The Impact of Lean Techniques on Factors Influencing Defect

Injection in Software Development

Rob J. Kusters

1

, Fabian M. Munneke

1

and Jos J. M. Trienekens

2

1

Department MST, Open University The Netherlands, Heerlen, The Netherlands

2

Department IE&IS, Eindhoven University of Technology, Eindhoven, The Netherlands

Keywords: Lean Techniques, Defect Injection.

Abstract In this paper we will focus on the impact that lean may have in preventing the injection of defects. We will

research the impact of a number of lean techniques on defect injection factors. Date have been obtained

from a single large Dutch governmental organization which has been using lean techniques routinely for

more than three years. To investigate the impact of lean on defect injection we developed a survey which

focused on the perceptions of the software developers of this organisation. The results suggest that the link

between lean techniques and factors influencing defect injection is real and they explain to a certain extent

the positive impact of the usage of lean techniques on software productivity.

1 INTRODUCTION

The notion of ‘lean’ development, first developed by

Toyota in a setting of complex repetitive production

(Womack et. al., 2008), has been moving towards

other types of production. Software engineering is

one of those. We see a significant focus both in

literature and practice on the application of lean

concepts to the field of software engineering. The

‘translation’ of lean concepts developed in complex,

but repetitive production of physical goods, to the

admittedly complex non-repetitive and not physical

production of software, is not immediately evident

but has been made (Poppendieck and Poppendieck,

2003).

Suggestions in literature are, that this move will

lead to improvements in both productivity and defect

reduction. However, Jonsson (2012), in a structured

review of empirical research, states that the actual

evidence for this is sparse and unconvincing.

In this paper we will take a closer look at the

impact that lean may have on preventing the injection

of defects. More specifically, we will look at the

perceived impact of a number of lean techniques on

those factors that during development influence the

injection of defects in software. Finding such

relationships will provide a further step toward

showing empirically the existence of effects of lean

on software engineering. We choose to focus on

defect injection since lean aims at reducing waste and

one of the most obvious forms of waste in software

development is the injection of, the searching for and

the solution of defects. A recent study (Cambridge

2013) estimates that software bugs cost the global

economy $312 billion per year.

To investigate the impact of lean on defect

injection we developed a survey which was deployed

in a large Dutch governmental organization which

has been using lean routinely for more than three

years. Although the research results on this impact

are restricted to perceptions, they suggest that the

link between lean techniques and factors influencing

defect injection are real and they explain to a certain

extent the positive impact of lean on software

development productivity.

In the next section current work is discussed,

followed by the research methodology. Since this

methodology requires a set of defect injection

factors, the literature survey executed to identify

these is described next, followed by the design of the

survey and its results. The paper finishes with a

discussion of results and conclusions.

2 CURRENT WORK

The notion that lean will impact defect injection

(positively) has been claimed since the transfer of the

412

J. Kusters R., M. Munneke F. and J. M. Trienekens J..

The Impact of Lean Techniques on Factors Influencing Defect Injection in Software Development.

DOI: 10.5220/0005400204120419

In Proceedings of the 17th International Conference on Enterprise Information Systems (ICEIS-2015), pages 412-419

ISBN: 978-989-758-097-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

notion of lean to software development. Schulmeyer

(1990) reports on the application of ideas for

achieving zero defects from manufacturing industry

to software development. He focused on defect

prevention, and estimates that savings of up to 40%

are possible. Poppendieck and Poppendieck (2003)

also named defects as one of the seven forms of

waste that lean should attack. Middleton (2001)

stated that lean will encourage looking at underlying

problems behind the injection of defects, resulting in

finding them before they become failures. Cook and

Semouchtchak (2004) also state that implementing

lean should reduce the number of defects, but also

recognize it requires a long and complex

transformation process.

As to how lean will accomplish this effect, Mehta

et al (2008) state that reducing system complexity

where possible, and delivering in smaller increments

(both possible effects of lean), should contribute.

They also point out the positive effect of lean

techniques, such as root cause analysis, which allow

the identification and prevention of root causes.

Similar claims are made by Card (2006) and Jalote

and Agrawal (2005). Cottyn et al (2008) state that

application of lean techniques such as “pull” and

“standardization” will impact defect injection. A

similar claim is made for the lean technique

"kanban", which also should support early

identification of defects (Ikonen, 2010), and Ikonen

et al (2010). Petersen and Wohlin (2010) investigated

a method SPI-LEAM that supports the identification

of defects in development.

Finally, some studies indicate that the reduction

of defect injection actually occurs. Middleton and

Joyce (2012) show a decrease in the number of

detected defects of 24%. McKinsey (2010) claim a

decrease of 20 to 45% of defects detected.

All in all there appears to be substantial literature

claiming an effect of lean on defect injection.

However in a recent structural literature review

(Jonsson, 2010) states that the actual evidence for the

effect of lean is still sparse and not always

convincing. Also, although in some papers the effect

of lean is detailed to the effect of underlying

techniques, the relationship between lean techniques

and lean effectiveness is not well researched. Only

two papers address this issue. McConnel (1997)

shows that removal of non-required functionality

reduces ‘complexity’, as is the case for simplification

of functionality. Mehta et al (2008) show that

frequent delivery of smaller functionality will impact

both ‘complexity’ and ‘lack of traceability’. Both

complexity (Fenton, 1999) and lack of traceability

(O’Neill, 1997) are recognized as defect injector

factors. Therefore these two papers provided limited

support for explaining the impact of lean. We

propose to contribute to the explanation of the impact

of lean.

3 APPROACH

In principle for this type of research we can choose

between measuring actual impact and capturing

perceptions of an improvement by surveying

developers. Obtaining accurate measurements is

exceedingly difficult. The environment in which

software development is being executed is

continuously changing, e.g. by the introduction of

new methods and techniques, by changes in staff and

of course by the fact that every system being

developed is by definition new. Measurement will

therefore capture the compounded impact of all of

these changes, and not just that of implementation of

lean. Distinguishing the impact of a single action

from that of a number of others is not feasible.

That brings us to surveys as an instrument of

research. In principle the same problem is present.

Asking if lean has had an impact will force

developers / practitioners to try to identify and

distinguish the impact of all of these changes.

Reliable answers are not likely. However, if

questions can be formulated that are sufficiently

concrete and tie in to the personal experience of the

respondent, more reliable information can be

gathered (Lenzner, 2011). So, instead of asking

questions as “did the introduction of lean impact of

defects injection” we decided to be more specific.

First, instead of asking about the impact of lean

as a whole, we decided to focus on a limited number

of well-known and well used techniques. We

appreciate that lean is a coherent approach, where the

added value is achieved by combining a number of

specific techniques and where the impact of the

whole is meant to exceed the sum of the impact of

the individual elements. However, that still allows us

to look at the (perceived) impact of individual

techniques for understanding the impact of lean (see

e.g. Rivera and Chen (2007).

Secondly, on the other side of the question we did

not look at the (perceived) impact on the injection of

defects. This was seen as too abstract and difficult a

question. Here we went one step deeper and looked

in literature for factors that are seen to influence the

injection of defects in software. Take e.g. the notion

of complexity. There is evidence in literature (see

e.g. Fenton and Neil, 1999) that the complexity of the

problem solution will impact the injection of defects.

TheImpactofLeanTechniquesonFactorsInfluencingDefectInjectioninSoftwareDevelopment

413

And the impact of a lean technique on complexity is

easier to assess by persons involved in the process.

Therefore we decomposed the single question:

“does usage of lean reduce the number of defects

injected into the software” into a number of easier

sub-questions: “will usage of technique X impact

defect injection factor Y”. This results in a fairly

large number of questions. The number of sub-

questions will explode rapidly if the number of

techniques and the number of factors increase. In a

survey, an increase in the number of questions will

both tend to reduce the response rate as well as

reducing the quality of the answers that are delivered.

This implies that in order to obtain a decent response,

we limited the number of sub-questions. The factors

used result from a literature search. When compiling

the results from such a literature search there is

always a choice in the level of detail used. For this

research, it was decided to aim for a higher level of

abstraction, thus reducing the number of factors,

while still striving for factors that were sufficiently

concrete to result in reliable answers.

Similarly we choose to reduce the number of

techniques used in the survey. The number and type

of technique used is of course closely linked to the

type of organization that is included in the survey.

Two extremes are possible. One is a survey sent out

to different organizations. A way to reduce the

number of techniques in such a context is to have

respondents select a limited number of techniques

that they are familiar with from a larger list and

generate the sub-questions based on this selection.

Another approach is to select a single organization,

identify a limited number of techniques in use in this

organization and use these in the survey.

A choice here would be impacted by possibilities

for a wider response and more options for

generalizability when taking the first approach and

more limited but probably more reliable results when

focusing on a single organization. More reliable since

more information on the experience with lean is

available and we can assume that the technique

referred to in the survey is actually in use. There is

less scope for misunderstanding. Given that, as far as

we could ascertain, this is the first survey of this

type, we opted for the more limited, but hopefully

more reliable, option of obtaining data from a single

organization.

As a result, the research follows the steps:

a) identify a list of relevant defect injection factors

b) select a relevant organization where lean is used

c) identify a number of lean techniques that are in

use in this organization

d) conduct a survey and analyze the results.

4 IDENTIFYING DEFECT

INJECTION FACTORS

A literature survey was executed in order to identify

a list of defect injection factors. The search was

based on key-words supported by a snowball

approach (forward and backward). This resulted in 7

papers (see table 1). The results from these papers

were merged in a single list, which should not be too

large, in order not to have a negative impact on

response rate. On the other hand the factor should be

sufficiently clear to allow people answering the sub-

questions with a degree of confidence. The final

selection made was principally based on the set

provided by Travassos et al (1999) ‘incompleteness’,

‘ambiguity’, ‘inconsistency’, ‘incorrect fact’, and

‘extraneous information’.

They used more global terms, which we still

assessed as being sufficiently specific for answering

the sub-questions. Results from other sources were

classified to the Travassos terminology if possible.

The remaining terms were used as the basis for

additions to the list of Travassos resulting in the

following additions:

Lack of traceability (O’Neill, 1997);

Complexity (Fenton and Neil, 1999; Bennett and

Wennberg, 2005);

Lack of skills (Fenton and Neil, 1999; Leszak et

al, 2002);

Lack of knowledge (Leszak et al, 2002);

Time pressure (Leszak et al, 2002).

5 IDENTIFYING TECHNIQUES

AND SURVEY DESIGN

The survey was done in the software group of a large

Dutch government organization. It supports the

primary processes of the organization. For this a staff

of over 1600 developers is available. Lean as a core

development approach was rolled out in 2010. The

research was done in 2013, giving us an organization

with three years of experience which we deemed this

to be sufficient.

First we identified the techniques most commonly

used. For this, four coaches with responsibility for

the lean methodology were interviewed independent

from each other. They all agreed as to the two most

used techniques: “Day-start” and “Week-start”. After

that, as a third most used technique various forms of

"Coaching" were mentioned. Finally three out of four

lean coaches mentioned structured improvement

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

414

("Kaizen"), while the fourth respondent did not name

a fourth technique. Giving this almost complete

agreement we decided to proceed with these four

techniques. Table 2 gives a description of the

techniques used.

Based on the results so far, i.e ten defect injection

factors and four lean techniques, a survey was

developed and sent out to all (approximately 1600)

members of staff. For each of the four techniques

they were asked if they use this technique on a

regular basis to filter out staff members with no

experience of this technique. Next (for this

technique) for each of the defect injection factors the

question was asked: “to what degree do you think

this technique contributes to the basic causes of

software defects”.

For the answer options we selected a five point

labelled Likert scale starting with “not” indicating no

effect and ending with “excellent”. A sixth item “I

don’t know” was added to prevent people from being

‘forced’ to give an opinion without actually having

one. This survey was tested on a lean-coach to check

for comprehensibility and ease of use. After a

positive response it was sent out to all members of

staff.

Some limitations to the study are obvious. Data

from a single organization limits the validity of the

results. This is partly compensated for by the size of

the organization, the response and the experience

available within the organization with its way of

working. A second limitation is the specific set of

techniques that is in use. "Kaizen" is generally

recognized as a ‘lean’ technique and is one of the

original 14 principles of the Toyota production

system. The others are less known. However, both

"Daystart" and "Weekstart" enable team

communication and leverage team knowledge, and

they both further effective and efficient teamwork

which is seen as an important effect of ‘lean’

techniques. "Coaching" supports staff development,

one of the Toyota principles. This shows that the set

of techniques discussed is relevant.

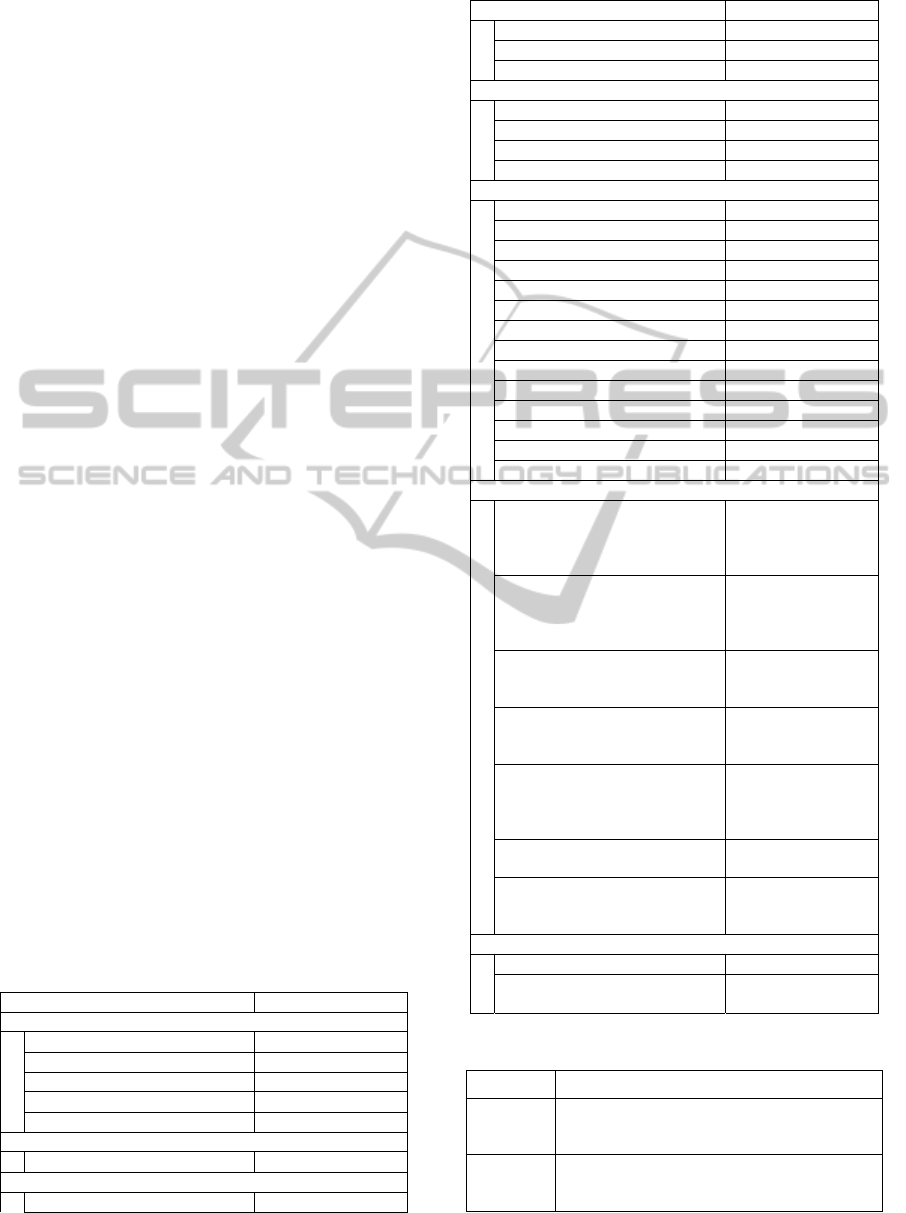

Table 1: the mapping to identified factors.

Found in literature Factor identified

(Travassos, et al., 1999)

Omission Incompleteness

Ambiguity Ambiguity

Inconsistency Inconsistency

Incorrect fact Incorrectness

Extraneous information External factors

(O'Neill, 1997)

Lack of traceability Lack of traceability

(Chulani & Boehm, 1999)

Incorrect requirements Incorrectness

Table 1: The mapping to identified factors (cont.).

Found in literature Factor identified

Incomplete requirements Incompleteness

Design defects Incorrectness

Programming defects Incorrectness

(Fenton, 1999)

Difficulty of the problem Complexity

Complexity of designed solution Complexity

Programmer / analyst skill Lack of skills

Design methods and procedures Incorrectness

(Leszak, et al., 2002)

Incorrect documentation Incorrectness

Incomplete documentation Incompleteness

Unclear documentation Ambiguity

Change in coordination Lack of skills

Lack of domain knowledge Lack of knowledge

Lack of system knowledge Lack of knowledge

Lack of tool knowledge Lack of knowledge

Lack of process knowledge Lack of knowledge

Individual error Incorrectness

Time pressure Time pressure

Management error Incorrectness

Error caused by other products External factors

Insufficient preparation Incompleteness

Insufficient participatin Incompleteness

(Bennet & Wennberg, 2005)

Assumptions/ambiguities

affecting the interpretation of

customer descriptions of desired

system behavior

Ambiguity

The difficulty in fully

understanding the real-world

environment in which the

system will interact

Complexity

The difficulty in anticipating all

of the possible modes and states

that the system may encounter

Complexity

The difficulty in thoroughly

validating and verifying

requirements

Complexity

Capturing accurate,

unambiguous representations of

requirements in a written

document

Incompleteness

Misinterpretation of system-

level requirements

Incorrectness

The difficulty in verifying that

the design has correctly

implemented the requirements.

Complexity

(D’Ambros, et al., 2010)

Design flaws Incorrectness

Violations of design principles

and practices

Incompleteness

Table 2: description of the techniques used in the survey.

Technique Description

Day-start A daily session of approximately 15 minutes

where staff share the status of their work with

direct co-workers

Week-

start

A weekly session of approximately one hour

where staff look at the results obtained last

week and set targets for the upcoming week

TheImpactofLeanTechniquesonFactorsInfluencingDefectInjectioninSoftwareDevelopment

415

Table 2: description of the techniques used in the survey

(cont.).

Technique Description

Coaching Regular interactions between managers and

staff to develop insight into current performance

and options for improvement

Kaizen An approach to implement process

improvement during a short period of time by

going through the cycle: define – measure –

analyze – generate improvements – implement

– control – secure

6 RESULTS OF THE SURVEY

The response of approximately 34% is high for a

survey and gives confidence in the results. Of the

respondents 89% indicate they use lean in some

form. Taking this as the basis for relevant response,

we see differences in usage between the techniques.

Day-start is commonly in use (95.3%) as is Week-

start (80.7%). Both Coaching and Kaizen are used

less. For Kaizen the result is reasonable. Not

everyone will regularly be involved in Kaizen type

improvement projects. With 43.3% of staff members

involved in this activity it shows a decent result. That

little usage was made of Coaching is surprising, since

the lean-coaches of the department all agreed on its

importance. However, there was already during the

discussions with these lean-coaches some confusion

in this area, since many different names for the

technique were mentioned. In discussion with the

lean-coaches a term (Coaching) was selected that

they felt would be understood by most people. This

might have been over optimistic. However, a

response of 26.3% is still large enough to be able to

draw conclusions.

If respondents indicate an effect is present they

can indicate the size of this effect. Answer options

range from “moderate” to “excellent”. To get a better

show the results, we added two notions. The first is a

“significant effect” that adds responses of “average”

and higher. The second is a “major effect” that adds

responses of “good” and “excellent”. More detailed

results are presented in table 5, where we give results

(in percentages) for each combination of technique

and defect injection factor. To facilitate reading this

table, highest scores within a technique are indicated

in bold.

Results for the sub-questions are summarized in

tables 3 and 4. In table 3 we provide a first overview

of average results per technique across defect

injection factors. The first block gives the answers to

the question “is there an impact of this technique”.

Answer options are “no”, “don’t know”, and “yes”).

The basis of this percentage is the number of

respondents, indicating they use the technique, minus

those with a "no" answer on the sub-question

(resulting in a missing value). If we deduct also the

answer “don’t know” from the response we see the

result of those respondents that felt sufficiently

secure to give an answer. This is presented in a

further column “yes-2”.

7 DISCUSSION

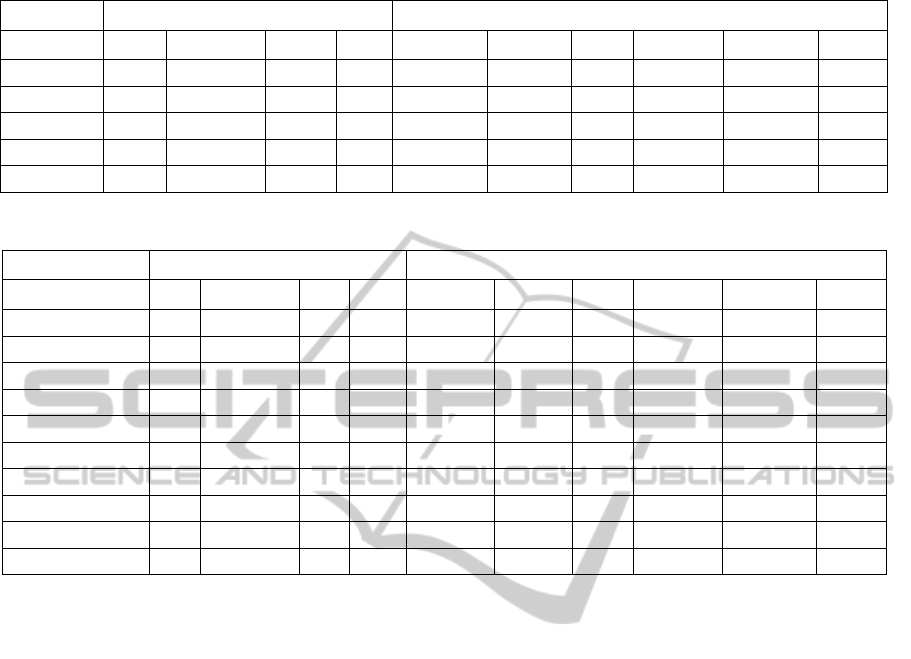

Across all techniques and defect injection factors, an

average of 61.8 % of respondents perceive the

existence of an impact of the identified lean

techniques on the identified defect injection factors.

If they see such an effect, its degree is estimated at

“significant” by 66.4% of respondents and as

“major” by 30.8%. These results seem to support the

notion that ‘lean’ positively impacts defect injection.

It goes some way toward explaining the reason for

the existence of this effect of lean.

If we look across techniques we can see that the

existence of an impact of Kaizen, a technique aimed

at structural continuous improvement, is perceived to

be (on average across defect injection factors) highest

at 70.6%. Also the degree of this impact (significant:

74.1%; major: 39.6%) scores very high. This is

followed by both Coaching (impact: 63.5%;

significant: 72.2%; major: 31.8%) and Day-start

(impact: 61.2%; significant: 62.2%; major: 30.8%).

They are definitely trailed by Week-start (impact:

52.0%; significant: 57.2%; major: 20.9%), which

shows a decidedly lower result. Similarly, if we look

at the defect injection factors to see where the impact

is seen most across techniques, “external factors” and

“time pressure” score high, both with existence of

impact and degree of impact, with “lack of skills”

and “lack of knowledge” following close behind.

Day-start is a daily session of about 15 minutes

aimed at discussing the performance of the previous

day and the goals of the current day, identification of

improvement options and work allocation. Given this

purpose, the major impact on ‘time pressure’ that is

identified should not come as a surprise. Planning

work based on the current situation is its main

purpose and this should indeed isolate the team from

undue expectations. The impact on ‘external factors’

is more surprising, since the technique is not

specifically aimed at these. A possible explanation

could be that this isolation also extends to other

issues, which are handled of line. The higher impact

on ‘lack of knowledge’, ‘lack of skills’ and

‘incompleteness’ could be explained by the

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

416

Table 3: Average results per technique across injection factors (in percentages).

Technique Is there an impact Degree of impact if there is an impact

no don't know yes yes-2 Moderate Average Good Excellent Significant Major

Daystart 32.1 17.1 50.8 61.2 37.8 31.4 25.5 5.3 62.2 30.8

Week-start 40.5 15.7 43.8 52.0 42.8 36.3 18.6 2.4 57.2 20.9

Coaching 32.5 11.0 56.5 63.5 27.8 40.4 21.9 10.0 72.2 31.8

Kaizen 23.1 21.6 55.3 70.6 25.9 34.5 27.2 12.4 74.1 39.6

Over all 32.1 16.3 51.6 61.8 33.6 35.6 23.3 7.5 66.4 30.8

Table 4: Average impact on defect injection factors across techniques (in percentages).

Factor Is there an impact Degree of impact

no don't know yes yes-2 Moderate Average Good Excellent Significant Major

Incompleteness 33.4 15.6 51.0 60.5 35.1 33.8

26.2

4.9 64.9 31.1

Incorrectness 34.8 15.6 49.6 58.9 36.3 38.0 21.4 4.2 63.7 25.6

Inconsistency 34.1 15.9 50.0 59.7 39.2 35.7 21.0 4.1 60.8 25.1

Ambiguity 34.0 16.6 49.4 59.4

39.5

38.0 17.7 4.8 60.5 22.5

Complexity 32.3 16.2 51.6 61.7 34.3 33.5 25.0 7.2 65.7 32.3

Time pressure 28.9 15.6

55.6

65.8 28.6 33.0 26.0

12.4

71.4

38.4

Lack of traceability

35.5

17.6 46.9 57.1 36.6 36.9 21.6 4.9 63.4 26.5

Lack of skills 31.8 15.6 52.7 62.4 29.8 35.1 23.8 11.3 70.2 35.1

Lack of knowledge 29.6 15.3 55.1 65.1 29.4 33.8 24.6 12.1 70.6 36.8

External factors 26.3

19.2

54.5

67.6

26.9

38.5

25.7 8.9

73.1

34.6

communication among the team that is fostered by

this frequent contact. The purpose of a Day-start is

also asking or offering knowledge or availability.

Week-start is a weekly session of about an hour

with similar purposes to the Day-start, now only with

a time frame of one week. Given the same

approximate purpose we see a similar result, with

‘time pressure’ and ‘external factors’ scoring highest,

again followed by ‘lack of knowledge’, ‘lack of

skills’ and ‘incompleteness’. However, we also see

that the impact of this technique is rated decidedly

lower when compare to that of day-start. This is

surprising. A possible explanation could be that a

time frame of one week is too much to provide the

‘isolation’ effects postulated above. However, we

also see that participation for the Day-start (95.3%) is

higher than that for the Week-start (80.7%) which is

still high but might indicate a lower acceptance of the

practice and its results.

Coaching and performance dialogues are aimed at

coaching the employee of discussing his – hers

performance. Each employee is supposed to have

such a talk at least once per week. Indicated

participation for this technique is low with 26.3%. As

stated a possible explanation might be that some

confusion exists about the name of the activity.

Another reason might be that the recipients of the

regular coaching discussions no longer see it as a

separate technique but as a part of the common daily

activities. The technique is then so embedded in the

way of working of the organization that only (team-)

managers are likely to notice it. However as stated,

the perceived impact of this technique, aimed at

continuous improvement, is high. Impact and degree

of impact score high for both by ‘lack of knowledge’,

‘lack of skills’, as is to be expected with a technique

aimed at improving the human capability. Somewhat

more surprising, ‘time pressure’ also received a high

score, maybe because of time management issues

being taken along with the coaching. The factor

‘external factors’ scores very high in input, but fairly

low in its degree of impact. Since coaching is aimed

at the improvement of the human resource, and not

specifically at the management of work processes

this might explain the lower degree of impact.

Kaizen, a technique aimed at structural

continuous improvement, is aimed at developing and

implementing concrete improvements. In a (limited)

number of sessions a small team guided by a kaizen

facilitator follows a structured process aimed at

developing and implementing an improvement for an

identified issue. Since this is usually more product

and process oriented, factors associated with this are

more likely to be impacted as opposed to the more

TheImpactofLeanTechniquesonFactorsInfluencingDefectInjectioninSoftwareDevelopment

417

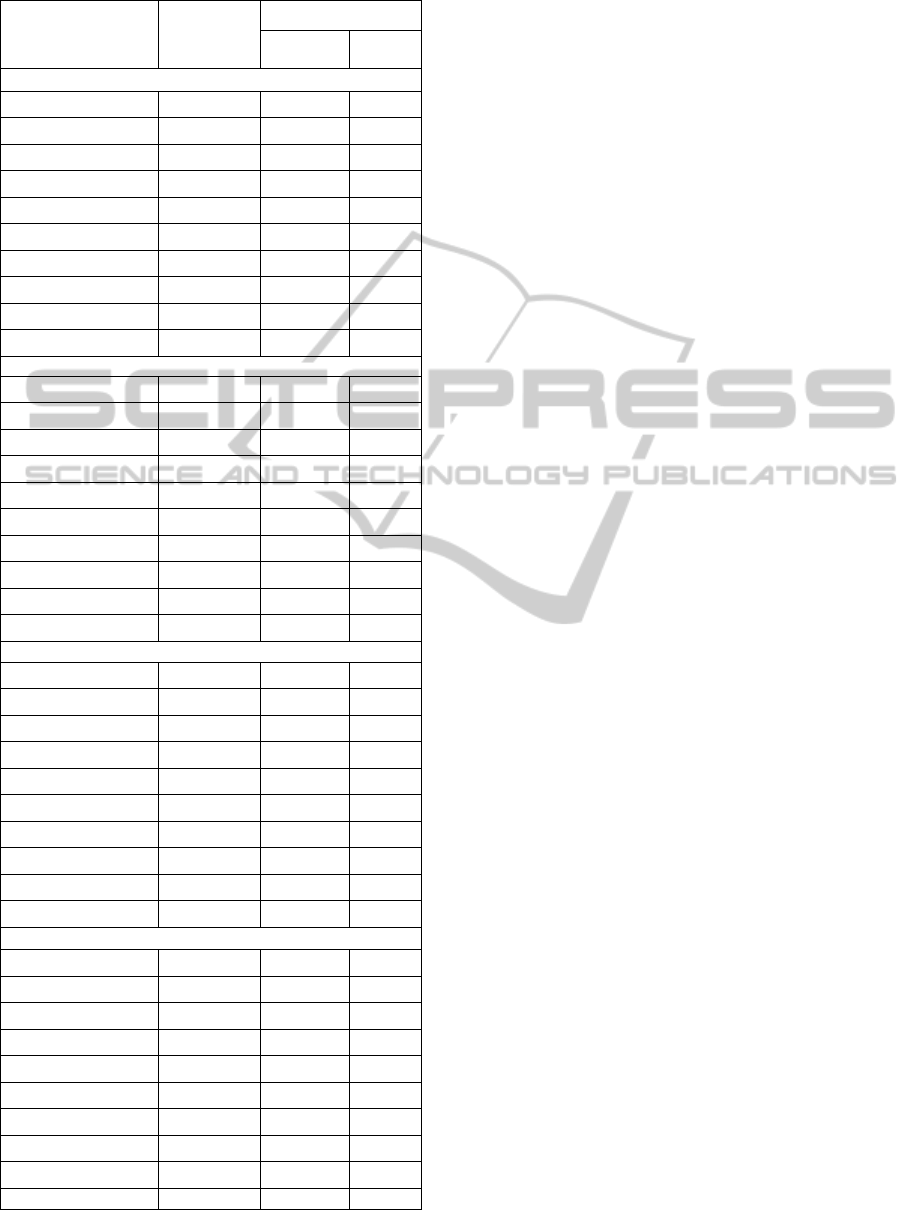

Table 5: results / technique / defect injection factor ( %).

Technique / Defect

injection factor

Is there an

impact?

Degree of impact

Signifi-

cant

Major

DAY START

Incompleteness 61.7 62.1 33.2

Incorrectness 58.1 57.6 26.3

Inconsistency 60.2 55.4 26.0

Ambiguity 56.4 56.3 20.5

Complexity 57.0 61.0 30.8

Time pressure

71.6

71.7

45.1

Lack of traceability 52.6 55.5 23.1

Lack of skills 60.3 65.4 32.7

Lack of knowledge 67.4 64.2 33.6

External factors 67.2

72.4

36.7

WEEK START

Incompleteness 49.2 53.5 20.8

Incorrectness 47.2 55.3 18.4

Inconsistency 47.7 49.0 15.7

Ambiguity 48.1 50.6 13.0

Complexity 53.0 52.7 18.3

Time pressure 60.0 64.1

31.3

Lack of traceability 45.4 55.6 18.8

Lack of skills 53.1 60.5 22.1

Lack of knowledge 55.9 63.0 23.2

External factors

60.3 67.9

27.8

COACHING

Incompleteness 62.7 65.2 21.7

Incorrectness 60.9 62.7 17.9

Inconsistency 58.2 67.2 17.2

Ambiguity 61.1 62.1 16.7

Complexity 62.4 70.6 32.4

Time pressure 66.7 81.1

50.0

Lack of traceability 58.3 68.3 22.2

Lack of skills

68.5

82.9 51.3

Lack of knowledge 67.6

84.0

53.3

External factors 68.2 78.1 35.6

KAIZEN

Incompleteness 68.5 78.8

48.7

Incorrectness 69.3

79.1

40.0

Inconsistency 72.7 71.7 41.7

Ambiguity 72.0 72.9 39.8

Complexity 74.4 78.7 47.5

Time pressure 65.0 68.9 27.4

Lack of traceability 72.2 74.4 41.9

Lack of skills 67.7 72.1 34.2

Lack of knowledge 69.5 71.1 36.8

External factors

74.7

73.9 38.3

human oriented factors targeted by coaching. This is

indeed confirmed by the results. The factors

‘incompleteness’, ‘incorrectness’, ’inconsistency’,

‘complexity’, and ‘lack of traceability’ are the ones

that are identified by the respondents as having a

high degree of impact (‘major’ above 40%) with the

other factors scoring (sometimes well) below that.

The one defect injection factor that had not

surfaced in any of the techniques as having a major

degree of impact is ‘ambiguity’. It scored not only

lowest overall, but also lowest for three out of four of

the individual techniques (based on the ‘major’

degree of impact). Apparently this is too complex a

concept and cannot be easily dealt with by these

fairly straightforward techniques. Also, ‘ambiguity’

is likely to be caused to a large degree by the

interaction with the user community, which is not

involved in either of these techniques, suggesting the

need for other means to deal with this issue.

8 CONCLUSIONS

Notions of ‘lean’ and associated techniques are being

used more and more in practice in software

engineering. Literature suggests that adoption of

these practices could lead to improved productivity

and a reduction of the number of defects injected.

Literature also suggests that the actual proof for this

is still not very convincing. In this paper we added to

the body of knowledge by looking at a detailed level

at the possible impact of a number of lean techniques

on a number of defect injection factors. A survey,

conducted within a single large software

development organization, shows that respondents

indeed perceive that such an impact is present.

Different techniques have to a different degree an

expected impact on the defect injection factors. This

provides additional proof for the effectiveness of lean

in software engineering and also gives some more

detailed explanation for this effect.

Having said this, the research has a number of

limitations. The context is a single (albeit large)

organization. Also, the research does not look at the

comprehensive concept of lean, but only at a limited

number of techniques. Both issues limit the

generalizability of the results, suggesting immediate

areas for further research.

Another limitation is due to the fact that the

results are based on subjective assessments of the

respondents taking part. They are in principle

knowledgeable, and the questions were tailored to be

answerable. Also the ‘don’t know’ option, which was

used on average by 16% of respondents should weed

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

418

out uninformed answers. But still people have to

assess the impact of techniques they use on factors

that are fairly abstract. We do indeed see a fairly

strong respondent bias. People tend to be more

optimistic / pessimistic across the board, resulting in

a high correlation between the individual answers.

However, even when taking into account this effect,

differences between different techniques are

considerable and reasonable explanations for these

differences can be provided. All in all the main

direction of the results is in our mind sufficiently

reliable and therefore relevant and warrants further

research.

REFERENCES

Bennett, T. L., and Wennberg, P.W. "Eliminating

embedded software defects prior to integration test."

Crosstalk, Dec., pp. 13-18 (2005).

Cambridge. http://www.prweb.com/releases/2013/1/prweb

1029

8185.htm (2013).

Card, D. N. "Myths and strategies of defect causal

analysis." Proceedings of Pacific Northwest Software

Quality Conference. 2006.

Chulani, S., and Boehm, B. Modeling software defect

introduction and removal: COQUALMO

(COnstructive QUALity MOdel). Technical Report

USC-CSE-99-510, University of Southern California,

Center for Software Engineering, 1999.

Cook, J., & Semouchtchak, V. Lean object-oriented

software development. SAM Advanced Management

Journal, 69(2), 2004.

Cottyn, J., Stockman, K., and Landeghem, H. van. "The

Complementarity of Lean Thinking and the ISA 95

standard." WBF 2008: Bridging the Divide between IT

and Manufacturing. 2008.

D'Ambros, M., Bacchelli, A., and Lanza, M. "On the

impact of design flaws on software defects." Quality

Software (QSIC), 2010 10th International Conference

on. IEEE, 2010.

Fenton, N. E., and Neil, M. "A critique of software defect

prediction models." Software Engineering, IEEE

Transactions on 25.5 (1999): 675-689.

Ikonen, M., Kettunen, P., Oza, N., and Abrahamsson, P.

"Exploring the sources of waste in kanban software

development projects." Software Engineering and

Advanced Applications (SEAA), 2010 36th

EUROMICRO Conference on. IEEE, 2010.

Ikonen, M. "Leadership in Kanban software development

projects: A quasi-controlled experiment." Lean

Enterprise Software and Systems. Springer Berlin

Heidelberg, 2010. 85-98.

Jalote, P., and Agrawal, N. "Using defect analysis

feedback for improving quality and productivity in

iterative software development." Information and

Communications Technology, 2005. Enabling

Technologies for the New Knowledge Society: ITI 3rd

International Conference on. Ieee, 2005.

Jonsson, H. "Lean Software Development: A Systematic

Review." IDT Miniconference on Interesting Results

in Computer Science and Engineering (IRCSE)

(2010).

Lenzner, T. A Psycholinguistic Look at Survey Question

Design and Response Quality. PhD-thesis Universität

Mannheim, 2011.

Leszak, M, Perry, D. E., and Stoll, D. "Classification and

evaluation of defects in a project retrospective." J. of

Systems and Software 61.3, pp. 173-187, 2002.

McConnell, S. (1997). Archieving Leaner Software. IEEE

Software(November/December).

McKinsey & Company. (2010). Ten Core Principles for

Applying Lean ADM: McKinsey & Company, 2010.

Mehta, M., Anderson, D., and Raffo, D. "Providing value

to customers in software development through lean

principles." Software Process: Improvement and

Practice 13.1 (2008): 101-109.

Middleton, P., and Joyce, D. "Lean software management:

BBC Worldwide case study." Engineering

Management, IEEE Trans. on 59.1 (2012): 20-32.

Middleton, P. "Lean software development: two case

studies." Software Quality J. 9.4 (2001) 241-252.

O'Neill, D. "Issues in software inspection." Software,

IEEE 14.1 (1997): 18-19.

Petersen, K., and Wohlin, C. "Software process

improvement through the Lean Measurement (SPI-

LEAM) method." J. of systems and software 83.7

(2010) 1275-1287.

Poppendieck, M, and Poppendieck, T. Lean software

development: an agile toolkit. Addison-Wesley

Professional, 2003.

Rivera, L., and Chen, F.F. "Measuring the impact of Lean

tools on the cost–time investment of a product using

cost–time profiles." Robotics and Computer-

Integrated Manufacturing 23.6 (2007): 684-689.

Schulmeyer, G. G. Zero defect software. McGraw-Hill,

Inc., 1990.

Travassos, G., Shull, F., Fredericks, M., & Basili, V. R.

"Detecting defects in object-oriented designs: using

reading techniques to increase software quality." ACM

Sigplan Notices. Vol. 34. No. 10. ACM, (1999): 47-56.

Womack, J. P., Jones, D. T, and Roos D. The machine that

changed the world. Simon and Schuster, 2008.

TheImpactofLeanTechniquesonFactorsInfluencingDefectInjectioninSoftwareDevelopment

419