Simulation of HDS Tests in Trickle-Bed Reactor

V. Tukač

1

, A. Prokešová

1

, J. Hanika

1

, M. Zbuzek

2

and R. Černý

2

1

Institute of Chemical Technology, Prague, Technická 5, CZ-16628 Prague, Czech Rebublic

2

Research and education centre UniCRE Litvínov, CZ-43670 Litvínov, Czech Rebublic

Keywords: Hydrodesulfurization Simulation, Catalyst Tests, Trickle-Bed Reactor.

Abstract: The paper deals with methodology of simulation study devoted to evaluation of reliability of HDS catalyst

testing procedure in pilot three phase fixed bed reactor. Hydrodynamic behaviour of test reactor was

determined by residence time distribution method. Residence time and Peclet number of axial dispersion of

liquid phase were obtained by nonlinear regression of experimental data. Hydrodesulfurization reaction

kinetics was evaluated by analysis of concentration data measured in high pressure trickle-bed reactor and

autoclave. Simulation of reaction courses were carried out both by pseudohomogeneous model of ODE in

Matlab and heterogeneous reactor model of PDE solved by COMSOL Multiphysics. Final results confirm

presumption of eliminating influence of hydrodynamics on reaction kinetic results by dilution of catalyst

bed by inert fine particles.

1 INTRODUCTION

Sustainable development demands ultra-low

concentrations of sulfur and nitrogen compounds in

produced engine fuels – gasoline and diesel. Present

sulfur content valid in EU 10 ppm represents less

than one thousands of sulfur content of original

crude oil. Deep hydrodesulfurization (HDS) of

engine fuels is dominantly carried out in catalytic

trickle-bed reactors. Also testing of catalysts

affectivity and life cycle needs expensive long time

experimentation in pilot scale reactors to evaluate

catalyst decay and activity loses. Pilot trickle-bed

reactor for catalyst tests needs to produce reliable

results not affected by mass and heat resistance. To

avoid occurrence of temperature gradients, poor

catalyst wetting and fluid maldistribution a dilution

of bed of industry scale catalyst particles by fine

inert grains is used (Bej et al., 2001). In

contradiction to full scale reactors this dilution

changes interfacial area in the bed and affects

namely external mass transfer of hydrogen (Tukač et

al., 2007). Also hydrodynamics, pressure drop, gas

and liquid holdups and fluid axial dispersion seems

to be quite different (Mary et al., 2009).

The goal of this study was to compare

experimental HDS catalyst activity measurement

carried out in pilot scale trickle-bed reactor with

result of computational model. Catalyst activity tests

were supplemented by kinetic measurement of

reaction rate constants and activation energies of

selected sulfuric compounds. Parallel to HDS

reaction also hydrodenitrogenation (HDN) takes

place in the catalytic reactor. Hydrodynamic data

were evaluated by residence time distribution (RTD)

method in laboratory glass model of pilot reactor.

Mathematical models of the process (Ancheyta,

2011) were formulated both like 1D

pseudohomogeneous and 3D heterogeneous ones.

The aim of this work was generally to evaluate

extent of dilution influence on operation of pilot test

reactor and to forecast interaction between intrinsic

reaction kinetic, hydrodynamic parameters and mass

transfer.

2 EXPERIMENTAL

Pilot catalyst activity tests were carried out in high

pressure trickle-bed reactor of 30 mm I.D and 887

mm length. In the axis of the reactor 9 mm O.D.

temperature probe was located. Reactor bed consists

of three section of different porosity, from the top to

the bottom: 765 mm calming section of 1-2 mm

grain inert, which was followed by two section (110

and 172 mm) of commercial catalyst diluted by

different amount (2:1 and 1:1, resp.) of inert.

Catalyst particles were in form of trilobe alumina

739

Tuka

ˇ

c V., Prokešová A., Hanika J., Zbuzek M. and

ˇ

Cerný R..

Simulation of HDS Tests in Trickle-Bed Reactor.

DOI: 10.5220/0005090807390744

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 739-744

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

extrudes of 1.3 mm O.D. and 6 mm mean length and

silicon carbide of grain diameter 0.1 - 0.2 mm was

used as inert diluent. Scheme of pilot reactor is

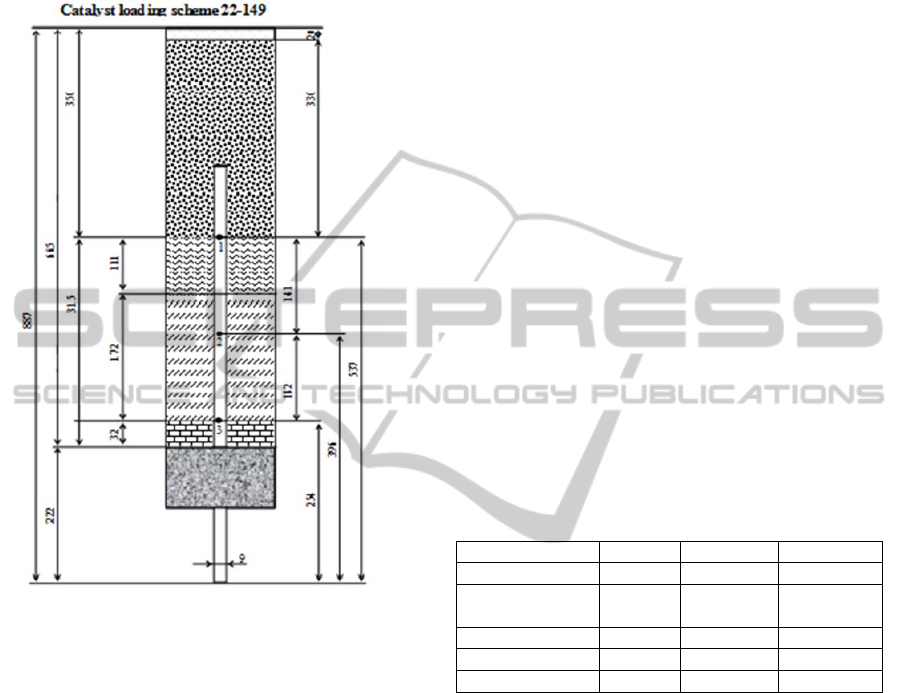

presented in Figure 1.

Figure 1: Scheme of pilot trickle-bed reactor with packing

layers from top to bottom: silica wool, coarse SiC, diluted

catalyst by fine SiC 1:2, diluted catalyst by fine SiC 1:1,

coarse SiC, silica wool.

Middle distillates, petroleum fractions for diesel

fuel – atmospheric gas oil (AGO) and light cycle oil

(LCO) were chosen for catalyst activity tests, their

main properties are presented in Table 1. Results of

hydrodesulfurization tests carried out with these oils

were available to evaluate kinetic parameters,

example see in Figure 2.

Kinetic experiments with chosen typical sulfuric

substances were carried out in 500 mL stainessteel

autoclave equipped by catalyst basket to test activity

of industrial shaped hydrodesulfurization catalysts.

Both different temperature and hydrogen partial

pressure were applied to evaluate kinetic parameters

- rate constant and activation energy.

Chemical analysis of content of sulfuric

compounds in raw liquid feed and product was made

by ASTM standard methods.

Laboratory hydrodynamics test column having

identical geometry with pilot reactor consist of glass

tube, equipped by three conductivity electrodes with

axially located joint ground, which was represented

by temperature probe located in axis of tube.

Residence time distribution (RTD) method and

piston-dispersion (PD) hydrodynamic model were

used. Signal responses to impulse injection of

concentrated aqueous solution of potassium chloride

were measured by three conduct-meters connected

with fast multichannel data acquisition system. Air

(7.10

-4

– 42.10

-4

kg m

-2

s

-1

) and water (0.02 – 0.12 kg

m

-2

s

-1

) feed rate was controlled by mass flow meters

on the same values of mass superficial velocities as

in the case when diesel fuel and hydrogen were

applied. Hydrodynamic parameters (residence time,

liquid holdup and Peclet number of axial dispersion)

were obtained both by moment method of response

curves and nonlinear fitting by numerical simplex

method.

Typical properties of raw feed liquid are

presented in Table 1. While, AGO exhibits two

times greater sulfur content compared to LCO, the

last one contains much greater concentration of

nitrogen compounds responsible for transient

catalyst deactivation.

Table 1: Properties of middle distillates.

Feedstock AGO LCO

Density, 15 °C kg/m

3

857.1 968.6

Refractive index,

20 °C

1.4763 1.563

Color 0.9 2.8

Sulfur content mg/kg 12900 6346

Nitrogen content mg/kg 201 750

3 PROCESS SIMULATION

Evaluation of experimental data and process

simulation are divided to several sections: i)

evaluation of kinetic parameters of chemical

reactions by nonlinear simplex method, ii) linear

regression of catalyst deactivation kinetics, iii)

fitting of RTD data to find parameters of PD

hydrodynamic model, and finally, iv) formulation of

heterogeneous reactor model.

3.1 Reaction Kinetics

In the porous bed, a reaction takes place (Bellos and

Papayannakos, 2003) that consumes species A and B

and produces C and D, where A, B, C, D represent

hydrogen, dibenzothiophene, sulphane, and

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

740

biphenyle, respectively in case of sulfur compounds

and hydrogen, carbazole, ammonia and biphenyle

for nitrogen compounds.

2A + B C + D (1)

R

i

the reaction rate for species i (mol/(m

3

s)).

Because the reaction takes place in the porous

catalytic bed only, the reaction term is zero in the

free-flow regions. The reaction rates are given by

R

A

= -2 k p

A

c

B

n

(2)

R

B

= R

A

/2 (3)

R

C

= -R

B

(4)

R

D

= -R

B

(5)

where k is the reaction rate constant, p

A

partial

pressure of hydrogen and c molar concentration.

3.2 Pseudohomogeneous Reactors

Psudohomogeneous plug flow 1D model in Matlab

was used to evaluate kinetic parameters of HDS and

HDN from the pilot tests. Pseudomomogeneous

model represents reactor approximation by ideal

piston fluid flow and neglecting of mass and heat

transfer limitations. Integrated forms of reactor

model for first and other than first reaction order are

described by equations 6 and 7, respectively.

Parameter WHSV represents weight liquid hourly

space velocity. Parameters of the equations were

estimated by nonlinear simplex Nelder-Mead fitting

procedure.

2

0

1

ln

i

iH

i

c

kp

cWHSV

(6)

1

1

(7)

3.3 Heterogeneous Reactor

CFD 3D model of hydrodynamics in pilot reactor

was made in Comsol Multiphysics FEM solver

(Zimmerman, 2007). Heterogeneous reactor model

incorporates mass and heat transfer limitations. The

developed model incorporates of Navier-Stokes

momentum balance of fluid flow with Brinkman

extension for porous reactor bed. Both chemical

kinetic, mass transfer of reactants and heat

convention and conduction are taking into account.

3.3.1 Domain Equations - Fluid Flow

The stationary Navier-Stokes equations describe the

fluid flow in the free-flow regions. In the porous

bed, the Brinkman equations for porous media is

applied.

From assumption that the modeled species are

present in low concentrations compared to the

solvent oil. follows that using of a Fickian approach

for the diffusion term in the mass transport is

aproved. Model involve the mass transport for the

four species A, B, C, and D with the convection-

diffusion equation

This model shows the flow field in an

experimental reactor for studies of heterogeneous

catalysis.

0

0

T

p

uu uu

u

(8)

The model couples the free fluid and porous

media flow through the Navier-Stokes equations and

Brinkman’s extension of Darcy’s law.

The mass transport of three species in the reactor

is modelled through the diffusion and convection

equation.

0

0

T

p

k

uu u

u

(9)

In the above equations

denotes the viscosity,

the density, and k the permeability.

3.3.2 Domain Equations – Mass Transport

The mass transport is given by the diffusion and

convection equation:

()

ii i i

Dc c R

u

(10)

where c

i

denotes the concentration (mol/m

3

)

of species i, u the velocity vector D

i

the diffusivity

(m

2

/s), and R

i

the reaction rate (mol/(m

3

.s)) for

species i.

3.3.3 Boundary Conditions

A constant velocity profile is assumed at the inlet

boundaries:

u = u

i

n

(11)

1/WHSV

,

h

.

k

g

K

/k

g

L

SimulationofHDSTestsinTrickle-BedReactor

741

For the outlets, pressure conditions are applied.

In the mass transport, the concentrations at the inlet

are fixed:

c

i

= c

i0

,

inlet

(12)

At the outlet, assume that convection dominates

the mass transport:

n (-D

i

c

i

) = 0

(13)

This implies that the gradient of c

i

in the

direction perpendicular to the outlet boundary is

negligible. This is a common assumption for tubular

reactors with a high degree of transport by

convection in the direction of the main reactor axis.

The condition eliminates the need for specifying a

concentration or a fixed value for the flux at the

outlet boundary. At all other boundaries, insulating

conditions apply:

n (-D

i

c

i

+ c

i

u) = 0

(14)

4 RESULTS AND DISCUSSION

Following presented results deals with estimated

kinetic parameters and catalyst deactivation rate

combined with hydrodynamic results obtained by

RTD method. The last part represents results of

reactor model.

4.1 Kinetic Parameters

Kinetic parameters of equation 2 were evaluated

from experiments with different weight liquid hourly

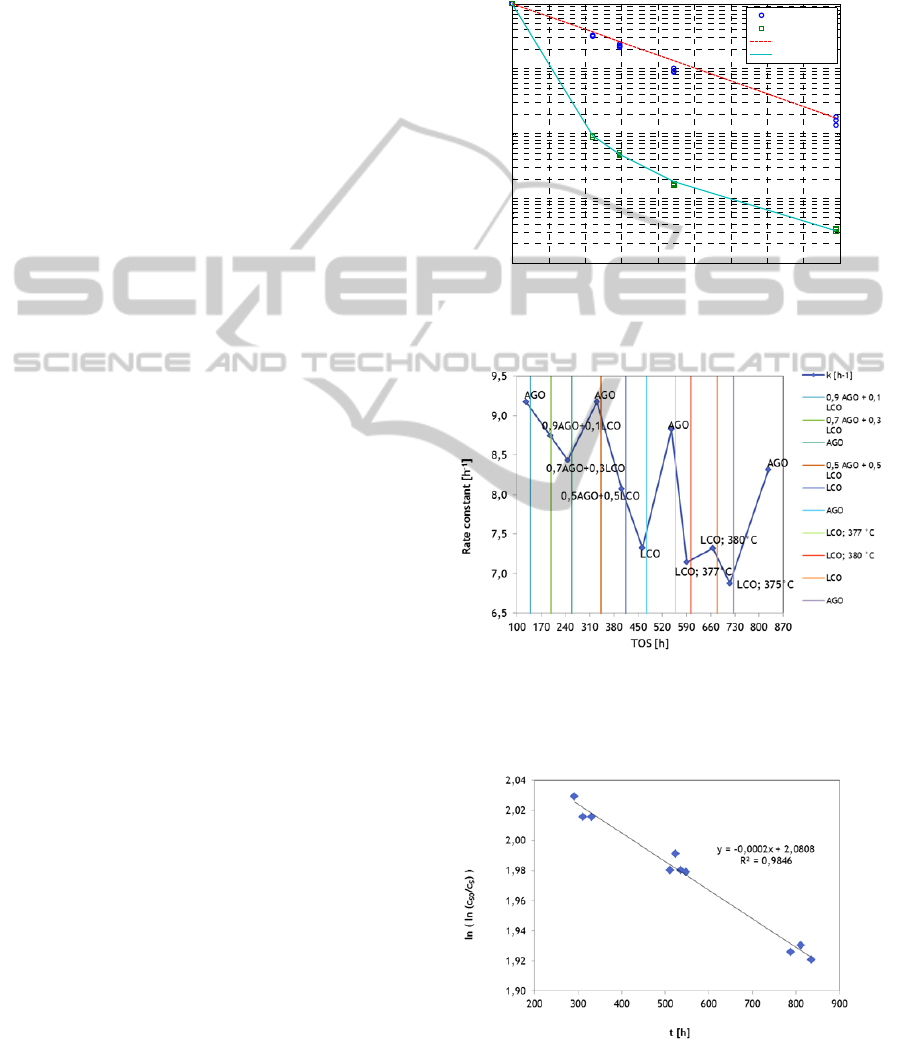

space velocity (WHSV). It follows from Figure 2

that reaction order with respect to sulfuric

compounds was found 1.37 and first order with

respect to nitrogen compounds.

4.2 Catalyst Deactivation

Deactivation of HDS catalyst in course of operation

period represents a serious problem. To predict

kinetics of deactivation a long time experiments are

necessary. Possible way how to accelerate

deactivation process is to combine raw liquid feeds,

AGO and LCO, respectively, with different content

of coke precursors, e.g., aromatics.

Result of this arrangement is possible to see on

Figure 3, HDS rate constant course in time on

stream (TOS). By periodic setting of standard

reaction condition: feed composition and

temperature and pressure, data presented in Figure 4

were obtained. Data measured at standard reaction

conditions represent decrease of reaction rate in time

due to catalyst deactivation. From this Figure 4

deactivation constant for presumed first deactivation

order was evaluated by linear regression.

Figure 2: Rate constant and reaction orders with respect to

sulfuric and nitrogen compounds.

Figure 3: Example of typical accelerated activity test with

AGO an LCO feedstock. Operating parameters: pressure

4.5 MPa, Oil feed 1 kg/dm

3

cat.

, hydrogen/liquid feed 300

Nm

3

/m

3

.

Figure 4: Linear fitting of first order deactivation.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

10

-4

10

-3

10

-2

10

-1

10

0

1/WHSV, h.kg

K

/kg

L

C/C

0

N

S

N:order 1.00

S:order 1.37

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

742

4.3 RTD

To formulate hydrodynamic model of the pilot

reactor determination of flow pattern in catalytic bed

is necessary. This is possible experimentally by the

RTD method. Resulting parameters of piston

dispersion (PD) model (Villermaux and van Swaaij,

1969), ie, Pe number and liquid holdup were

evaluated by nonlinear fitting simplex procedure of

Equation 15.

1/2 1/2

2

1(1) /1

() exp

2422

Pe

Pe Pe Pe Pe

Eeerfc

(15)

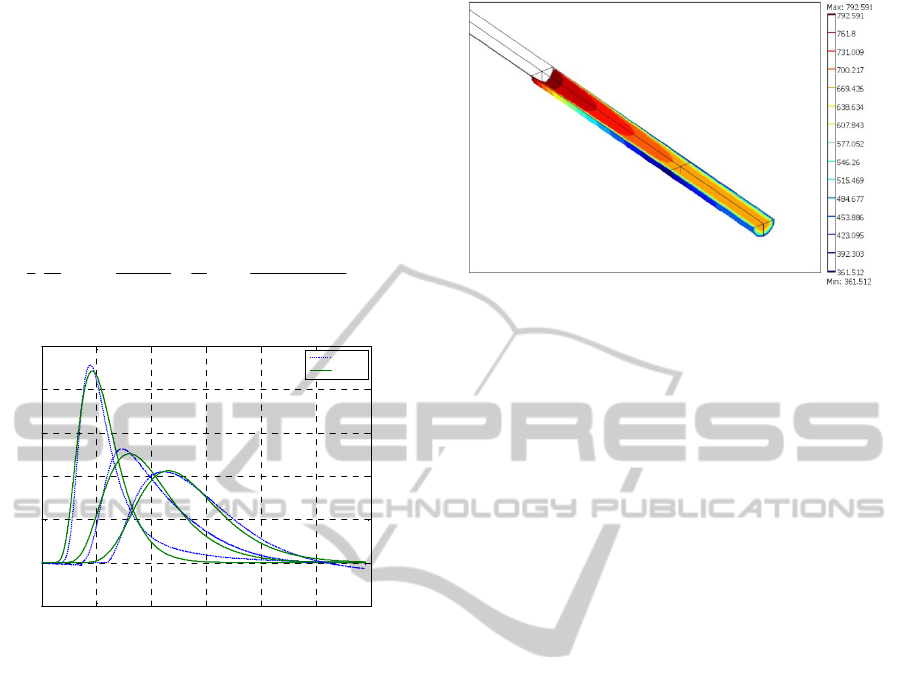

Figure 5: Comparison of PD model with RTD experiment.

E represents tracer distribution function,

is

dimensionless time, and Pe is Peclet number. Good

agreement between PD hydrodynamic model

(Equation 15) and experiment is presented in Figure

5.

4.4 CFD Reactor Model

In the Figure 5 the CFD model solution of sulfur

concentration field in tested trickle bed reactor is are

presented. Reactor bed is divided to three zones with

different porosity: i) calming zone to reach phase

equilibrium and steady state fluid velocity profile, ii)

first reaction zone of diluted catalyst and, iii) second

reaction zone of diluted catalyst. To evaluate an

influence of resulting parabolic velocity profile on

sulfur compound concentration is possible.

Decreased porosity of diluted catalytic reactor bed

exhibit more flat velocity profile, so as more even

reactants concentration on bed cross-section. Kinetic

Equation 2 of hydrodesulfurization of different

compounds, e.g. dibenzothiophene, were

incorporated into model to simulate real reactor

behavior.

Figure 6: CFD model of pilot reactor with

dibenzothiophene concentration field.

5 CONCLUSIONS

To support experimental testing of

hydrodesulfirization catalysts in pilot scale trickle-

bed reactor a methodology based on process

simulation was developed. Time dependent models

were used to evaluate both kinetic of HDS and HDN

reactions and description of catalyst activity decay

based on experiments. Also RTD measurement of

liquid holdup and axial dispersion in catalytic bed

was evaluated by piston dispersion (PD)

hydrodynamic model of time response characteristic.

Resulting kinetic parameters, deactivation constant

and Peclet number were used to formulate steady

state heterogeneous reactor model. Effect of

different inert diluent grain size on performance of

pilot scale HDS catalytic reactor was successfully

evaluated by CFD model. Time dependent kinetic in

combination with steady state flow velocity was

used to compare with experimental measurements.

ACKNOWLEDGEMENTS

This publication is a result of the project no. FR-

TI3/084, supported by the Ministry Industry and

Trade, which is being carried out in the UniCRE

centre whose infrastructure was supported by the

European Regional Development Fund and the state

budget of the Czech Republic. Also financial

support from specific university research (MSMT

CR no. 20/2014) is also acknowledged.

0 500 1000 1500 2000 2500 3000

-0.5

0

0.5

1

1.5

2

2.5

x 10

-3

t, s

E(t), s

-1

exp

model

SimulationofHDSTestsinTrickle-BedReactor

743

REFERENCES

Ancheyta, J., 2011. Modeling and Simulation of Catalytic

Reactors for Petroleum Refining, John Wiley & Sons,

Inc. Hoboken, 1

st

edition.

Bej, S.K., Dalai, A.K., Maity, S.M., 2001. Effect of diluent

size on the performance of a micro-scale fixed bed

multiphase reactor in up flow and down flow modes of

operation. Catalysis Today 64, 333-345.

Bellos, G.D., Papayannakos, N.G., 2003. The use of a

three phase microreactor to investigate HDS kinetics.

Catalysis Today 79–80, 349-355.

Mary, G., Chaouki, J., Luck, F., 2009. Trickle-bed

laboratory reactors for kinetic studies. International

Journal of Chemical Reactor Engineering 7 R2, 1-68.

Tukač, V., Šimíčková, M., Chyba, V., Lederer, J., Kolena,

J., Hanika, J., Jiřičný, V., Staněk, V., Stavárek P.,

2007. The behavior of pilot trickle-bed reactor under

periodic operation. Chemical Engineering Science 62,

4891-4895.

Villermaux, J., van Swaaij, W.P.M., 1969. Modèle

représentatif de la distribution des temps de séjour

dans un réacteur semi-infini à dispersion axiale avec

zones stagnantes. Application a l’écoulement

ruisselant dans des colonnes d’anneaux Raschig.

Chemical Engineering Science 24, 1097-1111.

Zimmerman, W.B.J., 2007. Multiphysics Modelling with

Finite Element Methods, World Scientific, Singapore.

2

nd

edition.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

744