A Label-free Detection of Carcinoembryonic Antigen (CEA) using

Micromechanical Biosensors

Meisam Omidi

1

, Mohammadmehdi Choolaei

2

, F. Haghiralsadat

1

, M. Azhdari

3

,

N. Davodi Moghadam

4

and F. Yazdian

1

1

Faculty of New Science and Technology University of Tehran, Tehran, Iran

2

Research Institute of Petroleum Industry (RIPI), Tehran, Iran

3

Department of biochemistry, Medical University, Shahid Sadoughi University of Medical Sciences, Yazd, Iran

4

Department of Biology, Payame Noor, Yazd, Iran

Keywords: Micromechanical Biosensors, Carcinoembryonic Antigen (CEA), Surface Stress.

Abstract: we have used arrays of micromechanical biosensors to detect carcinoembryonic antigen (CEA), a protein

biomarker associated with various cancers such as colorectal, lung, breast, pancreatic, and bladder cancer.

The sensing principle is based on the surface stress changes induced by antigen–antibody interaction on the

micromechanical membrane (MM) surfaces. MM consists of a membrane suspended by four piezoresistive

sensing components. The isotropic surface stress on the membrane results in a uniaxial stress in each

sensing component, which efficiently improves the sensitivity. According to the experiments, it was

revealed that MMs have surface stress sensitivities in the order of 2 (mJ/m). This matter allows them to

detect CEA concentrations as low as 500 pg mL

-1

or 3 pM. This indicates the fact that the self-sensing MM

approach is beneficial for pathological tests.

1 INTRODUCTION

The simplest micro-electromechanical systems

(MEMS) structures are a new alternative technology

for fabricating simple, portable, fast response and

high sensitivity analytical devices for many

application areas including clinical diagnosis, food

quality control and environmental monitoring (Arlett

2011, Boisen et.al. 2011 and Alvarez and Lechuga

2010).

The central element in many traditional

mechanical biosensors is a small cantilever that is

sensitive to the biomolecule of interest. It is

possible to operate micro-cantilever sensors in two

different modes, i.e. cantilever bending (surface

stress method) and resonance response variation

(microbalance method). In the first mode, static

mode, the induced surface stress that is due to the

presence of the adsorbates results in a deflection in

the cantilever (Wu et.al. 2001), while in the second

mode, dynamic mode, the adsorbates change the

resonance frequency of a cantilever due to mass

loading (Omidi et al., 2013).

A sensitive readout system is crucial for

monitoring the deflection of cantilevers. For this

reason several read-out methods have been

presented. The most extended readout methods for

biosensing are optical, and piezoresistive ones. The

optical method is simple to implement and shows a

linear response with sub-angstrom resolution, also is

currently the most sensitive method. This method is

employed for detecting the cantilever deflection in

most studies (Omidi et al., 2013; Thunda et al.,

1994; Lang et al., 1999 and Ghatkesar et al., 2008).

Nevertheless, the optical detection mechanism

presents some disadvantages for example, bulky,

time-consuming laser alignment on each cantilever,

low applicability for large one- or two-dimensional

arrays, and the difficulty of performing

measurements in opaque liquids, such as blood, may

hinder the potential application of this method for

actual applications.

The piezoresistive sensing method is known as a

good alternative for the optical detection in

biosensing application. The benefit of this method is

that the principle works well in both liquid and gas

phase and large arrays can be realized and read-out.

Also, the technique is applicable for static as well as

dynamic measurements (Mukhopadhyay et al., 2005;

134

Omidi M., Choolaei M., Haghiralsadat F., Azhdari M., Davodi Moghadam N. and Yazdian F..

A Label-free Detection of Carcinoembryonic Antigen (CEA) using Micromechanical Biosensors.

DOI: 10.5220/0004800701340139

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 134-139

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Aeschimann et al., 2006; Arlett et al., 2006; Boisen

and Thundat, 2009). Although piezoresistive

cantilevers have proven to be highly beneficial

detection methods, without effective mechanical

amplification schemes, their sensitivity is far below

that of optical methods. In order to overcome this

problem, several researches have focused on

applying structural modification, such as making a

through hole, (Yu et al., 2007) patterning the

cantilever surface, (Privorotskaya et al., 2008) or

variation of geometrical parameters (e.g., length,

width, and overall shapes) (Goericke et al., 2008 and

Loui et al., 2008). Although all these methods have

proven to improve the sensitivity of piezoresistive

cantilevers for surface stress sensing, they have still

not yielded significant stress amplification to make

piezoresistive detection comparable to the optical

approach, which this can be due to the fact that all

these approaches rely on suppressing one of the

isotropic stress components. Analytical

consideration of strain amplification schemes for

sensing applications based on the strategies of the

constriction and double lever geometries (Yang et

al., 2007) has resulted in the introduction of MMs,

which have shown a considerable improvement in

amplifying piezoresistive detection signals.

Yoshikawa et al. (Yoshikawa et al., 2011) have

experimentally evaluated a prototype

nanomechanical membrane and the results have

illustrated a significant sensitivity for piezoresistive

cantilevers. In comparison with the standard

piezoresistive cantilever, this study demonstrated a

factor of more than 20 times higher sensitivity than

that obtained with a standard piezoresistive

cantilever.

Presently, Lung cancer, breast cancer and

prostate cancer are considered as the most prevalent

form of cancer in Unite State. Research findings

indicate the importance of CEA as a useful marker

for early detection of various cancers such as

colorectal, lung, breast, pancreatic, and bladder

cancer, monitoring patients for disease progression,

and studying the effects of treatment (Brian et.al.

2011 and Noelia et al., 2012). It is worth mentioning

that the critical value of CEA concentration is

known as 3 ng/ml.

In this study, the performance of the signal

transduction biosensor was studied by using

different concentrations of CEA marker in human

serum albumin (HSA). A direct nano-mechanical

response of micro-fabricated self-sensing MM was

used to detect the surface stress changes of antigen–

antibody specific binding. After injecting the CEA

target, as model biocontents, the piezoresistive

responses were carefully analyzed and the feasibility

of the piezoresistive membranes for biosensing were

discussed in terms of device performance measures

such as sensitivity, accuracy, and specificity.

2 THEORETICAL

BACKGROUND

Molecular adsorptions on a surface do not only add

mass, but also can induce surface tension or surface

stress (Berger et al., 1997). As the molecules bind,

surface stress is developed — owing to electrostatic

repulsion or attraction, steric interactions, hydration

and entropic effects — and this can induce

deflection in the mechanical element. In the

piezoresistive micro/nanomechanical sensors the

electrical resistivity of a piezoresistive film varies

with the applied surface stress. The resistance of the

silicon piezoresistor is a function of stress and the

orientation of the piezoresistors. The relation

between resistivity and stress can be expressed as

(Tufte and Stelzer 1963):

0

[]{}[]

R

R

(1)

where R

0

is the isotropic resistivity of the

unstressed crystal, σ

i

is the stress components, and

the terms π

ij

the component of the piezoresistance

tensor. According to equation (1), for plain stress

(i.e., σ

z

= 0), relative resistance change can be

described as follows:

44

0

()

2

x

y

R

R

(2)

From equation (2), it is clear that (∆R/R

0

) is

completely dependent on σ

x

and σ

y

values. In

cantilevers sensors, surface stress induces an

isotropic stress, and the piezoresistive signal is

nearly zero except at the clamped end where the

isotropic symmetry is broken. Thus, the sensor

sensitivity efficiently reduces in comparison with

cantilevers when a point force is applied at the free

end. According to this problem MM approach was

presented by Yoshikawa et al. (Yoshikawa et al.,

2011).

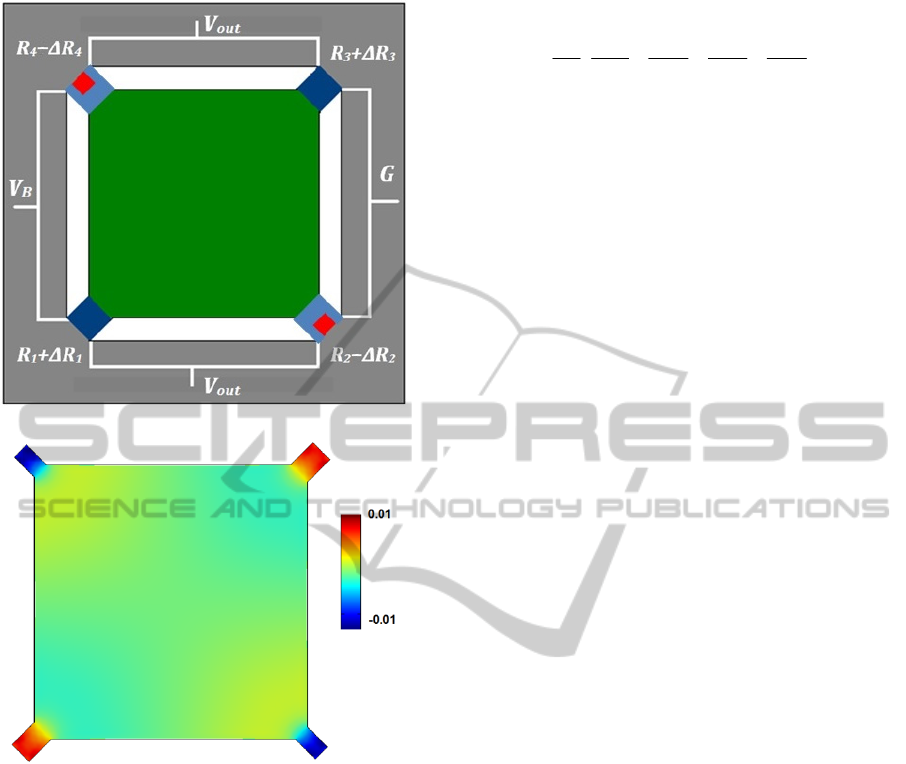

A simple illustration of the final MM sensor with

piezoresistive sensing component can be observed in

figure 1a. Owing to equation (2), isotropic surface

stress leads to zero piezoresistive signal, but in the

MM structure the isotropic deformation effectively

converts into a concentrated force at the connection

between the membrane and the piezoresistive

ALabel-freeDetectionofCarcinoembryonicAntigen(CEA)usingMicromechanicalBiosensors

135

(a)

(b)

Figure 1: (a) A schematic of the MM sensor with

piezoresistive sensing component (b) distribution of ΔR/R

on the surface of MM with a dimension of 400 μm 400 μm

2 μm when a compressive surface stress of -1.0 N/m

applied uniformly calculated by finite element analyses

(FEA) using COMSOL Multiphysics 4.2.

sensing component. Figure 1b shows (∆R/R

0

)

distribution for MM with a dimension of 400 μm x

400 μm x 2 μm, when a compressive surface stress

of -1.0 N/m is applied uniformly on the MM.

COMSOL Multiphysics 4.2 finite element software

was used for extracting (∆R/R

0

) distribution. The

number of elements for modeling the sensor was

about 25000, which gave sufficient resolution for the

present simulation.

The membrane-type geometry allows us to place

a full Wheatstone bridge on the chip, when all four

resistors are practically equal and the relative

resistance changes are small, the total output signal

V

out

can be approximated by:

3

12 4

1234

()

4

in

out

R

VRR R

V

RR RR

(3)

According to equations (1-3), the average values

of relative resistance change in the MM has a higher

value in comparison with the standard cantilever

(about 43 times) (Yoshikawa et al., 2011).

The intrinsic noise level for the modified

piezoresistor can be estimated by Johnson (thermal)

and Hooge (1/f) noise equations (Harley et al., 2000,

Yu et.al. 2002 and Hooge 1969). The total intrinsic

noise for MM is reported as 0.01- 0.5 µV

(Yoshikawa et al., 2011 and 2012), which is still

lower than the experimental noises (2.0~2.5 μV),

mainly caused by the electrical circuit.

3 EXPERIMENTAL

3.1 Fabrication of MM Sensor

We used Silicon on Insulator (SOI) wafers with a 2

μm device layer and a 0.3 μm buried oxide (BOX)

layer as the substrate material. Then a 25 nm silicon

dioxide layer was grown by a thermal oxidation to

electrically insulate the device layer from the

subsequent metal layers. The first lithographic

process to define the first metal layer for electrode

and sensor platform for subsequent liftoff process

has been accomplished. After patterning, the

photoresist, chrome (10 nm) and gold (50 nm) layers

were deposited by e-beam evaporator and patterned

by a liftoff process with the previously patterned

photoresist. The patterned metal layer from previous

step and the patterned layer of photoresist, from the

second photolithographic process were used to

define the areas to be etched to define the sensor

structure. The exposed device layer was etched

completely by RIE to define the sensor structure.

Then, a third photolithographic step for the second

liftoff process, followed by the deposition of a 30-

nm chrome layer and a 150-nm gold layer for wire-

bonding pads. After the liftoff, a release window

was photolithographically defined by the fourth

lithographic process and the exposed BOX was

etched by RIE leaving the Si substrate exposed.

Then the wafer was diced into individual chips.

Through the release window, the exposed Si

substrate was etched by vapor phase etching using

xenon difluoride (XeF

2

) to release the sensor

structure. After XeF2 etching, the photoresist and

the BOX were removed by BHF etching and solvent

cleaning. The die was cleaned with oxygen plasma

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

136

and then a 100-nm thick silicon dioxide layer was

deposited with plasma enhanced chemical vapor

deposition (PECVD) for insulation. Chrome (20 nm)

and gold (50 nm) layers were deposited using an e-

beam evaporator for an immobilization layer for

protein–protein interaction. The PECVD oxide on

the bonding pads was selectively etched for wire-

bonding. Then each die was attached to a custom

made printed circuit board (PCB) and was wire-

bonded. Fig. 2 presents the final picture of MM

using a Scanning electron micrograph (SEM).

3.2 CEA Antibody Immobilization

Process

A fresh piranha solution (a 4:1 ratio of H

2

SO

4

(98.08%) and H

2

O

2

(34.01%)) was used to wash and

clean the membranes, in order to remove

experimental contamination of the Au surface. After

1 min, the membranes were taken out of the solution

and were rinsed using deionized water. To complete

the cleaning process, the rinsed membranes were

dried using a stream of N

2

gas. For 2 h at room

temperature in darkness a 0.1 M deoxygenated

cysteamine (Sigma, 95%) aqueous solution was used

to functionalize the devices. Then, MMs were

washed with deionized water and soaked in water

for 12 h to remove the physically adsorbed

cysteamine. Moreover, for creating a covalent cross-

linker molecule between the amine groups on the

MM surface and antibodies, chips were soaked in a

5% solution of gluteraldehyde (Sigma, 50%) in

borate buffer for 2 hours. Following this and all

subsequent steps, device chips were washed twice,

each washing step was for two minutes, in purified

DI water on an orbital shaker operating at 95 RPM.

It should be mentioned that fresh water was used

between washes. The reason of using water instead

of buffer for washing was to prevent the abundant

formation of buffer salt crystals on the surface of

devices which make the sensors effectively useless.

Next, one hour incubation was used to immobilize

the monoclonal anti- CEA (Anti-carcinoembryonic,

Sigma), affinity-purified, with a concentration of 50

mg/mL on the surface. By immersing the MM in 50

mM solution of glycine for 30 minutes unreacted

gluteraldehyde was then quenched. In addition,

dissolved bovine serum albumin (BSA, Sigma) in

phosphate buffered saline (PBS) with 10 mg/ml

concentration was used to prevent non-specific

binding. For this purpose, the membranes were

immersed in this solution for 1 h at room

temperature. Then, they were rinsed with PBS (pH

7.4) containing polyoxyethyethylenesorbitan

monolaurate (Tween 20) and finally washing was

performed by only using PBS solution.

Figure 2: Scanning electron micrograph (SEM) of 400 μm

x 400 μm x 2 μm MM.

3.3 Electrical Measurements

For the electrical measurement of sensor, internal

dc-bias Wheatstone bridge was used.

A bridge supply voltage of 1.5V was applied

using a dc power supply (Agilent, E3631A), and the

sensor output voltage was measured by a multimeter

(keithley, 2010 7-1/2). Moreover, a faraday cage

was adopted for noise reduction. The above

components were used to measure the piezoreisitive

response of the MM in a liquid environment.

4 RESULTS AND DISCUSSION

In order to reach results with high reliability, the

surfaces of the membranes were stabilized by

treating them with a PBS buffer. The PBS buffer

was directed with a typical flow rate of 0.4 – 0.5

ml/hour, for 1 h, to the MM sensor arrays using a

flexible PDMS polymer microfluidic channel sealed

to the device chip. As a general trend, at the point of

initial injection of the PBS buffer the induced

voltage of the MM increased rapidly and steadily

decreased with time, which in this case the induced

voltage of the MM reached dynamic equilibrium

after 10 min. For the bio-assay, CEA antigens were

injected into each liquid chamber, including the

ALabel-freeDetectionofCarcinoembryonicAntigen(CEA)usingMicromechanicalBiosensors

137

stabilized membrane. The liquid temperature was

precisely controlled and external noise sources were

excluded using a shield box. In order to estimate the

nonspecific adsorption on the MM surface, the

concentration of HSA in all solutions was stabilized

at 0.1 mg/ml.

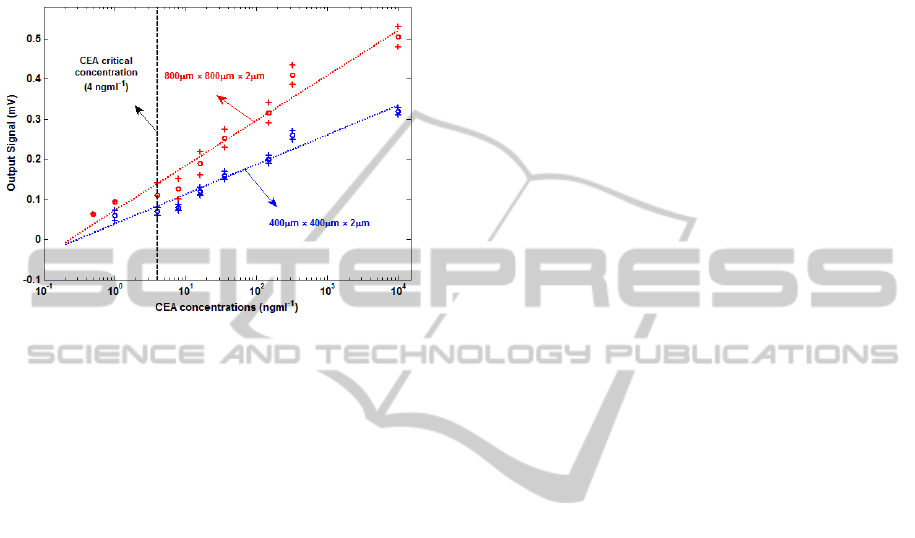

Figure 3: Steady-state output signals (V

out

) as a function of

CEA concentrations for two different MM geometries.

Every data point on this plot represents an average of

output signals obtained in multiple experiments done with

different MM, whereas the range of output signals

obtained from these experiments is shown as the error bar.

Figure 3 shows the steady-state output signals

(V

out

) as a function of CEA concentration in a HSA

background for different dimensions of MM. By

using a 400 µm x 400 µm x 2 µm MM, the lowest

CEA concentration that we could clearly detect

above noise was 1 ng/ml. However, when a 800 µm

x 800 µm x 2 µm MM was used, CEA concentration

as low as 0.5 ng/ml was detectable. This is close to

the resolution required for CEA-based diagnosis of

prostate cancer (Brian et al., 2011). The

experimental results presented a range of linearity of

0.5 ng/ mL to 10 µg/mL and 1 ng/mL to 10 µg/mL

for 800 µm x 800 µm x 2 µm and 400 µm x 400 µm

x 2 µm MM, respectively. The minimum detectable

surface stress for each sensor can be obtain when the

output signals are equal to the noise values. By using

the experimental results, 2 and 3.5 mJ/m were

respectively the minimum surface stress sensitivities

for the 800 µm x 800 µm x 2 µm and 400 µm x 400

µm x 2 µm MM.

5 CONCLUSIONS

We have reported a novel signal transduction

biosensor for detecting CEA, using a unique micro-

fabricated self-sensing array of MM sensors. Unlike

cantilever sensors, which are based on optical

readout systems, the MM integrated piezoresistive

readout sensors facilitate the detection of compact

devices in even non-transparent environments. our

unique MM design significantly improves sensor

sensitivity that allows us to detect CEA

concentrations as low as 500 pg/ mL, or 3 pM.

REFERENCES

Aeschimann L., Meister A., Akiyama T., Chui B. W.,

Niedermann P., Heinzelmann H., De Rooij N. F.,

Staufer U. and Vettiger P., Microelectron. Eng., 83

(2006) 1698.

Alvarez M. and Lechuga L. M., Analyst, 135 (2010) 827.

Arlett, J. L., Maloney, J. R., Gudlewski, B., Muluneh, M.,

Roukes, M. L. Nano Lett., 6 (2006) 10 00.

Arlett J. L., Myers E. B. and Roukes M. L., Nat.

Nanotechnol., 6 (2011) 203.

Berger R., Delamarche E., Lang H. P., Gerber C.,

Gimezewski J. K., Meyer E. and Guntherodt, H.-J.,

Science, 276 (1997) 2021.

Boisen A., Dohn S., Keller S. S., Schmid S. and Tenje M.,

Rep. Prog. Phys., 74 (2011) 036101.

Boisen A. and Thundat T., Mater. Today, 12 (2009) 32.

Brian B., Shaker A M., Nanotech. Sci. Applic, 4 (2011) 1.

Ghatkesar M. K., Lang H. P., Gerber C., Hegner M. and

Braun T., PLoS One, 3 (2008) 3610.

Goericke F. T. and King W. P., IEEE Sens. J., 8 (2008)

1404.

Guntherodt H. J., Anal. Chim. Acta 393 (1999) 59.

Harley, J.A.and Kenny, T.W., J. Microelectromech. Syst.,

9 (2000) 226.

Hooge, F. N., Phys. Lett. A, 29 (1969) 139.

Lang H. P., Baller M. K., Berger R., Gerber C.,

Gimzewski J. K., Battiston F. M., Fornaro P.,

Ramseyer J. P., Meyer E. And Guntherodt H. J., Anal.

Chim. Acta 393 (1999) 59.

Loui A., Goericke F. T., Ratto T. V., Lee J., Hart B. R.

and King W. P., Sens. Actuators, A, 147 (2008) 516.

Mukhopadhyay R., Sumbayev V. V., Lorentzen M.,

Kjems J., Andreasen P. A. and Besenbacher F., Nano

Lett., 5 (2005) 2385.

Noelia D., Paula D., Sergio M., María G., Sara P., Alberto

O. and Manuel F., Sens., 12 (2012) 2284.

Omidi M., Malakoutian M. A., Choolaei M., Chin. Phys.

Lett., 30(6) (2013) 068701.

Privorotskaya N. L. and King W. P., Microsyst. Technol.,

15 (2008) 333.

Tufte O. N., and E. L. Stelzer, J. Appl. Phys., 34 (1963)

313.

Wu G., Datar R. H., Hansen K. M., Thundat T., Cote R. J.

and Majumdar A., Nat. Biotechnol. 19 (2001) 856.

Yang, S. M., Yin, T. I. and Chang, C. Sens. Actuators. B,

121 (2007) 545.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

138

Yoshikawa G., Akiyama T., Gautsch S., Vettiger P., and

Rohrer H., Nano Lett., 11 (2011) 1044.

Yoshikawa G., Akiyama T., Gautsch S., Vettiger P., and

Rohrer H., Sensors, 12 (2012) 15873.

Yu, X. M.; Thaysen, J., Hansen, O. and Boisen, A., J.

Appl. Phys., 92 (2002) 6296.

Yu X. M., Tang Y. Q., Zhang H. T., Li T. and Wang W.,

IEEE Sens. J., 7 (2007) 489.

ALabel-freeDetectionofCarcinoembryonicAntigen(CEA)usingMicromechanicalBiosensors

139