MEASUREMENT OF CELL FORCES USING A POLYMER

MEMS SENSOR

Nicholas Ferrell, James Woodard and Derek Hansford

Department of Biomedical Engineering, Ohio State University, 1080 Carmack Rd. 270 Bevis Hall, Columubus, OH, USA

Keywords: Polymer MEMS, cell forces, microfabrication.

Abstract: Cellular mechanics are responsible for execution and regulation of a number of cell functions. Mechanical

forces generated within the cytoskeleton are transmitted via transmembrane linkages to the underlying

substrate. Measurement of these forces could lead to a wealth of additional information about the role of cell

mechanics in regulating cell function and signal transduction. Here we describe the design, fabrication, and

testing of a polystyrene cantilever beam array for measuring forces generated by WS1 human skin

fibroblasts. Finite element analysis was used to guide the design of a compound cantilever beam. Sensors

were fabricated from polystyrene to provide a well-studied and biocompatible surface for cell attachment.

Soft lithography based techniques were used for microfabrication of the sensors. Cells were placed on four

and eight probe cantilever sensors and deflection of the probes was measured optically during attachment

and spreading of the cells. The device was successfully used to measure time varying mechanical forces

generated by fibroblast cells.

1 INTRODUCTION

Mechanical forces generated by adherent cells play

an important role in execution and/or regulation of a

host of cellular processes. When anchorage

dependent cells attach to a surface, forces generated

in the cytoskeleton are transmitted to the underlying

substrate via transmembrane protein linkages. These

mechanical forces are involved in controlling cell

functions including adhesion, morphology, and

motility (Galbraith and Sheetz, 1998; Chicurel et al.,

1998) as well as apoptosis (Chen et al., 1997) and

wound healing (Wrobel et al., 2002) among others.

Measurement of mechanical forces generated by

adherent cells could provide additional insight into

the basic role of cell mechanics in regulating cell

function. In addition, monitoring time dependent cell

mechanics could lead to new routes of cell-based

sensing focused on mechanical changes in the cell

brought about by externally applied chemical or

mechanical stimuli.

Several devices have been utilized for observing

and measuring cellular forces. Some of the first

approaches involved growing cells on deformable

elastic substrates, which wrinkled in response to

mechanical forces (Harris et al., 1980; Beningno and

Wang, 2002). More recently, microfabrication

techniques have been used to fabricate force

measurement devices. This is an attractive approach

due to the ability to make precise structures on the

same size scale as biological cells. Galbraith and

Sheetz (1997) used micromachined silicon

cantilevers to measure localized forces generated by

fibroblasts. Single cantilevers with one direction of

motion were used, thus limiting the ability to

measuring forces directed along the axis of the

cantilever or determine the direction of the force.

Soft lithography based microfabrication techniques

(Xia and Whitesides, 1998) have also been used to

fabricate devices for measuring cell forces (Tan, et

al., 2003). In this case, elastic

poly(dimethylsiloxane) (PDMS) pillars acted as

vertical cantilevers. Cells were grown on top of the

pillars and deflections were measured and used to

calculate the force on each pillar.

Our approach to measurement of cell forces

involves the use of a polystyrene cantilever array

with a compound beam design. The compound beam

allows the forces to be measured in all directions,

thus allowing calculation of both the force

magnitude and direction. The choice of polystyrene

as the structural material also has a significant

impact on the function of the device. Polystyrene is

151

Ferrell N., Woodard J. and Hansford D. (2008).

MEASUREMENT OF CELL FORCES USING A POLYMER MEMS SENSOR.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 151-155

DOI: 10.5220/0001055001510155

Copyright

c

SciTePress

a well-characterized biocompatible material that is

used ubiquitously in cell culture applications. In

addition, it is well know that the stiffness of the

substrate can significantly affect the mechanical

behaviour of cells (Lo et al., 2000, Choquet et al.,

1997). Most devices to date have been fabricated

from relatively flexible (silicone rubber) or

relatively stiff (silicon) materials. In this case we use

a materials with intermediate stiffness.

The device consists of a four or eight probe

cantilever array fixed to a glass substrate at the base

of the beams. The ends of the beams were designed

to provide adequate surface area for cell spreading.

The fixed post at the center of the device was

included to provide a location for initial cell

attachment as well as provide a fixed reference point

for probe deflection analysis. As the cell attaches to

the beams and exerts forces, the deflection of each

cantilever is measured optically over time to give

spatially and temporally resolved measurement

capabilities.

2 MATERIALS AND METHODS

2.1

Device Fabrication and

Characterization

Devices were fabricated using sacrificial layer

micromolding as described in (Ferrell et al., 2007).

A water-soluble sacrificial layer was first patterned

by photolithography and reactive ion etching. A

layer of poly(vinyl alcohol) (PVA) was dissolved in

water to a final concentration of 10% (wt/wt). The

PVA solution was spin coated on 18 mm glass

coverslips at 1000 rpm. A protective layer of

poly(methyl methacrylate) (PMMA) was then spin

coated on top of the PVA. The PMMA layer

protected the PVA from the developer in the

upcoming photolithography process.

Photolithography was then used to pattern an etch

mask on the PVA/PMMA films. Reactive ion

etching in an O

2

plasma was used to removed both

the PVA and PMMA in the unmasked regions. The

remaining photoresist and PMMA layers were then

removed by sonication in acetone, leaving only the

patterned PVA.

A PDMS mold of the device was fabricated by

replica molding (Xia and Whitesides, 1998) of a

photolithographically patterned master. The PDMS

mold was spin coated with a solution of polystyrene

in anisole (7.5% wt/wt). The polystyrene was

removed from the raised portions of the mold by

contact with a glass slide heated to 200 ºC. The

remaining polystyrene was left in the recessed

portion of the mold. The mold was aligned with the

sacrificial layer and heat (120 ºC) and pressure (75

psi) were used to transfer the device onto the

sacrificial layer. The device was then annealed at

115 ºC for 15 minutes to improve adhesion of the

anchor regions and remove any residual stress in the

beams.

The thickness of each device was characterized

using a stylus profilometer. The thickness range for

the above processing parameters was 1.31-1.75 µm.

2.2 Design and Simulations

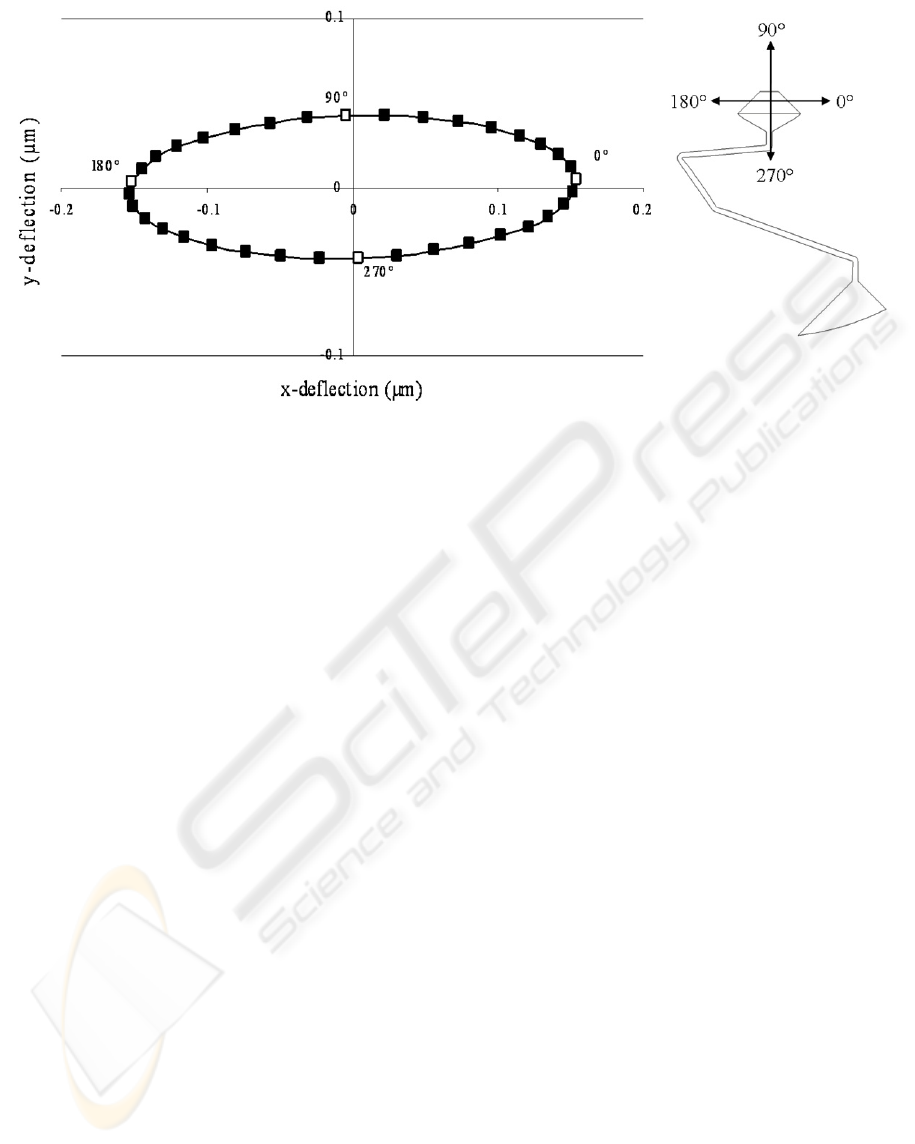

Finite element simulations (ANSYS) were used to

guide the design of the cantilever beam. The beam

was designed to give reasonable x,y deflection

response while still conforming to the geometrical

constraints of the devices circular configuration. The

deflection plot for a 5 nN force applied to an area at

the end of the cantilever beam at 10º increments

from 0º to 360º is shown in Figure 1.

An ideal beam response would be a circular

deflection profile with no offset between the

direction of the beam deflection and the force

direction. The plot shows a slight offset. The plot

also shows that the beam is stiffer in the 90º and

270º directions compared to the 0º and 180º

directions. This leads to slightly less sensitivity to

forces in those general directions, but the overall

response of the beam is adequate for the application

described here.

2.3 Cell Culture and Image Acquisition

The cells used in this study were WS1 human skin

fibroblasts (ATCC). Cells were cultured in

Minimum Essential Medium, Eagle (ATCC)

supplemented with 10% fetal bovine serum and 1%

penicillin-streptomycin. Cells were cultured at 37ºC

in a 5% CO

2

atmosphere. To obtain cells for

measurements, cells were detached from T75 tissue

culture flasks using .25% trypsin-EDTA.

Prior to performing measurements, the devices

were modified by a brief exposure to O

2

plasma in a

reactive ion etcher to make the surface more

hydrophilic and improve cell attachment. Devices

were fixed to a PDMS coated petri dish. The PDMS

coated dish allowed fixation of the device without

the use of a chemical adhesive. The devices were

placed in cell culture medium to dissolve the

sacrificial layer. After complete dissolution of the

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

152

Figure 1: Deflection plot for the compound cantilever beam with a 5 nN applied load.

PVA layer, the medium was aspirated and fresh

medium was added and aspirated three times to

remove the majority of the dissolved PVA. 20 ml of

fresh medium without cells was added to the petri

dish. A few drops of cell suspension were then

added to the dish. This provided a low cell density

and minimized the likelihood of having multiple

cells on a single device.

Measurements were performed on an inverted

microscope (Nikon TS100) with a custom stage

incubator. The incubator consisted of an acrylic

enclosure with the temperature regulated at 37ºC and

supplied with 5% CO

2

. A manual micromanipulator

(World Precision Instruments) with a 2µm inner

diameter glass micropipette was used to position a

single cell on the center region of sensor. Cells were

moved onto the device with the microscopy in phase

contrast mode to allow better visualization. A 6.6

megapixel CCD camera (Pixelink) was set to capture

images at 30 second intervals for the duration of the

experiment. For analysis, the phase contrast filter

was removed and brightfield images were captured

to facilitate easier edge detection.

2.4 Image Analysis and Force

Calculation

Images were analysed using NIH Image J software

(download available at http://rsb.info.nih.gov/ij/).

The x,y position of the end of the probe as well as a

fixed point on the device were determined prior to

cell attachment. The x,y displacement of the end of

each the cantilever was then monitored over time.

The x,y position of the fixed point was also

monitored to determine and correct for image shift.

After determining the magnitude and direction of the

cantilever deformation, the force magnitude and

direction were calculated based on the finite element

simulations.

3 RESULTS AND DISCUSSION

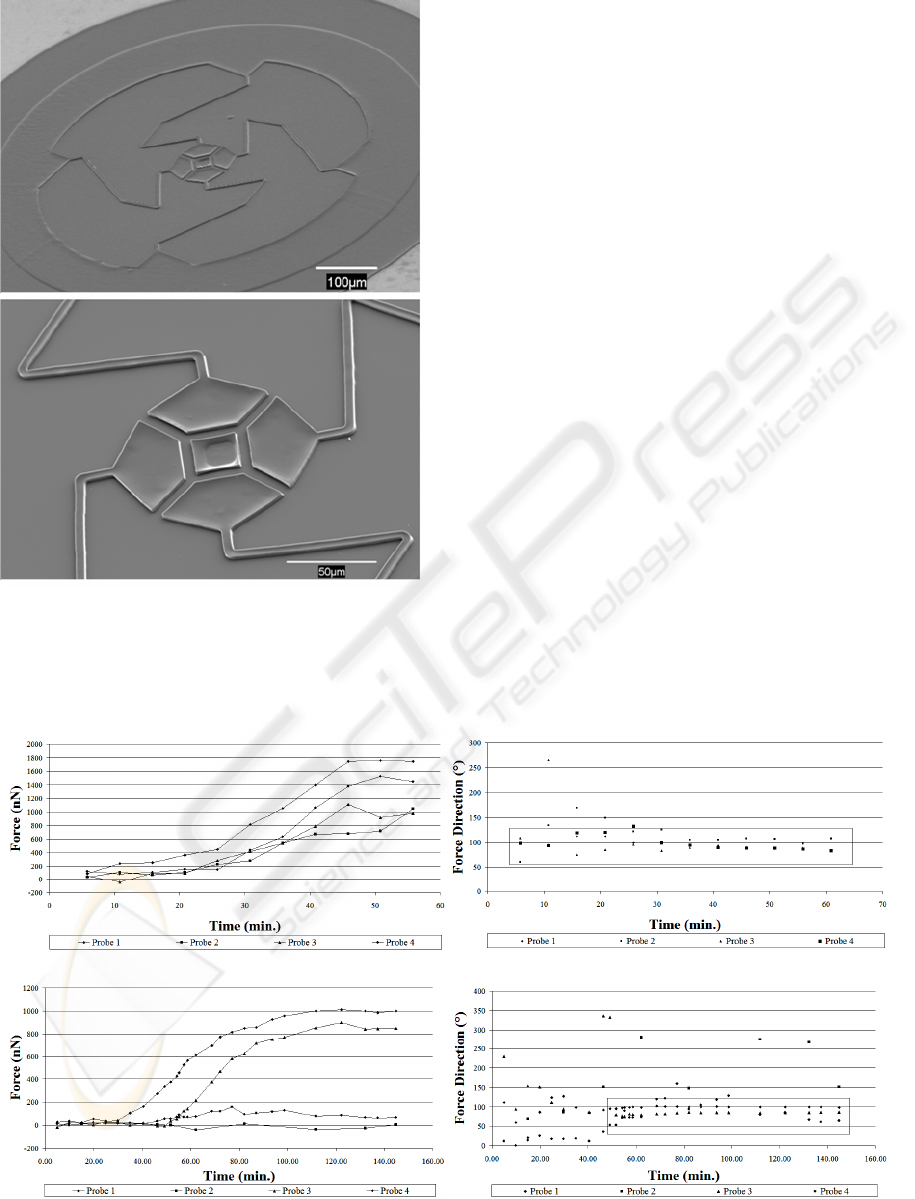

Scanning electron micrographs of the four probe

sensor prior to removal of the sacrificial layer are

shown in Figure 2. Figure 2(a) shows the entire

device with the anchor region at the outer perimeter

of the device. The close-up of the center of the

device shows the four adhesion pads as well as the

fixed post.

The force versus time plots for two different

experiments are shown in Figure 3 (a,c). The plots

show the force magnitude for each of the four

probes. Figure 3(a) shows that force is exerted on

each of the four probes. The graph also indicates that

the cell adhered to the sensor relatively quickly after

being placed on the device. Figure 3(c) shows that

force is only exerted on three of the four probes and

the magnitude of the force is significantly higher for

probes 1 and 3 compared to probe 4. This is likely

due at least in part to a smaller adhesion area on

probe 4 as compared to probes 1 and 3. This could

be a result of off center cell attachment and

spreading. In addition, Figure 3(c) shows that there

is a period of time prior to cell attachment with no

force generation. The plot clearly shows the onset of

MEASUREMENT OF CELL FORCES USING A POLYMER MEMS SENSOR

153

Figure 2: SEM micrographs of the cell force sensor.

cell attachment and force generation for each of the

probes. Probe 2 showed no force/deflection response

attributed to cell mechanics. The data is included to

show the noise in the measurement and analysis

system.

The angle of the force vectors are shown in

Figure 3(b,d). The boxes highlight that most of the

forces are oriented around 90º or toward the center

of the devices. This is expected given the nature of

the forces. In figure 3(d) the random orientation of

the angle prior cell attachment and for probe 2 are

due to noise.

Figure 4 shows optical phase contract

micrographs of the cantilevers corresponding to the

force and direction plots in Figure 3 (a,c). The force

vectors for each probe are overlaid on the images.

The images show the changes in the both the

magnitude and direction of the deformation at 0, 30,

37.5, and 50 minutes.

4 CONCLUSIONS

A novel force sensor was designed and fabricated

for measurement of mechanical forces generated by

fibroblast cells. The sensor was designed with the

aid of finite element simulations of the sensor

behavior. The device was fabricated from

polystyrene using a soft lithography based

fabrication procedure. Force magnitudes and

directions were measured using WS1 skin fibroblast

and show the ability to measure variation in the cell

mechanics over time.

Figure 3: (a,c) Force magnitude versus time for two separate experiments. (b,d) Force direction corresponding to the forces

in (a,c). The boxes highlight that the majority of the forces are oriented in the direction toward the center of the structure.

(a)

(b)

(

c

)

(d)

(

a

)

(

b

)

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

154

Figure 4: Phase contract micrographs with vector force overlays at (a) 0 min. (b) 30 min. (c) 37.5 min. and (d) 50 min. Note

the difference in the force vector scale in (d).

ACKNOWLEDGEMENTS

The authors would like to thank Derek Ditmer and

Paul Stefan at the Ohio Nanotech West Laboratory

for technical assistance. We also thank Derek

Ditmer and Landon McCaroll for assistance with

image analysis.

REFERENCES

Beningo, K.A., Wang, Y., 2002. Flexible substrata for the

detection of cellular traction forces. Trends in Cell

Biology, 12, 79-84.

Chen, C.S., Mrksich, M., Huang, S., Whitesides, G.M.,

Ingber, D.E., 1997. Geometric control of cell life and

death. Science, 276, 1425-1428.

Chicurel, M.E., Chen, C.S., Ingber, D.E., 1998. Cellular

control lied in the balance of forces. Current Opinions

in Cell Biology, 10, 232-239.

Choquet, D., Felsenfeld, D.P., Sheetz, M.P., 1997.

Extracellular matrix rigidity causes strengthening of

integrin-cytoskeletal linkages. Cell, 88, 39-48.

Ferrell, N., Woodard, J., Hansford, D., 2007. Fabrication

of polymer microstructures for MEMS: sacrificial

layer micromolding and patterned substrate

micromolding. Biomedical Microdevices, 9, 815-821.

Glabraith, C.G., Sheetz, M.P., 1998. Forces on adhesive

contacts affect cell function. Current Opinions in Cell

Biology, 10, 566-571.

Galbraith, C.G., Sheetz, M.P., 1997. A micromachined

devices provides a new bend on fibroblast traction

forces. PNAS, 94, 9114-9118.

Harris, A.K., Wild, P., Stopak, D., 1980. Silicone rubber

substrata: a new wrinkle in the study of cell

locomotion. Science, 208, 177-179.

Lo, C., Wang, H., Dembo, M., Wang, Y., 2000. Cell

movement is guided by the rigidity of the substrate.

Biophysical Journal, 79, 144-152.

Tan, J.L., Tien, J., Pirone, D.M., Gray, D.S., Bhadriraju,

K., Chen, C.S., 2003. Cell lying on a bed of

microneedles: an approach to isolate mechanical force.

PNAS, 100, 1484-1489.

Wrobel, L.K., Fray, T.R., Molloy, J.E., Adams, J.J.,

Armitage, M.P., Sparrow, J.C., 2002. Contractility of

Single Human Dermal Myofibroblasts and Fibroblasts.

Cell Motility and Cytoskeleton., 52, 82-90.

Xia, Y., Whitesides, G.M., 1998. Soft lithography. Angew.

Chem. Int. Ed., 37, 550-575.

(c)

(

d

)

(

a

)

(

b

)

MEASUREMENT OF CELL FORCES USING A POLYMER MEMS SENSOR

155