InterCriteria Decision Making Approach for Metal Chips

Briquetting

Dimitar Karastoyanov

1

, Lyubka Doukovska

1

, Stanislav Gyoshev

1

and Ivan Kalaykov

2

1

Institute of Information and Communication Technologies, Bulgarian Academy of Sciences

Acad. G. Bonchev str., bl. 2, 1113 Sofia, Bulgaria

doukovska@iit.bas.bg, dkarast@iinf.bas.bg, stanislavgyoshev@mail.bg

2

Örebro University, School of Science and Technology

SE-701 82 Örebro, Sweden

ivan.kalaykov@oru.se

Keywords: InterCriteria decision making, Index matrix, Impact briquetting.

Abstract: In the presented paper for the analysis purposes we have used experimental results of impact briquetting of

grey cast iron chips. The presented multicriteria decision making method is based on two fundamental

concepts: intuitionistic fuzzy sets and index matrices. We have named it ‘InterCriteria’ decision making

approach, which utilizes the apparatus of index matrices and intuitionistic fuzzy sets - takes an existing

multiobject multicriteria evaluation table and generates a new table that contains estimations of the pairwise

relations among the set of evaluating criteria. Our goal is to increase the efficiency of the process of

briquetting metal chips with good density and quality.

1 INTRODUCTION

Producing briquettes using metal chips and powder

is an actual scientific problem which is reflected in a

lot off publications. In paper (Bodurov et al., 2005)

is proposed an original construction of die forging

hammer propelled by industrial rocket engine. With

this machine it is possible to work with controlled

impact and with impact velocities from 4.5 [m/s] up

to 20 [m/s]. Laboratory set-up for controlled impact,

and the results of experimental study of metal chips

briquetting by controlled impact with impact speed

of 7 [m/s] are presented in paper (Gustavson et al,

2014). The potentiality to produce parts using such

briquettes is also illustrated.

The technological effects of a controlled impact

application in plastic deformation and briquetting of

metal chips processes are discussed in (Penchev et

al., 2013; Penchev et al., 2014; Penchev et al., 2014;

Radeva et al., 2014). It was found that using a

controlled impact increases the deformation up to

27% and the density of the briquettes up to 20%

when compared to the ordinary impact. In (Penchev

et al., 2014) is investigated the possibility of

processing briquettes via plastic deformation of

aluminum alloy chips (the density of the briquettes

in this case is 93% of the density of the solid alloy).

It was found that this is possible if stresses in the

deformed body are compressive. In the presented

paper for the analysis purposes we have used

experimental results of impact briquetting of grey

cast iron chips. In this study the parameters distance,

speed

, acceleration of the impacting bodies are

analysed by means of high speed camera and the

applicable software. They are part of the equipment

of the Smart Lab at IICT.

The impact energy (Е

у

) and power (F

у

) are

calculated. To get more experimental data an Xray

tomograph Nikon XTH 225 Compact Industrial CT

Scаnner has been used. This way the horizontal and

vertical briquette sections have been investigated.

The resolution of the obtained images is 5 [μm].

Based on these, we automatically determine the

briquette diameter (D [mm]) and its height (Н

[mm]), with 4

th

decimal symbol accuracy.

In process of the metal chips briquetting,

mechanical and hydraulic presses with nominal

force of several hundred to several thousand kN are

used. The goal is to obtain briquettes with good

297

Karastoyanov D., Doukovska L., Gyoshev S. and Kalaykov I.

InterCriteria Decision Making Approach for Metal Chips Briquetting.

DOI: 10.5220/0005888502970301

In Proceedings of the Fifth International Symposium on Business Modeling and Software Design (BMSD 2015), pages 297-301

ISBN: 978-989-758-111-3

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

density - the ratio H/D for different materials vary

within wide limits (H/D = 0.8 – 0.25), where H is

the height, and D is the diameter of the briquette.

The greater is the density of the briquettes, the

smaller are the losses in the transport and melting.

Basic data used to evaluate the effect of briquetting

operation is the specific density of the briquette (ρ,

[g/cm

3

]), and specific contact pressure for

briquetting (P, [MPa]).

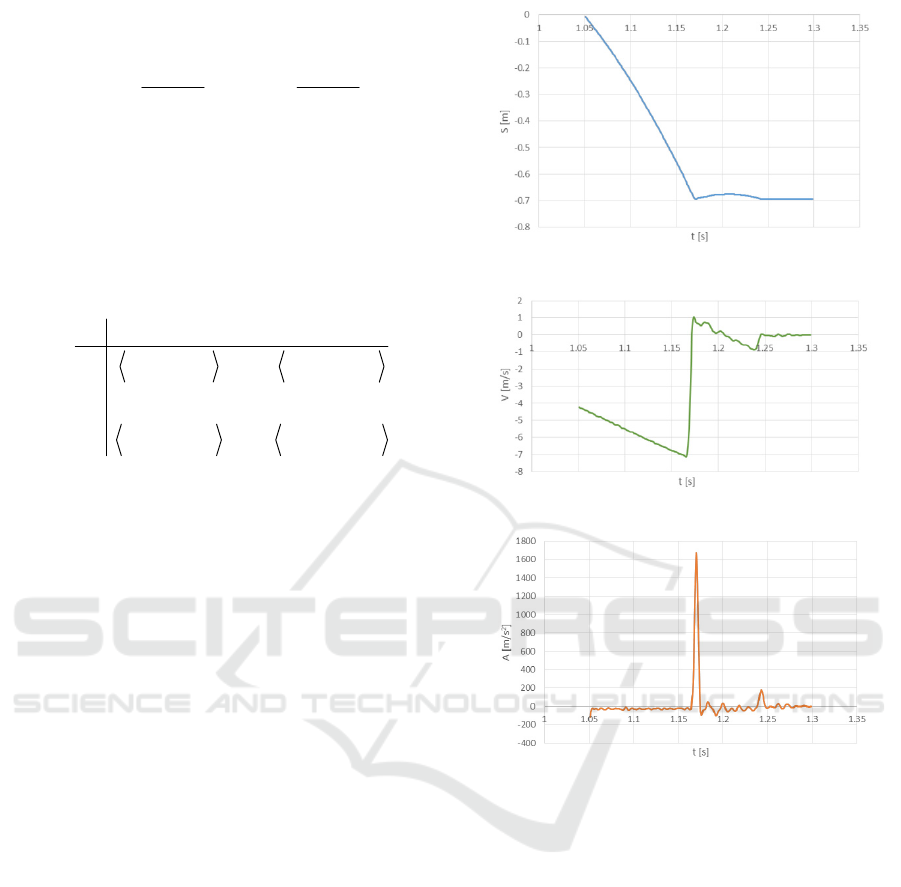

Figure 1 shows the laboratory stand with a high

speed camera and special lighting, for taking high-

speed video recordings. Using the camera and

software makes possible to determine the speed V

y

and acceleration A

y

and then to calculate the impact

energy E

y

and the power of impact F

y

.

Figure 1: Laboratory stend for a complicated impact with

high speed camera.

2 INTERCRITERIA DECISION

MAKING APPROACH

The presented multicriteria decision making method

is based on two fundamental concepts: intuitionistic

fuzzy sets and index matrices. It is called

‘InterCriteria decision making’.

Intuitionistic fuzzy sets defined by Atanassov

(Atanassov, 1983; Atanassov, 1986; Atanassov,

1999; Atanassov, 2012) represent an extension of

the concept of fuzzy sets, as defined by Zadeh

(Zadeh, 1965), exhibiting function µ

A

(x) defining the

membership of an element x to the set A, evaluated

in the [0; 1] - interval. The difference between fuzzy

sets and intuitionistic fuzzy sets (IFSs) is in the

presence of a second function ν

A

(x) defining the non-

membership of the element x to the set A, where:

0 ≤ µ

A

(x) ≤ 1,

0 ≤ ν

A

(x) ≤ 1,

0 ≤ µ

A

(x) + ν

A

(x) ≤ 1.

The IFS itself is formally denoted by:

A = {〈x, µ

A

(x), ν

A

(x)〉 | x ∈ E}.

Comparison between elements of any two IFSs,

say A and B, involves pairwise comparisons between

their respective elements’ degrees of membership

and non-membership to both sets.

The second concept on which the proposed

method relies is the concept of index matrix, a mat-

rix which features two index sets. The theory behind

the index matrices is described in (Atanassov, 1991).

Here we will start with the index matrix M with

index sets with m rows {C

1

,…,C

m

} and n columns

{O

1

,…,O

n

}:

11 1 1 1

1

1

1

1

1, , , ,

,, ,,

,, ,,

,, ,,

,

kln

iikilin

jjkjljn

m mjmlmn

kln

CO CO CO CO

iCO CO CO CO

jCO CO CO CO

mCO CO CO CO

OOOO

M

Ca a a a

Ca a a a

Ca a a a

Ca a a a

=

KKK

KKK

MMOMOMOM

KKK

MMOMOMOM

KKK

MMOMOMOM

KKK

where for every p, q (1 ≤ p ≤ m, 1 ≤ q ≤ n), C

p

is a

criterion (in our case, one of the twelve pillars), O

q

in an evaluated object, a

C

p

O

q

is the evaluation of the

q-th object against the p-th criterion, and it is

defined as a real number or another object that is

comparable according to relation R with all the rest

elements of the index matrix M, so that for each i, j,

k it holds the relation R(a

C

k

O

i

, a

C

k

O

j

). The relation R

has dual relation

R

, which is true in the cases when

relation R is false, and vice versa.

For the needs of our decision making method,

pairwise comparisons between every two different

criteria are made along all evaluated objects. During

the comparison, it is maintained one counter of the

number of times when the relation R holds, and

another counter for the dual relation.

Let

,kl

S

μ

be the number of cases in which the rel-

ations R(a

C

k

O

i

, a

C

k

O

j

) and R(a

C

l

O

i

, a

C

l

O

j

) are simul-

taneously satisfied. Let also

,kl

S

ν

be the number of

cases in which the relations R(a

C

k

O

i

, a

C

k

O

j

) and its

dual

R

(a

C

l

O

i

, a

C

l

O

j

) are simultaneously satisfied. As

the total number of pairwise comparisons between

the object is n(n – 1)/2, it is seen that there hold the

inequalities:

,,

(1)

0

2

kl kl

nn

SS

μν

−

≤+≤

.

Fifth International Symposium on Business Modeling and Software Design

298

For every k, l, such that 1 ≤ k ≤ l ≤ m, and for

n ≥ 2 two numbers are defined:

,,

,,

2, 2

(1) (1)

kl kl

kl kl

CC CC

SS

nn nn

μν

μν

==

−−

.

The pair constructed from these two numbers

plays the role of the intuitionistic fuzzy evaluation of

the relations that can be established between any two

criteria C

k

and C

l

. In this way the index matrix M

that relates evaluated objects with evaluating criteria

can be transformed to another index matrix M* that

gives the relations among the criteria:

11 11 1 1

11

1

1,C,C ,C,C

,C ,C ,C ,C

*

.

,,

,,

mm

m m mm mm

m

CC C C

mCC C C

CC

M

C

C

μν μ ν

μν μ ν

=

K

K

MMOM

K

The final step of the algorithm is to determine

the degrees of correlation between the criteria,

depending on the user’s choice of µ and ν. We call

these correlations between the criteria: ‘positive

consonance’, ‘negative consonance’ or ‘dissonance’.

Let α, β ∈[0; 1] be given, so that α + β ≤ 1. We

call that criteria C

k

and C

l

are in:

• (α, β) - positive consonance, if µ

C

k

,C

l

> α

and ν

C

k

,C

l

< β

;

• (α, β) - negative consonance, if µ

C

k

,C

l

< β

and ν

C

k

,C

l

> α

;

• (α, β) - dissonance, otherwise.

Obviously, the larger α and/or the smaller β, the

less number of criteria may be simultaneously

connected with the relation of (α, β) - positive con-

sonance. For practical purposes, it carries the most

information when either the positive or the negative

consonance is as large as possible, while the cases of

dissonance are less informative and can be skipped.

3 EXPERIMENTAL RESULTS

The metal chips briquettes preparation with good

density and quality is of great importance for the

efficiency of this industrial process. In the presented

paper for the analysis purposes we have used

experimental results of impact briquetting of grey

cast iron chips.

Figure 2 shows obtained experimental results for

the distance, the speed and the acceleration.

a)

b)

c)

Figure 2: Distance (a), speed (b) and acceleration (c)

diagrams in briquetting of grey cast iron chips.

In this paper are presented the results of impact

briquetting of grey cast iron chips with rectangular

shape. The average sizes are: length 25 [mm], width

15 [mm], thickness 1 [mm]. Diameter of the

produced briquettes is 20 [mm], as it is the opening

of the die for briquetting. Diameter of the punch is

19.6 [mm]. Density and quality of briquettes of these

chips are compared with those obtained in another

work of the authors using cast iron chips with

smaller sizes. It has been found that if using a

rectangular shape chips with a large size generates

briquettes with a very low density and poor quality.

From the photographs taken by X-ray tomography, it

makes clear that the reason for this is the orientation

of the chip in the peripheral wall of the briquettes,

which does not allow of the air to escape from it. It

InterCriteria Decision Making Approach for Metal Chips Briquetting

299

was concluded that in order to obtain briquettes of

cast iron chips with a large size, these chips must

first be crushed, for example in a small ball mill.

Preparation of metal chips briquettes with good

density and quality is important for the efficiency of

this process. The research conducted shows there is

no difference in the density of the briquettes made

from cleaned and not cleaned chips.

Based on the experimental research the values of

eleven parameters of grey cast iron chips briquetting

process have been obtained:

1 - V

y

– Impact speed, [m/s];

2 - A

у

– Impact acceleration, [m/s

2

];

3 - H

Δ

– Trimming height, [mm];

4 - Н

– Briquette height, [cm];

5 - D

– Briquette diameter, [cm];

6 - V – Briquette volume, [cm

3

];

7 - G

– Briquette weight, [gr];

8 - ρ – Briquette density, [gr/cm

3

];

9 - E

у

– Impact energy, [J];

10 - E

c

– Impact specific energy, [J/cm

3

];

11 - F

y

– Power of impact, [N].

Table 1: Membership pairs of the intuitionistic fuzzy InterCriteria correlations for the grey cast iron chips.

μ 1 2 3 4 5 6 7 8 9 10 11

1

1 0.6515 0.1969 0.7121 0.4090 0.6969 0.7121 0.3787 1 0.4848 0.6515

2

0.6515 1 0.51515 0.45454 0.34848 0.43939 0.48484 0.63636 0.65151 0.74242 1

3

0.1969 0.51515 1 0.24242 0.53030 0.22727 0.21212 0.66666 0.19697 0.62121 0.5151

4

0.71212 0.45454 0.24242 1 0.36363 0.95454 0.96969 0.36363 0.71212 0.19697 0.4545

5

0.40909 0.34848 0.53030 0.36363 1 0.40909 0.33333 0.28787 0.40909 0.42424 0.3484

6

0.69697 0.43939 0.22727 0.95454 0.40909 1 0.92424 0.31818 0.69697 0.18181 0.4393

7

0.71212 0.48484 0.21212 0.96969 0.33333 0.92424 1 0.39393 0.71212 0.22727 0.4848

8

0.37878 0.63636 0.66666 0.36363 0.28787 0.31818 0.39393 1 0.37878 0.71212 0.6363

9

1 0.65151 0.19697 0.71212 0.40909 0.69697 0.71212 0.37878 1 0.48484 0.6515

10

0.4848 0.7424 0.62121 0.19697 0.42424 0.181818 0.227273 0.712121 0.484848 1 0.7424

11 0.6515 1 0.51515 0.454545 0.348485 0.439394 0.484848 0.636364 0.651515 0.742424 1

These have been analysed applying InterCriteria

decision making approach. The results are presented

in Тable 1.

The results show a strong relation between the

parameter pairs: 1 (‘Impact speed‘) – 4 (‘Briquette

height‘); 1 (‘Impact speed‘) – 7 (‘Briquette weight‘);

2 (‘Impact acceleration‘) – 10 (‘Impact specific

energy‘); 4 (‘Briquette height‘) – 6 (‘Briquette

volume‘); 4 (‘Briquette height‘) – 7 (‘Briquette

weight‘); 4 (‘Briquette height‘) – 9 (‘Impact

energy‘); 6 (‘Briquette volume‘) – 7 (‘Briquette

weight‘); 7 (‘Briquette weight‘) – 9 (‘Impact

energy‘); 8 (‘Briquette density‘) – 10 (‘Impact

specific energy‘).

Part of these relations is due to the specific

physical properties of the briquettes, which confirms

the reliability of the proposed InterCriteria decision

making approach. The benefit here is that this allows

for finding strong dependencies as well as such

where the relations are not so visible.

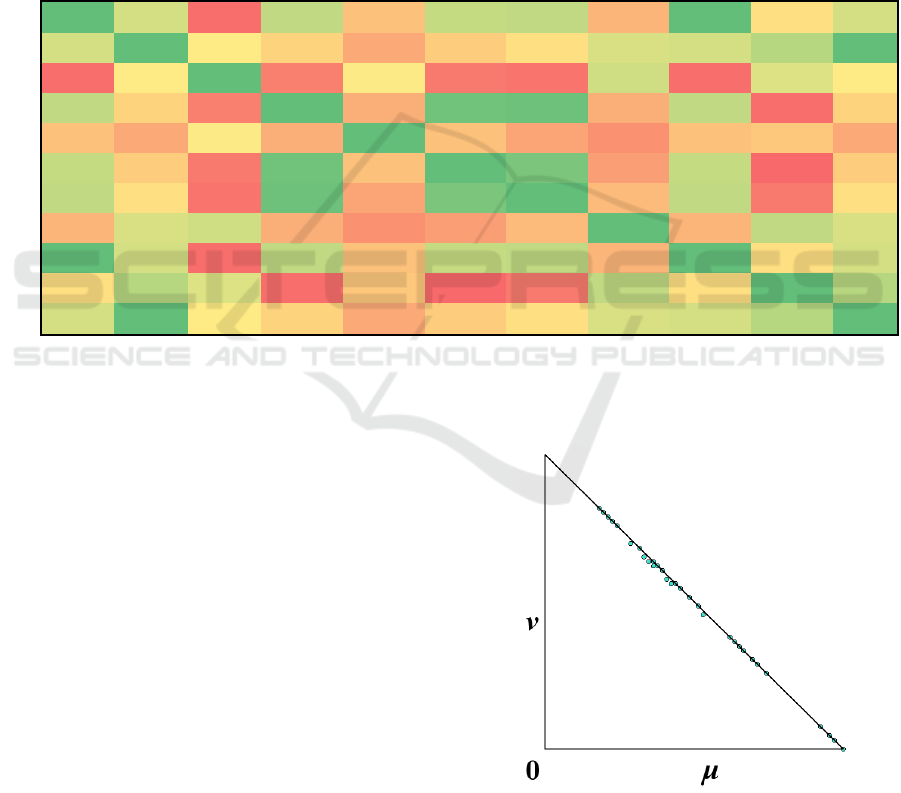

The geometrical visualisation of the InterCriteria

correlations for the case of iron powder briquette

onto the intuitionistic fuzzy interpretational triangle

is shown on Figure 3.

Figure 3: Geometrical visualisation of the InterCriteria

correlations for the case of iron powder briquette onto

the intuitionistic fuzzy interpretational triangle.

Fifth International Symposium on Business Modeling and Software Design

300

4 CONCLUSION

During the experiments it was seen that when

briquetting grey cast iron chips increasing the impact

specific energy to some point this increases the

density, but further increase leads to a decrease in

briquettes density. The conclusion that can be made

is that this is being influenced by the content of

carbon in the iron-carbon alloys.

The present paper proves the application of this

original InterCriteria decision making approach,

which eases the analysis if the relations between the

criteria, giving better production quality.

ACKNOWLEDGEMENTS

The research work reported in the paper is partly

supported by the project AComIn “Advanced

Computing for Innovation”, Grant №316087, funded

by the FP7 Capacity Programme (Research Potential

of Convergence Regions) and partly supported under

the Project № DFNI-I-02-5/2014.

REFERENCES

Atanassov K. (1983). Intuitionistic fuzzy sets, VII ITKR's

Session, Sofia, June 1983 (in Bulgarian).

Atanassov K. (1986). Intuitionistic fuzzy sets. Fuzzy Sets

and Systems. vol. 20, № 1, pp. 87–96.

Atanassov K. (1991). Generalized Nets. World Scientific,

Singapore.

Atanassov K. (1999). Intuitionistic Fuzzy Sets: Theory

and Applications. Physica-Verlag, Heidelberg.

Atanassov K. (2012). On Intuitionistic Fuzzy Sets Theory.

Springer, Berlin.

Atanassov K., D. Mavrov, V. Atanassova (2013). Inter-

Criteria decision making. A new approach for multi-

criteria decision making, based on index matrices and

intuitionistic fuzzy sets. Proc. of the 12

th

International

Workshop on Intuitionistic Fuzzy Sets and General-

ized Nets, Warsaw, Poland.

Zadeh L. A. (1965). Fuzzy Sets. Information and Control

vol. 8, pp. 333-353.

Bodurov P., T. Penchev (2005). Industrial Rocket Engine

and its Application for Propelling of Forging

Hammers, Journal of Material Processing Technology,

vol. 161, pp. 504-508.

Penchev T., I. Altaparmakov (2013). Experimental

Investigations on Controlled Impact Effect,

International Conference METAL 2013, Brno.

Penchev T., S. Gyoshev, D. Karastojanov (2014). Study of

parameters of controlled impact by impact

deformation of elastic and elastic-plastic materials,

Proceedings of Recent Advances in Mechanical

Engineering Conference, 21-23.11.2014, Florence,

Italy, pp. 113-118.

Penchev T., D. Karastoyanov (2014). Experimental Study

of Upsetting and Die Forging with Controlled Impact,

International Conference on Manufacturing Science

and Engineering (ICMSE 2014), 17-18 April 2014,

Lisbon, Portugal, published in: International Science

Index, vol. 8, № 4, Part IV, e-ISSN 1307-6892, pp.

529-533.

Radeva T., I. Yatchev, D. Karastoyanov, N. Stoimenov, S.

Gyoshev (2014). Coupled Electromagnetic and

Thermal Field Modeling of a Laboratory Busbar

System, International Conference on Electrical

Engineering and Technology, ICEET 2014, 8-9

September 2014, Geneva, Switzerland, published in:

International Science Index, vol. 8, № 9, Part I, e-

ISSN 1307-6892, pp. 172-176.

Gustavson G. at al. (2014). Experimental studies and

modelling of high – velocity loaded iron-powder

compacts, Powder Technology, vol. 268, pp. 293-305.

http://www.iict.bas.bg/acomin/

InterCriteria Decision Making Approach for Metal Chips Briquetting

301