Ablation of (Ges

2

)

0.3

(Sb

2

S

3

)

0.7

Employing Nanosecond UV Laser

Petr Knotek

1, 3

, Jakub Navesnik

1

, Milan Vlcek

2, 3

and Ladislav Tichy

2, 3

1

University of Pardubice, Faculty of Chemical Technology, Studentska 573, 532 10 Pardubice, Czech Republic

2

Institute of Macromolecular Chemistry, AS CR, Heyrovskeho sq. 2, 162 06 Prague, Czech Republic

3

Present address: Joint Laboratory of Solid State Chemistry of Institute of Macromolecular Chemistry Academy of Sciences

of Czech Republic, v.v.i., and University of Pardubice, Studentska 84, 532 10 Pardubice, Czech Republic

Keywords: Chalcogenide Glass, Ablation, UV Nanosecond Laser, Microlens.

Abstract: The interaction of (GeS

2

)

0.3

(Sb

2

S

3

)

0.7

glass and UV nanosecond laser has been described. The material was

ablated and the dependencies of the most important parameters as number and energy of the pulses and

repetition rate to the volume of the craters were correlated.

1 INTRODUCTION

Laser based fabrication technologies are widely used

to prepare: thin films (PLD (Frumar et al., 2006)),

optical waveguide (Bryce et al., 2004), convex or

concave microlenses and microlens arrays (Lim et

al., 2006); (Fritze et al., 1998) as the passive optical

elements. The patterns are formed by the focusing

laser energy in order to process materials at the

microstructure (Hitz et al., 2012). Different types of

laser operation (continuous or pulsed modes) enable

to use proper combination of laser experimental set-

up to studied material and demanding process. The

absorption of photons can lead to excitation of

electrons in target materials. If the energy is high

enough, the energy transfer leads to the material

release by thermal vaporization or by photochemical

interactions (Hitz et al., 2012); (Knotek et al., 2012).

The influence of ultraviolet light (UVL) to the

certain optical and physical behavior of the

chalcogenide glasses and films has been previously

studied. There were described the classical photo-

induced effects as photo-darkening, photo-expansion

and decrease of the refractive index (Bryce et al.,

2004); (Messaddeq et al., 2001); (Marquez et al.,

2009). The unique changes of behavior were

accounted to the photo-induced structural changes in

an amorphous state, reaction with surroundings as

photo-oxidation or crystallization of the material

(Messaddeq et al., 2001), (Bryce et al., 2004).

In this communication we focused on the

interaction of UV pulsed laser with the bulk glassy

(GeS

2

)

0.3

(Sb

2

S

3

)

0.7

material. Ge-Sb-S system, mainly

(GeS

2

)

x

(Sb

2

S

3

)

1-x

stoichiometric system, renewed

attractiveness (Fatome et al., 2009); (Lin et al.,

2012) for a high stability to the humid air, high

linear and non-linear values of the refractive index

and high glass forming and crystallization

temperatures. We selected this chemical

composition as chemically (stoichiometric system)

and mechanically stable system (mean coordination

number of the glass (CN=2.45) is close to the

threshold value according Phillips model (Phillips,

1979)). The aim of this study was to examine

interaction of nanosecond UV laser with

(GeS

2

)

0.3

(Sb

2

S

3

)

0.7

glass and to determine some of

the most important parameters as the pulse laser

energy, the repetition rate and the number of pulses

in relation to the modification of the sample.

2 EXPERIMENTAL

The glassy (GeS

2

)

0.3

(Sb

2

S

3

)

0.7

bulk was prepared by

a direct synthesis from elements (5N purity)

according procedure described elsewhere (Knotek

and Tichy, 2012). The optically polished samples

were illuminated under the air atmosphere through 5

nsec pulsed laser operating at a wavelength 213 nm

in the laser ablation system LSX-213 G2 (CETAC,

USA) with the maximum emitted energy 4.5 mJ per

pulse.

The laser beam was focused onto the upper

surface by means of an optical microscope objective

to the spot with a diameter 25 µm. Two sets of

illuminated spots were formed for each combination

5

Knotek P., Navesnik J., Vlcek M. and Tichy L..

Ablation of (Ges2)0.3(Sb2S3)0.7 Employing Nanosecond UV Laser.

DOI: 10.5220/0004312300050009

In Proceedings of the International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2013), pages 5-9

ISBN: 978-989-8565-44-0

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Table 1: Material characteristics of the (GeS

2

)

0.3

(Sb

2

S

3

)

0.7

glass (E

03

band gap energy, the average coordination number

(CN)) and certain parameters which characterize the conditions of illumination: the wavelength (λ

ill

and photon energy

(ħω

ph

), the pulse energy (E

pulse

), the average emitted light intensity at repetition 20 Hz (I

aver.

), the corresponding penetration

depth of the light (d

p

), the area of the light spot on the sample (A), the effective volume (V

eff

=A*d

p

), where photons are

adsorbed and the absorbed light power (P

A

) during the pulse and average value.

E

03

/CN

*

(eV/-)

λ

ill

/ħω

ph

(nm/eV)

E

p

ulse

/

I

aver.

(mJ/mW)

d

p

(nm)

A

(cm

2

)

V

eff

(cm

3

)

P

A

aver.

/ P

A

p

ulse

(W.cm

-3

)

2.11/2.45 213/5.82 4.5/90 5 4.9×10

-6

2.5×10

-12

3.7×10

10

/3.7×10

17

* CN = 4x+3y+2(1-x-y) for Ge

x

Sb

y

S

1-x-y

(Philips, 1979)

of experimental parameters.

The chemical composition was verified using

electron microprobe X-ray (EDX) analyses (Jeol

JSM 5500-LV). In order to monitor surface and

near-sub-surface states the penetration depth of

electrons was adjusted to be at around 500 nm. The

transmission was measured using a Perkin-Elmer

Lambda 12 spectrophotometer.

Measurements with a digital holographic

microscope (DHM) were realized by means of a

DHMR1000 (Lyncée Tec, Switzerland) operating at

785 nm in a reflection configuration (Knotek et al.,

2009).

3 RESULTS AND DISCUSSION

Certain material characteristics of the studied glass

and the conditions of the samples illumination are

summarized in Table 1 (see (Knotek and Tichy,

2012); (Knotek et al., 2010) for details of analysis).

The UV photon energy was highly over-band gap

energy (E

ph

=5.82 eV >>E

03

=2.11 eV) and photons

were absorbed in thin layer (d

p

= 5 nm). These

conditions resulted to the high values of absorbed

light power (P

A

pulse

= 4x10

17

W.cm

-3

) followed by a

destruction of the bonding system, photons energy

conversion to the heat with low dissipation of the

heat and vaporization of the material (Mendes,

2006).

There were tested three the most important

parameters for laser-material interaction: the pulse

laser energy (0.2 – 4.5 mJ per pulse denoted as

series 1), the number of pulses (1 – 50 pulses - series

2) and the repetition rate (1 – 20 Hz - series 3). If not

mentioned elsewhere, the typical conditions were

4.5 mJ per pulse, 20 Hz repetition rate, number of

pulses 50 and 25 µm spot diameter.

Under all mentioned conditions, there were

created craters after UV exposition of

(GeS

2

)

0.3

(Sb

2

S

3

)

0.7

as summarized in Fig. 1a. The

SEM details of craters “drilled” with the maximum

energy (4.5 mJ) and 50 pulses with the repetition

rate 20 Hz and 1 pulse with 4.5 mJ energy are

depicted in Fig. 1b and 1c, resp. All the craters were

subsequently topographically analysed employing

digital holographic microscope (DHM). The typical

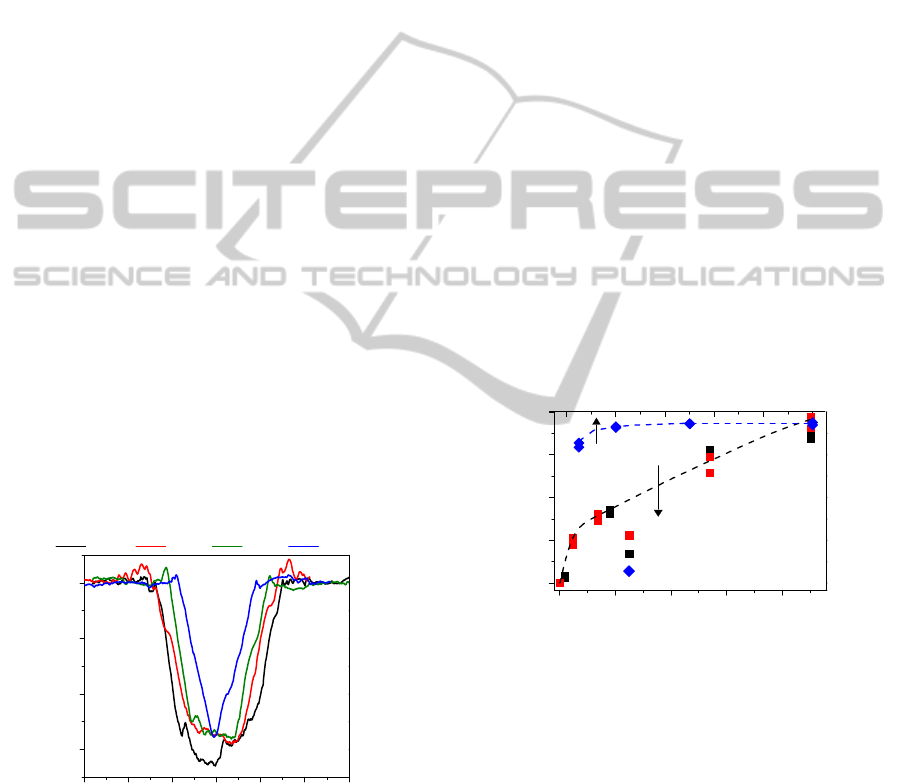

line-scans across the centre of the craters are

illustrated in Fig. 2.

The diameter of the craters with maximal pulse

energy was 95 – 100 µm with the depth 3.3 µm. The

obtained craters were analyzed employing AFM

software (Klapetek et al., 2011) to determine the

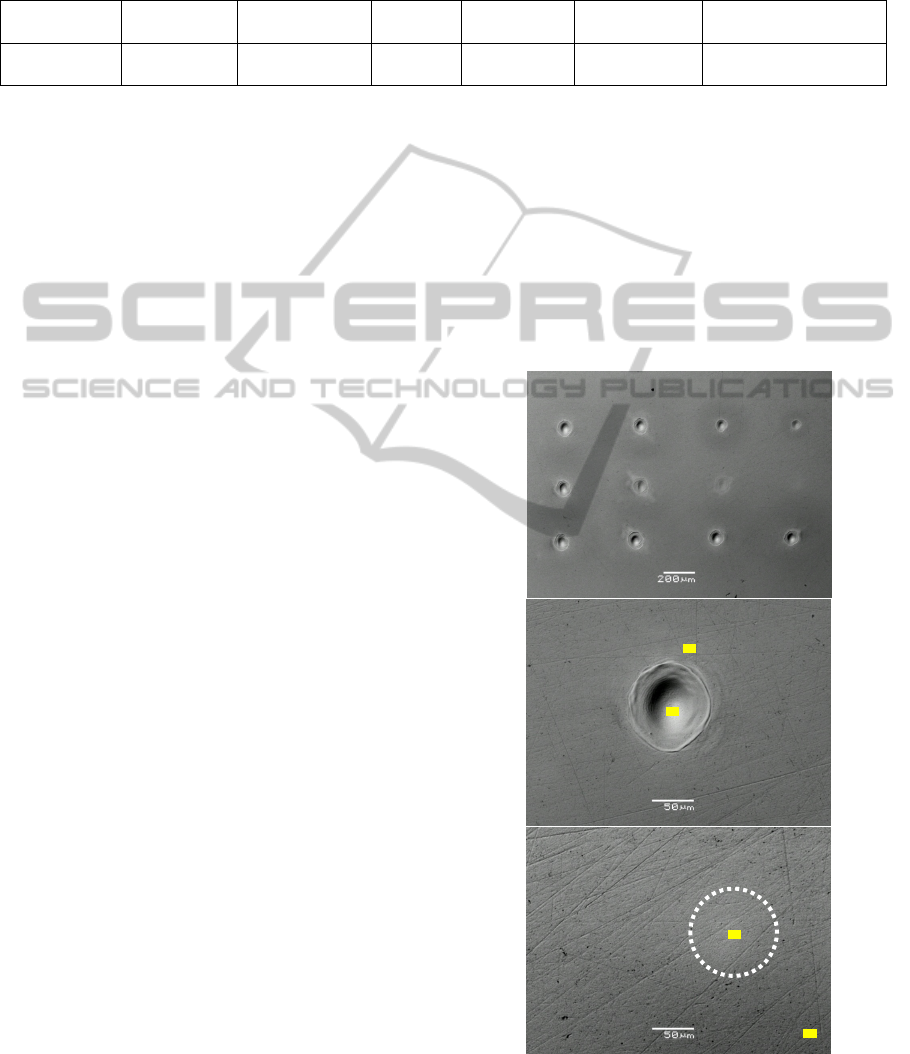

Figure 1: SEM images of ablated craters a) summarizing

photo; b,c) details of the crater created by 50 pulses, 4.5

mJ per pulse, and by single 4.5 mJ pulse, resp.

centre of the crater

non illuminated

centre of the crater

serie 2

serie 1

serie 3

out of the crater

a

b

c

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

6

-90 -60 -30 0 30 60 90

-3000

-2000

-1000

0

Topography (nm)

X line (µm)

serie 1 - pulse energy

4.5 mJ 2.7 mJ 0.7 mJ 0.2 mJ

volume of the crater as the parameter chosen for a

crater characterization. The reproducibility of the

process was checked by analysis of the six craters

prepared under similar conditions of illumination

(50 pulses, 4.5 mJ per pulse and 20 Hz repetition).

The average volume was determined as 10 600 µm

3

with standard error less than 300 µm

3

which seems

to be reproducible values and the process.

The volume of the craters increased nonlinearly

with the increase of the counts or the pulse energy

(Fig. 3) independently on the way of supply of the

cumulative energy. The line-scans detected the

differences in the shape of the craters. If the craters

were formed by low pulse energy (0.2 mJ per pulse),

the profile is “V-shaped”, however with the higher

pulse energy (>0.6 mJ per pulse) the profile is “U-

shaped”. The craters formed with low energy pulse

(0.2 mJ) could be used as an element of the

microlens array. The curvature (R) of the circle

formed when passes through the three points (two on

the basal plane and one at a maximum of

microlenses) equals to: R = (d

2

+ r

2

)/2d =

(2.7

2

+(54/2)

2

/(2×2.7)=136 µm, where d is the depth

of the microlens and r is the radius of the basal

plane. This value seems to be well comparable to R

values for the microlens in oxide (R ≈ 150 µm) or in

chalcogenide (R ≈ 170 µm) glasses (Beadie et al.,

1998); (Huang et al., 2008); (Knotek and Tichy,

2012). The micro-scratches, as the consequence of

the polishing of the bulk material, were partly

smoothed even after single pulse (marked spot area

on Fig. 1c).

Figure 2: The line-scans of the craters of the serie 1 (the

energy of the pulses in range 4.5 – 0.2 mJ, 50 pulses -see

text).

The volume of the craters are independent on the

repetition rate in the range 5 – 20 Hz (see Fig. 3,

blue line); whereas the volume slightly decrease

(<15 %) for the lowest repetition rate (1 Hz). The

low sensitivity of the volume to the repetition rate

could by caused by the nanosecond time period for

energy of UV photons to transfer to the heat and to

vaporize the material during the pulse.

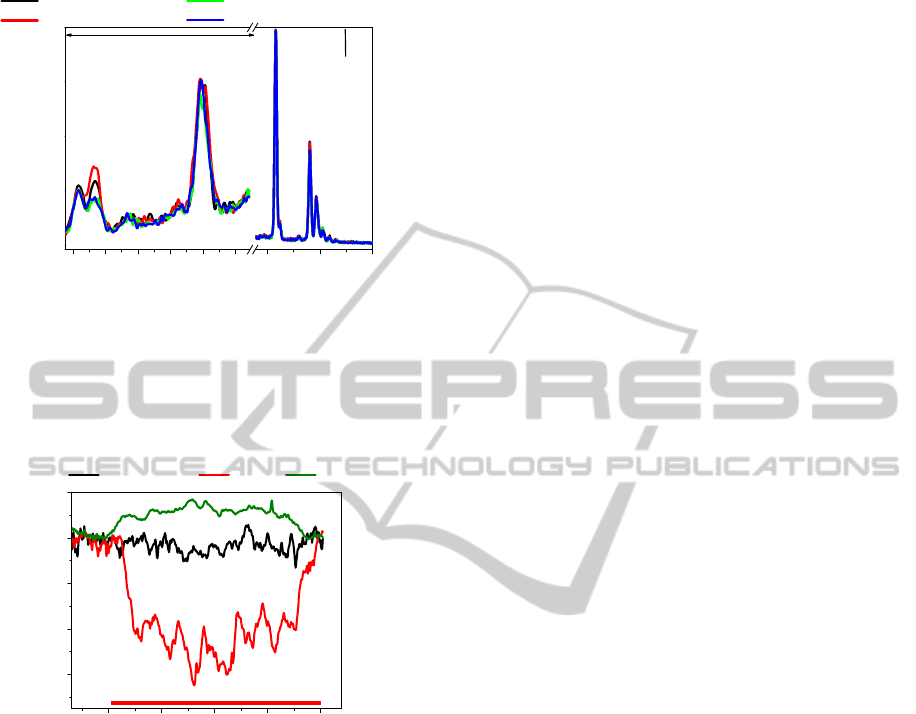

The chemical composition and its changes after

the process of illumination were tested by EDX

analysis on the areas denoted on Fig. 1 as the yellow

rectangles. From the EDX analyses we found a

constant ratio of small and rather broad K

O

line at

around 0.55 eV and L

Ge

line at around 1.2 eV (I

Ge

/I

O

≈ 3.6) for the non-illuminated sample and for the

sample illuminated for 1 pulse with P

A

pulse

=

1.6×10

16

W.cm

-3

. Hence we suppose that within the

sensitivity of EDX analyses there is practically no

serious indication of photo-oxidation. We believe

that this is an acceptable result because from kinetics

limits photo-oxidation requires a time > 5 nsec even

for the photons with an energy above 5 eV. On the

other hand, the partial oxidation is evident in EDX

comparing the centre of the crater and the deposit

after ablation near the crater formed by 50 pulses

(for location see Fig 1b) with non-illuminated glassy

bulk as an increase of the broad O band near 0.55 eV

(I

Ge

/I

O

= 2.6 and 2.1 for the crater center and the

deposit out of the crater, resp.).

048121620

0 50 100 150 200

0

3000

6000

9000

12000

Repetition rate (Hz)

V

crater

(µm

3

)

Cumulative energy (mJ)

serie 1 - pulse energy

serie 2 - pulse number

serie 3 - repetition

Figure 3: The dependences of the crater volume on the

experimental conditions.

As mentioned in Introduction, the UV photo-

induced expansion of the material is described in the

literature. In present experiments the “gentle”

exposition condition was realized by increasing of

the diameter of the illuminated spot to the 200 µm

and minimal pulse energy 0.2 mJ (P

A

pulse

= 2.5×10

14

W.cm

-3

). The material was still ablated after 5 pulses

even under the low energy conditions (0.2 mJ)

however the single pulse led to the elevation of the

material (Fig. 5). Observed expansion of the material

by 50 nm had to be connected with thermal-effect.

UV photons can penetrate less than 5 nm which is

Ablationof(Ges2)0.3(Sb2S3)0.7EmployingNanosecondUVLaser

7

-100 -50 0 50 100

-300

-200

-100

0

100

spot 200 µm

Topography (nm)

X line (µm)

non illuminated 5 pulses 1 pulse

0,4 0,6 0,8 1,0 1,2 1,4 2 4 6

1

pu

l

se

centre of the crater

non illuminated

200 counts

Sb

Sb

Sb

Sb

Sb

S

S

intenzity x5

Ge

O

Sb

EDX signal

E

(

keV

)

50

pu

l

ses

centre of the crater

out of the crater

Figure 4: The EDX spectra of the samples, for location of

analysis see Fig. 1 and the text.

too small depth to expand the material by 50 nm.

Hence the heat should be dissipated deeper into the

bulk.

Figure 5: The line-scans of non-illuminated material,

material after 5 and single pulse (200 µm diameter of the

spot, pulse energy 0.2 mJ)

4 CONCLUSIONS

- The interaction of the 213 nm UV nanosecond

laser with chalcogenide glass (GeS

2

)

0.3

(Sb

2

S

3

)

0.7

has

been described;

- Influence of the most important parameters as

energy of the pulse, number of pulses and repetition

rate on the volume of the craters has been described;

- The shape of the craters is dependent on the

condition of illumination and at low energy pulses

created craters could be used for formation of

microlens array;

- Future work will be focused on the structural

changes of the material and analysis of the ablated

material.

ACKNOWLEDGEMENTS

The authors acknowledge financial support from the

project Grant Agency of the Czech Rep. (GPP108/

12/P044). We are indebted to Dr. M. Kincl for

technical assistance.

REFERENCES

Beadie, G., Rabinovich, W. S., Sanghera, J. & Aggarwal,

I. 1998. Fabrication of microlenses in bulk

chalcogenide glass. Opt. Commun., 152, 215-220.

Bryce, R. M., Nguyen, H. T., Nakeeran, et al. 2004. Direct

UV patterning of waveguide devices in As

2

Se

3

thin

films. J. Vac. Sci. Technol. A, 22, 1044-1047.

Fritze, M., Stern, M. B. & Wyatt, P. W. 1998. Laser-

fabricated glass microlens arrays. Opt. Let., 23, 141-

143.

Frumar, M., Frumarova, B., Nemec, P., Wagner, T.,

Jedelsky, J. & Hrdlicka, M. 2006. Thin chalcogenide

films prepared by pulsed laser deposition - new

amorphous materials applicable in optoelectronics and

chemical sensors. J. Non-Cryst. Solids, 352, 544-561.

Hitz, B., Ewing, J. & Hecht, J. 2012. Introduction to Laser

Technology, New York (USA), Wiley-IEEE Press.

Huang, Y., Liu, R., Lai, J. J. & Yi, X. J. 2008. Design and

fabrication of a negative microlens array. Opt. Laser

Technol., 40, 1047-1050.

Klapetek, P., Nečas, D. & Anderson, C. 2011. Gwyddion -

Free SPM data analysis software; v. 2.25.

Knotek, P., Arsova, D., Vateva, E. & Tichy, L. 2009.

Photo-expansion in Ge-As-S amorphous film

monitored by digital holographic microscopy and

atomic force microscopy. J. Optoelectron. Adv. M., 11,

391-394.

Knotek, P., Kincl, M., Tichy, L., Arsova, D., Ivanova, Z.

G. & Ticha, H. 2010. Oxygen assisted photoinduced

changes in Ge

39

Ga

2

S

59

amorphous thin film. J. Non-

Cryst. Solids, 356, 2850-2857.

Knotek, P. & Tichy, L. 2012 On photo-expansion and

microlens formation in (GeS

2

)

0.74

(Sb

2

S

3

)

0.26

chalcogenide glass. Mater. Res. Bull., 47, 4246-4251.

Knotek, P., Vlcek, M., Kincl, M. & Tichy, L. 2012. On the

ultraviolet light induced oxidation of amorphous As

2

S

3

film. Thin Solid Films, 520, 5472-5478.

Lim, C. S., Hong, M. H., Kumar, A. S., Rahman, M. &

Liu, X. D. 2006. Fabrication of concave micro lens

array using laser patterning and isotropic etching. Int.

J. Mach. Tool Manu., 46, 552-558.

Lin, C. G., Li, Z. B., Ying, L., Xu, Y. S., Zhang, P. Q.,

Dai, S. X., Xu, T. F. & Nie, Q. H. 2012. Network

Structure in GeS

2

-Sb

2

S

3

Chalcogenide Glasses: Raman

Spectroscopy and Phase Transformation Study. J.

Phys. Chem. C, 116, 5862-5867.

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

8

Marquez, E., Jimenez-Garay, R. & Gonzalez-Leal, J. M.

2009. Light-induced changes in the structure and

optical dispersion and absorption of amorphous

As

40

S

20

Se

40

thin films. Mater. Chem. Phys., 115, 751-

756.

Mendes, M. 2006. Semiconductor applications using

short-pulsed UV lasers. Solid State Technol., 49, 42-

46.

Messaddeq, S. H., Siu LI, M., Lezal, D., Ribeiro, S. J. L.

& Messaddeq, Y. 2001. Above bandgap induced

photoexpansion and photobleaching in Ga-Ge-S based

glasses. J. Non-Cryst. Solids, 284, 282-287.

Phillips, J. C. 1979. Topology of covalent non-crystalline

solids 1- short-range order in chalcogenide alloys. J.

Non-Cryst. Solids, 34, 153-181.

Ablationof(Ges2)0.3(Sb2S3)0.7EmployingNanosecondUVLaser

9