CaPLIM: The Next Generation of Product Lifecycle Information

Management?

Sylvain Kubler and Kary Fr¨amling

Aalto University, School of Science and Technology

P.O. Box 15500, FI-00076 Aalto, Finland

Keywords:

Product Lifecycle Information Management, Context-awareness, Internet of Things, Enterprise Information

Systems, Quantum Lifecycle Management.

Abstract:

Product Lifecycle Information Management (PLIM) aims to enable all participants and decision-makers to

have a clear, shared understanding of the product lifecycle, and to get feedback on product use conditions.

Each product, whether as a physical or virtual product is designed to provide a range of services aimed at

supporting daily activities of each product stakeholder (e.g., designers, manufacturers, distributors, users,

repairers, or still recyclers). Such services are usually considered once, where parameters are fine-tuned once

and for all. A future generation of services could attempt to self-adapt to the product context by discovering

and exchanging helpful information with other devices and systems within its direct or indirect surrounding.

The so-called Internet of Things (IoT) is a tremendous opportunity to support the development of such a

new generation of services by taking advantage of powerful concepts such as context-awareness. Embedding

context-awareness into the product is a possible solution to learn about the product’s context and to make

appropriate decisions. However, today, this is not enough because of the large number of objects, systems,

networks, and users comprising the IoT that require, more than ever before, standardized ways and interfaces

to exchange all kinds of information between all kinds of devices. In an IoT context, this paper opens up new

research directions for providing a new generation of PLIM services by investigating context-awareness. The

combination of these two visions is referred to as CaPLIM (Context-awareness & PLIM), whose originality

lies in the fact that it takes maximum advantage of IoT standards, and particularly of the recent Quantum

Lifecycle Management (QLM) standard proposal.

1 INTRODUCTION

Since 1960’s, the concept of Product Life Cycle

(PLC) was used in different areas such as in product

management, marketing mix, linking production pro-

cesses and pricing (Utterback and Abernathy, 1975).

Today, the study of the PLC is an integral part of

the company strategy to plan, design and manage the

whole life of their products more effectively (Asiedu

and Gu, 1998). From the 1990

′

s onwards, many new

information systems have been brought to market,

giving the opportunity to work more efficiently in-

ternally and externally, for instance by getting closer

to customers, suppliers and partners (Rockart and

Short, 2012). With the arrival of these new systems

and applications, the concept of Product Lifecycle

Management (PLM) was born to manage the entire

product’s life, from Beginning of Life (BoL) includ-

ing design, production and distribution of the prod-

uct, through Middle of Life (MoL) including use and

maintenance, up to End of Life (EoL) including recy-

cling and disposal. Lee et al. (Lee et al., 2008) ex-

plain that PLM originated from two types of manage-

ment: enterprise management and product informa-

tion management. Enterprise management involves

material and enterprise resource planning (MRP &

ERP), customer relationship management (CRM) and

supply chain management (SCM). Product infor-

mation management involves Computer-Aided De-

sign/Manufacturing (CAD/CAM), Computer Aided

Process Planning (CAPP) and Product Data Manage-

ment (PDM). PLM evolved rapidly and now aims to

integrate people, data, products, processes, organiza-

tions, equipments, and methods throughout the PLC

(Stark, 2011).

To date, many solutions, concepts, standards have

emerged and have been integrated into PLM systems

in order to achieve, among others, Product Lifecy-

cle Information Management (PLIM). PLIM can be

defined as a subpart of PLM since it essentially fo-

539

Kubler S. and Främling K..

CaPLIM: The Next Generation of Product Lifecycle Information Management?.

DOI: 10.5220/0004861705390547

In Proceedings of the 16th International Conference on Enterprise Information Systems (ICEIS-2014), pages 539-547

ISBN: 978-989-758-028-4

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

cuses on the product data aspect, while PLM deals

with all elements involved in a PLC (not only product

data but also people, facilities, workflows...). PLIM

is commonly understood as a strategic approach that

incorporates the management of data associated with

products of a particular type, and perhaps the ver-

sions and variants of that product type. PLIM was

first mentioned by Harrison et al. in a manufacturing

context (Harrison et al., 2004), where product-related

data was linked to the product itself via RFID tech-

nologies. Later, the same authors(Harrison, 2011) ex-

plained that PLIM could be interpreted as a certain ex-

tent of the so-called Internet of Things (IoT) since the

IoT also relies on automaticcapture of observationsof

physical objects at various locations and times, their

movements between locations, data collected from

sensors attached to the objects or within their imme-

diate surroundings. The advent of the IoT and related

concepts such as context-awareness provides tremen-

dous opportunitiesto proposemore advanced services

to all product stakeholders (e.g., services able to self-

adapt to the product and user contexts). Embedding

context-awareness into the product is, indeed, a pos-

sible solution to learn about the product’s context and

to make appropriate decisions. However, today, this

is not enough because of the large number of objects,

technologies, and users comprising the IoT, which re-

quire standardized ways and interfaces to exchange

all kinds of information between all kinds of devices.

In lack of standardized approaches and protocols, it

is difficult to access the right information, whenever

needed, wherever needed, by whoever needs it, which

is a major hurdle to efficient context-aware systems

(Perera et al., 2013). This research initiative aims

at investigating a new generation of PLIM services

that takes advantage of both context-aware systems

and standardized communication interfaces defined

by IoT standards. These new types of systems will

play an accelerating role to help companies to deal

with complex, changing product environments and to

meet the new organizational and customer needs.

Section 2 provides the necessary background on

PLIM and context-awareness to better understand the

ongoing relevance of the CaPLIM research initiative.

The IoT standard used to support CaPLIM devel-

opments are briefly introduced in section 3. Sec-

tion 4 opens up new research directions consider-

ing CaPLIM and provides preliminary thinking about

the research objectives and contributions. Section 5

presents a few examples of IoT applications with var-

ious actors, within which it could be benefit to use

CaPLIM services to improve various aspects of prod-

uct information management.

2 BACKGROUND

PLIM deals with various information aspects and

challenges that are introduced in section 2.1. Sec-

tion 2.2 provides the necessary research background

on context-awareness in order to better understand the

ongoing relevance of the CaPLIM research initiative.

2.1 PLIM Background

PLIM aims to enable all product stakeholders and

decision-makers to have a clear, shared understand-

ing of the product’s life. As mentioned, PLIM is

understood to be a strategic approach that incorpo-

rates the management of data associated with prod-

ucts (Fr¨amling et al., 2013). These product definition

data are generated when the product is first conceived,

and it then continues to evolve with the addition of

detailed specifications, user manuals, computer-aided

design drawings, manufacturing instructions, service

manuals, disposal and recycling instructions. In tra-

ditional PLIM, the product information generation

process seems to end after BoL. When the prod-

uct enters actual use (i.e., MoL), PLIM mainly sig-

nifies providing access to the existing information

but hardly any new information is generated about

the products. Within this context, there has been

only slight interest in how the customer uses each

individual product, or in how that product has be-

haved. Concepts such as “product agents” and “intel-

ligent products” (Meyer et al., 2009) have been pro-

posed as solutions for enabling such item- or instance-

enabled PLIM. Such concepts were the cornerstones

of the product instance-enabled PLIM solutions de-

veloped in the PROMISE EU FP6 project

1

, in which

the paradigm of closed-loop PLM

R

, recently re-

named CL

2

M (Closed-Loop Lifecycle Management),

was introduced (Kiritsis et al., 2003). The break-

through challenge of CL

2

M is to enable the informa-

tion flow to include the customer and to enable the

seamless transformation of informationto knowledge.

CL

2

M and similar paradigms like “Closed-Loop Sup-

ply Chains” (Van Wassenhove and Guide, 2003) con-

tribute to enhance various aspects of PLIM, five of

which being of the utmost importance:

1. Information Security: to maintain the level of se-

curity and confidentiality required by organiza-

tions (Dynes et al., 2007);

2. Information Manageability: to efficiently process

large amounts of raw data (Perera et al., 2013);

3. Information Interoperability: to manage the many

changes in data media and formats throughoutthe

1

http://promise-innovation.com

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

540

product lifecycle and to ensure information ex-

changes between any kinds of products, users and

systems (Panetto and Molina, 2008);

4. Information Visibility: to make data available for

any system, anywhere and at anytime. The CL

2

M

consortium defines the visibility of the informa-

tion as the possibility to gather, process and ex-

change the desired information throughout the

whole life of a “thing” (Fr¨amling et al., 2013);

5. information sustainability: to make data capable

of outliving systems, while being consistent (Mc-

Farlane et al., 2013).

Since PLIM is a wide-ranging concept intended

to manage the entire PLC in all possible domains,

one can understand that it is important to develop and

propose sufficiently generic and portable services and

systems to efficiently address each of these aspects.

In this regard, the PROMISE consortium proposed

a set of specifications aimed primarily at improving

information interoperability and visibility throughout

the PLC. Two main specifications were proposed: the

PROMISE Messaging Interface (PMI) that defines

what kinds of interactions between objects are possi-

ble, and the PROMISE System Object Model (SOM)

that provides specifications for representing PLIM in-

formation. At the end of the PROMISE project, the

work on these standards proposals was moved to the

Quantum Lifecycle Messaging (QLM) workgroup of

The Open Group

2

. QLM messaging standards are

derived from PMI and are intended to provide suffi-

ciently generic and standardized application-level in-

terfaces for exchanging the kind of information re-

quired by an IoT (Fr¨amling and Maharjan, 2013)

and, accordingly, to properly support PLIM infras-

tructures.

2.2 Context-awareness in the IoT

Context-awareness. Since the 1990’s, research on

context-awareness also gained a great success in the

IoT community (Perera et al., 2013). The term

context-awarenesswas first introduced by (Schilit and

Theimer, 1994) but a definition that is widely ac-

cepted by the research community today was pro-

posed by (Abowd et al., 1999):

“A system is context-aware if it uses context

to provide relevant information and services,

where relevancy depends on the user’s task”

Although the product context plays a significant role

when dealing with the reality of product and infor-

mation management (i.e., PLIM), there is still too lit-

tle research on context-aware systems/products that

2

http://www.opengroup.org/qlm/

considers the entire product’s life and experience.

This often leads to context-aware systems designed

vendor-, domain- or application-specific, and that use

communication interfaces and data formats barely

compatible with each other (Baldauf et al., 2007).

Such a design strongly limits data exchange interop-

erability in the IoT and, as a consequence, hinders

the development of more advanced, standardized and

pervasive services. Numerous scholars provide evi-

dence and argumentsin this respect (Dey et al., 2001),

one of which being the recent survey made by (Perera

et al., 2013) on context-aware computing for ubiqui-

tous systems. The authors state that: “sharing context

information between distinct organizations is one of

the toughest challenges because systems are designed

in isolated factions, thus limiting their openness and

collaboration”. Various types of middleware support-

ing context-awarenessbased on CORBA, CARISMA,

Gaia, MoCA, Jini, etc., have been developed and en-

able communication between different entities. How-

ever, they always fail to answer one or more require-

ments for data exchange interoperability in the IoT

3

.

For instance, some of these solutions rely on central-

ized architectures like CORBA or Jini (somehow pre-

vents “real” peer-to-peer communications), are lim-

ited to a unique message payload (e.g., CARISMA,

Moca only support XML), do not include strategies

to deal properly with products and systems that are

mobile or located behind firewalls (e.g., the support

of the “piggy-backing” property), and so on.

In this regard, QLM messaging standards are a

tremendous opportunity to investigate new ways to

design and use context-aware systems by taking max-

imum advantage of the standardized IoT interfaces,

which should leverage traditional context-aware ap-

proaches and support the development of portable

product management services. In order to better un-

derstand the interest of using QLM messaging stan-

dards as foundation of CaPLIM, section 4 introduces

the main properties of that standards.

3 QLM MESSAGING STANDARDS

In this section, the two standards proposals derived

from PMI are briefly introduced, namely the QLM

Messaging Interface (QLM-MI) and the QLM Data

Format (QLM-DF). These standards are described in

greater detail in (Fr¨amling and Maharjan, 2013). In

the QLM world, communication between the partici-

pants is done by passing messages between nodes us-

ing the set of interfaces defined in QLM-MI. Whereas

3

See (Fr¨amling and Maharjan, 2013) for such require-

ments.

CaPLIM:TheNextGenerationofProductLifecycleInformationManagement?

541

the Internet uses the HTTP protocol for transmitting

HTML-codedinformation mainly intended for human

users, QLM is used for conveyinglifecycle-related in-

formation mainly intended for automated processing

by information systems. In the same way that HTTP

can be used for transporting payloads in formats other

than HTML, QLM can be used for transporting pay-

loads in nearly any format. The accompanying stan-

dard QLM-DF partly fulfills the same role in the IoT

as HTML does for the Internet, meaning that QLM-

DF is a generic content description model for things

in the IoT.

3.1 QLM Data Format

QLM-DF is defined as a simple ontology that is

generic enough for representing “any” object and in-

formation that is needed for information exchange

in the IoT. It is intentionally defined in a similar

manner as data structures in object-oriented program-

ming. QLM-DF is structured as a hierarchy with an

“Object” element as its top element. The “Object”

element can contain any number of “Object” sub-

elements, which can have any number of properties,

referred to as InfoItems. The resulting Object tree

can contain any number of levels. Every Object has

a compulsory sub-element called “id” that identifies

the Object. The “id” should preferably be globally

unique or at least unique for the specific application,

domain, or network. XML Schema might currently

be the most common text-based payload format due

to its flexibility but others such as JSON, CSV can

also be used.

3.2 QLM Messaging Interface

A defining characteristic of QLM-MI is that QLM

nodes may act both as “servers” and as “clients”, and

thus communicate directly with each other or with

back-end servers in a peer-to-peer manner. Typical

examples of exchanged data are sensor readings, life-

cycle events, requests for historical data, notifications,

etc. One of the fundamental properties of QLM-MI is

that QLM messages are protocol agnostic so they can

be exchanged using HTTP, SOAP, SMTP or similar

protocols. Three QLM operations are possible:

1. Write: used to send information updates to QLM

nodes;

2. Read: used for immediate retrieval of informa-

tion and for placing subscriptions for deferred re-

trieval of information from a node;

3. Cancel: used to cancel a subscription.

The subscription mechanism is a cornerstone of

that standard. Two types of subscriptions can be

performed: i) subscription with callback address:

the subscribed data is sent to the callback address

at the requested interval (two types of intervals can

be defined: interval-based or event-based), and ii)

subscription without callback address: the data is

memorized on the subscribed QLM node as long as

the subscription is valid. Historical data can therefore

be retrieved by issuing a new QLM read query.

It must be noted that other relevant interfaces and

properties (not detailed in this paper) are proposed by

the QLM-MI standard, which cover most of the IoT

requirementsas discussed in (Fr¨amlingand Maharjan,

2013).

4 CaPLIM: RESEARCH

OBJECTIVES

CaPLIM is primarily intended to reliably and dy-

namically manage context-aware product data and

services, and to efficiently support product context

acquisition, discovery, and reasoning. Given this

consideration, the research hypothesis of CaPLIM is

twofold. First, the development of CaPLIM services

should consider the whole product’s life and experi-

ence, and thereby should include life cycle assess-

ment. Second, because of changing product envi-

ronmental factors, technological solutions cannot be

developed in isolation from product lifecycle actors

and systems; rather, all solutions must take into ac-

count changing behaviors of actors using context-

aware techniques.

Using the framework of (Denyer et al., 2008) for

evidence-based management research, the research

contributions can be articulated around four pillars:

• the problem in context is introducing context-

awareness to product information management;

• the interventions of interest are the development

of CaPLIM services using generic and standard-

ized interfaces for data exchange in the IoT so as

to reach our objectives in terms of service porta-

bility and interoperability;

• the generative mechanisms studied are the ways

through which the interventions affect the overall

adaptability, portability and security of services

provided to users;

• the outcomes of the interventionsare concrete and

easy-to-use algorithms, software, and methodolo-

gies that users and system managers can safely

implement and adapt to their own application.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

542

Table 1: CaPLIM contributions.

Framework n ˚ Contributions

Problem in 1a Compare with traditional PLIM, what are the fundamental issues underlying CaPLIM

context 1b Define what is called “context” in CaPLIM and the respective working assumptions

Interventions

of interest

2a Provide context-aware and personalized dynamic product services (and information) using generic

IoT interfaces

2b Effectively communicate with users through an easy-to-use context-aware query language

Generative

mechanisms

3 Qualitatively and quantitatively evaluate the benefits to use CaPLIM strategies in real and diversified

applications, systems and projects

Outcomes 4 Provide self-adapting services, techniques and algorithms to be used in any information manage-

ment project/system

The major contributions related to these four pillars

are presented in Table 1. As mentioned, all CaPLIM

originality comes from the use of generic and stan-

dardized IoT interfaces to support the development

of portable and self-adapting context-aware prod-

uct services. Appropriate QLM interfaces must be

solicited according to the product context, user re-

quirements, and system constraints, and should lead

to make appropriatedecisions. These decisions could,

in turn, eventually use specific QLM interfaces to ac-

complish their tasks (e.g., by subscribing new infor-

mation or by controlling particular devices). Ulti-

mate, the goal is to propose product services to ad-

dress each of the five PLIM aspects introduced in sec-

tion 2.1. Examples of such services include:

1. Information Security Services: to decide what in-

formation must be hide or shared with product

stakeholders throughout the PLC. The benefits of

taking into account the product context is that it

provides more meaningful information that helps

understanding a situation or data. However, at the

same time, it increases the security threats due to

possible misuse of the context (e.g., identity, loca-

tion, activity, and behavior) (Perera et al., 2013).

New services able to handle the challenging con-

flict between data “security” and “usability” must

be proposed in CaPLIM;

2. Information Manageability Services: to automat-

ically understand the raw data (e.g., generated

by sensors) and related context. In this regard,

CaPLIM services should integrate, among others,

tools for data analysis, reasoning, and machine

learning, but also strategies for refining as much

as possible the context modeling within which the

product operates in order to draw correct conclu-

sions (e.g., an unusual value collected on a prod-

uct can be due to external events and does not nec-

essary imply a product malfunction). Such a re-

finement is made possible using particular QLM

messaging interfaces to discover, read or sub-

scribe in “real-time” any new information about

the product and its surrounding;

3. Information Interoperability Services: to support

a wide variety of ontologies for semantic con-

text representation, context reasoning and knowl-

edge sharing, context classification, context de-

pendency and quality of context (Chen et al.,

2003). CaPLIM services should support such on-

tologies to provide knowledge sharing in an open

and dynamic distributed systems, and means for

intelligent devices not expressly designed to work

together to interoperate, thus achieving “serendip-

itous interoperability” (McIlraith et al., 2001);

4. Information Visibility Services: to assess and rank

product-related information as well as sensors

and other information systems generating this in-

formation to help deciding what information, or

piece of this information, is relevant to be used

and shared between product stakeholders. Assess-

ment models developed in CaPLIM should pro-

pose dynamic combinations of information qual-

ity factors such as data accuracy, accessibility,

completeness, interoperability, intelligibility, and

privacy (Maurino and Batini, 2009);

5. Information Sustainability Services: to handle

outdated or wrong product-related data, which is

a frequent and significant problem in PLIM envi-

ronments. Indeed, product data is often accessed

and modified by different actors, stored in differ-

ent systems and organizations, which leads to nu-

merous replicas of the same data (Stark, 2011).

To address this issue, CaPLIM should provide

suitable peer-to-peer data synchronization mech-

anisms able to self-adapt according to the product

context. Accordingto (Bellavista et al., 2013), de-

veloping context data distribution strategies (in-

cluding data synchronization) able to self-adapt

autonomously depending on current management

conditions is still an unexplored research field.

A key challenge in CaPLIM is to be able to ex-

trapolate the key features of traditional context-aware

models and to combine, or enrich them, using the

generic interfaces defined in the QLM standards (or

similar IoT standards) in order to benefit from their

CaPLIM:TheNextGenerationofProductLifecycleInformationManagement?

543

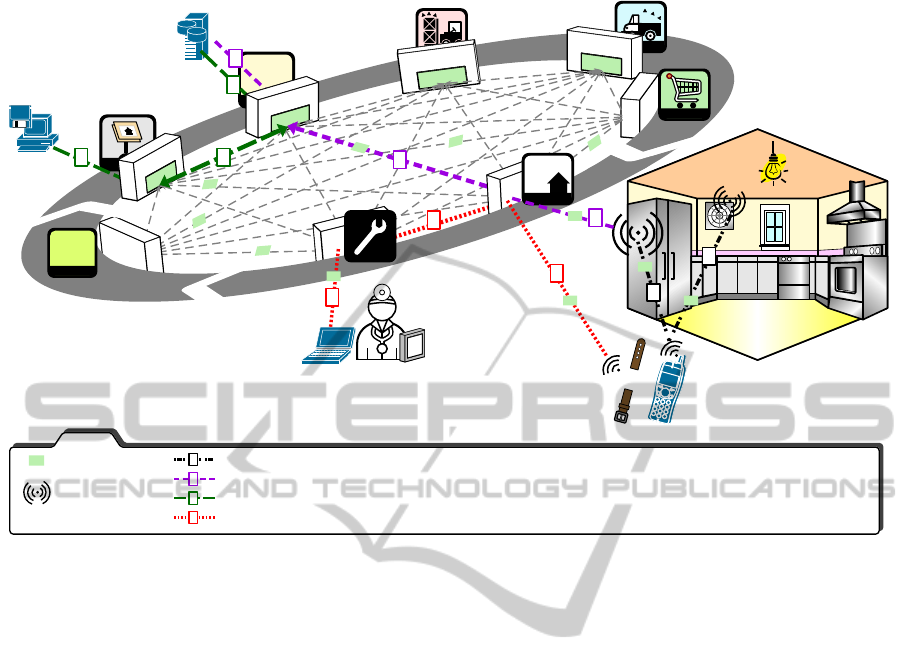

Real-time appliance monitoring

Study of future

product generations

Designer

Manufacturer

Warehouser

Dealer

M

b

I

CaPLIM

QLM

CaPLIM

QLM

CaPLIM

QLM

CaPLIM

QLM

B

o

L

E

o

L

M

o

L

x

A

Distributor

Users

Cardiologist

Recycler

)

)

)

)

)

)

2

x

U

HRV

sensor

+

Monitoring of user body features by subscribing

appropriate information to the smart watch

e.g., heart rate variability (HRV), muscle activity. . .

1

4

4

4

1

2

3

2

33

)

)

))

)

Legend

)

QLM messages

Smart appliances

or devices

2

3

4

1

Design of future product generations (automatic retrieval of historical values in the manufacturer database)

Maintenance appliance scheduling (automatic self-diagnosis about appliances based on “real-time” data)

Healthcare assistance (automatic self-diagnosis about residents based on “real-time” data)

Home automation (automatic house control services)

Figure 1: Possible scenarios using CaPLIM for various product information management purposes.

high portability and interoperability. Another major

challenge in CaPLIM is to propose strategies to mea-

sure both ab initio and in fine the benefits of using

CaPLIM solutions over traditional ones.

5 REAL-LIFE

IMPLEMENTATIONS

Several demonstrators developed in PROMISE ought

to be re-used in this research (i.e., updated with QLM

messaging standards) to investigate, deploy, and as-

sess CaPLIM services. Such demonstrators have the

particularity to be defined in different PLC phases

and contexts such as for monitoring EoL vehicles,

for heavy load vehicle decommissioning (EoL), for

predictive maintenance for trucks (MoL), for predic-

tive maintenance for machine tools (MoL), or still for

adaptive production (BoL).

The CaPLIM research initiative makes a point of

using real-life implementations for deploying and as-

sessing services offered to users, which will enable

to refine as much as possible the CaPLIM’s theoreti-

cal body. The following sections present several sce-

narios considering a unique platform (a smart apart-

ment), whose objective is to show how CaPLIM ser-

vices could contribute to enhance product informa-

tion management from different user perspectives. In

these different scenarios, first insights into concrete

actions to be fulfilled/undertaken by the CaPLIM al-

gorithms are provided. Figure 1 depicts the smart

apartment and some of the actors/devices/systems in-

volved in its lifecycle. This figure also provides a

viewof the QLM “cloud” that interconnectsall phases

and organizations/actorsfrom the apartment lifecycle.

5.1 Home Automation

Numerous services for automatic house control could

be developed and proposed by the CaPLIM initiative,

whose product and user contexts will play a signifi-

cant role in decisions making. In our scenario, smart

appliances and users are able to exchange specific in-

formation with each other using the generic QLM in-

terfaces (see communications denoted by “1” in Fig-

ure 1), which is a good opportunity to learn in “real-

time” about their respective features (e.g., about the

appliance mode “On mode”, “Sleep mode”; the en-

ergy consumed over a certain period of time...), but

also to learn about the user context (at home, at work,

in vacation) or to be notified about unusual event oc-

currences (e.g., the resident no longer move in the

apartment). Such “real-time” data are more than nec-

essary to provide the types of information required by

context-aware systems.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

544

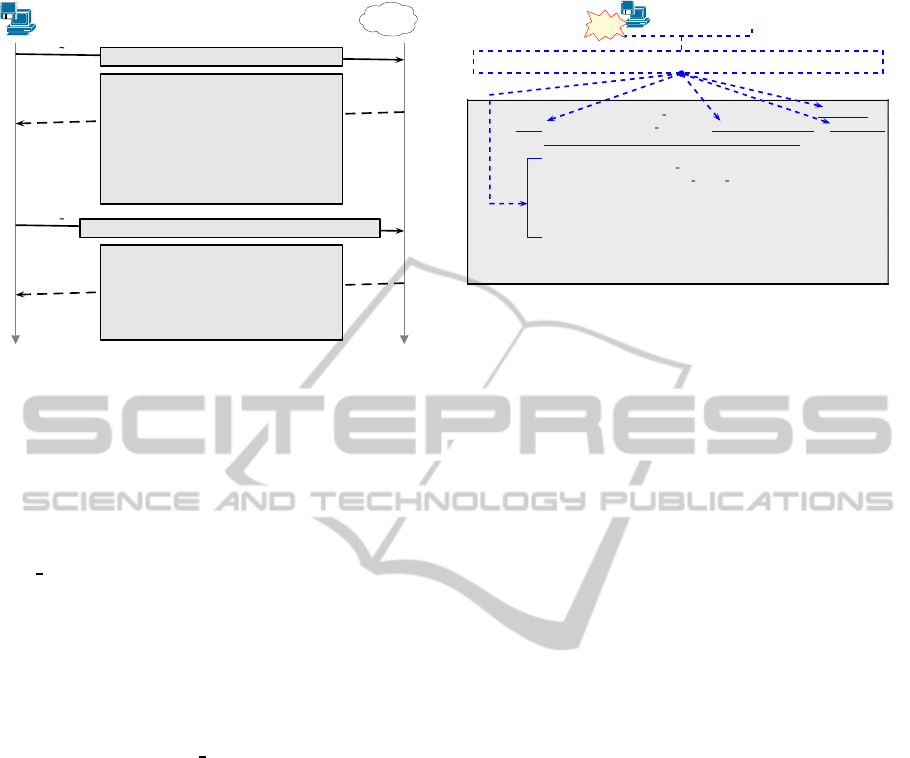

CaPLIM service

Internet

t t

wget

1

wget http://dialog.hut.fi/qlm/Objects/

<Objects>

<Object>

<id>Fridge123</id>

</Object>

<Object>

<id>AirConditioner321</id>

</Object>

<Object>

<id>Watch448</id>

</Object>

</Objects>

wget

2

wget http://dialog.hut.fi/qlm/Objects/Fridge123

<infoItemList>

<infoItem>

<id>Temperature</id>

</infoItem>

<infoItem>

<id>PowerConsumption</id>

</infoItem>

</infoItemList>

Figure 2: RESTful QLM “discovery” mechanism.

To succeed in this task, fundamental interfaces are

required such as the automatic discovery of informa-

tion about the product or about its (direct or indirect)

surrounding. The RESTful QLM “discovery” mech-

anism is an undeniable asset for developing such data

discovery services. An example of this mechanism

using the Unix

wget

utility is shown in Figure 2.

wget 1

requests for receiving the set of devices in the

smart apartment (devices that implement QLM mes-

saging standards to be more accurate). Three appli-

ances implement such standards, namely

Fridge123

,

AirConditioner321

, and

Watch448

(see Figure 2).

Algorithms developed in CaPLIM could eventually

refine their research (if needed) by retrieving the set

of InfoItems related to one or several of those de-

vices, and so on.

wget 2

(cf. Figure 2) requests

for such information regarding

Fridge123

, whose re-

sult highlights that two InfoItems are reachable on

that appliance (e.g., for read, write, or subscription

operations), namely InfoItems named

Temperature

and

PowerConsumption

. One can then understand

how such a mechanism will help to built dynamic and

portable algorithms to discover and monitor, at any

time, aspects required by context-aware algorithms.

5.2 Maintenance Appliance Scheduling

Manufacturers or a service providers could use

CaPLIM services to monitor in “real-time” appliances

and to eventually detect product discrepancies. This

scenario is depicted in Figure 1 with communica-

tions denoted by “2”, through which the manufacturer

subscribes to particular InfoItems to the smart fridge

(namely InfoItem named

PowerConsumption

). Such

a subscription request is provided in Figure 3 includ-

ing:

• the type of operation: the operation is of type

CaPLIM service

Parameters to be automatically discover and set up according to the product’s context

1 <q lm En v el op e xml n s =”QLM mi . x sd ” v e r s i o n = ” 1. 0 ” t t l =”−1”>

2 <r e a d m sg for ma t =”QLM mf . x sd ” i n t e r v a l =” 3600 ” c a l l b a c k

3 =” h t t p : / / 2 0 7 . 4 6 . 1 3 0 . 1 / D B ma n uf a ct u re r”>

4 <msg>

5 <O bj e c t s xmln s =”QLM mf . xs d ”>

6 <O b j e c t t y p e =” F ri d g e U s e r X ”>

7 <i d>Fridge123</ i d>

8 <I n f o I t e m c l a s s = ” Te m pe r at u re ”></ I n f o I t em>

9 </ O b j e c t>

10 </ O b j e c t s>

11 </ msg>

12 </ r e a d>

13 < / q lmE nv el ope>

New

Figure 3: Automatic self-setting of the QLM parameters.

“read” (see row 2) since it is a subscription re-

quest;

• the callback address: the callback address corre-

sponds to the manufacturer’sdatabase system (see

rows 2-3);

• the interval parameter: set to “3600 s” (see

row 2), which means that at the requested inter-

val the subscribed value is pushed to the callback

address;

• the TTL parameter: the TTL is set to “-1” (see

row 1), which indicates that the subscription is

“forever”;

• InfoItem(s) to be subscribed: the subscribed In-

foItem is

Temperature

(see row 8).

Currently, such parameters must be specified by the

user/engineer. CaPLIM should provide algorithms

able to automatically set the appropriate parameter

values according to the product context, the manufac-

turer needs, etc. This contribution is emphasized in

Figure 3 (see CaPLIM service), and will help make

the tasks of the engineer easier, even transparent for

such configuring settings. Once subscriptions have

been set up, CaPLIM algorithms should be able to

process values received at the requested interval, to

identify unusual behaviors, and to react accordingly.

5.3 Future Product Generations

Product designers are increasingly looking for full-

services that make it possible to retrieve information

about their products under in-use conditions, to learn

how the product behave, and to enhance their design

for generations to come. CaPLIM should provide al-

gorithms and methodologies that could automatically

retrievesuch information, at the right time, in the right

format and from the appropriate information system

(e.g., it could be retrieved either from the manufac-

turer’s database system or from the fridge itself de-

CaPLIM:TheNextGenerationofProductLifecycleInformationManagement?

545

pending on privacy rules). Figure 1 illustrates the

first situation where historical information related to

the smart fridge of ID Fridge123 is retrieved from the

manufacturer’s database (see communication denoted

by “3” in Figure 1). Considering a wide panel of users

(fridges to be more exact), such information could be

used as inputs to machine learning algorithms, neu-

ral networks, statistical algorithms, and so on. Ulti-

mately, CaPLIM should make use of appropriate tools

according to the designer needs, the product environ-

ment under in-use conditions, and other factors.

6 CONCLUSION

To a certain extent, the IoT relies on automatic cap-

ture of observations of physical objects at various

locations and times, their movements between loca-

tions, data collected from sensors attached to the ob-

jects or within their immediate surroundings. Each

of these objects or products is designed to provide

a range of services aimed at supporting daily activi-

ties of each product user (e.g., designers, manufactur-

ers, users, repairers...) . Such services are usually

considered once and parameters are fine-tuned once

and for all. A future generation of services could at-

tempt to self-adapt to the product context by discov-

ering and exchanging helpful information with other

devices and systems within its direct or indirect sur-

rounding. The IoT and related concepts like context-

awareness are key ingredients for supporting the de-

velopment of such a new generation of services. Em-

bedding context-awareness into the product is a pos-

sible solution but is not enough because more ad-

vanced and standardized interfaces are required to ex-

change the kind of information required by an IoT,

which has a direct impact on Product Lifecycle Infor-

mation Management (PLIM). In an IoT context, this

paper opens up new research directions for providing

a new generation of PLIM services by investigating

context-awareness. The combination of these two vi-

sions is referred to as CaPLIM (Context-awareness&

PLIM), whose originality lies in the fact that it takes

maximum advantage of IoT standards, and particu-

larly of the recent QLM standard proposal. This new

generation of services will play an accelerating role to

provide new generations of services that help compa-

nies to deal with complex and changing product en-

vironments. This should lead to propose ideas for

new environment-friendly products, and to improve

the customer experience.

ACKNOWLEDGEMENTS

We would like to thank Prof. Yves LE TRAON and

Dr. Patrice CAIRE from the University of Luxem-

bourg, as well as Prof. Andr´e THOMAS and Dr.

William DERIGENT from the University of Lorraine

for their contribution and support regarding this re-

search initiative.

REFERENCES

Abowd, G. D., Dey, A. K., Brown, P. J., Davies, N., Smith,

M., and Steggles, P. (1999). Towards a better under-

standing of context and context-awareness. In Hand-

held and ubiquitous computing, volume 1707, pages

304–307. Springer Berlin Heidelberg.

Asiedu, Y. and Gu, P. (1998). Product life cycle cost anal-

ysis: state of the art review. International journal of

production research, 36(4):883–908.

Baldauf, M., Dustdar, S., and Rosenberg, F. (2007). A sur-

vey on context-aware systems. International Journal

of Ad Hoc and Ubiquitous Computing, 2(4):263–277.

Bellavista, P., Corradi, A., Fanelli, M., and Foschini, L.

(2013). A survey of context data distribution for mo-

bile ubiquitous systems. ACM Computing Surveys,

45(1):1–49.

Chen, H., Finin, T., and Joshi, A. (2003). An ontology for

context-aware pervasive computing. The Knowledge

Engineering Review, 18(3):197–207.

Denyer, D., Tranfield, D., and Van Aken, J. E. (2008). De-

veloping design propositions through research synthe-

sis. Organization Studies, 29(3):393–413.

Dey, A. K., Abowd, G. D., and Salber, D. (2001). A concep-

tual framework and a toolkit for supporting the rapid

prototyping of context-aware applications. Human-

computer interaction, 16(2):97–166.

Dynes, S., Kolbe, L., and Schierholz, R. (2007). Informa-

tion security in the extended enterprise: A research

agenda. In 13th Americas conference on information

systems, pages 4322–4333.

Fr¨amling, K., Holmstr¨om, J., Loukkola, J., Nyman, J., and

Kaustell, A. (2013). Sustainable PLM through intelli-

gent products. Engineering Applications of Artificial

Intelligence, 26(2):789–799.

Fr¨amling, K. and Maharjan, M. (2013). Standardized com-

munication between intelligent products for the IoT.

In 11th IFAC Workshop on Intelligent Manufacturing

Systems, S˜ao Paulo, pages 157–162.

Harrison, M. (2011). The’internet of things’ and commerce.

XRDS: Crossroads, The ACM Magazine for Students,

17(3):2011.

Harrison, M., McFarlane, D., Parlikad, A. K., and Wong,

C. Y. (2004). Information management in the prod-

uct lifecycle-the role of networked rfid. In 2nd IEEE

International Conference on Industrial Informatics,

Berlin, pages 507–512. IEEE.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

546

Kiritsis, D., Bufardi, A., and Xirouchakis, P. (2003). Re-

search issues on product lifecycle management and

information tracking using smart embedded systems.

Advanced Engineering Informatics, 17(3):189–202.

Lee, L., Fiedler, K., and Smith, J. (2008). Radio frequency

identification (RFID) implementation in the service

sector: A customer-facing diffusion model. Interna-

tional Journal of Production Economics, 112(2):587–

600.

Maurino, A. and Batini, C. (2009). Methodologies for data

quality assessment and improvement. ACM Comput-

ing Surveys, 41(3):1–52.

McFarlane, D., Giannikas, V., Wong, A. C. Y., and Harri-

son, M. (2013). Product intelligence in industrial con-

trol: Theory and practice. Annual Reviews in Control,

37(1):69–88.

McIlraith, S. A., Son, T. C., and Zeng, H. (2001). Semantic

web services. IEEE Intelligent Systems, 16(2):46–53.

Meyer, G., Fr¨amling, K., and Holmstr¨om, J. (2009). In-

telligent products: A survey. Computers in Industry,

60(3):137–148.

Panetto, H. and Molina, A. (2008). Enterprise integration

and interoperability in manufacturing systems: Trends

and issues. Computers in industry, 59(7):641–646.

Perera, C., Zaslavsky, A., Christen, P., and Georgakopoulos,

D. (2013). Context aware computing for the internet

of things: A survey. IEEE Communications surveys &

Tutorials, (99):1–41.

Rockart, J. F. and Short, J. E. (2012). It in the 1990s: man-

aging organizational interdependence. Sloan Manage-

ment Review, 30(2).

Schilit, B. N. and Theimer, M. M. (1994). Disseminating

active map information to mobile hosts. IEEE Net-

work, 8(5):22–32.

Stark, J. (2011). Product lifecycle management: 21st cen-

tury paradigm for product realisation. Springer.

Utterback, J. M. and Abernathy, W. J. (1975). A dynamic

model of process and product innovation. Omega,

3(6):639–656.

Van Wassenhove, L. N. and Guide, V. D. R. (2003). Closed-

loop supply chains. Pittsburgh.

CaPLIM:TheNextGenerationofProductLifecycleInformationManagement?

547