mixed model assembly line in order to assign

different weights to various criteria. This

formulation can effectively handle the vagueness

and imprecision of input data and the varying

importance of criteria in mixed model assembly line

problem.

Also in this model, the α-cut approach can be

utilized to ensure that the achievement level of

objective functions should not be less than a

minimum level α.

In a real situation, the proposed model can be

implemented as a vector optimization problem; the

basic concept is to use a single utility function to

express the preference of DM, in which the value of

criteria and constraints are expressed in vague terms

and are not equally important.

REFERENCES

Bard, J.F., Shtub, A., Joshi, S.B., 1994. Sequencing

mixed-model assembly lines to level parts usage and

minimize the length. International Journal of

Production Research 32, 2431–2454.

Bellman, R.G., Zadeh, L.A., 1970. Decision making a

fuzzy environment. Management Sciences 17, B141-

B164.

Chen, S.H., 1985. Ranking fuzzy numbers with

maximizing set and minimizing set. Fuzzy Sets and

Systems 17, 113-129.

Chul J. H., Yeongho K., Yeo, K. K., 1998. A genetic

algorithm for multiple objective sequencing problems

in mixed model assembly lines. Computers &

Operations Research 25(7-8), 675-690.

Ding, F.Y., Zhu, J., Sun, H., 2006. Comparing two

weighted approaches for sequencing mixed-model

assembly lines with multiple objectives. International

Journal of Production Economics 102(1), 108-131.

Korkmazel, T., Meral, S., 2001. Bi-criteria sequencing

methods for the mixed model assembly line in just-in-

time production systems. European Journal of

Operational Research 131(1), 188-207.

Mansouri, S. A., 2005. A Multi-Objective Genetic

Algorithm for mixed-model sequencing on JIT

assembly lines. European Journal of Operational

Research 167(3), 696-716.

Miltenberg, J., 1989. Level schedules for mixed-model

assembly lines in just-in-time production systems.

Management Science 35, 192-207.

Ponnambalam, S. G., Aravindanb, P., Subba Raoc M.,

2003. Genetic algorithms for sequencing problems in

mixed model assembly lines. Computers & Industrial

Engineering 45(4),669-690.

Sakawa, M., 1993. Fuzzy sets and Interactive

Multiobjective Optimization. Plenum Press, New

York.

Zimmermann, H.J., 1978. Fuzzy programming and linear

programming with several objective functions. Fuzzy

Sets and Systems 1, 45-55.

SOLVING THE MULTI-OBJECTIVE MIXED MODEL ASSEMBLY LINE PROBLEM USING A FUZZY

MULTI-OBJECTIVE LINEAR PROGRAM

373