TRAJECTORY PLANNING USING OSCILLATORY CHIRP

FUNCTIONS APPLIED TO BIPEDAL LOCOMOTION

Fernando Juan Berenguer Císcar

Escuela Superior Politécnica, Universidad Europea de Madrid,C/ Tajo s/n, Villaviciosa de Odón, Spain

Félix Monasterio-Huelin Maciá

E.T.S.I. de Telecomunicación,Universidad Politécnica de Madrid, C/ Ciudad Universitaria s/n, Madrid, Spain

Keywords: Trajectory planning, bipedal walking robot, chirp functions.

Abstract: This work presents a method for planning sinusoidal traj

ectories for an actuated joint, so that the oscillation

frequency follows linear profiles, like trapezoidal ones, defined by the user or by a high level planner. The

planning method adds a cubic polynomial function for the last segment of the trajectory in order to reach a

desired final position of the joint. We apply this planning method to an underactuated bipedal mechanism

which gait is generated by the oscillatory movement of its tail. Using linear frequency profiles allow us to

modify the speed of the mechanism and to study the efficiency of the system at different speed values.

1 INTRODUCTION

Trapezoidal and linear velocity profiles are widely

used in trajectory planning for mobile robots and

robot manipulators. The necessary procedure for

defining this kind of trajectories can be found in

many robotic textbooks (Spong, 1989, Sciavicco,

1996, Craig, 2006). In other robotic areas, as in the

case of walking machines and nonholonomic

locomotion systems, the robot joints execute

oscillatory motions, and some planning methods are

based on using sinusoidal trajectories with constant

frequencies (Morimoto, 2006, Sfakiotakis, 2006,

Murray, 1993). In (Berenguer, 2006) we presented

an underactuated bipedal mechanism that is able to

walk using only one actuator that moves a tail

following a sinusoidal trajectory. The displacement

velocity of these systems depends on the oscillation

frequencies together with other parameters. The

planning method presented here provides continuous

sinusoidal joint trajectories that follow desired

piecewise-linear frequency profiles and generate

smooth variation of the systems speed.

On the other hand, swept sinusoids (chirps) are

usu

ally used for identifying and modelling actuators

and mechanisms (McClung, 2004, Leavitt, 2006). In

this work, we estimate the optimal stride frequency

of a biped by means of analyzing the step length at

different frequencies, during the execution of a

trajectory generated by the proposed planning

method.

This paper is organized as follows. Next section

p

resents an initial example problem and shows

perhaps a common beginner’s mistake in the way of

solving this problem. The correct problem’s solution

is also provided in this section. Section III sets out

the planning problem in a general form and presents

the proposed solution method. Section IV shows the

application of this method to a bipedal model and

how we can use the results for analyzing the

efficiency of the model at different speeds. Finally,

section V presents conclusions and future work.

2 AN INITIAL EXAMPLE

Suppose we want to generate a sinusoidal trajectory

with unit amplitude for a robot joint. The joint is

initially at its central position (0rad) with zero

velocity, and will start to oscillate with an increasing

frequency. The joint must reach a frequency of

πrad/s at instant t=10s and keep this value during 20

seconds. Finally, the joint must reduce its frequency

to zero and achieve the central position again at

70

Juan Berenguer Císcar F. and Monasterio-Huelin Maciá F. (2007).

TRAJECTORY PLANNING USING OSCILLATORY CHIRP FUNCTIONS APPLIED TO BIPEDAL LOCOMOTION.

In Proceedings of the Fourth Inter national Conference on Informatics in Control, Automation and Robotics, pages 70-75

DOI: 10.5220/0001643600700075

Copyright

c

SciTePress

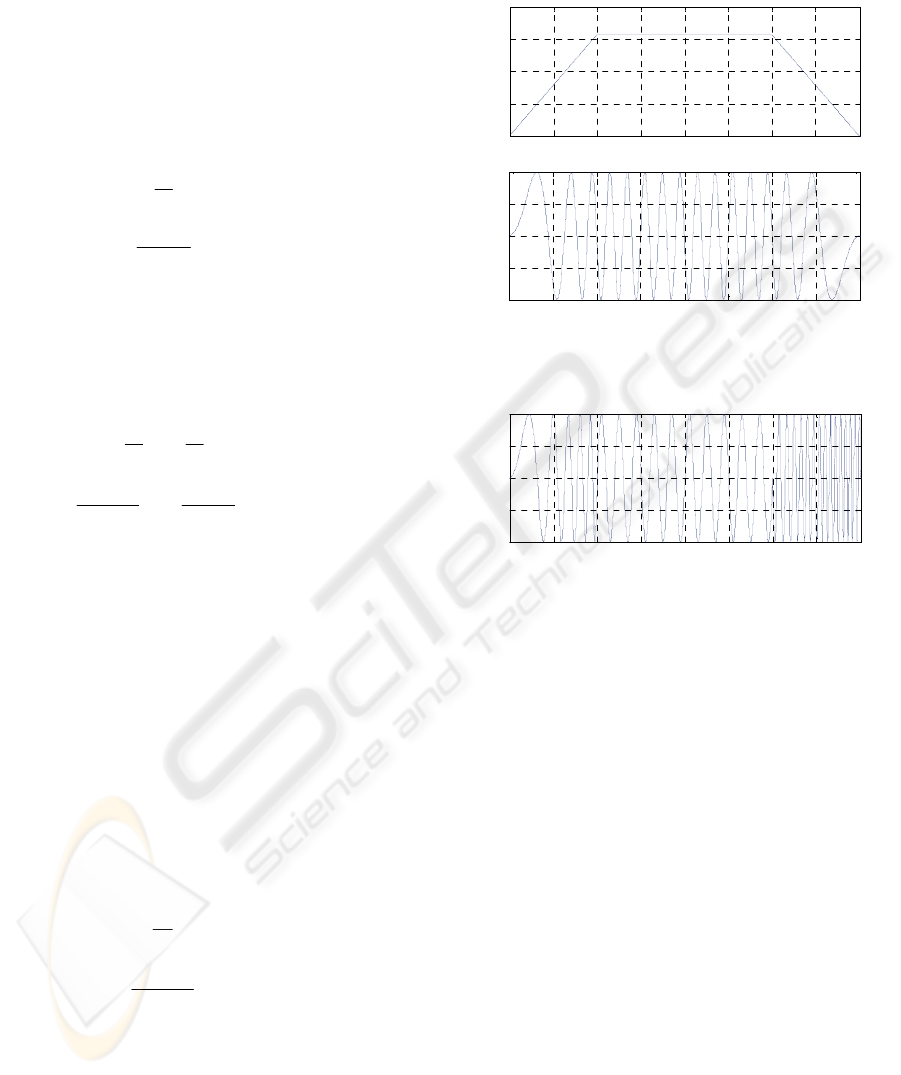

instant t=40s. Figure 1 shows this trapezoidal

frequency profile and a continuous joint trajectory

q(t) that follows it and finishes at zero position.

As a first solution to this problem, a beginner

might propose the expression in (1) for the joint

trajectory q(t). This is a sine function and we can

check that the function ω(t) follows the trapezoidal

profile.

⎪

⎪

⎩

⎪

⎪

⎨

⎧

≤<

−

π

<≤π

<≤π

=ω

ω=

40t30

10

)t40(

30t10

10t0

10

t

)t(

where)t)t(sin()t(q

(1)

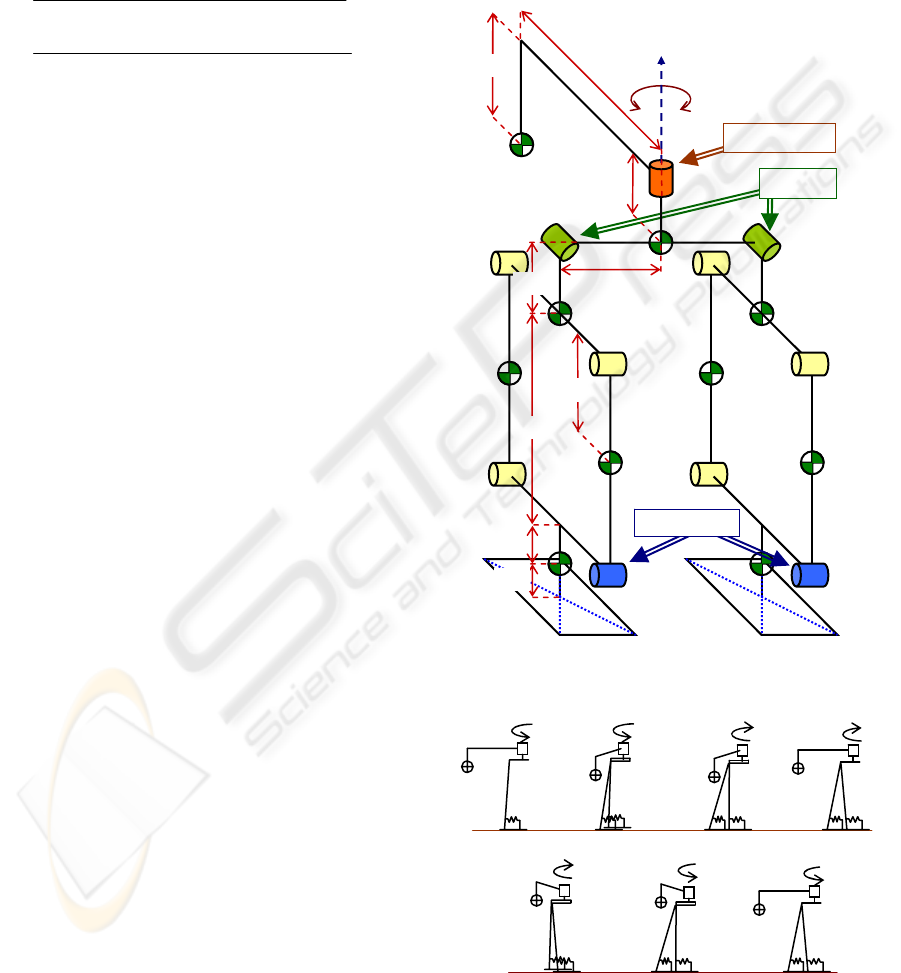

Figure 2 shows this function (1) and of course

this is not the correct solution. We can see the reason

for this result by analyzing the time derivative

given by (2).

)t(q

⎪

⎪

⎩

⎪

⎪

⎨

⎧

≤≤

−

π

−

π

<≤ππ

<≤ππ

=

40t30)t

10

)t40(

cos(

10

)t240(

30t10)tcos(

10t0)

10

t

cos(

10

t

2

)t(q

2

(2)

First, at instant t=10s, the left value of is

twice as much as the right value, and we can see this

effect in the slope change of q(t) in figure 2. We find

a similar result at time t=30s, where there is a

discontinuity in from π to -2π. It is also

unexpected that increases during the last

trajectory segment and at t=40s, when ω(t)=0rad/s

and we expected zero velocity, its value is -4π rad/s.

)t(q

)t(q

)t(q

The right solution for this example problem is

(3), where θ(t) is the phase of the sinusoidal

function, and its time derivative also follows

the trapezoidal profile in figure 1.

)t(θ

⎪

⎪

⎩

⎪

⎪

⎨

⎧

≤≤

−

π

<≤π+π

<≤π

=θ

θ=

40t30

20

)t40(

30t10t

10t0

20

t

)t(

where))t(sin()t(q

2

2

(3)

Using (3) the final value of q(t) is the desired

zero value. In a general problem, a desired final

value of q(t) can’t be reached if we use only linear

functions in the profile and impose time instants and

frequency values. We will see that we need another

degree of freedom using, for example, a last

quadratic function in the profile, to obtain a desired

final value for the sinusoidal trajectory.

0 5 10 15 20 25 30 35 40

0

1

2

3

4

Time (s)

Radian frequency (rad/s)

0 5 10 15 20 25 30 35 40

-1

-0.5

0

0.5

1

Time (s)

Joint position (rad)

(a)

(b)

Figure 1: (a) Desired trapezoidal frequency profile and (b)

desired trajectory for an actuated robot joint.

0 5 10 15 20 25 30 35 40

-1

-0.5

0

0.5

1

Time (s)

Joint position (rad)

Figure 2: Graphical representation of function (1).

2.1 Basic Definitions

Given a sinusoidal function (sine or cosine) like (4),

the argument θ(t) is the instantaneous phase and its

time derivative is the instantaneous radian

frequency. When θ(t) varies linearly with time, its

time derivative is constant and its value is the radian

frequency, as in the time interval [10s, 30s] in (3).

(

)

)t(sinA)t(f

θ

=

(4)

When the phase is quadratic, as in the first and

last intervals in (3), the instantaneous radian

frequency varies linearly between two values and

f(t) is called a chirp function. So, the profile in

figure 1 shows the instantaneous radian frequency of

a sinusoidal function and represents the

concatenation of chirp functions. We will consider

here constant frequency sinusoids as a subset of

chirp functions, with the same initial and final

frequencies.

TRAJECTORY PLANNING USING OSCILLATORY CHIRP FUNCTIONS APPLIED TO BIPEDAL LOCOMOTION

71

3 INTERPOLATION OF CHIRP

FUNCTIONS

We now present a method for planning trajectories

without discontinuities in the joint position and

velocity by means of the concatenation of chirp

functions. First we obtain the solution without a

desired final position, and in section 3.1 we add this

constraint to the problem and solve it using a final

cubic phase function.

Problem statement: Given a set of N+1 time

instants t

i

(for i=1 to N+1), and a set of N+1 desired

radian frequencies ω

i

at each instant t

i

, find a set of

N chirp functions f

i

(t) so that their concatenation

represents a continuous trajectory with amplitude A,

initial value q(t

1

)=q

1

, and which instantaneous

frequency interpolates the frequencies ω

i

.

To solve this problem, we will use the function

family given by (5).

()

⎪

⎩

⎪

⎨

⎧

≤

<≤+−+−

<

=θ

θ=

+

+

tt0

tttc)tt(b)tt(a

tt0

)t(

where)t(sinA)t(f

1i

1iiiii

2

ii

i

i

ii

(5)

The problem centres on finding the coefficients

of the phases θ

i

(t), and it is basically the same

problem of interpolating trajectories with linear

velocity profiles.

The set of conditions that allow us to solve this

problem is:

ii1ii1i1ii

iiii

ii1iii

1111

b)tt(a2)t(

b)t(

c)t()t(

c)A/qarcsin()t(

+−=ω=θ

=ω=θ

=θ=θ

==θ

+++

−

(6)

From these expressions, the values of a

i

and b

i

are directly calculated, and the c

i

coefficients, that

represent the initial phase in each profile’s segment,

must be calculated iteratively:

1i1ii1i

2

1ii1ii

11

ii

i1i

i1i

i

c)tt(b)tt(ac

)A/)t(qarcsin(c

b

)tt(2

a

−−−−−

+

+

+−+−=

=

ω=

−

ω−ω

=

(7)

The main problem of this solution is that we can

not establish a desired final value of the joint

position.

3.1 Concatenation of Chirp Functions

with a Final Cubic Phase

Usually, a planned trajectory finishes with zero

velocity, and in these cases it is interesting also to

reach a desired joint position q

N

. This condition adds

a new constraint for selecting the last trajectory

function f

N

(t) and therefore the phase θ

N

(t) needs

another degree of freedom, that is, we need to use a

cubic function instead of a quadratic one:

(

)

⎪

⎩

⎪

⎨

⎧

≤

<≤+−+−+−

<

=

=θ

θ

=

+

+

tt0

tttn)tt(m)tt(l)tt(k

tt0

)t(

where)t(sinA)t(f

1N

1NNN

2

N

3

N

N

N

NN

(8)

The set of conditions that θ

N

(t) must satisfy is:

(

)

1N1NN

NNN

N1NNN

1NNN

)t(

)t(

)t()t(

)t(sinAq

++

−

+

ω=θ

ω=θ

θ=θ

θ=

(9)

The first of these conditions has many solutions,

so we will find the solution corresponding to an

almost linear profile, that is, the final phase value

will be the nearest to the final value that we will

obtain from (7) for i=N. To obtain the coefficients k,

l, m and n, we use the next procedure:

1-. First, we calculate the final phase in the quadratic

case using the coefficients a

N

, b

N

and c

N

obtained

from (7), and also the integer number of revolutions

around the unit circle:

NN1NN

2

N1NNquad

c)tt(b)tt(a +−+−=θ

++

(10)

(

)

π

θ

=

2/floorr

quad

(11)

2-. Next, we select an angle α

∈

[0, 2π), in the same

side of the unit circle as θ

quad

, that satisfies the first

condition in (9).

⎩

⎨

⎧

≥θ

<θ−π

=α

0)cos()A/qarcsin(

0)cos()A/qarcsin(

quadN

quadN

(12)

If α<0, we will add 2π (α=α+2π).

3-. The desired phase at t

N+1

is then given by (13).

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

72

π+α

=

θ=θ

++

r2)t(

1N1NN

(13)

4-. Finally, we calculate the coefficients by means of

(14). These expressions are obtained from (13) and

the last three conditions in (9).

3

N1N

N1N1NNN1N1N

2

N1N

N1N1NNN1N1N

N

N1N

)tt(

)tt)(())t((2

k

)tt(

)tt)(2())t((3

l

m

)t(n

−

−ω+ω+θ−θ−

=

−

−ω+ω−θ−θ

=

ω=

θ=

+

++−+

+

++−+

−

(14)

4 APPLICATION TO AN

UNDERACTUATED BIPEDAL

MECHANISM

We now present experimental results from

simulations where we apply this trajectory planning

method to a bipedal walking model. This model is

described in more detail in (Berenguer, 2007), and

we now include a brief description.

4.1 Bipedal Model and Gait

Descriptions

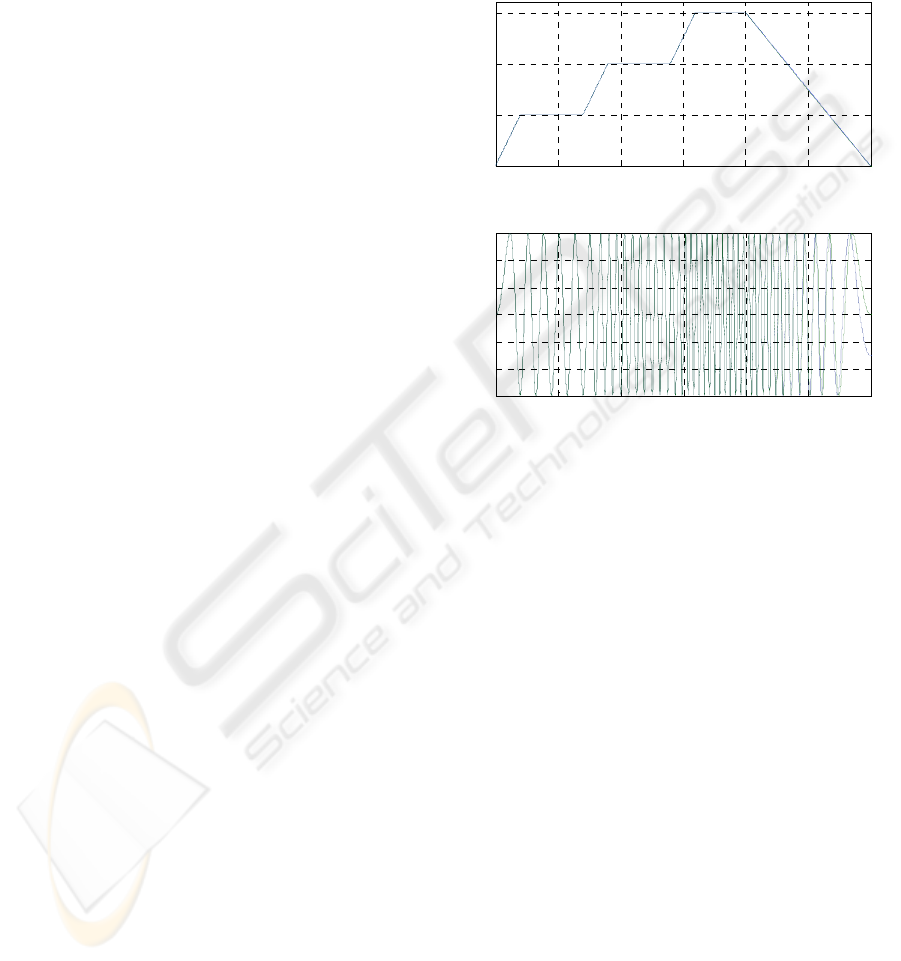

The walking model, shown in figure 3, consists of a

light body, a tail connected to it and two legs. Each

leg is formed by a parallel link mechanism and a flat

rectangular foot. The tail, with an almost horizontal

displacement, works as a counterbalance and

controls the movement of the biped.

The joint connecting the tail to the body is

actuated by an electric motor and it is the only

actuated degree of freedom. Connecting the body to

each leg are the top joints. Their rotation axis is

normal to the frontal plane, so they allow the

mechanism to raise a foot while both feet remain

parallel to the ground. These top joints are passive

joints with negligible friction. Finally, each parallel

link mechanism has four joints, and we consider that

in one of these joints (the ankle joint) there is a

spring with friction. Due to the characteristics of the

parallel link mechanism, these four joints represent

only one passive degree of freedom for each leg of

the mechanism. In summary, the model has eleven

joints, four passive degrees of freedom and one

actuated degree of freedom.

We now describe how the mechanism can walk

when the tail moves side to side in an oscillating

way. We start by supposing that the biped is at an

equilibrium position with the tail in its central

position (Fig.4.a). Both ankle springs hold the

weight of the mechanism and it stays almost vertical.

When the tail moves to a lateral position of the

mechanism, its mass acts as a counterbalance and

produces the rise of one of the feet (Fig.4.b). Then

only one spring holds the body, so the stance leg

falls forward and the swing leg moves forward as a

pendulum until the foot contacts the ground (fig.4.c).

Figure 3: Model of the biped mechanism.

Figure 4: Phases during a stride.

(a)

(b)

(c)

(d)

(e)

(f) (g)

Top joints

q(t)

Actuated joint

Ankle joints

150mm

35mm

20mm

50mm

200mm

400mm

5mm

5mm

30mm

700gr

50gr

50gr

200gr

200gr

200gr

TRAJECTORY PLANNING USING OSCILLATORY CHIRP FUNCTIONS APPLIED TO BIPEDAL LOCOMOTION

73

During the new double support phase, the tail

moves to the other side and the ankle springs move

the body backwards (fig.4.d). When the tail reaches

the other side, the second foot rises and a new step is

generated (fig.4.e). In this single support phase, the

spring of the foot that is in the ground produces

enough torque to take the body forward again. This

second step finishes with a new contact of the swing

leg with the ground (fig.4.f).

Figure 4.g represents the last instant of this initial

stride, and the starting point of a new one or the final

configuration of a completed trajectory. We can see

that if the tail stops, the system will stay in a steady

configuration with no energy cost.

4.2 Example of Trajectory Generation

We want to design a trajectory that allows us to

evaluate and analyze the biped behaviour at three

different oscillation frequencies. The frequency

profile must achieve these frequencies in a linear

way, and keep them during some periods, so we can

suppose a quasi-periodic gait at the end of each

constant frequency segment. The desired oscillation

amplitude is 1.5 rad and the radian frequencies and

time instants are:

[]

{

}

[]

{

3002001601409070200st

05.15.1115.05.00s/rad

i

i

=

=ω

}

(15)

Using (7) we obtain q(t) with a linear profile shown

in figure 5.

()

180)200t(5.1)200t(0075.0)t(

120)160t(5.1)t(

95)140t()140t(0125.0)t(

45)90t()t(

30)70t(5.0)70t(0125.0)t(

5)20t(5.0)t(

t0125.0)t(

tttat)t()t(

)t(sin5.1)t(q

2

7

6

2

5

4

2

3

2

2

1

1iii

+−+−−=θ

+−=θ

+−+−=θ

+−=θ

+−+−=θ

+−=θ

=θ

<≤θ=θ

θ=

+

(16)

As we can see in figure 6, this solution provides

the final joint position q(300)= -0.76rad. If the

desired final tail position is q=0rad, it will be

necessary to apply the procedure in section 3.1. The

solution in this case is the same as in (16) but with

the last phase θ

7

(t) given by:

180)200t(5.1)200t(10659.7

)200t(10062.1)t(

23

36

7

+−+−×+

+−×=θ

−

−

(17)

Figure 5 shows the frequency profiles of both

solutions. We can see a most linear segment in the

last time interval for the second solution which

practically overlaps the first solution’s profile.

Figure 6 shows both trajectories nearly overlapping

during the last time interval, with the same number

of oscillations but different final value.

0 50 100 150 200 250 300

0

0.5

1

1.5

Time (s)

Figure 5: Instantaneous frequency profiles.

Figure 6: Trajectory of the tail joint.

4.3 Evaluation of the Mechanism

Behaviour

The bipedal mechanism walks with a forward speed

which is proportional to the stride length and

frequency. The stride frequency is the same as the

tail oscillation frequency and the stride length

depends on the tail frequency and also on other

parameters of the model. If we fix the values of

these other parameters, the speed and energy

consumption of the mechanism will depend in a non

linear way on the stride frequency. Using linear

frequency profiles we can analyze this dependency

and estimate a near optimal joint frequency for an

established set of model parameters.

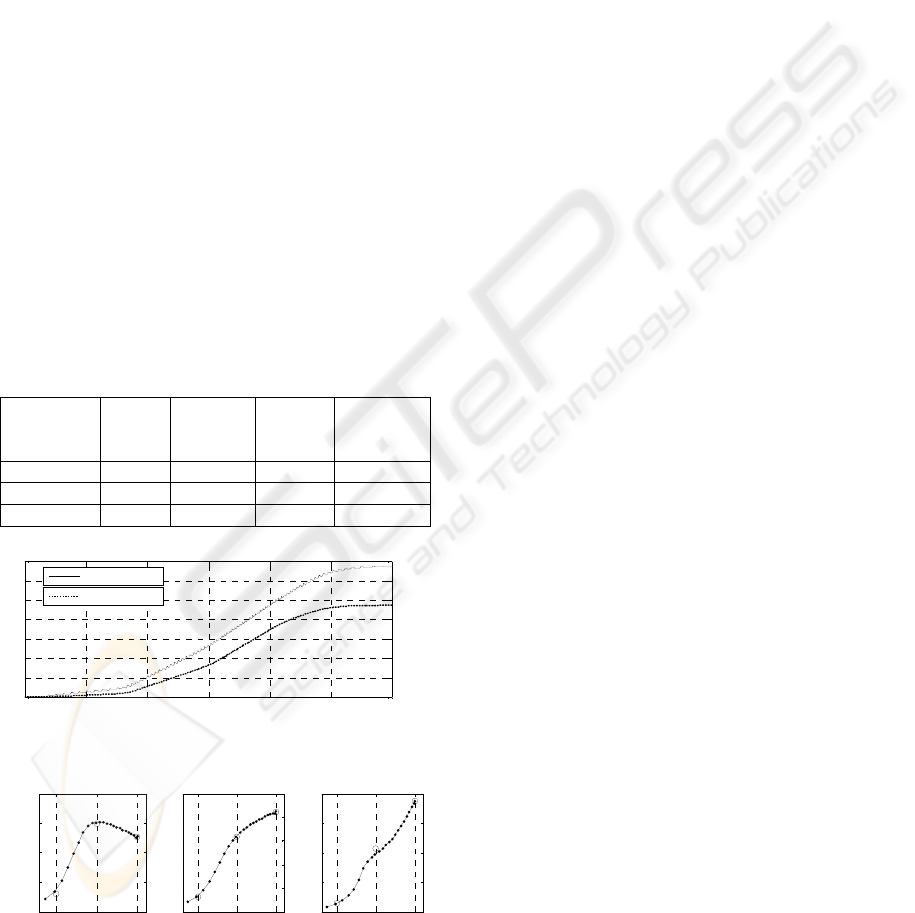

Figure 7 shows the distance covered by the biped

and the mechanical energy required by the tail joint

during the execution of the last trajectory defined in

section 4.2. The relative small amplitude oscillations

are due to the forward and backward oscillation of

the body during walking. The mechanical energy has

been calculated by the integration of the absolute

value of the product between the angular velocity of

the joint and the required torque. We observe an

important difference in the walking speed for the

first and second oscillation frequencies, and a much

Frequency (rad/s)

0 50 100 150 200 250 300

-1.5

-1

-0.5

0

0.5

1

1.5

Time (s)

Tail joint position (rad)

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

74

smaller variation for the second and third ones,

while the power consumption varies significantly for

these last frequencies. So, we find a loss of

efficiency when we increment the stride frequency.

Table 1 presents numerical data considering the

last stride period just before a change in the

oscillation frequency. We suppose that the gait is

almost periodic during this last period. Figure 8

shows these values and also an estimation of the

same magnitudes at different frequencies. This

estimation is obtained from the last profile’s

segment, which covers all frequencies between 0

and 1.5rad/s, considering each half-oscillation as an

approximation of half-period of a sinusoid.

As we can see, speed goes up quickly at low

frequencies because stride length also grows. For

frequencies greater than 1.04rad/s, stride length

decreases with frequency and speed rises more

slowly. We also notice that speed and power have

similar behaviour (S-curve) before this frequency.

After that, the power slope increases whereas speed

slope decreases. We consider this 1.04rad/s

frequency as a near optimal oscillation frequency for

the actuated joint.

Table 1: Stride length, speed and mechanical power at

three different stride frequencies during a stride.

Stride

frequency

(rad/s)

Stride

period

(s)

Stride

length

(m)

Speed

(m/s)

x10

-3

Power

(W)

x10

-3

0.5 12.57 0.0807 6.422 1.386

1.0 6.283 0.1992 31.704 10.707

1.5 4.188 0.1767 42.184 18.694

Figure 7: Crossed distance and mechanical energy during

the trajectory execution.

0.5 1 1.5

0.05

0.1

0.15

0.2

0.25

Frequency (rad/s)

Stride length (m)

0.5 1 1.5

0

10

20

30

40

50

Frequency (rad/s)

Speed (mm/s)

0.5 1 1.5

0

5

10

15

20

Frequency (rad/s)

Mechanical Power (mW)

Figure 8: Stride length, mechanism speed and required

mechanical power at different joint frequencies.

5 CONCLUSIONS

In this work we propose a method for planning

oscillatory trajectories based on the concatenation of

chirp functions. By means of adding a final cubic

function, the joint can also reach a desired final

position following a nearly linear frequency profile.

Our aim is to apply this method to a bipedal robot

that walks moving a tail in an oscillatory way.

This planning method allows us to study the gait

efficiency at different stride frequencies during the

design and adjusting phase. On the other hand, the

implementation of this planner will allow a real

prototype to select the forward speed as a function of

the obstacles density, ground inclination or for

optimization requirements.

REFERENCES

Spong, M. W., Vidyasagar, M., 1989, Robot Dynamics

and Control, John Wiley & Sons.

Sciavicco, L., Siciliano, B., 1996. Modeling and Control

of Robot Manipulators, The McGraw-Hill Comp., 1

st

edition.

Craig, J. J., 2006. Introduction to robotics, Prentice Hall,

3

th

edition.

Morimoto, J., Gen Endo, Jun Nakanishi, Hyon, S., Cheng,

G., Bentivegna, D., Atkeson, C.G., 2006, “Modulation

of simple sinusoidal patterns by a coupled oscillator

model for biped walking”, in Proc. 2006 IEEE

International Conference on Robotics and

Automation, USA, pp.1579-1584.

Sfakiotakis, M., Tsakiris, D. P., Vlaikidis, A., 2006,

“Biomimetic Centering for Undulatory Robots”, in

Proc. of the 1st IEEE Int. Conference on Biomedical

Robotics and Biomechatronics, pp.744- 749.

0 50 100 150 200 250 300

0

1

2

3

4

5

6

7

Time (s)

Crossed distance (m)

0 50 100 150 200 250 300

0

0.5

1

1.5

2

2.5

3

3.5

Time (s)

Mechanical energy (J)

Crossed distance

Mechanical energy

Murray, R. M., Sastry, S., 1993, “Nonholonomic motion

planning: Steering using sinusoids”, IEEE Trans. on

Automatic Control, 38(5), pp.700-716.

McClung, A. J., Cham, J. G., Cutkosky, M. R., 2004,

“Rapid Maneuvering of a Biologically Inspired

Hexapedal Robot” in ASME IMECE Symp. on Adv. in

Robot Dynamics and Control, USA.

Leavitt, J., Sideris, A., Bobrow, J. E., 2006, “High

bandwidth tilt measurement using low-cost sensors”,

IEEE/ASME Trans. on Mechatronics, 11(3), pp.320-

327.

Berenguer, F. J., Monasterio-Huelin, F., 2006, “Easy

design and construction of a biped walking mechanism

with low power consumption”, in Proc. of

CLAWAR’06, the 9th Int. Conference on Climbing and

Walking Robots, Belgium, pp. 96-103.

Berenguer, F. J., Monasterio-Huelin, F., 2007, “Stability

and Smoothness Improvements for an Underactuated

Biped with a Tail”, in Proc. of the 2007 IEEE Int.

Symposium on Industrial Electronics, Vigo, Accepted.

TRAJECTORY PLANNING USING OSCILLATORY CHIRP FUNCTIONS APPLIED TO BIPEDAL LOCOMOTION

75