Gamma-ray Dose-rate Dependence of Fiber Bragg Grating Inscribed

Germano-silicate Glass Optical Fiber with Boron-doped Inner

Cladding

Seongmin Ju

1

, Youngwoong Kim

1

, Seongmook Jeong

1

, Jong-Yeol Kim

2

, Nam-Ho Lee

2

,

Hyun-Kyu Jung

2

and Won-Taek Han

1

1

School of Information and Communications, Department of Physics and Photon Science,

Gwangju Institute of Science and Technology, 1 Oryong-dong, Buk-gu, Gwangju, Republic of Korea

2

Nuclear Convergence Technology Development Department,

Korea Atomic Energy Research Institute, 989-111 Daedeok-daero, Yuseong-gu, Daejeon, Republic of Korea

Keywords: Optical Fiber, Fiber Sensor, Fiber Bragg Grating, Gamma-Ray Radiation, Radiation Effect.

Abstract: The dose-rate effect on the spectral characteristics of the fiber Bragg grating written in the germano-silicate

optical fiber incorporated with boron oxide in the inner cladding under gamma-ray radiation was

investigated for sensing applications. The Bragg peak shift of the FBG was found to saturate at a 78 pm

level and a radiation-induced attenuation of 1.345 dB/m was obtained with the accumulated dose-rate of

22.86 kGy/h. However, the full-width half maximum bandwidth of the FBG remained practically

unchanged.

1 INTRODUCTION

A real-time monitoring system for stable usage of

nuclear power using an optical fiber sensing

technology has drawn much attention in nuclear

industry (Shah, 1975). Recently, the optical fiber

sensor based on the fiber Bragg grating (FBG) as a

sensing probe have come into spotlight for structural

integrity monitoring in harsh nuclear environments,

mainly due to the advantages of electromagnetic

interferences (EMI) immunity, remote metering,

lightweight, intrinsic safety, multiplexing

capabilities, high sensitivity, fast response, and

durability. However, the effect of radiation on the

FBG written in the optical fiber is well-known to be

an increase of the transmission loss and the shift of

the Bragg peak wavelength (Gusarov, et al. 1999;

Gusarov, et al. 2000; Fernandez, et al. 2002;

Gusarov, et al. 2010; Gusarov, et al. 2008).

Regarding the radiation effect on transmission, the

signal transmission loss increased due to the

formation of radiation-induced defects and color

centers (Fernandez, et al. 2002; Gusarov, et al. 2010;

Evans, 1998; Iino, et al. 2010). The radiation-

resistant optical fibers including pure silica core

fiber, fluorine doped silica core fiber, and OH doped

silica core fiber have been reported (Gusarov, et al.

2010; Evans, 1998; Iino, et al. 2010; Sanada, et al.

1994; Henschel, et al. 2005; Nagasawa, et al. 1985;

Kakuta, et al. 1998; Dianov, et al 1995). The

radiation resistance of optical fibers is dependent on

the glass composition, especially with dopants, by

reducing the non-bridging oxygen hole center

(NBOHC) and blocking the formation of E

‘

center in

SiO

2

glass (Evans, 1998; Iino, et al. 2010; Kakuta, et

al. 1998). Also, by decreasing the residual stress in

the fiber core or defects at the interface of the core

and the cladding, the radiation resistance can be

increased due to the small number of defect centers

such as NBOHC or E

‘

center (Nagasawa, et al. 1985).

As for the Bragg peak wavelength shift of the

FBG under radiation, the reported shift values varied

from tens to several hundreds of pico-meters for a

dose in the 100 kGy range (Gusarov, et al. 1999;

Gusarov, et al. 2000; Gusarov, et al. 2008). The

direction of the Bragg peak shift depended on

dopants in the optical fiber core region due to its

effect on refractive index change (Gusarov, et al.

2008; Gusarov, et al. 2010) and thus it is probably

not linked to the inscription of the FBG but is a

property of the fiber. Thus the FBG based sensor is

107

Ju S., Kim Y., Jeong S., Kim J., Lee N., Jung H. and Han W..

Gamma-ray Dose-rate Dependence of Fiber Bragg Grating Inscribed Germano-silicate Glass Optical Fiber with Boron-doped Inner Cladding.

DOI: 10.5220/0004716201070113

In Proceedings of 2nd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2014), pages 107-113

ISBN: 978-989-758-008-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

insensitive to radiation-induced loss because the

information on the measured parameters such as

temperature, bend, or strain is wavelength-encoded.

However, when the fiber is exposed under high dose

irradiation, the Bragg resonance or the transmission

is highly attenuated and the resonance wavelength is

hard to define. Therefore, the radiation resistant

optical fiber is a key component for the optical fiber

temperature sensors based on the FBG under

gamma-ray radiation.

In this paper, we fabricated the germano-silicate

glass optical fiber with boron-doped inner cladding

to enhance the radiation resistance and investigated

the gamma-ray dose-rate dependence and the

radiation-induced attenuation (RIA) of the fiber and

the FBG written in the fiber.

2 EXPERIMENTS

The germano-silicate glass optical fiber preform

doped with boron oxide in the inner cladding was

fabricated by using the modified chemical vapor

deposition (MCVD) process. BCl

3

gas was added

with SiCl

4

during the MCVD process to incorporate

boron oxide in the inner cladding region in order to

make a depressed-index layer. Then the silica glass

tube with depressed-index inner cladding layer was

collapsed and jacketed with the germano-silicate

glass core rod. To decrease possible residual stress

in the fiber core or defects at the interface of the core

and the cladding due to their different volume

expansions, a buffer layer of a pure silica glass was

made between the core and the inner cladding. The

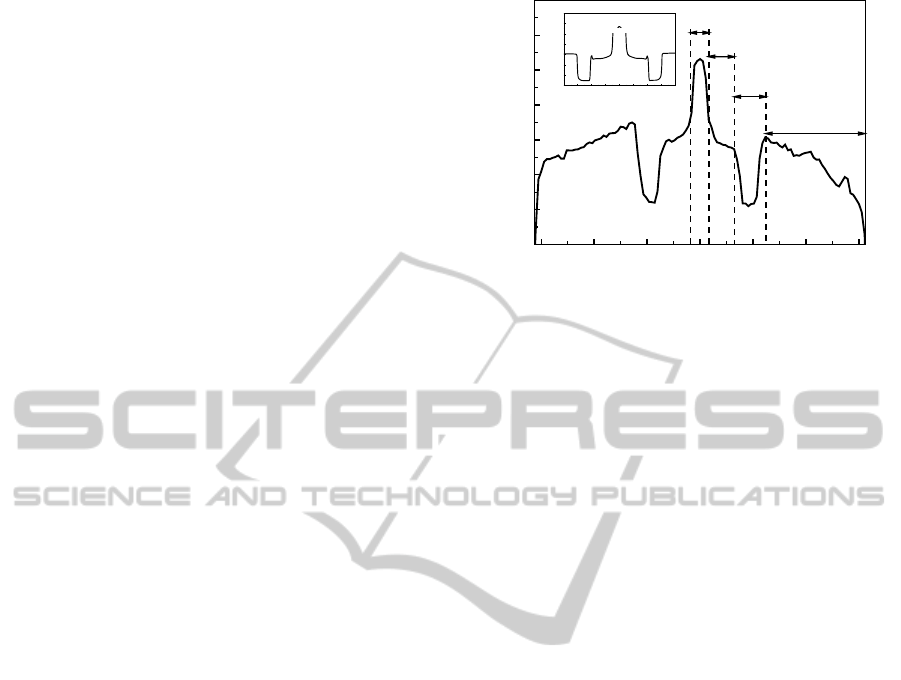

index profile of the fiber preform is shown in Figure

1. Finally, the preform was drawn into a fiber with

outer diameter of 125 µm using the draw tower at

2150 °C. The core diameter and the cut-off

wavelength of the fiber with boron oxide in the inner

cladding region (fiber 1) were 8.30 μm and 1,208

nm, respectively. The length of the buffer layer

between the core and the depressed-index inner

cladding layer was 11.16 μm and the width of the

depressed-index layer was 8.93 μm. The refractive

index differences between the core and the buffer

layer (∆n

core

) and between the buffer layer and the

depressed-index inner cladding layer (∆n

depressed-index

)

were 0.0050 and -0.0035, respectively, as shown in

Figure 1. For a comparison, a commercial single-

mode fiber without depressed-index inner cladding

(fiber 2) as a reference was also used. The core

diameter and the cut-off wavelength of the fiber 2

were 9.5 μm and 1.19 μm, respectively.

Using the fabricated optical fiber (fiber 1), the

-60 -40 -20 0 20 40 60

1.450

1.452

1.454

1.456

1.458

1.460

1.462

1.464

-4 -3 -2 -1 0 1 2 3 4

-0.006

-0.004

-0.002

0.000

0.002

0.004

0.006

0.008

Refractive index difference, ∆n(@632.8nm)

Position in preform[mm]

Refractive Index [n]

Radius [

µ

m]

Core : Germano-silicate glass

Buffer layer : Pure silica glass

Inner cladding

: Boron-doped silicate glass

Outter cladding

: Silica glass

Figure 1: The refractive index profile of the germano-

silicate glass optical fiber incorporated with boron oxide in

the inner cladding together with the buffer pure silica layer

(inset : optical fiber preform).

optical fiber sensor probe based on FBG was made.

To facilitate the FBG formation by increasing

photosensitivity of the fibers, the hydrogen loading

process was carried for the fibers 1 and 2 under the

pressure of 100 bars at room temperature for 96

hours. Note that the fibers 1 and 2 were pre-

irradiated under γ-ray @ 7.20 kGy before FBG

inscription. FBGs were written on the stripped

portion of the fibers by using a phase mask (Pitch

No. 1071.2, QPS Photronics Inc.) with a KrF

excimer laser (248 nm) near 1550 nm. The fibers

were then annealed at 80 °C for 10 hour to release

weak photo-induced changes from hydrogen

molecules penetrated in the optical fiber core during

the hydrogen loading process (Ju, et al. 2010; Hill, et

al. 1997). Then the fibers were recoated with

acrylate polymer and cured with UV light. The dose-

rate dependent characteristics of the fibers with the

FBG on RIA and FBG properties under gamma-ray

radiation was measured by using the optical

spectrum analyzer (OSA, Ando AQ6317B) together

with the amplified spontaneous emission source

(ASE source, Optoware-B200) operating around

1550 nm as an input light source. The fibers with the

FBG were irradiated by

60

Co γ-ray (MSD Nordion,

pencil type/C-198 sealed) at a dose rate of 1.20

kGy/h and

60

Co γ-ray (MSD Nordion, pencil type/C-

188 sealed) at dose rate of 22.86 kGy/h for low

dose-rate (20 Gy/min) and high dose-rate (381

Gy/min), respectively, at room temperature in air.

The RIA and the shift of the Bragg peak wavelength

were measured during the γ-ray irradiation of the

fibers for 1 hour with annealing of the fibers for 40

minutes after the γ-ray irradiation where the total

length of the fiber included FBG was 200 mm. The

measurement set-up for the dose-rate effect of

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

108

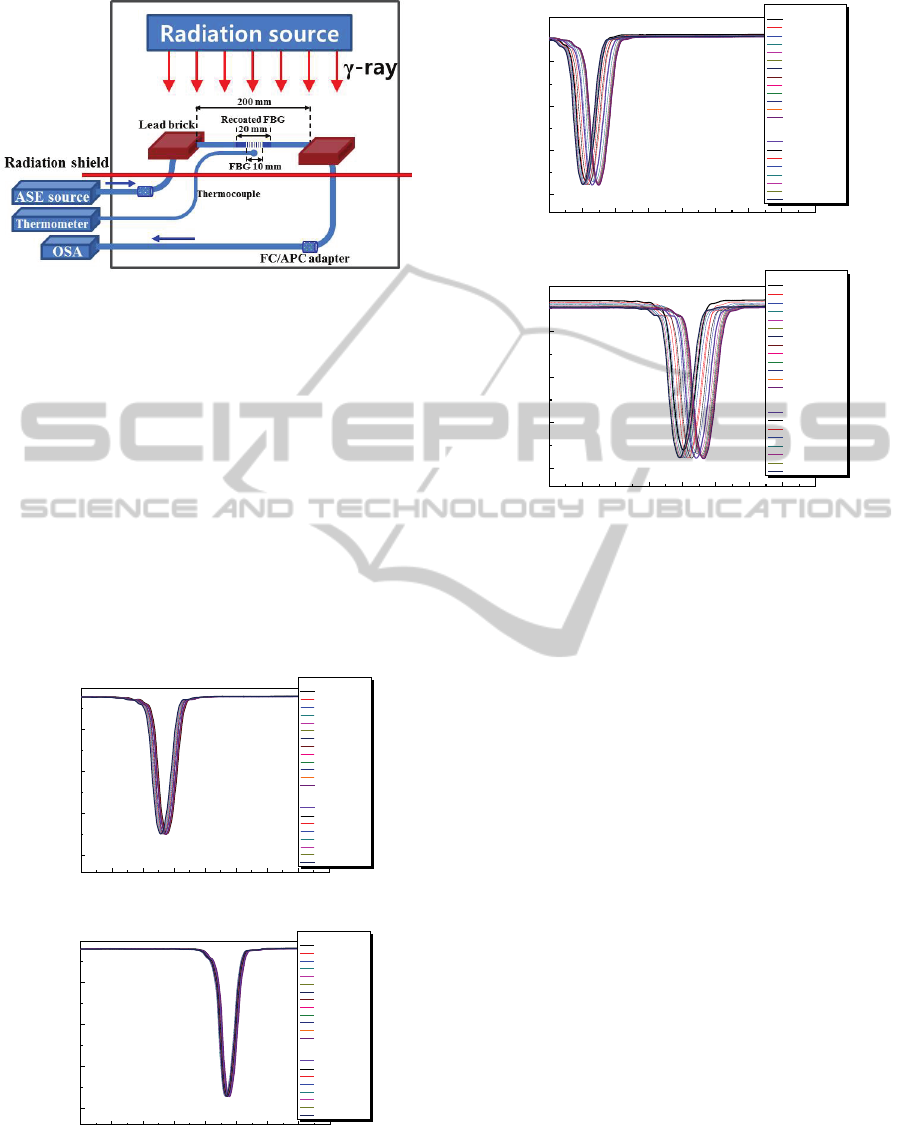

Figure 2: Schematic diagram of the experimental setup for

γ-ray irradiation on the optical fibers with the FBG.

radiation on the FBG written in the fibers is shown

in Figure 2, where the length of the FBG and the

recoated region were about 10 mm and 20 mm,

respectively.

3 RESULTS AND DISCUSSION

The transmission spectra of the FBG written in the

fibers 1 and 2 during and after γ-ray irradiation to

1.20 kGy/h and 22.86 kGy/h are shown in Figures 3

and 4, respectively. Detailed specifications of the

1548.6 1548.8 1549.0 1549.2 1549.4 1549.6 1549.8 1550.0 1550.2

-40

-35

-30

-25

-20

Irradiation condition

0 Gy (16.7 °C)

100 Gy (16.8 °C)

200 Gy (17.0 °C)

300 Gy (17.0 °C)

400 Gy (16.9 °C)

500 Gy (17.1 °C)

600 Gy (17.1 °C)

700 Gy (17.2 °C)

800 Gy (17.3 °C)

900 Gy (17.2 °C)

1,000 Gy (17.3 °C)

1,100 Gy (17.4 °C)

1,200 Gy (17.3 °C)

Annealing condition

(@ 1,200 Gy)

5 mi n (17.3 °C)

10 min (17.3 °C)

15 min (17.2 °C)

20 min (17.2 °C)

25 min (17.0 °C)

30 min (17.0 °C)

35 min (16.9 °C)

40 min (16.9 °C)

Wavelength [nm]

Transmission [dBm]

(a)

1548.6 1548.8 1549.0 1549.2 1549.4 1549.6 1549.8 1550.0 1550.2

-40

-35

-30

-25

-20

Wavelength [nm]

Transmission [dBm]

Irradiation condition

0 Gy (17.5 °C)

100 Gy (17.4 °C)

200 Gy (17.3 °C)

300 Gy (17.3 °C)

400 Gy (17.4 °C)

500 Gy (17.4 °C)

600 Gy (17.5 °C)

700 Gy (17.4 °C)

800 Gy (17.4 °C)

900 Gy (17.4 °C)

1,000 Gy (17.4 °C)

1,100 Gy (17.4 °C)

1,200 Gy (17.6 °C)

Annealing condition

(@ 1,200 Gy)

5 mi n (17.4 °C)

10 min (17.3 °C)

15 min (17.2 °C)

20 min (17.1 °C)

25 min (17.1 °C)

30 min (17.4 °C)

35 min (17.4 °C)

40 min (17.4 °C)

(b)

Figure 3: Transmission spectra of the FBG written in (a)

fiber 1 and (b) fiber 2 at dose-rates ranging from 0 to 1.20

kGy/h.

1548.8 1549.0 1549.2 1549.4 1549.6 1549.8 1550.0 1550.2 1550.4

-40

-35

-30

-25

-20

Irradiation condition

0 Gy (17.6 °C)

1,905 Gy (19.1 °C)

3,810 Gy (20.1 °C)

5,715 Gy (20.9 °C)

7,620 Gy (21.5 °C)

9,525 Gy (21.9 °C)

11,430 Gy (22.3 °C)

13,335 Gy (22.6 °C)

15,240 Gy (22.8 °C)

17,145 Gy (22.9 °C)

19,050 Gy (23.0 °C)

20,955 Gy (23.0 °C)

22,860 Gy (23.1 °C)

Annealing condition

(@ 22,860 Gy)

5 mi n (21.6 °C)

10 min (20.5 °C)

15 min (19.8 °C)

20 min (19.2 °C)

25 min (18.8 °C)

30 min (18.6 °C)

35 min (18.2 °C)

40 min (18.1 °C)

Transmission [dBm]

Wavelength [nm]

(a)

1548.8 1549.0 1549.2 1549.4 1549.6 1549.8 1550.0 1550.2 1550.4

-40

-35

-30

-25

-20

Irradiation condition

0 Gy (17.2 °C)

1,905 Gy (18.7 °C)

3,810 Gy (19.8 °C)

5,715 Gy (20.7 °C)

7,620 Gy (21.4 °C)

9,525 Gy (21.9 °C)

11,430 Gy (22.2 °C)

13,335 Gy (22.4 °C)

15,240 Gy (22.6 °C)

17,145 Gy (22.7 °C)

19,050 Gy (22.8 °C)

20,955 Gy (22.9 °C)

22,860 Gy (22.9 °C)

Annealing condition

(@ 22,860 Gy)

5 mi n (21.4 °C)

10 min (20.3 °C)

15 min (19.4 °C)

20 min (18.7 °C)

25 min (18.2 °C)

30 min (17.8 °C)

35 min (17.5 °C)

40 min (17.3 °C)

Wavelength [nm]

Transmission [dBm]

(b)

Figure 4: Transmission spectra of FBG written in (a) fiber

1 and (b) fiber 2 at dose-rates ranging from 0 to 22.86

kGy/h.

fibers 1 and 2 with the FBG during and after γ-ray

irradiation are listed in Table 1. As shown in Figure

3(a), the temperature change, the Bragg reflection

wavelength, the reflected peak power, and the

transmission power at 1550 nm of the fiber 1 with

FBG were 0.6 ˚C, -10 pm, -0.070 dB, and -0.056 dB

with the increase of γ-ray irradiation to 1.20 kGy/h,

respectively. In the case of the fiber 2 with the FBG,

the temperature change, the Bragg reflection

wavelength, the reflected peak power, and the

transmission power at 1550 nm were 0.1 ˚C, 5 pm, -

0.057 dB, and -0.072 dB with increase of γ-ray

irradiation to 1.20 kGy/h as shown in Figure 3(b),

respectively. From the results of Figure 3, the RIA

of the fibers 1 and 2 at 1550 nm were 0.280 dB/m

and 0.360 dB/m, respectively. As γ-ray irradiation

on fiber 1 with the FBG increased, the temperature

was found to increase and the Bragg reflection

wavelength and the reflected peak power were

shifted toward shorter wavelengths and decreased,

respectively. However, in the case of the fiber 2 with

the FBG, the Bragg reflection wavelength was

shifted toward longer wavelengths with the increase

of γ-ray irradiation. However, the FWHM

bandwidth of the fibers 1 and 2 remained unchanged

during and after γ-ray irradiation to 1.20 kGy/h.

Gamma-rayDose-rateDependenceofFiberBraggGratingInscribedGermano-silicateGlassOpticalFiberwith

Boron-dopedInnerCladding

109

Table 1: Specifications of the fibers 1 and 2 with the FBG during and after γ-ray irradiation.

Temperature

[°C]

Bragg

reflection

wavelength

[nm]

FWHM

bandwidth

[nm]

Reflected

peak

power

[dB]

Transmission

@ 1550 nm

[dBm]

RIA

@ 1550 nm

[dB/m]

Low

dose-rate

(20 Gy/min)

Fiber 1

Before irradiation

(0 Gy)

16.7 1549.155 0.130 16.463 -20.968

0.280

After irradiation

(1.2 kGy)

17.3 1549.145 0.130 16.393 -21.024

After annealing

(40 min)

16.9 1549.113 0.131 16.331 -21.010 -

Fiber 2

Before irradiation

(0 Gy)

17.5 1549.548 0.104 17.744 -20.846

0.360

After irradiation

(1.2 kGy)

17.6 1549.553 0.104 17.687 -20.918

After annealing

(40 min)

17.4 1549.535 0.104 17.666 -20.895 -

High

dose- rate

(381 Gy/min)

Fiber 1

Before irradiation

(0 Gy)

17.6 1549.020 0.126 16.474 -21.911

1.345

After irradiation

(22.86 kGy)

23.1 1549.098 0.126 16.743 -22.180

After annealing

(40 min)

18.1 1549.004 0.129 16.729 -22.110 -

Fiber 2

Before irradiation

(0 Gy)

17.2 1549.604 0.150 16.438 -21.539

4.210

After irradiation

(22.86 kGy)

22.9 1549.726 0.150 16.556 -22.381

After annealing

(40 min)

17.3 1549.584 0.151 16.579 -22.242 -

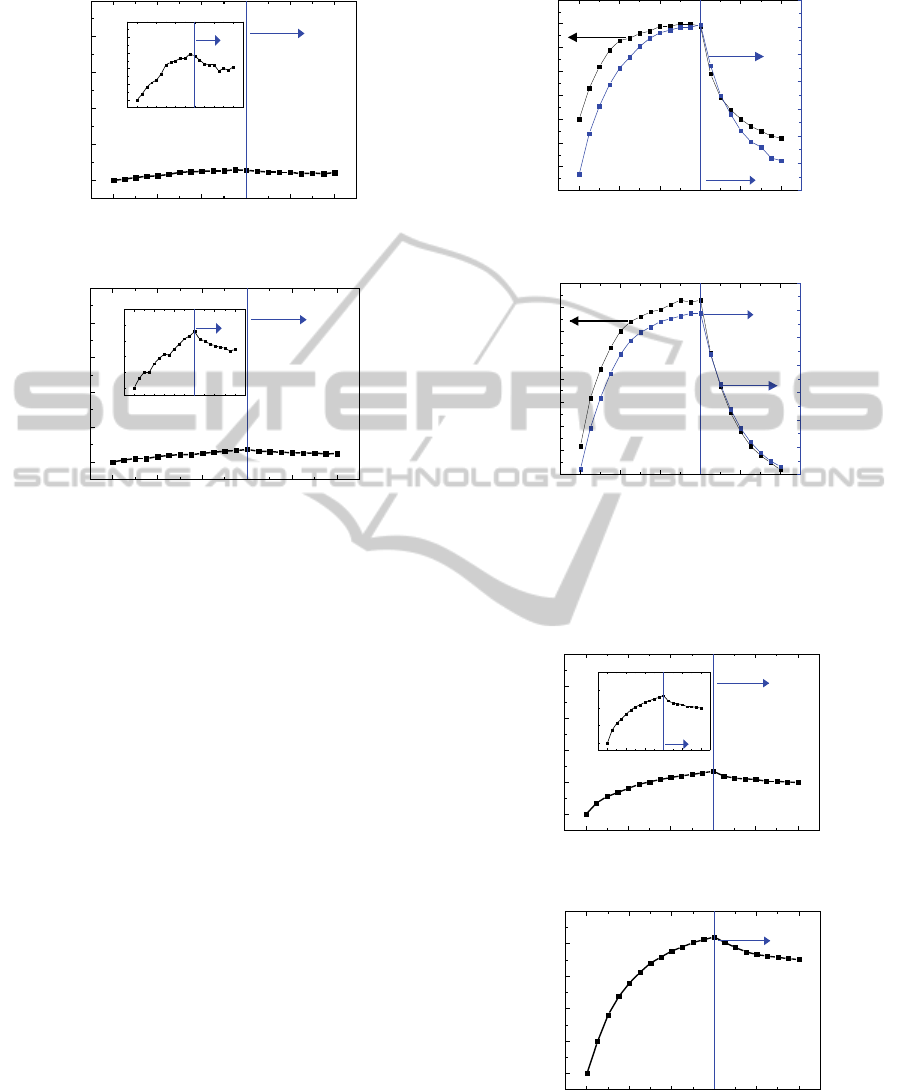

The change in the temperature, the Bragg reflection

wavelength, and the RIA at 1550 nm during and

after γ-ray irradiation to 1.20 kGy/h are shown in

Figures 5 and 6. While the temperature, the Bragg

peak shift, and the RIA at 1550 nm have clearly

shown the dose-rate dependence, no influence on the

FWHM bandwidth and the reflected power was

observed, within the accuracy of our measurements.

It is interesting that as shown in Figures 5 and 6,

after γ-ray irradiation, the temperature, the Bragg

reflection wavelength, and the RIA at 1550 nm

became recovered. And the reflected peak power

was found to decrease regardless of γ-ray irradiation

and the annealing process. Note that the radiation

resistance characteristics was unaffected by the

buffer layer and boron-doped inner cladding region

of optical fiber and by γ-ray irradiation to 1.20

kGy/h because of the low dose-rate or small total

dose of the pre-irradiation (7.20 kGy γ-ray).

When the dose rate of γ-ray irradiation increased

to 22.86 kGy/h, the radiation resistance

characteristics during irradiation was strongly

dependent on the large dose-rate and total dose, as

shown in Figure 4. The change in the temperature,

the Bragg reflection wavelength, the reflected peak

power, and the transmission power at 1550 nm of

the fiber 1 with the FBG were 5.5 ˚C, 78 pm, 0.269

dB, and -0.269 dB with the increase of γ-ray

irradiation to 22.86 kGy/h, respectively. In the case

0 20 40 60 80 100

1549.06

1549.08

1549.10

1549.12

1549.14

1549.16

1549.18

1549.20

1549.22

Dose [Gy]

Time [min]

Bragg Reflection Wavelength, λ

B

[nm]

14

15

16

17

18

19

20

21

Temperature, T [°C]

0

400 800 1,200 1,200 1,200

Annealing Process

(a)

0 20 40 60 80 100

1549.46

1549.48

1549.50

1549.52

1549.54

1549.56

1549.58

1549.60

1549.62

14

15

16

17

18

19

20

21

Time [min]

Temperature, T [°C]

Dose [Gy]

Bragg Reflection Wavelength, λ

B

[nm]

Annealing Process

0

400 800 1,200 1,200 1,200

(b)

Figure 5: Variations of the Bragg reflection wavelength

and the temperature during γ-ray irradiation of 1.20 kGy/h

for (a) fiber 1 and (b) fiber 2 with the FBG.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

110

0 20 40 60 80 100

0

1

2

3

4

5

0 20 40 60 80 100

0.0

0.1

0.2

0.3

0.4

0.5

Dose [Gy]

Time [min]

Radiation-induced

attenuation [dB/m]

0

400 800 1,200 1,200 1,200

Annealing Process

Dose [Gy]

Radiation-induced

attenuation [dB/m]

Time [min]

Annealing Process

0

400 800 1,200 1,200 1,200

(a)

0 20 40 60 80 100

0

1

2

3

4

5

0 20 40 60 80 100

0.0

0.1

0.2

0.3

0.4

0.5

Dose [Gy]

Radiation-induced

attenuation [dB/m]

Ti me [ min]

0

400 800 1,200 1,200 1,200

Annealing Process

Dose [Gy]

Radiation-induced

attenuation [dB/m]

Time [min]

0

400 800 1,200 1,200 1,200

Annealing Process

(b)

Figure 6: Variations of the RIA during γ-ray irradiation of

1.20 kGy/h for (a) fiber 1 and (b) fiber 2 with the FBG.

of the fiber 2 with the FBG, the same four

parameters of the fiber 2 with FBG were 5.7 ˚C, 122

pm, 0.118 dB, and -0.842 dB with the increase of γ-

ray irradiation to 22.86 kGy/h as shown in Figure

4(b), respectively. The RIA of the fibers 1 and 2 at

1550 nm were 1.345 dB/m and 4.210 dB/m,

respectively, from Figure 4. As γ-ray irradiation on

the fibers 1 and 2 with the FBG increased, the

temperature and the reflected peak power increased

and the transmission power at 1550 nm decreased.

While the Bragg reflection wavelengths were shifted

toward longer wavelengths during γ-ray irradiation,

the FWHM bandwidth remained unchanged. With

the increase of γ-ray irradiation to 22.86 kGy/h, the

temperature, the Bragg reflection wavelength, and

the RIA at 1550 nm became saturated. As shown in

Figures 7 and 8, after γ-ray irradiation to 22.86

kGy/h, the temperature, the Bragg reflection

wavelength, and the RIA at 1550 nm were recovered

similar to those by γ-ray irradiation to 1.20 kGy/h.

From the above results, it can be distinguished that

the observed radiation-induced hardening strongly

depends on the pure silica glass layer (buffer layer)

of the germano-silicate glass optical fiber with

boron-doped inner cladding region because the

buffer pure silica layer blocks the increase of the

0 20 40 60 80 100

1548.96

1548.98

1549.00

1549.02

1549.04

1549.06

1549.08

1549.10

1549.12

17

18

19

20

21

22

23

24

Time [min]

Dose [Gy]

Bragg Reflection Wavelength, λ

B

[nm]

Temperature, T [°C]

0

7,620 15,240 22,860 22,860 22,860

Annealing Process

(a)

0 20 40 60 80 100

1549.58

1549.60

1549.62

1549.64

1549.66

1549.68

1549.70

1549.72

1549.74

17

18

19

20

21

22

23

24

Dose [Gy]

Temperature, T [°C]

Bragg Reflection Wavelength, λ

B

[nm]

Time [min]

Annealing Process

22,86022,86022,86015,2407,620

0

(b)

Figure 7: Variations of the Bragg reflection wavelength

and the temperature during γ-ray irradiation of 22.86

kGy/h for (a) fiber 1 and (b) fiber 2 with the FBG.

0 20 40 60 80 100

0

1

2

3

4

5

0 20 40 60 80 100

0.0

0.5

1.0

1.5

2.0

0

7,620 15,240 22,860 22,860 22,860

Annealing Process

Time [min]

Dose [Gy]

Radiation-induced

attenuation [dB/m]

0

7,620 15,240 22,860 22,860 22,860

Dose [Gy]

Radiation-induced

attenuation [dB/m]

Time [min]

Annealing Process

(a)

0 20 40 60 80 100

0

1

2

3

4

5

0

7,620 15,240 22,860 22,860 22,860

Dose [Gy]

Radiation-induced

attenuation [dB/m]

Time [min]

Annealing Process

(b)

Figure 8: Variations of the radiation-induced attenuation

during γ-ray irradiation of 22.86 for (a) fiber 1 and (b)

fiber 2 with the FBG.

Gamma-rayDose-rateDependenceofFiberBraggGratingInscribedGermano-silicateGlassOpticalFiberwith

Boron-dopedInnerCladding

111

NBOHC and the formation of E

‘

center in SiO

2

glass

under γ-ray irradiation (Iino, et al. 2010; Kakuta, et

al. 1998). The optical fiber with different glass

compositions between the core and the cladding was

known to contain a large amount of residual stress

because it was made by simultaneous drawing of the

core glass and the cladding having different volume

expansions (Nagasawa, et al. 1985), Furthermore,

the interface of the core and the cladding contained a

large number of defect centers such as NBOHC or

E

‘

center, probably produced at some stages of the

manufacturing process. However, the proposed

germano-silicate glass optical fiber with inner

cladding and the buffer layer of the present study has

different structure compared with the jacketed

optical fibers such as F-doped glass cladding or B-

doped glass cladding fiber as shown in Figure 1.

Therefore the germano-silicate glass optical fiber

with inner cladding structure can significantly

decrease the RIA value about 3 times, as compared

with that of the commercial single-mode fiber at

dose-rate of 22.86 kGy/h because the buffer layer

could minimize the stress in the fiber core or defects

at the interface of the core and the cladding.

Generally, the sensitivity of optical fiber sensor

based on FBG depends on the Bragg wavelength

shift per temperature, usually about 0.01 nm per 1 ˚C

(Gusarov, et al. 1999; Ju, et al. 2010). Also, when

the optical fiber sensor with the FBG is exposed to

radiation, the Bragg reflection wavelength and the

transmission power are shifted and decreased due to

the change of the reflective index of glass and the

radiation-induced defects and the formation of color

centers (Fernandez, et al. 2002; Gusarov, et al. 2010;

Evans, 1998; Iino, et al. 2010). Thus, the

measurement sensitivities from temperature and

radiation are limited by possible cross-sensitivity

problems. The measuerd temperature sensitivities of

the fibers 1 and 2 at a dose-rate of 1.20 kGy/h were

about -16 pm/˚C and 50 pm/˚C, respectively, and at

a dose rate of 22.86 kGy/h were about 14 pm/˚C and

21 pm/˚C, respectively. Although the dose-rate

effect of radiation on the FBG written in the optical

fiber was limited at low dose-rate of 1.20 kGy, the

temperature sensitivity of the fiber 1 was lower than

that of the fiber 2 at a dose-rate of 22.86 kGy/h

because the presence of boron oxide in the inner

cladding of the optical fiber may lead to a decrease

of the refractive index as well as to a decrease in

thermo-optic coefficient (Cavaleiro, et al. 1999).

Also, in the case of the fiber 1, the temperature

sensitivity was found to be unaffected at any dose-

rate of γ-ray irradiation as compared with that of the

fiber 2. Therefore, the germano-silicate glass optical

fiber incorporated with boron oxide in the inner

cladding is useful for a real-time temperature

monitoring system in harsh nuclear environments.

4 CONCLUSIONS

The germano-silicate glass optical fiber incorporated

with boron oxide in the inner cladding and with the

buffer pure silica glass layer was fabricated by using

the MCVD and the drawing process to increase

radiation resistance in harsh nuclear environments.

The formation of NBOHC was reduced and the

formation of E

‘

center was blocked under γ-ray

irradiation. The residual stress in the fiber core or

the defects at the interface of the core and the

cladding was found to decrease due to the buffer

layer between the core and the inner cladding. As

the γ-ray irradiation on the FBG inscribed in the

fabricated fiber increased, the Bragg reflection

wavelength was shifted toward longer wavelength.

With the increase of γ-ray irradiation, the Bragg

peak shift became saturated at a 78 pm level. The

temperature sensitivity and the RIA were about 14

pm/˚C and 1.345 dB/m with the accumulated dose

rate of 22.86 kGy/h, respectively. However, the

FWHM bandwidth of the FBG remained practically

unchanged.

ACKNOWLEDGEMENTS

This work was partially supported by the National

Research Foundation of Korea (NRF) grant funded

by the Korea government (MEST) (No.2011-

0031840), the New Growth Engine Industry Project

of the Ministry of Knowledge Economy, the Brain

Korea-21 Information Technology Project through a

grant provided by the Gwangju Institute of Science

and Technology, South Korea.

REFERENCES

Shah, J., 1975. Effects of Enviromental Nuclear Radiation

on Optical Fibers, The Bell System Technical Journal,

vol. 54, no. 7, pp. 1207-1213.

Gusarov, A. I., Berghmans, F., Deparis, O., Fernandez, A.

F., Defosse, Y., Mégret, P., Decréton, M., and Blondel,

M., 1999. High Total Dose Radiation Effects on

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

112

Temperature Sensing Fiber Bragg Gratings, IEEE

Photon. Technol. Lett., vol. 11, no. 9, pp. 1159-1161.

Gusarov, A. I., Berghmans, F., Fernandez, A. F., Deparis,

O., Defosse, Y., Starodubov, D., Decréton, M., Mégret,

P., and Blondel, M., 2000. Behavior of Fiber Bragg

Grating Under High Total Dose Gemma Radiation,

IEEE Trans. Nucl. Sci., vol. 47, no. 3, pp. 688-692.

Fernandez, A. F., Brichard, B., Berghmans, F., and

Decréton, M., 2002. Dose-Rate Dependencies in

Gamma-Irradiated Fiber Bragg Grating Filters, IEEE

Trans. Nucl. Sci., vol. 49, no. 6, pp. 2874-2878.

Gusarov, A., Kinet, D., Caucheteur, C., Wuilpart, M., and

Mégret, P., 2010. Gamma Radiation Induced Short-

Wavelength Shift of the Bragg Peak in Type I Fiber

Gratings, IEEE Trans. Nucl. Sci., vol. 57, no. 6, pp.

3775-3778.

Gusarov, A., Vasiliev, S., Medvedkov, O., Mckenzie, I.,

and Berghmans, F., 2008. Stabilization of fiber Bragg

Gratings against Gamma Radiation, IEEE Trans. Nucl.

Sci., vol. 55, no. 4, pp. 2205-2212.

Evans, B. D., 1998. The Role of Hydrogen as a Radiation

Protection Agent at Low Temperature in a Low-OH,

Pure Silica Optical Fiber, IEEE Trans. Nucl. Sci., vol.

35, no. 6, pp. 1215-1220.

Iino, A. and Tamura, J., 2010. Radiation Resistivity in

Silica Optical Fibers, J. Lightwave Technol., vol. 6,

no. 2, pp. 145–149.

Sanada, K., Shamoto, N., and Inada, K., 1994. Radiation

Resistance of Fluorine-doped Silica-core Fibers, J.

Non-Cryst. Solids, vol. 179, no. 4, pp. 339-344.

Henschel, H., Kuhnhenn, J., and Weinand, U., 2005.

Radiation Hard Optical Fibers, in Proceedings of

Optical Fiber Communication Conference, (Academic,

Anaheim, California, 2005), OThI1, pp. 1-3.

Nagasawa, K., Hoshi, Y., Ohki, Y., and Yahagi, K., 1985.

Improvement of Radiation Resistance of Pure Silica

Core Fibers by Hydrogen Treatment, Jpn. J. Appl.

Phys., vol. 24, no. 9, pp. 124-1228.

Kakuta, T., Shikama, T., Narui, M., and Sagawa, T., 1998.

Behavior of Optical Fibers under Heavy Irradiation,

Fusion Eng. Des., vol. 41, no. 1, pp. 201-205.

Dianov, E. M., Golant, K. M., Khrapko, R. R., and

Tomashuk, A. L., 1995. Nitrogen Doped Silica Core

Fibers: A New Type of Radiation-resistant Fiber,

Electron. Lett., vol. 31, no. 17, pp. 1490-1491.

Ju, S., Watekar, P. R., and Han, W.-T., 2010. Enhanced

Sensitivity of the FBG Temperature Sensor Based on

the PbO-GeO

2

-SiO

2

Glass Optical Fiber, J.

Lightwave Technol., vol. 28, no. 18, pp. 2697–2700.

Hill, K. O. and Meltz, G., 1997. Fiber Bragg Grating

Technology Fundamentals and Overview, J.

Lightwave Technol., vol. 15, no. 8, pp. 1263–1276.

Cavaleiro, P. M., Araújo, F. M., Ferreira, L. A., Santos, J.

L., and Farahi, F., 1999. Simultaneous Measurement

of Strain and Temperature Using Bragg Gratings

Written in Germanosilicate and Boron-Codoped

Germanosilicate Fibers, IEEE Photon. Technol. Lett.,

vol. 11, no. 12, pp. 1635-1637.

Gamma-rayDose-rateDependenceofFiberBraggGratingInscribedGermano-silicateGlassOpticalFiberwith

Boron-dopedInnerCladding

113