MULTI-AGENTS BASED REFERENCE MODEL FOR FAULT

MANAGEMENT SYSTEM IN INDUSTRIAL PROCESSES

Mariela Cerrada, Juan Cardillo

Universidad de Los Andes, Facultad de Ingeniería, Dpto. de Sistemas de Control, Av.Tulio Febres, Mérida,Venezuela

Jose Aguilar, Raúl Faneite

Universidad de Los Andes, Facultad de Ingeniería, Dpto. de Computación, Av.Tulio Febres, Mérida,Venezuela

Keywords: Multi-Agent Systems, Fault Management, Distributed Control Systems, Automation

Abstract: Nowadays, industrial necessities claims global

management procedures integrating information systems in

order to manage and to use the controlled-processes information and thus, to assure a good process

behaviour. These aspects aim to the development of fault detection and diagnosis systems and making-

decision systems. In this work, a reference model for fault management in industrial processes is proposed.

This model is based on a generic framework using multi-agent systems for distributed control systems; in

this sense, the fault management problem is viewed like a feedback control process and the actions are

related to the making-decision in the preventive maintenance task scheduling and the running of preventive

and corrective specific maintenance tasks.

1 INTRODUCTION

Automation is an important aspect that permits to

improve the industrial processes performance

(Williams et al, 1994) and Fault Management

Systems (FMS) are vital part of the automations

process. In (Bravo et al, 2003), a multi-agent based

automation model is proposed, taking into account

the general objects of production processes:

production planning, production factors

management, processes control, fault management

and abnormal situations management.

In this work, an agent-based reference model for

FMS is p

roposed, as part of the automation model

proposed in (Bravo et al, 2003), and it is based on

the generic framework proposed in (Aguilar et al,

2001). The FMS objectives are achieved by the

coordinated interaction of the agents. This way, the

agent-based FMS provides the assistance in the

detection-diagnosis-decision process, as well as in

the planning and running of maintenance tasks.

2 REFERENCE MODEL FOR

FAULT MANAGEMENT

SYSTEMS

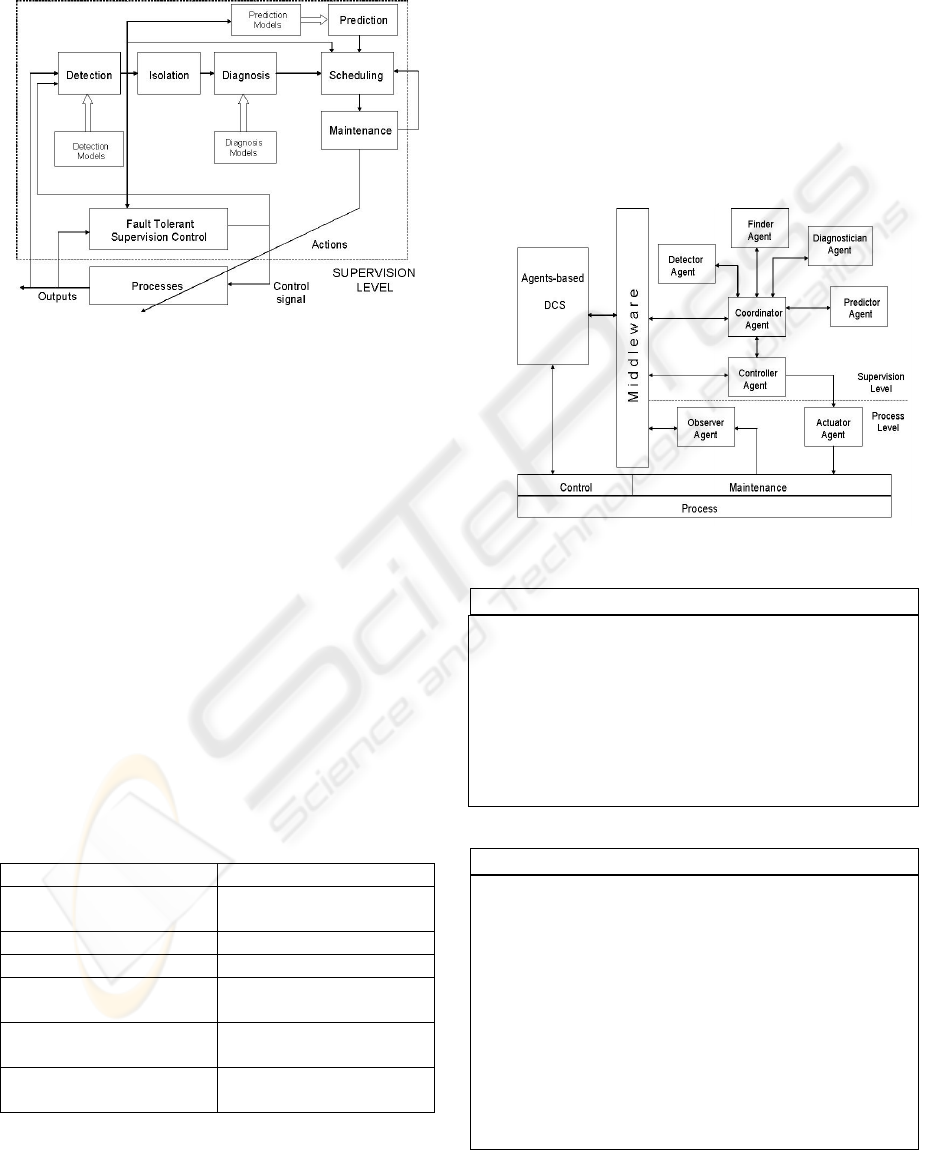

The FMS proposed in this work is composed by two

blocks Monitoring and Fault Analysis Tasks

(MFAT) and the Maintenance Management Tasks

(MMT).The MFAT block is concerned to the

detection, isolation, diagnosis, prediction and

planning. MMT block is concerned to the set up and

running of the maintenance tasks according to the

maintenance plan. A reference model permitting the

adequate interaction between the previous blocks is

showed in figure 1. (Cerrada et al, 2003)

3 MULTI-AGENT SYSTEMS AND

DESIGN METHODOLOGY

Multi- Agents Systems (MAS) theory can be viewed

as an evolution of artificial intelligence, in order to

attain autonomous computational systems. Although

the agent’s definition has been argued into the

Distributed Artificial Intelligence (DAI) researchers

community, it is accorded the autonomy is the main

342

Cerrada M., Cardillo J., Aguilar J. and Faneite R. (2004).

MULTI-AGENTS BASED REFERENCE MODEL FOR FAULT MANAGEMENT SYSTEM IN INDUSTRIAL PROCESSES.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 342-345

DOI: 10.5220/0001139703420345

Copyright

c

SciTePress

characteristic describing an agent, the autonomy

being the ability to accomplish a task and to reach its

objectives without human or any other assistance

(Weiss, 1999;Waterbury, 2002).

Figure 1: Reference Model for Fault Management System.

MAS-CommonKADS is a general methodology for

the agents modelling (Iglesias, 1998). In (Aguilar et

al, 2004), the MAS-CommonKADS methodology

has been enhanced by incorporating new aspects for

agent modelling. The enhanced methodology

MASINA (Multi-Agent Systems-based INtegrated

Automation) is a new approach for MAS modelling

in industrial automation processes. This new

modelling approach allows the developing of the

Agent Model, Tasks Model, Intelligence Model,

Communication Model and Coordination Model.

4 MAS-BASED REFERENCE

MODEL FOR FMS

The Conception and Analysis phase is only

developed here, and the MASINA methodology is

used in order to propose the models mentioned

above. Actors and cases of use are listed in Table 1.

Table 1: Actor and cases of use

Actor Case of Use

Detector System Monitoring

State Identification

Finder Finding-Failure

Diagnostician Failure Analysis

Predictor Failure Occurrence

Estimation

Scheduler

Tasks Scheduling

Redefining Plans

Executor Running Tasks

Reporting Tasks

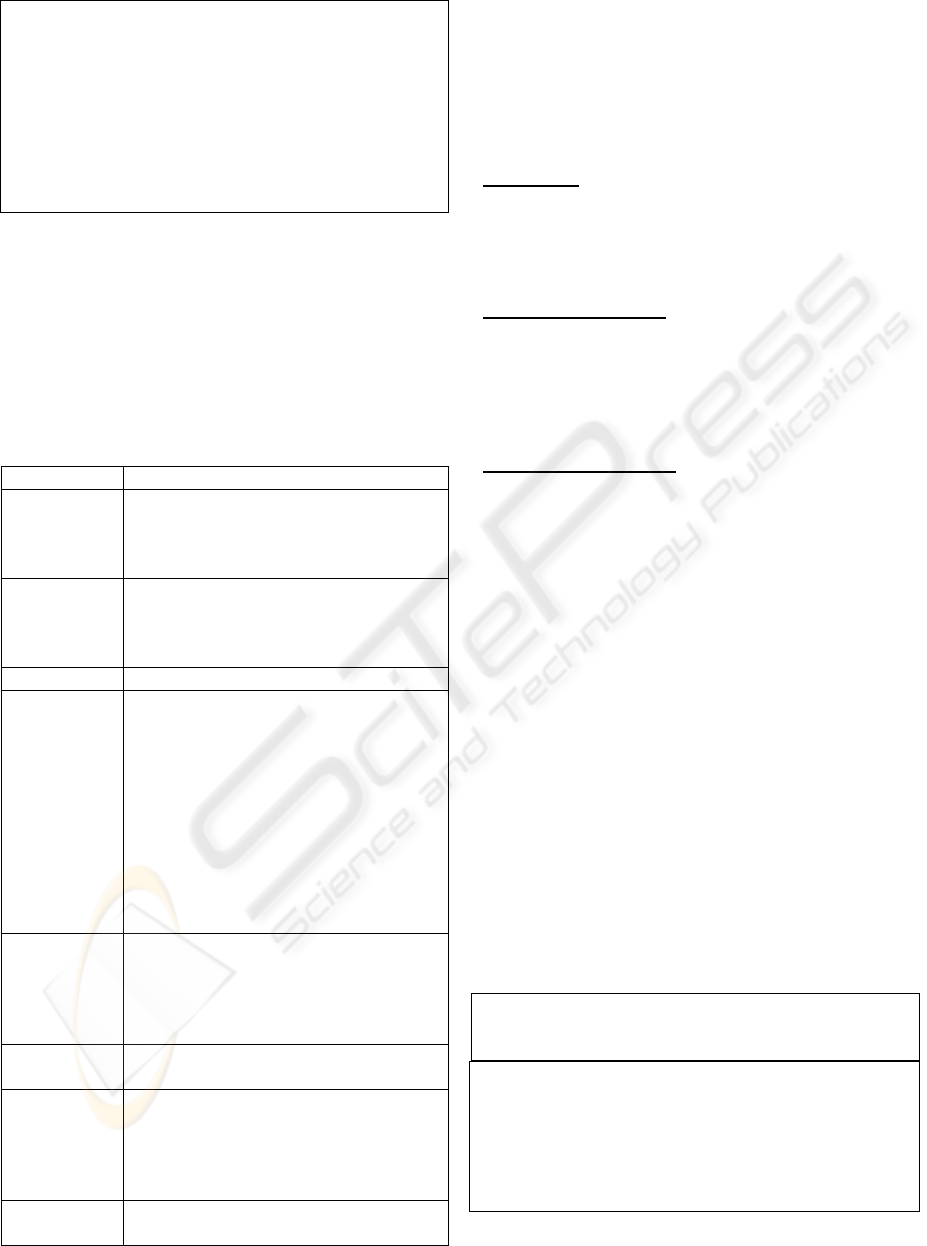

4.1 Agent Model

The roles of the mentioned actors can be embedded

into the agents defined in the generic conceptual

framework for the Agents-based Intelligent

Distributed Control Systems (AIDCS) (Aguilar et al,

2002). Thus, the following agents are defined,

(figure 2): Specialized Agent Detector, Specialized

Agent Finder, Specialized Agent Diagnostician,

Specialized Agent Predictor, Agent Coordinator,

Agent Controller, Agent Actuator, Agent Observer.

Characteristics and requirements of the Agent

Coordinator are presented in tables 2 and 3.

Figure 2: MAS-based FMS.

Table 2: Agent Coordinator

Agent: Coordinator

Name: Coordinator

Type: Software agent.

Roles: Making decision for the maintenance tasks

planning.

Description: It gathers the information, from the

specialized agents, about the process’ items and it

schedules the maintenance tasks. The timeline should

be defined according to the item’s reliability, the

failure effects and urgent tasks.

Table 3: Agent Coordinator Objective

Objective – Coordinator Agent

Name: To schedule the maintenance tasks according

to the item’s reliability, the failure effects and urgent

tasks.

Type: On-condition objective

Input Parameters: Data from the Specialized

Agents, Observer Agent, and Controller Agent.

Output Parameters: Maintenance plan and/or

corrective maintenance order (urgent tasks).

Activation Condition: Information is received from

Specialized Agents, Observer agent, and Controller

agent.

End Condition: The maintenance plan or corrective

actions are stated.

MULTI-AGENTS BASED REFERENCE MODEL FOR FAULT MANAGEMENT SYSTEM IN INDUSTRIAL

PROCESSES

343

Success Condition: A maintenance plan or

corrective actions are proposed, permitting to achieve

adequate reliability levels on the item’s process.

Failure Condition: ¬Success Condition.

Representation Language: Natural Language.

Description: Coordinator Agent assesses the

different setting in order to create the best general

maintenance plan on a long time horizon (Long Term

Plan (LTP)) and it produces the best set of corrective

actions (urgent tasks) in case of emergency.

Coo ices:

aintenance Plan Proposition, Maintenance Plan

d tasks for the MAS based

FMS.

Table 4: MAS-based FMS Tasks

Agent Tasks

rdinator Agent provides the following serv

M

Redefinition and Specialized Agent Calling

4.2 Tasks Model

Table 4 shows the define

Observer failures

ation.

ate estimation

Abrupt o functional

identific

Operational index estimation.

Maintenance st

Detector t failures

n methods incorporation.

Statistical estimation abou

occurrence.

Selection of detection techniques.

New detectio

Finder Finding Failure

Diagnostician es

is models readjustment.

Failure modes and failure caus

identification.

Statistical estimation about failures

modes.

Statistical estimation about failures

causes.

Failure consequences analysis.

Diagnos

New diagnosis models incorporation

New failure modes identification

New failure causes identification

Predictor of the Reliability curves estimation

process’ items.

Reliability index estimation of the

process.

New prediction models incorporation

Controller enance plan proposition ST maint

ST maintenance plan processing

Coordinator

rective action

LT maintenance plan proposition

Resources Evaluation.

Application order of DIDP tasks

Application order of cor

Maintenance plans redefinition

Actuator On-time maintenance tasks run

Urgent tasks run

4.3 Intellig

ents in the FMS

lligent. A general

structure of the intelligence model is presented

ence Model

Excepting the Actuator Agent, all ag

may be sensitive to be inte

bellow:

Experience

Represe

ntation: Rules.

ype: Based on cases.

is related to the data completeness.

edge parameters tuning

ation.

T

Reliability: It

Processing scheme: Knowl

and new models incorpor

Learning Mechanism

Type: Adaptive

Representation: Rules, neural

techniques, genetic

s: Success or failures during DIDP

hanism: Experiences feedback.

techniques.

Learning Source

tasks.

Update Mec

Reasoning Mechanism

Inform

ation Source: Previous results from de

duling tasks, DIDP tasks.

onship: It decides if the used

n

ed.

ns.

cations scheme of

s and associated

languages. The following conversations have been

the

FMS’s agents.

Activation Source: Sche

Type of Inference: Based on rules.

Task-Objective Relati

algorithm is adequate for DIDP tasks or if a

adequate maintenance plan is propos

Reasoning Strategy: It can be deductive or

inductive: evaluate the causes of success or failure in

DIDP tasks or confront unknown situatio

4.4 Coordination Model

This model describes the communi

the MAS: conversations, protocol

defined: On-Condition Maintenance, Maintenance

Plan, Urgent Maintenance Tasks, Maintenance Plan

Redefinition, Maintenance State, Functional Failure

Identification. The conversation Maintenance Plan

Redefinition (MPR) is presented in table 5.

Table 5: Conversation “MPR”

Objective: To redefine the execution timeline of

maintenance tasks that have not been put up and

running on the process.

Agents: Coordinator, Data-base (MAS-based

Middleware), Human.

Beginner: Coordinator Agent

Speaking interactions: Expecting Maintenance

Tasks Search, Alarm, Maintenance Plan Shipment

Precondition: A particular maintenance task has not

been put up and running on the process.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

344

End Condition: A new timeline has been proposed

and a new plan is sent to Data-Base, else, an Alarm is

sent to the Human Agent (User).

Description: This conversation permits the

information search on the Data-Base about the

maintenance tasks that have not put up and running

(Expecting Tasks)

4.5 tion Model

been defined

and they are suitably arranged into the conversations

Spe king Interaction: Expecting Maintenance Tasks

Communica

A set of 21 speaking interaction has

in the Coordination Model. In the case of the

previous conversation Maintenance Plan

Redefinition, the following speaking interactions are

performed: Expecting Maintenance Tasks Search

(Table 6), Alarm and Maintenance Plan Sending

Table 6: Speaking Interaction

a

Search.

Type: Query.

Objective: To search in the Data-Base the expecting

maintenance tasks that have not executed on the process.

Agents: Coordinator, Data-Base (MAS-based

Middleware)

Beginner oordinator Agent. : C

Precondition: An active flag about expecting tasks.

End Condition: The Coordinator Agent receives, from the

Data-Base Agent, the whole information about the

expecting tasks.

Conversations: Maintenance Plan Redefinition, Urgent

Maintenance Tasks.

Description: The Coordinator Agent requests the whole

information about the expecting tasks reported by the

Observer Agent.

4.6 Conclusions

tion and analysis of a Multi-

Agents System-based reference model for Fault

In this work, the concep

Management System has been proposed. This model

has been developed into a generic framework

proposed for Intelligent Distributed Control

Systems. In this sense, the system performs a set of

tasks (actions) permitting the maintenance tasks

planning and the application of specific maintenance

tasks as fault detection, isolation, diagnosis and

prediction. The enhanced methodology MASINA

has provided a set of models permitting to describe

the main characteristics of the MAS. The resulting

models have a generic structure that permits to

incorporate it into the automation process of a

distributed control systems.

REFERENCES

T.J Williams, P. Bernous, J Brosvic, D. Chen, G,

Doumeingts, 1994. Architectures for integrating

manufacturing activities and enterprises, Computer in

Industry 24, pp.11-39.

C. Iglesias, 1998. Definición de una metodología para el

desarrollo de sistemas multiagentes, Ph.D Thesis,

Dpto. de Ingeniería de Sistemas Telemáticos,

Universidad Politécnica de Madrid-España.

G. Weiss, 1999. "Multiagent Systems". The MIT Press.

Massachusets, USA.

J. Aguilar, M. Cerrada, F. Hidrobo, G. Mousalli, F. Rivas,

2001. Application of the Agent Reference Model for

Intelligent Distributed Control System, in: N.

Mastorakis and L. Pecorelli-Peres (Eds.), “Advances

in System Sciences: Measurements, Circuits and

Control”, p.p. 204-210, WSES Press.

B. Waterbury, 2002. Artificial Intelligence Expands

Frontiers in Asset Management, Control Magazine.

J. Aguilar, G. Mousalli, V. Bravo y H. Díaz, 2002.

Agentes de control y de gestión de servicio para el

modelo de referencia SCDIA, Memorias del II

Simposio Internacional de Automatización y Nuevas

Tecnologías, TECNO2002, pp. 45-50, Mérida-

Venezuela.

M. Cerrada, J. Aguilar, J Cardillo, R. Faneite, 2003.

Agent-based reference model for fault management,

technical report, Grant Project I-621-98-02-

A,CDCHT-ULA, Mérida-Venezuela.

C. Bravo, J. Aguilar, F. Rivas, M. Cerrada.2003. Diseño

de una Arquitectura de Automatización Industrial

Basada en Sistemas Multiagentes. Memorias del IV

Congresos de Automatización y Control CAC’2003.

Universidad de los Andes. Mérida-Venezuela.

J. Aguilar, M. Cerrada, F. Hidrobo, F. Rivas, 2004.

Especificación detallada de los agentes del SCDIA,

Technical Report, Grant Project Agenda Petróleo No.

97003817, CEMISID-Universidad de Los Andes.

Mérida-Venezuela.

MULTI-AGENTS BASED REFERENCE MODEL FOR FAULT MANAGEMENT SYSTEM IN INDUSTRIAL

PROCESSES

345