Towards Teleoperation and Automatic Control Features of an

Unmanned Surface Vessel-ROV System: Preliminary Results

L. Nava-Balanzar

1

, J. L. Sanchez-Gaytán

1

, F. Fonseca-Navarro

1

, T. Salgado-Jimenez

1

,

M. Á. Reyna-Alonso

2

, L. G. Garcia-Valdovinos

1

, O. Rubio-Lopez

1

,

A. Gómez-Espinosa

2

and A. Ramirez-Martinez

1

1

Center for Engineering and Industrial Development - CIDESI, Energy Division, Querétaro, Mexico

2

Tecnológico de Monterrey, Campus Querétaro, Querétaro, Mexico

Keywords: Unmanned Surface Vessels (USV), ROV, USV-ROV System and Auto Tuned PID.

Abstract: This paper presents the design, construction and control of an Unmanned Surface Vessel (USV) along with a

ROV (Remotely Operated Vehicle) system, called USV-ROV system. These systems are mainly used for

underwater inspection of shallow water structures, such as: ports, bridges bases and platforms. The USV-

ROV, developed at CIDESI-Mexico, has been designed for academic purposes. This paper describes the

Surface Control Unit (SCU), the ROV and the USV, including: electronics architecture, data managing,

sensors, actuators and mechanical design considerations. USV and ROV control strategies preliminary results

are presented. Real time experiments are shown for: USV heading control, and ROV depth and heading

control. The goal of this paper is to present preliminary results of a coordinated USV-ROV system, desgined

for the development of inspection and surveillance techniques accroding to the marine and submarine

application; however, these techniques are not commercially available and have to be developed with an open

architecture system like the presented here.

1 INTRODUCTION

Unmanned Surface Vessels (USV) and Remotely

Operated underwater Vehicles (ROV) are widely

used by academic laboratories, corporations and

governments. Some examples of USV and

applications are mentioned in (Manley, 2008), (V.

Bertram, 2005). The USV-ROV systems are the

improvement of the USVs, motivated by the

applications, such as inspection of ports, bridge bases

and platforms, etc. (Vladimir, 2010), (Healey, 2007).

Some examples of commercial USV-ROV systems

are: (1), (2) and (3).

In this paper an academic USV-ROV System

designed at CIDESI-Mexico is described. The section

II details: the Surface Control Unit (SCU), the ROV

(Remotely Operated Vehicle) and the Unmanned

Surface Vessels (USV), including: electronic

architecture, data managing, sensors, actuators and

mechanical considerations. Section III explains the

control techniques used to control the USV - ROV

system. Real time experiments are presented to show:

the heading control for the vessel, and depth and

heading control for the ROV. Finally, the section IV

discloses conclusions and future work.

2 USV-ROV SYSTEM

DESCRIPTION

This paper describes the development of a small-sized

underwater vehicle ROV deployed by an

instrumented USV. Some real applications of the

USV-ROV system are: marine survey and USV-

ROV collaborative work. The general architecture,

shown in Figure 1, consists of three main parts: The

Surface Control Unit (SCU), a tele-operated Vessel

and a ROV. These systems, including their

mechanical design considerations are described in

this section.

292

Nava-Balanzar, L., Sanchez-Gaytán, J., Fonseca-Navarro, F., Salgado-Jiménez, T., Reyna-Alonso, M., Garcia-Valdovinos, L., Rubio-Lopez, O., Gómez-Espinosa, A. and Ramirez-Martinez,

A.

Towards Teleoperation and Automatic Control Features of an Unmanned Surface Vessel-ROV System: Preliminary Results.

DOI: 10.5220/0006414302920299

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 292-299

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: USV – ROV system.

2.1 Surface Control Unit

The SCU is the conjunction of the hardware (WiFi

modem, PC, XBee, Joysticks, Keyboard, etc) and the

software like the IP camera viewer and the Human

Machine Interface (HMI) that generates the

commands to perform a specific task. Additionally,

the SCU receives the status of the vehicles in real

time. The SCU is based on a computer that hosts the

HMI which is programmed in LabVIEW software,

where the data, status and images of both vehicles are

displayed. All the data and commands generated from

and to the vehicles are received and sent in real time

by a RF Xbee radio transmitter/receiver which uses

Zigbee protocol.

The SCU has two joysticks to command the

vehicles, one for the Surface Vessel and another one

for the ROV. The video transmission of the cameras

(one at the vessel and one at the ROV) is performed

by a dedicated WiFi communication channel. Figure

2 shows the Human Machine Interface (HMI).

Figure 2: Human Machine Interface.

• Data Managing: Both vehicles have a main

processing data board, which will be described

later in the sections ROV description and Vessel

description, these boards are responsible for

managing the data sent from the SCU to each

vehicle. The way that the data is sent is simple:

data frames are generated by the LabVIEW

program. Those frames contain values like:

thruster speed (for each thruster), thrust

direction (for each thruster) and others digital

functions, separated by commas. It’s important

to know that both vehicles have their own data

frame that is sent from the SCU by a serial port.

When the frames are received by the appropriate

vehicle each main board separates every data,

assigning it a value that generates a specific

output signal for each actuator. Backwards,

sensors data frames are generated by the main

boards of the vehicles, and sent via serial port to

the SCU, where they are classified and separated

to be displayed in their correct position.

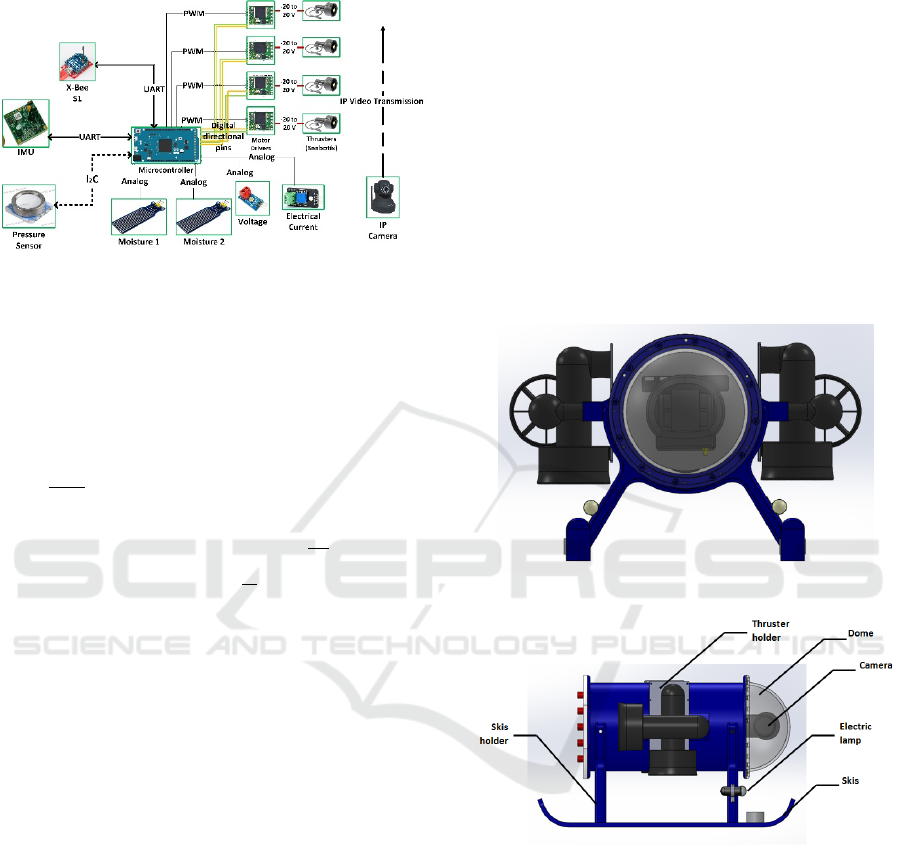

2.2 ROV Description

The underwater vehicle is a small-sized ROV, named

Nu’ukul Ha (which in Mexican Mayan language

means “water instrument”). Its dimensions are: 50 cm

long, 30 cm wide and 30 cm height; as shown in

Figure 3. It has a cylindrical pressure chamber of 15

cm in diameter, where the major part of the electronic

architecture is placed. The total weight of the ROV is

10 kg. The electronic architecture of the ROV (shown

in Figure 3) was placed in a plastic 3D printed rack.

This architecture is divided into three groups:

instrumentation, signal and data acquisition, and

actuators. The instrumentation involves: pressure

sensor, leakage sensors, IMU (Inertial Measurement

Unit), voltage and electric current sensors.

The electronic architecture is managed by a

microcontroller (main board). Finally, the actuators

consist of four thrusters used to provide direction and

Figure 3: ROV Nu' ukul Ja (“water instrument” in Mexican

Mayan language). This ROV is connected to the boat by a

tether, which has twelve wires: eight are used to receive

video from the IP camera, two for the power connections

(24V and Ground) and four for the data UART transmission

(TX)/reception (RX).

Towards Teleoperation and Automatic Control Features of an Unmanned Surface Vessel-ROV System: Preliminary Results

293

displacement to the ROV, and an IP camera for

inspection missions.

Figure 4: ROV’s electronic architecture Diagram.

• Instrumentation: This ROV has a MS5837-

30BA pressure sensor which is placed outside

the pressure chamber of the submarine. This

sensor is a high resolution barometer which

obtains data of the surrounding hydrostatic

pressure. Once the hydrostatic pressure is

obtained the depth level is calculated by: ℎ=

, where ℎ= depth [m], = hydrostatic

pressure [mbar],

= atmospheric pressure

[mbar], = water density

and =

acceleration of gravity

.

In order to measure 3 DOF (degrees of freedom)

of the ROV (pitch, yaw and roll), a TCM-MB IMU is

used. The TCM sends hexadecimal serial packages

with a frequency up to 30 Hz. To prevent malfunction

of the electronics due to water presence, leakage

sensors are used. Besides, a voltage sensor (5 to 1 Vdc

divider) offers analog signal of voltage of the

batteries. A Hall effect current sensor (Pololu AC715)

measures the current consumption of the vehicle,

while the current sensors embedded in the motor

driver (Pololu VNH5019) allows to monitor the

operation of the thrusters.

• Signal and Data Acquisition: Inside the

pressure chamber of the submarine is located a

SAM3X8E ARM Cortex embedded in the

Arduino Due board. It has 54 general purpose

inputs and outputs, 12 of them PWMs, 12 analog

inputs, 4 UART ports and one I2C bus. This

board is used to manage communication

between the user and the small-sized ROV.

• Actuators: As mentioned previously, to control

the submarine in the horizontal plane, two

brushed SeaBotix BTD150 thrusters are placed

horizontally on each side of the underwater

robot. Two more BTD150 thrusters are placed

vertically on each side of the ROV to sink the

vehicle at will (Robert D, 2014), (see Figure 5).

The BTD150 thrusters are powered by 20

VDC@ 4 A.

• ROV Mechanical Considerations: The

mechanical considerations for the ROV design

were: small-sized remotely operated vehicle (50

cm long, 30 cm wide and 30 cm height),

maximum working depth 10 m. Additionally,

the ROV has a convenient shape to be launched

and recovered by the remotely controlled vessel

by using a LARS (Launch and Recovery

System). The Figure 5 shows some CAD views.

By using CAD the center of gravity and center

of buoyancy were calculated, and a structural

analysis was performed.

(5.a)

(5.b)

Figure 5: ROV’s frontal view (5.a) and lateral view (5.b).

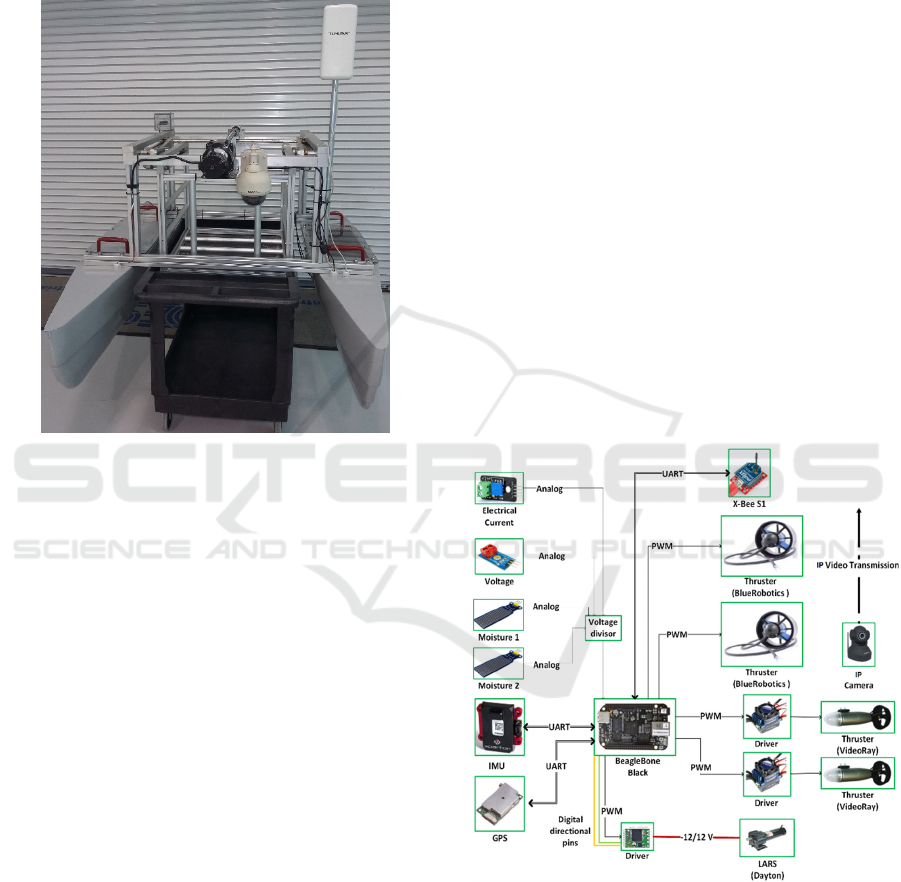

2.3 Unmanned Surface Vessel (USV)

The instrumented vessel was developed at CIDESI.

Its dimensions are: 204 cm long, 137.5 cm wide, and

92 cm height (Figure 6). It has two floats: one has the

rack with the electronic architecture and the second

the batteries. Both floats have humidity sensors for

leak detection. The electronic architecture is shown in

figure 7, it is divided into three groups: instrumenta-

tion, signals and data acquisition, and actuators. The

instrumentation includes the following devices:

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

294

current, voltage and humidity sensors, IMU and GPS.

A BeagleBone Black computer is used to manage the

signal and data acquisition. Finally, the actuators

consist of four thrusters to provide direction and

displacement to the vehicle, and an IP camera is used

for surface inspections.

Figure 6: USV developed at CIDESI, mounted in a carriage

for ground transportation.

The communication SCU - Vessel is wireless

(Xbee cards) by using the UART peripheral, while the

wired communication Vessel - ROV uses another

UART peripheral. The vessel power supply is 24

Vdc.

• Instrumentation: The Surface Vessel, is a

mothership vehicle that carries the ROV, which

has data reception functions, a camera, while the

instrumentation has the following sensors:

Current Sensor: to monitor vehicle’s electrical

current consumption. Pololu ACS714 is a linear

sensor with a resolution of 0.066 V/A. Voltage

sensor: to measure the power supply. It is B25 analog

device with a resolution of 0.00489 Vdc. Two

humidity sensors: to detect water leakage, the high

sensitivity water sensors have an analog interface

with an output voltage signal of 0~4.2 Vdc. Inertial

sensor: to determine the Euler angles of the vehicle

(roll, pitch and yaw), (Robert D, 2014) the AHRS

DC-4EP Sparton device is used; this sends NMEA

serial packages or Euler angles only with a frequency

of 10 Hz. GPS 15xl-w Garmin device: for global

location of the Surface Vessel, this sends NMEA

serial packages with acquisition time less than 2

seconds.

The current, voltage and humidity sensors are analog

devices; these are connected to a voltage divisor

because the analog inputs of the BeagleBone Black

are 3.3 Vdc, while the AHRS and GPS are connected

to UART peripherals.

• Signal and Data Acquisition: A BeagleBone

Black development board is used for signal and

data acquisition, which has the following

specifications: a Sitara ARM Cortex-A8

processor running at 1000 MHz, 512 MB of

RAM, 4 UART ports, 8 PWM signals, 2 SPI

ports, 2 I2C ports, 7 A/D Converters, 2 CAN

bus, 4 Timers and a consumption of 210–460

mA, programmed with the software Eclipse IDE

Development (version Mars 2.0).

• Actuators: Two brushless motors VideoRay

with a Pololu’s VNH5019 driver at rear for

forward and reverse motion, they are powered

by 12Vdc and maximum current to 17 A. Two

brushless motors BlueRobotics for lateral

motion, the T100 Thruster are powered by

12Vdc and maximum current to 11.5 A. One

Permanent Magnet DC motor Dayton for the

LARS motion, it is powered by 12Vdc and 1/8

HP.

Figure 7: Vessel electronics Architecture Diagram.

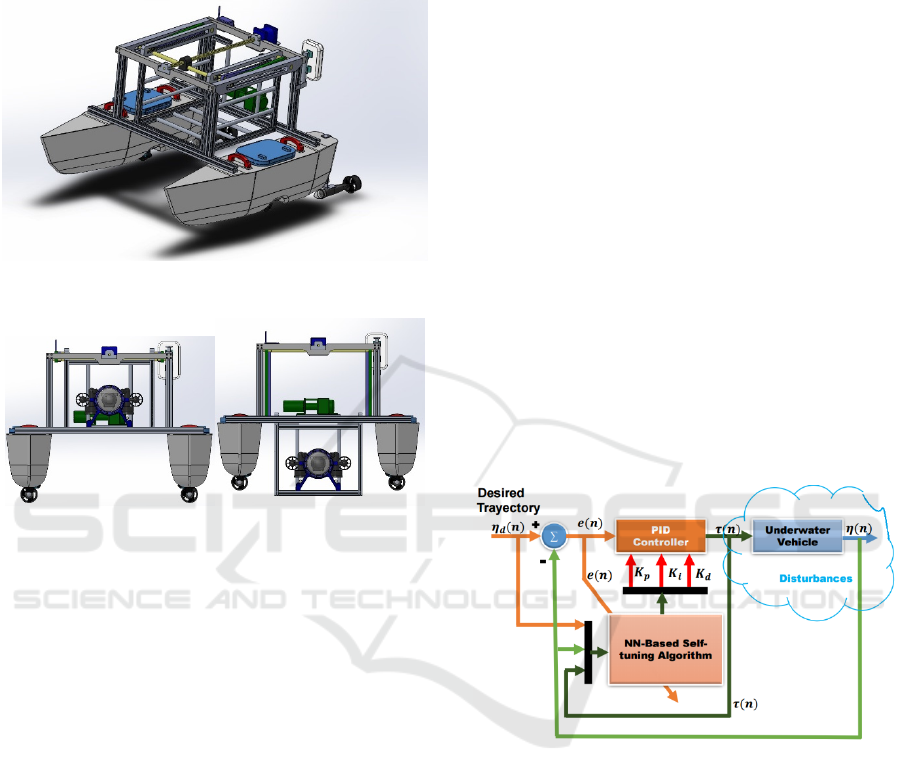

• Vessel Mechanical Design: The mechanical

considerations for the vessel design were: The

boat is used for the surveillance in collaboration

with a ROV. The main task of the vessel is to

transport, launch and recover a small sized

ROV. The Figure 8 shows some views from the

CAD. A LARS is used to launch the underwater

Towards Teleoperation and Automatic Control Features of an Unmanned Surface Vessel-ROV System: Preliminary Results

295

vehicle into the water and to recover it, without

direct human intervention. Figure 9 shows

LARS transportation position (top) and launch

and recovery position (bottom).

Figure 8: Vessel isometric view.

Figure 9: LARS (Launch and Recovery System). LARS

transportation position (left) and launch and recovery

position (right).

2.4 USV-ROV System Control

The USV-ROV system has two modes of control:

teleoperation and automatic control. In this section,

the implemented automatic control are explained.

Two control algorithms were implemented: a

conventional PID and an auto-tuned PID. The

controllers were tested in a set of real time

experiments.

2.4.1 PID Control

The PID controller is well known and widely used in

the industry and robotics to improve the dynamic

response of a system as well as to reduce or eliminate

the steady state error. PID control consists of three

types of control: Proportional, Integral, and

Derivative control. The tuning of PID controllers

depends on adjusting its gains (

,

,

) so that the

performance of the system under control becomes

robust and accurate according to the established

performance criteria. In the discrete time domain, the

digital PID algorithm can be expressed as follows

(10):

τ(n)=τ(n-1)+K_p (e(n)-e(n-1))+K_i e(n)+

K_d (e(n)-2e(n-1)+e(n-2)) (1)

where τ(n) is the original control signal,

=

− represents the position tracking error,

denotes the desired trajectory,

is the proportional

gain,

the integral gain,

the derivative gain, and

n-the sample time. This controller was applied to

heading control (ψ) in both vehicles: ROV and

Vessel.

2.4.2 Auto Tuned PID Control

In order to control the depth (z) of the ROV, an auto-

tuned PID controller based on an online Neural

Network (NN) was implemented. The purpose of

having an auto tuned depth control, was to allow the

vehicle to be modular, which means, makes the ROV

capable of adding or changing tools or different kinds

of instrumentation depending the mission to be

performed, avoiding the necessity to re-adjust the

control parameters.

A block diagram of the auto-tuning control with

an artificial neural network (NN) is shown in figure

10.

Figure 10: Auto-tuned PID control block diagram (8).

The algorithm used as auto-tuning is the

backpropagation method, chosen for its ability to

adapt to changing environments. The back-

propagation algorithm looks for the minimum of the

error function in weight space using the method of

gradient descent (D. Maalouf, 2013), (Hernández,

2016). The combination of weights which minimizes

the error function is considered to be a solution of the

learning problem.

The NN has seven neurons in the input layer, three

neurons on the hidden layer and three on the output

layer. The neurons placed on the output layer

correspond to the PID gains:

,

and

. The PID

algorithm used in the automatic tuning control is the

same as that presented in equation (1).

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

296

3 USV AND ROV REAL TIME

EXPERIMENTS

This sub-section describes the heading control for the

vessel and the ROV. The pilot defines heading set

points in degrees referenced to the magnetic North.

These set points are sent to the Vessel and the ROV,

the automatics controls algorithms cause the two

vehicles headed to the same direction. The way that

the ROV and the boat change the heading is spinning

in opposite direction their lateral thrusters, generating

in this way a moment of torque with respect the center

of gravity of each vehicle.

3.1 Experiment Description

The procedure to perform the experiment is:

1) Locating the ROV at 1 m of depth by an auto

tuned PID, a set point of 110 ° heading is sent to

the ROV and the Vessel.

2) Once both vehicles are stable in the reference,

the experiment starts recording samples of:

actual heading, set points and output control

signals every 100 ms by 2 minutes.

3) After two minutes and without stop the

sampling, a reference of 45° is sent to the

vehicles for another two minutes.

4) Then, the set point is changed to 80° for 2

minutes.

5) Finally, the reference is changed to 180° for the

last two minutes.

6) The sampling time is 100 ms.

3.2 USV and ROV Heading Control:

Experimental Results

Following the procedure mentioned above, the PID

controllers for the vessel and the ROV were tested. In

the figure 11, graphs of the heading behavior are show.

Figure 11: Heading vs time behavior for the vessel (above)

and the ROV (bottom).

Figure 11 shows that the vehicles have about the same

behavior when they are exposed to the same reference

signal. It is important that the vehicles have an

identical heading, which would be useful when they

are carrying out a structural inspection. The Root of

the Mean Squared value (RMS) was obtained for the

experiments. The vessel has 17.787 degrees and ROV

has 13.134 degrees.

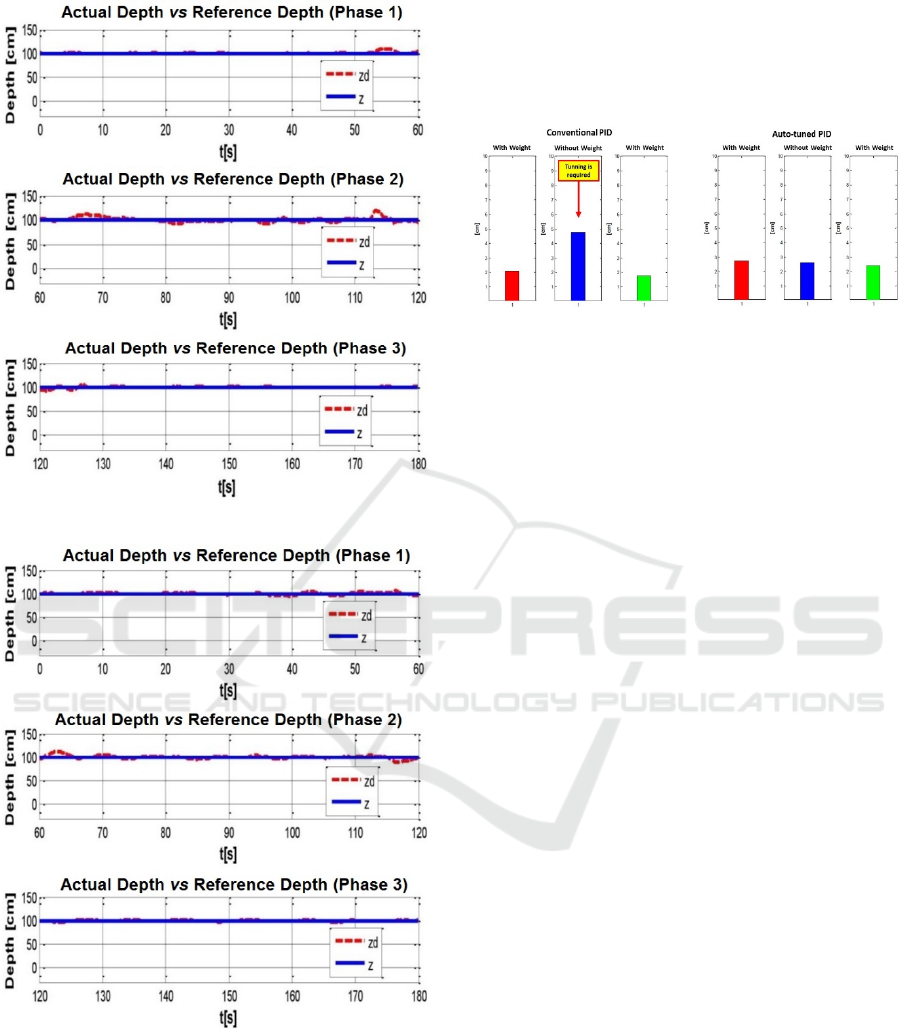

3.3 ROV Depth Control

As detailed above: Throughout the heading

experiments the ROV depth reference point was 1 m.

The implemented controls were: PID and auto-tuned

PID.

These controls were evaluated by performing a

three-minute test with the following characteristics

(phases):

Phase 1:

- The ROV is placed at 1 m depth.

- Not disturbance was given to the ROV during

the first minute.

Phase 2:

- During the second minute, a 400 g lead weight

was placed on the top of the ROV.

Phase 3:

- Finally, at the third minute the weight was

removed, making the parameters of the vehicle

be exactly the same as when the experiment

was started.

The gains of the conventional PID control were

obtained by means of the NN. The ROV was

requested to get the set point of 1 m depth by using

the Auto-tuned PID controller. Once the ROV

reached the stability and the control gains computed

by the NN became stationary, these gains were

programmed into the conventional PID. It is

important to remark that once the conventional PID

was tuned, the gains remained constant along the

experiment, even when the disturbances took place.

The graphs obtained by this experiment divided

by its three phases are the ones shown in the figure

12, comparing the reference (blue) and the actual

depth (red) of the ROV during the experiment. Figure

12.a conventional PID control and figure 12,b auto-

tuned PID control.

Towards Teleoperation and Automatic Control Features of an Unmanned Surface Vessel-ROV System: Preliminary Results

297

(12.a)

(12.b)

Figure 12: Depth control. Conventional PID Controller

(12.a). Auto-tune PID (12.b).

The Root Mean Square Error (RMSE) is computed in

each experiment; A 3.51 cm error is obtained for the

conventional PID, while a 2.47 cm error is obtained

for the self-adjusted PID.

The RMSE of three phases was obtained and it is

shown in figure 13. It is important to note: the

conventional PID presents the biggest error in the

second phase (when the weight is added), proving the

need of re-tuning the PID gains.

Figure 13: RMSE of both experiments (convwnbtional PID

and auto-tuned PID) for each phase.

4 CONCLUSION

The development of an academic USV – ROV system

was presented, including electronic, data trans-

mission and mechanical considerations. Preliminary

control results are presented, towards automatic

collaborative techniques.

This USV – ROV system was designed thinking

in the application of inspection and surveillance of

marine and submarine structures. The main

contribution of this work is the collaborative USV –

ROV techniques considering a low cost - open

architecture system.

Future Work:

• Improve collaborative USV - ROV control

techniques.

• USV-ROV system field test.

• Suggest improvements to develop the inspection

of oil platforms in Mexican waters.

ACKNOWLEDGEMENT

Research supported by CONACYT projects:

PDCPN2013-01-215770.

This study is part of the project number 201441

“Implementation of oceanographic observation

networks (physical, geochemical, ecological) for

generating scenarios of possible contingencies related

to the exploration and production of hydrocarbons in

the deepwater Gulf of Mexico”, granted by SENER-

CONACyT Hydrocarbons Sectorial Fund.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

298

REFERENCES

Subsea Tech, Cat – Surveyor. (http://www.subsea-tech.com)

Marine Tech, RSV Sea Observer. (http://en.marinetech.fr/)

Thales-SAAB Seaeye, Halcyon USV & Falcon Remotely

Operated Vehicle (ROV). (https://www.thalesgroup.

com/)

J. Manley, “Unmanned Surface Vehicles, 15 Years of

Development”, Proc. MTS/IEEE Oceans’08

Conference, Québec, 2008.

V. Bertram, “Unmanned Surface Vehicles – A Survey”,

IEEE Standard for Application and Management of the

Systems Engineering Process, IEEE Std 1220-2005,

September 2005.

Vladimir Djapic and Dula Nad. “Using collaborative

autonomous vehicles in mine countermeasures”. Proc.

MTS/IEEE OCEANS’10, Sydney 24-27 May 2010.

Healey, Anthony J., Horner, D. P., Kragelund et al.

“Collaborative unmanned systems for maritime and

port security operations”. 7th IFAC Conference on

Control Applications in Marine Systems. 2007.

Robert D. Christ and Robert L. Wernli Sr., “The ROV

Manual”, Second Edition, Elsevier, 2014.

Fossen, T. I. “Guidance and Control of Ocean Vehicles”,

John Wiley & Sons, 1994.

Katsuhiko Ogata. “Discrete-Time Control Systems”,

Prentice Hall. Edición 2. 1995.

D. Maalouf, I. Tamanaja, E. Campos, A. Chemori, and V.

Creuze, “From PD to Nonlinear Adaptive Depth-

Control of a Tethered Autonomous Underwater

Vehicle,” 5th IFAC Symposium on System Structure

and Control, Volume 46, Issue 2, Pages 743-748,

Elsevier, 2013.

Hernández-Alvarado R., García-Valdovinos L. G.,

Salgado-Jiménez T., Gómez-Espinosa A. and Fonseca-

Navarro F., Neural Network-Based Self-Tuning PID

Control for Underwater Vehicles. Sensors (Basel).

2016 Sep 5; 16(9). 2016.

Towards Teleoperation and Automatic Control Features of an Unmanned Surface Vessel-ROV System: Preliminary Results

299