Optimizing Operation Costs of the Heating System of a Household

using Model Predictive Control Considering a Local PV Installation

Cosmin Koch-Ciobotaru

1

, Fridrik Rafn Isleifsson

2

and Oliver Gehrke

2

1

Automation and Applied Informatics, Politehnica University of Timisoara, Blv. Parvan 2, Timisoara, Romania

2

Intelligent Energy Systems, Technical University of Denmark, Frederiksborgvej 399, Roskilde, Denmark

Keywords: Model Predictive Control, Optimization, Cost Minimization, Dynamic Thermal Storage, PV Penetration.

Abstract: This paper presents a model predictive controller developed in order to minimize the cost of grid energy

consumption and maximize the amount of energy consumed from a local photovoltaic (PV) installation. The

usage of as much locally produced renewable energy sources (RES) as possible, diminishes the effects of

their large penetration in the distribution grid and reduces overloading the grid capacity, which is an

increasing problem for the power system. The controller uses 24 hour prediction data for the ambient

temperature, the solar irradiance, and for the PV output power. Simulation results of a thermostatic

controller, a MPC with grid price optimization, and the proposed MPC are presented and discussed.

1 INTRODUCTION

The main issue (Vandoorn, 2011) is that the

electrical distribution grid was not designed for bi-

directional power flow, i.e. that power would not

only flow to the lower voltage levels where most

consumer are connected, but that it could also flow

“up” to the higher voltage levels.

The increased amount of PV plants in the

distribution grid introduces some complications,

such as the fluctuating nature of PV production

which has limited predictability (Madureira, 2009).

There are fast fluctuations, due to cloud transients,

which cause problems with voltage regulation. There

are also slower fluctuations due to the movement of

the sun and changes in cloud cover, so if the PV

plant generation is not coordinated with the local

consumption it might be necessary to invest in more

grid capacity as presented in (Ueda, 2007).

In the distribution grid there is also a foreseeable

increase in new types of loads, such as heat pumps

and electric vehicles, both loads that can to some

degree act as flexible loads as shown in

(Madureira,2009).

If loads that are flexible can be intelligently

managed, it could be possible to help the distribution

grids to cope with both increased renewable

production and increased loads. Furthermore, this

intelligent control could also reduce the need for

expensive grid extensions if loads and production

are coordinated locally.

This control is seeking to incorporate predictions

of weather, occupancy behaviour, renewable energy

availability, and price signals from the grid. The

model predictive control (MPC) presents a

methodology that can use all these predicted values

in order to improve the energy efficiency

consumption by load shifting and peak shaving,

minimize the cost of operation by using low price

energy, as shown in (Nagai, 2002) and in (Ma 2011),

and maximizing the use of renewable energy.

This paper proposes a MPC that minimizes the

overall electrical energy cost of heating a building

which also has a local PV installation. By using the

buildings ten 1 kW heaters, a price signal for

electrical energy, a prediction of solar irradiation, of

PV output power, and of ambient temperature it is

possible to coordinate the heaters consumption so

that as much energy as possible is consumed from

the locally produced PV.

2 MODEL OF THE SYSTEM

Model predictive control uses a model of the system

in order to predict the process output over a future

horizon of N time steps and solves a quadratic

optimization problem with the control signal as the

decision variable. In addition, constraints can be

formulated both for manipulated and controlled

431

Koch-Ciobotaru C., Rafn Isleifsson F. and Gehrke O..

Optimizing Operation Costs of the Heating System of a Household using Model Predictive Control Considering a Local PV Installation.

DOI: 10.5220/0004054804310436

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 431-436

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

variables as formulated in (Huusom, 2010) and

(Oldewurtel, 2010).

The model used in this paper is extensively

presented in (Bacher, 2010) and represents a house

of approximately 125 m

2

divided between eight

rooms. Every room is equipped with heaters: two

rooms have two heaters and the others have one

heater each. The heaters are considered to have the

output power of 1kW.

The model approximates the interior of the

building to be one room with a uniform inside

temperature. The state variable is the inside

temperature (T

i

), the input is the power to the heaters

(P

H

) and the disturbances are the solar irradiance (G)

and the ambient temperature (T

a

).

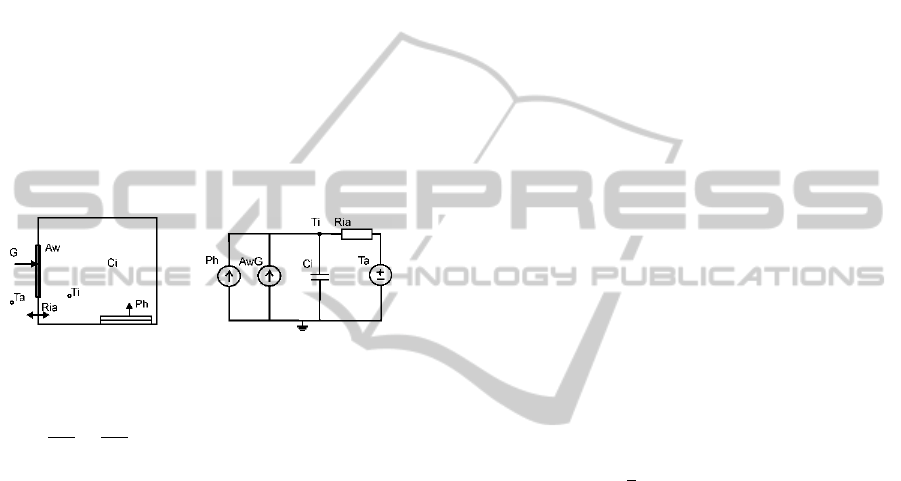

The temperature dynamics of a given space can

be modelled using a resistance-capacitance (RC)

circuit analogy, see figure 1, and formulated as a

linear state space model.

(a) (b)

Figure 1: Thermal dynamic model of the house.

(1)

Where C

i

is the heat capacity of the house. This

includes the indoor air and the interior objects

(=3.42 [kW/°C])

R

ia

is the thermal resistance from the indoor to

the ambient environment (=4.87 [°C/kW])

A

w

is the effective window area of the house

with heating influence (=5.53 [m

2

])

3 OFFSET FREE MPC

The predicted disturbances values that are available

to the model usually present an error compared to

the real measured values. In order to eliminate the

offset caused by these differences, filters have to be

implemented for each of the predicted values fed

into the controller. In this way, the controller will

not track the predicted values, but their variations.

This gives, compared to Equation 1, an extended

state space model with an additional state for each

filtered variable:

(2a)

(2b)

For simplification, we introduce the new state

model on the basis of equation 3:

(3a)

(3b)

The usage of a Kalman filter in the algorithm

consists of two stages that run cyclically:

- Time update – responsible for projecting the

state ahead

(4)

- Measurement update – which has the role to

‘correct’ the estimated values by considering the

measurements taken from the system

(5)

The covariance P is a symmetric positive

semidefinite solution of the discrete Ricatti equation:

(6)

The covariance of the innovations R

e

and the

predictive Kalman gain K

f

are computed using

equations 7 and 8:

(7)

(8)

The simulation uses the quadprog solver from

Matlab for which the optimization problem has to be

rewritten in the form of Equation 9:

(9)

Subject to

(10)

The model output for the predicted horizon of N

time steps is:

(11)

Equation 4 has the following coefficients:

(12)

(13)

Where

(14)

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

432

In this case, the result of the MPC optimization

problem is the difference ∆u

k

and the command to

the system is u

k

= u

k-1

+ ∆u

k

.

4 SIMULATION SCENARIOS

In all the simulations the MPC controller uses the

model described in Equation 2.

These two additional state variables are used for

implementing the filter in order to achieve offset

free control in the presence of deviations from the

predicted values of the two disturbances.

The MPC controller has hard limitations on the

controlled variable – the inside temperature, that has

to be inside [20...22]°C interval and on the

manipulated variable – power supplied to the

heaters, that has to be in the [0...10] kW interval, and

can have only integer as power steps.

The MPC controller starts with offline predicted

values for solar irradiance, temperature, and grid

price and for the third simulation case, the predicted

PV power output.

The time step of the simulations is 10 minutes,

and the prediction horizon is 80 time steps.

During each simulation, two different cases can

be studied:

- The first, when the house does not have any PV

installation – the heaters are consuming power

entirely from the grid

- The second, when the house has a PV

installation – the heaters are consuming power both

from the PV plant and from the grid. The higher

priority is to consume from the local PV plant and

the remaining required power is taken from the grid.

The amount of unused PV energy is sold to the grid.

4.1 Simulation Scenario 1

A thermostatic controller is implemented to maintain

the temperature inside given limits: [19.2...21]. For

comparison reasons, the limits in this simulation

scenario differ from the other two scenarios in order

that the average temperature in the house, for the

simulation time, to be the same. This has the purpose

to accurately reflect the MPC controller’s effect in

similar operation conditions.

4.2 Simulation Scenario 2

The MPC tracks the inside temperature with

minimal overall energy cost. The controller is

considering all the energy to be taken from the grid,

at a market imposed price (C

G

).

The optimization function is represented by

Equation 15:

(15)

4.3 Simulation Scenario 3

The MPC controller tracks the inside temperature

with minimal overall energy cost, also considering

the power production of the installed PV panels. The

controller calculates a virtual price on which the

available PV power, that has a lower cost for the

user (C

PV

) of 0.02 Euros, is considered to alter, with

a weight factor, the market imposed price.

(16)

The cost minimization function would be

(17)

Considering U as the optimization variable and

replacing 16 in 17 the equation 18 is obtained:

(18)

Where C

G

– is the predicted price of the grid

energy

U – represents the vector with the next N

command values for the time horizon

P

PV

– represents the predicted output power from

the PV installation

(19)

Where additional assumptions were made:

-

- a weight factor

- at each optimization step, u

s

is taken as the

last command value, u

k-1

.

The optimization function is written as:

(20)

5 RESULTS

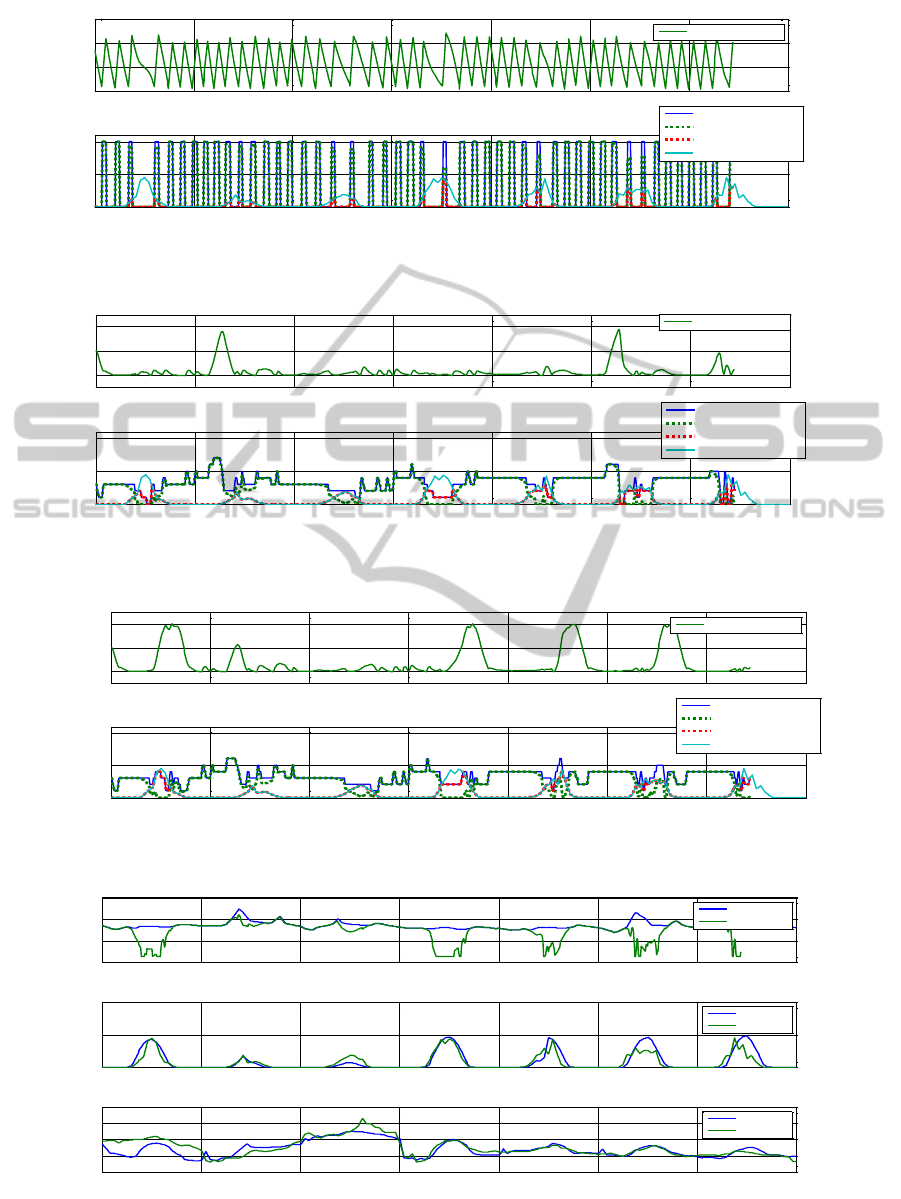

Results from the three simulation scenarios are

presented in Figures 2 to 4 and compared in Table 1,

where the following notations have been used:

Optimizing Operation Costs of the Heating System of a Household using Model Predictive Control Considering a Local PV

Installation

433

Figure 2: Thermostatic control.

Figure 3: MPC with grid price optimization.

Figure 4: MPC with virtual price optimization considering PV power output prediction.

Figure 5: Data used by controllers: price values, predicted and measured ambient data.

24 48 72 96 120 144 168

19

20

21

22

Inside temperature (

0

C)

t (hours)

Inside Temperature (

0

C)

24 48 72 96 120 144 168

0

5

10

Power

t (hours)

Power (kW)

Power for Heaters

Power from Grid

Power from PV

PV power generation

Inside temperature

24 48 72 96 120 144 168

20

21

22

Inside temperature (

0

C)

t (hours)

Inside Temperature (

0

C)

24 48 72 96 120 144 168

0

5

10

Power

t (hours)

Power (kW)

Power for Heaters

Power from Grid

Power from PV

PV power generation

Inside temperature

24 48 72 96 120 144 168

20

21

22

Inside temperature (

0

C)

t (hours)

Inside Temperature (

0

C)

24 48 72 96 120 144 168

0

5

10

Power

t (hours)

Power (kW)

Power for Heaters

Power from Grid

Power from PV

PV power generation

Inside temperature

24 48 72 96 120 144 168

0

0.02

0.04

0.06

Price

t (hours)

Price (Euros/kWh)

24 48 72 96 120 144 168

0

0.5

1

Solar irradiance

t (hours)

Solar irradiance (kW/m

2

)

24 48 72 96 120 144 168

-5

0

5

10

15

Ambient temperature

t (hours)

Ambient temperature (

0

C)

Real price

Virtual price

Predicted

Measured

Predicted

Measured

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

434

Table 1: Energy consumption and cost results from simulations.

Sim.

ID

Config.

Type

E

H

(kWh)

E

PV2H

(kWh)

E

G2H

(kWh)

E

PV

(kWh)

E

PV2G

(kWh)

C

G2H

(Euros)

C

PV2H

(Euros)

Avg Ti

(°C)

Simulation 1, with thermostatic controller around 20.14°C

S

11

No PV

496.66

-

496.66

-

-

16.75

-

20.14

S

12

PV

496.66

21.68

474.98

110.58

88.90

15.98

0.43

20.14

Simulation 2, with grid price optimization

S

21

No PV

496.66

-

496.66

-

-

16.61

-

20.14

S

22

PV

496.66

71.01

425.65

110.58

39.57

14.12

1.42

20.14

Simulation 3, with grid price and PV availability

S

3

PV

500.8

94.37

406.4

110.08

16.21

13.57

1.88

20.34

Sim. ID – simulation identifier

Config. Type – type of house configuration: with

or without PV installation

E

H

– the total energy consumed by the heaters

during simulation interval

E

PV2H

– the amount of energy consumed by the

heaters from the local produced PV energy

E

G2H

– the amount of energy consumed by the

heaters from the grid

E

PV

– the amount of energy produced by the PV

installation

E

PV2G

– the amount of energy produced by the

PV to be sold to the grid

C

G2H

– cost of E

G2H

in Euros

C

PV2H

– cost of E

PV2H

in Euros

Avg. Ti – average inside temperature over the

simulated time horizon

The grid energy prices are shown in the first plot

from Figure 5. It is assumed that the predicted grid

energy prices coincide with the actual ones. In the

same figure, the virtual price used during Simulation

3 is also plotted.

During simulations S

1x

and S

2x

the controller

does not present information regarding the presence

of an PV installation and acts according only to

signals available for each case, as stated in section 3.

Achieving the same average inside temperature

implies the same amount of energy is used. As the

ambient temperature and the solar irradiance are the

same for each simulation, the amount of electric

energy used to keep the inside temperature is the

same. The difference is represented by the heaters

consumption shifting according to the used

controller.

In S

1x

a thermostatic controller is used, as

presented in section 3. It can be seen that during

clear days, with large solar irradiance values, the

heaters are turned off most part of the day, the

thermal energy being largely taken from the ambient

factors. In S

12

only 21.68 kWh, representing around

20% of the available PV local produced energy, is

consumed from the PV.

In S

2x

the MPC with grid price optimization is

used. The same amount of electric energy is used as

in S

1x

, for achieving the same inside temperature.

However, the MPC shifts the heaters’ consumption

to low price moments, and stores thermal energy

before price peaks as it can be seen in Figure 3,

before the energy price peaks at time 200 and 780,

shown in Figure 5.

The MPC controller from S

2x

achieves a cost

reduction from 16.75 to 16.61 Euros in the case of

S

21

and from 15.98 to 14.12 in the case of using a

PV installation of S

22

. In S

22

, 71.01 kWh of local PV

energy is consumed, representing 64% of the PV

production.

However, the local PV energy usage for S

12

and

S

22

are unpredictable since the controller does not

consider the PV production.

In S

3

the MPC’s objective is to consume as much

locally produced energy as possible. This is realized

by implementing the virtual price, presented in

section 3, in the optimization function. Figure 4

depicts the operation of the MPC which uses the

house’s thermal capacity to store the local PV

energy during large solar irradiance values.

In this case, the cost of the energy consumed

from the grid is 13.57 Euros and 85% of the local

PV produced energy is consumed.

6 CONCLUSIONS

The paper emphasises the benefits of using model

predictive control for houses as dynamic thermal

energy storage.

By formulating the correct optimization

problems and feeding the controller with predictions

on the system’s variables, the MPC is able to

achieve cost reduction on the electrical energy

consumption from the grid.

As demonstrated through simulations in this

paper, the MPC can consider the presence of an

Optimizing Operation Costs of the Heating System of a Household using Model Predictive Control Considering a Local PV

Installation

435

installed PV plant maximizing the usage of locally

produced renewable energy. The consumption of

locally produced energy has a major benefit both for

the user, by lowering the overall cost of energy and

also for the operation of distribution grids with a

high penetration of renewable energy generation.

This paper presented an algorithm that deals with

the two problems: minimizing the operating cost of

the house heating system and maximizing the use of

local produced energy and lowering the burden on

the distribution grid.

From the source of power consumption

perspective, the algorithm can be extended to use the

energy from other types of local renewable energy

sources. It can be extended also from the perspective

of the types of loads that are shifted, not focusing

only on the heat system but also on different

household appliances.

The proposed algorithm can be used to manage

energy produced by other types of renewable energy

generation, such as wind turbines and combined heat

and power plants. The algorithm can also be

modified for other types of consumption that has the

ability to be shifted in time, such as water heaters,

air conditioning units and refrigeration systems.

ACKNOWLEDGEMENTS

This work was supported in part by the strategic

grant POSDRU/88/1.5/S/50783 (2009) of the

Ministry of Labor, Family and Social Protection,

Romania, co-financed by the European Social Fund

– Investing in people and also partially supported by

the E.U. Project No. 228449/2011.

REFERENCES

Bacher P., Thavlov A., Madsen H., Models for Energy

Performance Analysis, IMM-Technical Report-2010-

02.

Huusom J. K., Poulsen N. K. , Jørgensen S. B. and

Jørgensen J. B., 2010, Tuning of Methods for Offset

Free MPC based on ARX Model Representations. In

American Control Conference, ACC 2010, 30 June -02

July 2010 in Baltimore, USA.

Ma Y., Anderson G., Borrelli F., A Distributed Predictive

Control Approach to Building Temperature

Regulation. In American Control Conference, ACC

2011, 29 June – 01 July, 2011 in San Francisco, USA.

Madureira A. G. and Lopes J. A. P., Coordinated voltage

support in distribution networks with distributed

generation and microgrids. In IET Renewable Power

Generation, vol. 3, no. 4, pp. 439–454, Dec. 2009.

Nagai T., Optimization Method for Minimizing Annual

Energy, peak energy demand, and annual energy cost

through use of building thermal storage, ASHRAE

Transactions, vol. 108, no. 1, pp. 976-887, 2002.

Oldewurtel F., Parisio A., Jones C. N., Morari M.,

Gyalistras D., Gwerder M., Stauch V., Lehmann B.,

Wirth K., Energy Efficient Building Climate Control

using Stochastic Model Predictive Control and

Weather Predictions. In American Control

Conference, ACC 2010, 30 June -02 July 2010

Baltimore, USA.

Pannochia G. and Rawlings J., Disturbance Models for

Offset-Free Model Predictive Control. In AIChE

Journal 2003, Volume 49, Issue 2, pp. 426-437.

Ueda Y., Kurokawa K., Tanabe T., Kitamura K.,

Akanuma K., Yokota M., Sugihara H., Study On The

Over Voltage Problem And Battery Operation For

Grid-Connected Residential PV Systems. In 22nd

European Photovoltaic Solar Energy Conference, 3-7

September 2007, Milan, Italy

Vandoorn T. L., Renders B., Degroote L., Meersman B.,

and Vandevelde L., Active Load Control in Islanded

Microgrids Based on the Grid Voltage. In IEEE

Transactions on Smart Grid, Vol. 2, No. 1, pp. 139-

151, 2011

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

436