A Hybrid Multi-Experts Methodology for Mechanical

Defects’ Detection and Diagnosis

Kurosh Madani

1

, Moustapha Sene

2

and Véronique Amarger

1

1

Images, Signals, and Intelligent System Laboratory (LISSI/ EA 3956)

PARIS-EST/ PARIS 12 University, Senart Institute of Technology

Avenue Pierre Point, Lieusaint, 77127, France

2

Gaston Berger University, UFR SAT, Route de Ngallèle, BP 234 Saint-Louis, Sénégal

Abstract. Compared with parametric classifiers, several advantages set Neural

Networks as privileged approaches to be used as discriminating classifiers in

performing diagnosis tasks. In this paper, we present a hybrid Multi-Experts

neural based architecture for mechanical defects’ detection and diagnosis. This

solution is evaluated within vibratory analysis frame using a wavelet transform

faults’ detection scheme.

1 Introduction

Monitoring of mechanical systems requires development of adapted procedures com-

patible with the operation ranges (shapes) of the monitored devices. Generally, be-

haviours analysis is associated to a set of signals (called also signatures of the moni-

tored effects”). An example of such signatures could be obtained from chemical or

physical characteristics of materials composing the monitored mechanical devices or

involved in their operational phases, as: current, lubricant viscosity, acoustical signa-

tures, etc. For bearing defects, these signatures are characterized by transitory phe-

nomena (repetitive or random) due to the shocks’ effect on the structures. Such signa-

tures compile the frame of the vibratory analysis. A number of previous works show

that vibratory analysis issued signatures include pertinent information about mechani-

cal devices’ worsening [1], [2]. Note that conventional approaches of signal process-

ing don’t permit to exploit this information in its totality especially if the related sig-

natures are not periodical signals [3].

The general frame of the present work deals with early faults’ detection in indus-

trial plants, especially with mechanical faults’ detection in turning machines. For the

turning machines, the main faults which could be diagnosed through vibration analy-

sis are: imbalance, misalignment, looseness, shaft, bearing and gear damages, cavita-

tions in pumps, turbulent flows in ducts, foundation problems and electrical faults [4].

An additional difficulty related to the above-mentioned defects is due to the fact a

large part of mechanical devices in a turning machine are inaccessible, because they

are generally located inside the machine. Concerning inaccessible mechanical de-

vices, the vibratory analysis issued techniques show attractive features because they

may detect vibratory effects of internal devices from a global vibratory signature.

Proceedings of ICINCO 2009

6th International Conference on Informatics in Control, Automation and Robotics

Copyright © INSTICC

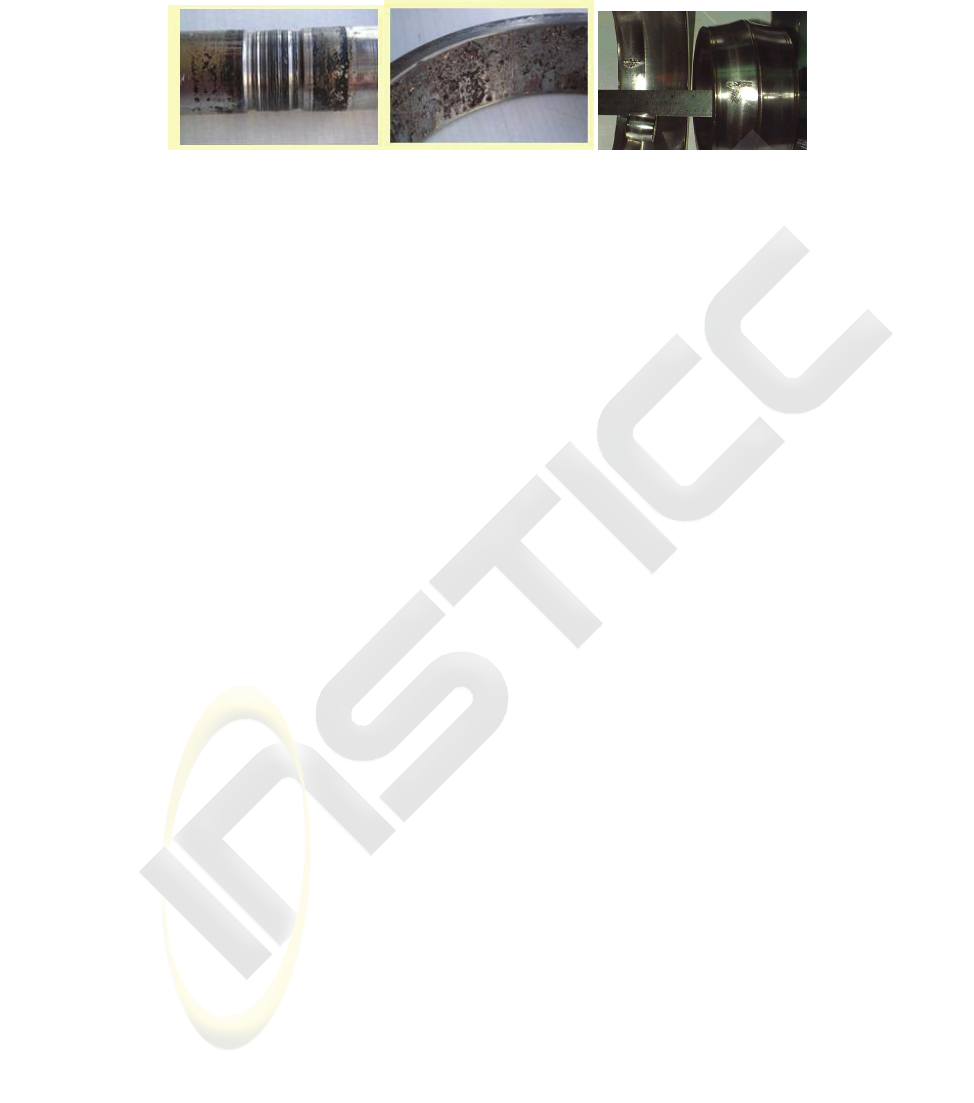

Fig. 1. Examples of “Unbalanced Force Defect’s” effect on turning plant’s rotation axis (left)

and “Flaking Path Defect” in a bearing device (middle and right).

We propose different slant, associating wavelet transform, vibratory analysis (be-

cause of the aforementioned advantages) and Artificial Intelligence issued approach-

es. In fact, beside the vibratory analysis issued techniques’ advantages, wavelet trans-

form could act as some kind of “zoom” effect (multi-resolution capability) in order to

separate appropriated frequencies’ components (those related to potential faulty be-

havior) from monitoring signal’s of others components. On the other hand, artificial

intelligence is used for classification tasks (fault’s nature authentication). Taking

advantage from neural networks’ based classifiers and their learning and generaliza-

tion [5], [6], these techniques are applied for characterizing bearings deterioration.

The two bearing device defects’ categories we are interested in this paper are: “Un-

balanced Force Defect” (UFD) and “Flaking Path Defect” (FPD). Fig. 1 shows exam-

ples of the impact of such defects on turning plants’ mechanical devices. A compara-

tive study between our hybrid technique and two neural network based architectures,

Radial Basis Function (RBF) network and Learning Vector Quantization (LVQ) net-

work, has been presented.

The paper will respect the following structure: the next section will briefly present

wavelet base defect detection within the vibratory analysis frame. The section 3 will

present the “expert-fusion” based classification approach: a key part of the proposed

solution. Section 4 and its subsections will give validation results and discussion.

Finally, the last section will conclude the paper and give a number o perspective

points.

2 Vibratory Analysis and Wavelet based Defects’ Detection

The detection procedure is based on the analysis of the minor (details) components of

the vibratory signature’s wavelet transform: the occurrence of a shock in the vibratory

behaviour is highlighted by the amplitude of the wavelet coefficients. The procedure

includes four steps:

1. Determining the needed resolution corresponding to the wavelet coefficients

ensuring the shocks’ detection,

2. Computing of detail (minor) wavelet transform coefficients,

3. Computing of indicators’ values relative to the vibratory signal,

4. Defect’s severity characterization by comparing the indicators’ values to a set

of knowledge based thresholds values.

The vibratory signature’s wavelet transform based processing opens the possibility

of a “multi-bands” vibratory analysis (e.g. multi-resolution detection), involving

several frequency bands. Thus, the proposed detection procedure could be run for

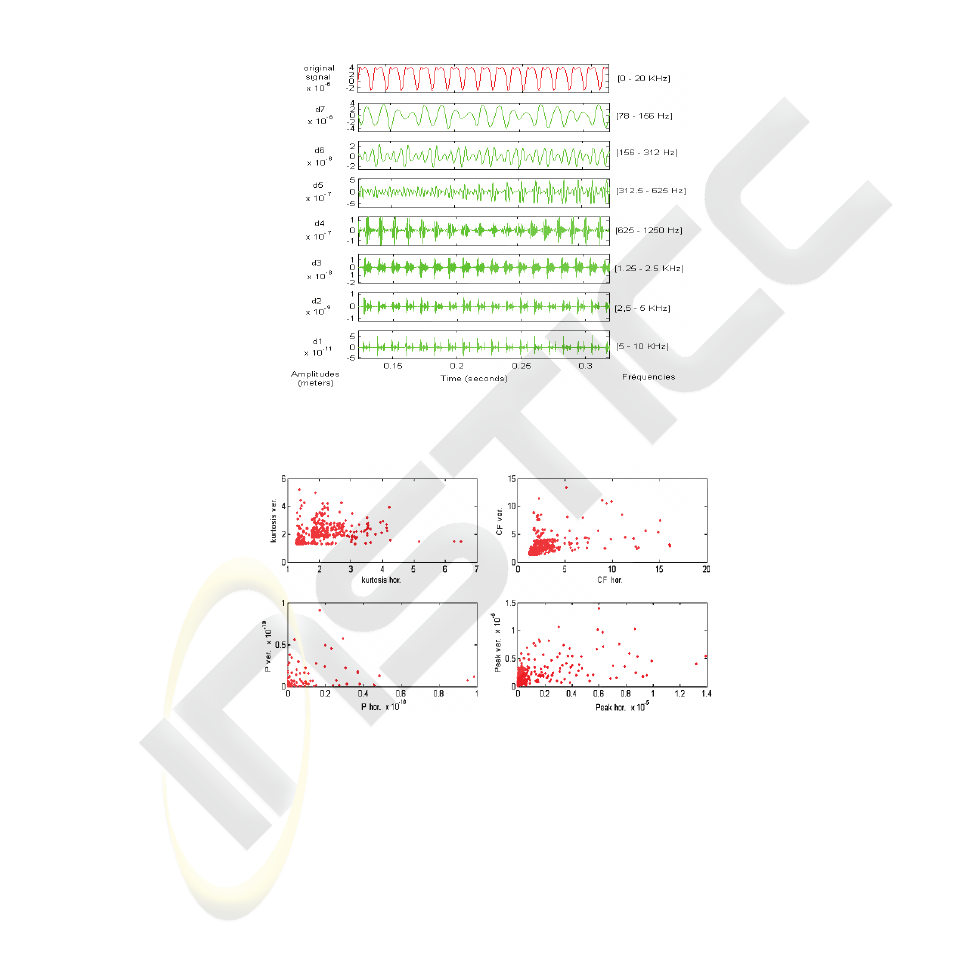

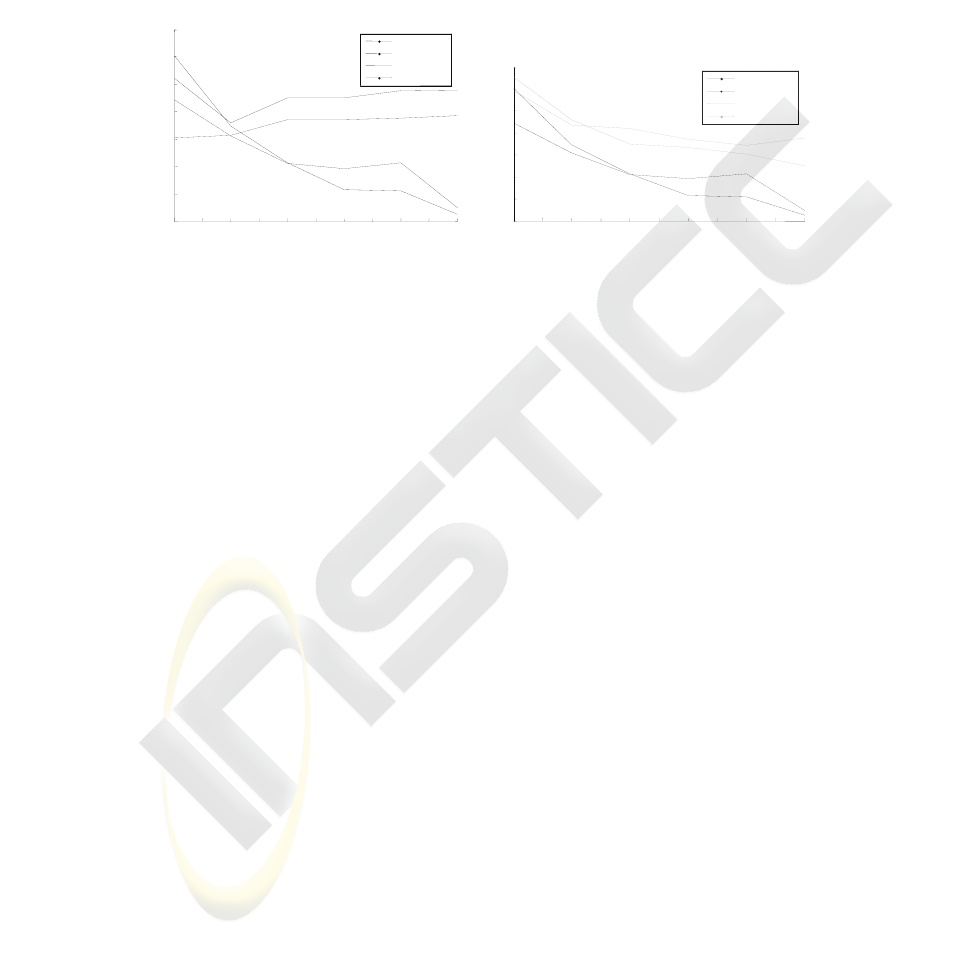

each of the obtained spectrum ranges (detail) [7], [8], [9], [10]. Fig. 2 shows an ex-

ample of obtained bands from an electromechanical turning machine issued vibratory

signature. The presence of one or several defects results in the apparition of new

frequencies. Detection of these new frequencies allows distinguishing potential

glitches, to classify them according to their typological features (unbalanced force

defect, flaking path defect, etc.) and to warn their consequences.

Fig. 2. Wavelet decomposition of a vibratory signal corresponding to flaking path defect (depth

157µm) at speed of 1500 rpm with wavelet sym7.

Fig. 3. Representation of the set of descriptions.

Concerning indicators, various scalar indicators as energy (E), peak, crest factor

(CF), power (P), root mean square (rms), shape factor (SF) and kurtosis (kur) [10]

[11] [12] could be valuable markers to define a “Multi-Features Vector” (MFV)

which will be used as input for the classification unit. Concerning bearing devices

such MFV are constructed for two directions of involved forces: horizontal and verti-

cal.

T

Pj

FeatureFeatureFeatureFV ],,,,[M

1

""=

(1)

],,,[M kurSF,rmsPCF,peakE,FV =

(2)

The analysis of data relative to the monitored plants’ faulty or healthy operational

modes in such feature spaces (defined on the basis of the constructed MFV) is a cru-

cial point in defining classes’ reparability boundaries and rules in order to make the

classifier’s action more accurate. Fig. 3 shows the data representation corresponding

to different aforementioned indicators in a bi-variables feature subspace constructed

from horizontal and vertical components of those indicators. It shows the possibility

to identify appropriated shapes of corresponding to healthy and deficient behaviours

of the concerned mechanical device (here a bearing device). So, if the classification

task is of major importance in the proposed technique, the choice of pertinent indica-

tors (via the above-mentioned data analysis in indicator’s issued feature space) and a

reliable detection (performed here by using a wavelet based multi-resolution ap-

proach) are two other strong points in our technique.

3 Multi-Experts based Classification

The classification strategy we propose is based on Multi-Experts principle also

known as “Mixture of Experts” based approach. In such class of processing strategy

the final output (the treatment’s result) is constructed (obtained) from a set of local

models (experts) which are specialized (devoted) either to a specific processing task

or to a specific region of the processed problem’s feature space. The final result is

obtained from a fusion of local models’ outputs or from a decision policy involving

either the whole experts or a reduced number (a subset) of specialized processing

units.

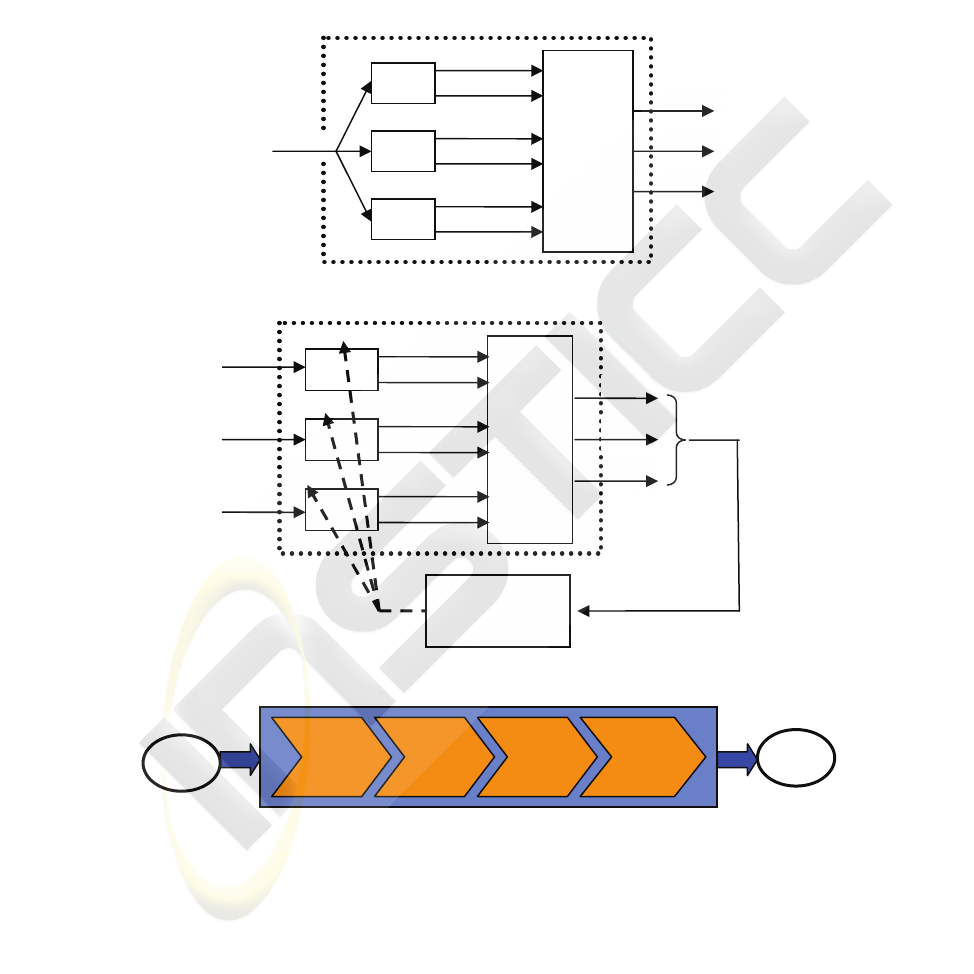

Fig.4. Single-Expert ANN based classifier.

It should be noted that the outputs’ fusion operation is not exclusive (specific) to

Multi-Experts schemes and may be used as a resource to perform the decision task.

An example is depicted in Fig.4 where a 3-categories classification, performed using

a single artificial neural network, takes advantage from a decision to carryout the

final classification. The decision policy could involve either matching rules or combi-

nation policy to construct the final decision.

In our approach, the proposed scheme is a Multi-Expert neural based classifier in-

cluding three neural networks (operating as local features’ classification modules)

where the final output (classification result) matches three possible turning plant’s

Class 1

Input x(n)

Neural

Network

COMBINATION

UNIT

y

2

(n)

Class 2

Class 3

y

1

(n)

y

3

(n)

operational categories. Two among those three categories correspond to a faulty bear-

ing device and one to a healthy bearing device meaning a “Normal” state (N) of the

concerned mechanical device. The two bearing device defects’ categories are “Unbal-

anced Force Defect” (UFD) and “Flaking Path Defect” (FPD), respectively. The

decision unit operates on the basis of combinatory matching rules in order to carryout

a unique class (category) among the three above-mentioned possible categories.

Fig. 5. Multi-Expert ANN based classifier’s bloc-diagram.

Fig. 6. Training scheme of Multi-Expert ANN based classifier.

Fig. 7. Global bloc-diagram of the proposed solution.

Concerning the experts, each of them is specialized in matching between two classes:

one of them is concerned with FPD and N classes’ discrimination, the other deals

with the classification of UFD and N functioning categories and the last one distin-

guishes between FPD and UFD classes of bearing defects. Fig. 5 gives the classifier’s

bloc diagram. The neural based classifier’s knowledge construction is done over a

PROPOSED SOLUTION

Defect

Diagnosis

Signa-

tures

Signals’

Processing

Fault

Detection

Behavior

Classification

Knowledge

Exploitation

Input 1

Class 3

Input 3

y

1

(n)

y

2

(n)

Input 2

ANN

2

FUSION

UNIT

Class 1

Class 2

ANN

3

ANN

1

y

3

(n)

y

4

(n)

y

5

(n)

y

6

(n)

Learning

Mechanism

Class 3

y

5

(n)

y

6

(n)

y

3

(n)

y

4

(n)

y

1

(n)

y

2

(n)

Input

ANN

2

FUSION

UNIT

Class 1

Class 2

ANN

3

ANN

1

training process involving each of the three neural networks separately. Fig. 6 gives

the learning mode’s bloc diagram. Two kind of local neural network based experts

have been implemented and compared: Learning Vector Quantization (LVQ) neural

structure and Radial Basis Function (RBF) neural model. The global bloc-diagram of

the proposed solution is shown in Fig. 7.

4 Validation, Results and Discussion

4.1 Experimental Set-up and Protocol

The experimental protocol for validation of the above-described automated diagnosis

chain has been based on detection and diagnosis (authentication) of the two afore-

mentioned defects in SKF-6002 bearing device. Table 1 gives topological and dy-

namical characteristics of the SKF-6002. So, three operational categories (classes)

have to be detected and

recognized: the normal class, the unbalanced defect class and

the flaking path defect class (correspondent to a diagnosis of the defect detected

which is being a failing of the flaking path of the outer race). According to the previ-

ously identified indicators, a training database containing 1594 MFV has been con-

structed, including a number of MFV corresponding to each possible class. The ratio

of each class in the learning database is reported in table 2. The same table gives the

ratio of each class within the testing database which includes 798 MFV. The two

kinds of above-described defects are present with different degrees of impairment as

well in learning database as in testing one. Concerning the unbalance forces’ related

defects, the considered rotation axis dislocations correspond to misbalancing forces

covering 10 to 100 g.cm. While, the flaking paths defects correspond to fissures of

280 μm average deep and a varying width covering the range of 30 to 910 μm.

Table 1. Technical and geometrical features of deep grove ball bearing SKF-6002.

4.762 mm

18.738 mm

28.262 mm

20

μ

m

3 μm

2

μ

m

6 N

0.6, 1.0 and 2.4 k

g

200 Ns/m

9

8

π/4

Constant for Hertzian contact elastic deformation

(

k

)

7,055.10

9

N/m

3/2

Ball diameter

Inner race diameter (

d

)

Outer race diameter (

D

)

Radial clearance (

γ

)

Maximum amplitude of waviness (

Πp

)

Initial amplitude of waviness (

Πo

)

Radial load (

W

)

Mass of rotor (

m

)

Damping factor (

c

)

Number of balls (

Nb

)

Number of wave lobes (

N

)

Angular location (

S

)

Table 2. Number of Multi-Feature Vectors (MFV) used in training and testing phases as well

as the ratio of signatures: healthy, unbalanced defect and flaking path defect (%).

Number of MFV Normal Unbalanced force Flaking path defect

1594 (for training) 34.6 29.9

35.5

798 (for testing) 49.9 30.1 20.0

For validation experiments we have considered two following cases: a detec-

tion/authentication chain based with a single neural network classifier and our hybrid

multi-experts scheme. As well for the single neural network based classifier as for the

hybrid solution, two kind of neural models (LVQ-like neural net and RBF-like

model) have been implemented.

4.2 Experimental Set-up

Table 3 summarizes results relative to obtained performances using single neural

network based scheme. For each kind of classifiers different MFV have been consid-

ered. The considered MFV are composed by previously introduced (in section 2)

scalar indicators measures in horizontal and vertical directions. They differ in number

of components (number of indicators composing the MFV). The number of compo-

nents varies from 4 (corresponding to horizontal and vertical measures of 2 indica-

tors) to 14 (corresponding to same measures of 7 indicators) and defines the number

of neurones of the input’s layer. The output layer of each neural classifier contains 3

neurons corresponding to the 3 possible operation categories.

Table 3. Performances of the single neural network based classifier – plant’s rotation speed is

400 rpm.

566

405

477

78

551

494

240

55

160

81

398

362

% 41,62

798

498

=

% 29,61

1594

977

=

160

112

240

222

398

299

% 32,79

798

633

=

566

542

477

426

551

371

% 00,84

1594

1339

=

566

539

477

388

551

446

% 14,86

1594

1373

=

160

97

240

206

398

297

% 19,75

798

600

=

551

450

477

427

566

561

% 21,90

1594

1438

=

160

145

% 21,82

798

656

=

240

213

398

298

Generalization

Memorization

Generalization

Memorization

Generalization

Memorization

Generalization

Memorization

Sequences of

observations

RBF

LVQ

Neural

Network

Type

16024039814

56647755114

1602403984

5664775514

16024039814

56647755114

1602403984

5664775514

FDRUDRNR

Average

Detection Rate

Correct Detect RateNumber of Data Sets

N UFD FPD

Dimension

of Input

Vector

Generalization

Memorization

Generalization

Memorization

Generalization

Memorization

Generalization

Memorization

Sequences of

observations

RBF

LVQ

Neural

Network

Type

16024039814

56647755114

1602403984

5664775514

16024039814

56647755114

1602403984

5664775514

FDRUDRNR

Average

Detection Rate

Correct Detect RateNumber of Data Sets

N UFD FPD

Dimension

of Input

Vector

In the same way and considering the same MFV, Table 4 gives the obtained results

for hybrid Multi-Experts chain. The local neural experts are RBF-like neural net-

works.

It is interesting to note from Table 3 that in the case of RBF-like single neural net-

work based classifier the generalization (e.g. testing) using MFV including 2 indica-

tors (e.g. 4 components) performs better results than those obtained with a 7 indica-

tors MFV (e.g. 14 components). This could be explained by the fact that considering

more indicators leads to increase the input feature space dimensionality for a same

number of learned (representative) patterns and thus, the RBF-like classifier (which

operates on the basis of a patters’ distance issued matching policy) has to map a lar-

ger feature space with the same number of learned patterns. While the same table

shows that LVQ-like neural classifier leads to quite similar (rates of defects’ correct

detection and classification between 75 and 80 %) either using MFV including 7

indicators or exploiting 2 indicators MFV (even if the obtained results are slightly

better when 7 indicators are used). This is due to the conjunction of two facts. The

first one is related to the fact that in LVQ-like neural model the matching is obtained

in “competitive layer” of such network performing a “Winner Takes All” (WTA)

policy. In fact, the two defects’ categories as well as the healthy operational state are

matched essentially on the basis of two (among seven) indicators, but as the matching

is obtained from a WTA based decision policy (excusive decision), the increase of the

input feature space’s dimensionality remains of a limited effect on classification per-

formance. Beside this first factor, another reason avoiding the classification rate de-

creasing here is related to the fact that the major data is discernible enough regarding

the above-described matching policy in 2-D feature space obtained from the first two

indicators. The similar performances obtained with RBF-like classifier (82% correct

classification) when 2 indicators are used confirms this purpose

Table 4. Performances of the Multi-Experts based classifier – plant’s rotation speed is 400

rpm.

1602400ANN

3

89,730240398ANN

2

1600398ANN

1

Generalization

4 indicators

5664770ANN

3

92,71 %0477551ANN

2

5660551ANN

1

Memorization

4 indicators

FDRUDRNR

Average

Detection Rate

Individual

Average

Detection

Correct Data Rate

Number of Data Sets

N UFD FPD

RBF architecture

1602400ANN

3

89,730240398ANN

2

1600398ANN

1

Generalization

4 indicators

5664770ANN

3

92,71 %0477551ANN

2

5660551ANN

1

Memorization

4 indicators

FDRUDRNR

Average

Detection Rate

Individual

Average

Detection

Correct Data Rate

Number of Data Sets

N UFD FPD

RBF architecture

477

419

566

559

% 77,93

1043

978

=

477

455

% 32,92

1028

949

=

566

566

% 03,92

1117

1028

=

551

462

160

145

398

324

% 05,84

558

469

=

160

159

240

211

% 50,92

400

370

=

398

360

% 63,92

638

591

=

551

494

240

231

However, the slightly better results obtained with RBF architecture with MFV includ-

ing 2 indicators (4 components) seems to privilege the use of this neural classifier

against in spite of the LVQ based classifier. That is why the Multi-Experts architec-

ture has been implemented including three RBF networks. Results are reported in

Table 4. It is pertinent to note the significant enhancement of classification rate. Fig.

8 completes the results of the two last tables by giving learning and generalization

performances versus the number of involved (exploited) indicators. If Fig. 8-a con-

firms the results consequences of the first table (Table 3), the second (e.g. Fig. 8-b)

reveals an additional interesting point. In fact it is interesting to note the enhancement

of classification rate as well when a 4 component MFV is exploited as when the input

MFV includes 14 components (a 15% classification rate increasing). That shows the

experts’ mixture strategy’s pertinence (efficiency).

(a)

4 5 6 7 8 9 10 11 12 13 14

60

65

70

75

80

85

90

95

Number of indicators in inputs vector

Average Detection Rate (%)

Global configuration of classifier

Memoriz. RBF

Generiz. RBF

Memoriz. LVQ

Generiz. LVQ

4 5 6 7 8 9 10 11 12 13 14

60

65

70

75

80

85

90

95

Number of indicators in inputs vector

Average Detection Rate (%)

Global configuration of classifier

Memoriz. RBF

Generiz. RBF

Memoriz. LVQ

Generiz. LVQ

(b)

4 5 6 7 8 9 10 11 12 13 14

60

65

70

75

80

85

90

95

Number of indicators in inputs vector

Average Detection Rate (%)

Based Configuration on the mixture of experts

Global RBF mem.

Global RBF gen.

Mixture RBFmem.

Mixture RBF gen.

4 5 6 7 8 9 10 11 12 13 14

60

65

70

75

80

85

90

95

Number of indicators in inputs vector

Average Detection Rate (%)

Based Configuration on the mixture of experts

Global RBF mem.

Global RBF gen.

Mixture RBFmem.

Mixture RBF gen.

Fig. 8. Performances of training and generalization versus number of involved features for

single neural network based classifier (a) and Multi-Expert solution (b).

5 Conclusions and Perspectives

We have presented a hybrid Multi-Experts neural network based architecture for

mechanical defects detection and authentication in turning plants, which are mas-

sively present in industrial production chains. The pertinence of the experts’ mixture

strategy has been shown and validated. On the other hand, the advantage of a wavelet

transform based multi-resolution detection leads to capability of simultaneous detec-

tion of different kind of mechanical defects. Finally, the use of vibratory analysis

technique make possible the inaccessible mechanical devices’ monitoring from a

global vibratory signature obtained from relatively low cost standard sensors.

Acknowledgements

Authors whish express their gratitude to Dr. Michel Barret, keeping his name alive.

Dr. M. Barret have worked during several years within this project and unfortunately

leave us after his last battle against a long diseases.

References

1. N. Tandon, A. Choudhury, “A review of vibration and acoustic measurement methods for

the detection of defects in rolling element bearings”, Trib. Internat. 32, p. 469-480, (1999).

2. S. P. Harsha, “Non linear dynamic response of a balanced rotor supported on rolling ele-

ment bearing”, Elsevier, Apr. (2004)

3. Juez, G. I. Sainz, E. J. Moya and J. R. Peran, Early detection and diagnosis of faults in an

AC Motor, Bio-Inspired Applications of Connectionism (J. Mira and A. Prieto (Ed.)), Lec-

ture Notes in Computer Science Series, Spinger Verlag, pp. 595-602, (2001)

4. Z. Chen, Y. He, F. Chu, J. Huang, “Evolutionary strategy for classification problems audits

application in fault diagnostics”, Pergamon, Engineering Applications of Artificial Intelli-

gence 16, p. 31-38, (2003)

5. R. P. Lippman, “An Introduction to Computing with Neural nets”, IEEE ASSP Magazine,

pp. 4-22, April (1987)

6. A. Boulenger, C. Pachaud, “Vibratory analysis in plants’ monitoring, maintenance and

diagnosis”, 2

nd

edition, Dunod, Paris, (2004) - (in French)

7. G. Zwinggelstien, “La maintenance basée sur la fiabilité, guide pratique d’application de

la RCM ”, Hermès, Paris, (1996) - (in French).

8. M. Barret, A-S Dujardin, V. Amarger, K. Madani, J-F. Durastanti, “Mechanical faults

recognition using wavelet transform and artificial neural network techniques”, in “Com-

puter Information Systems and Industrial Management Applications”, Ed. K. Saaed & al.,

Conradi Research Review, ISBN 83-87256-55-2, pp. 243-251, (2003)

9. J. Anoni, R.B. Randal, The spectral kurtosis: application to the vibratory surveillance and

diagnostics of rotating machines, Elsevier, Mechanical Systems and Signal Processing,

(2004)

10. J. P. Don, F. Bolaers, L. Rasolofondraibe, Optimization of the detection of rolling bearing

defects using spectral subtraction de-noising of the signal, Elsevier, pp. 213-219, (2003)

11. Z. Kiral, H. Karagulle, Simulation and analysis of vibration signals generated by rolling

element bearing with defects, Tribology International 36, p. 667–678, Elsevier, (2003)