Development of Architecture and Caching System for

Improving the Performance of Fuel Management System

Mahmoud Ali Ahmed and Mustafa Ali Taha

Department of Computer Science, Faculty of Mathematical Sciences

University of Khartoum, Khartoum, Sudan

Abstract. Fuel Management System (FMS) is about managing and accounting

for fuel. While implementing FMS in Sudan, some problems are noted, like

system delay, inaccuracy and unavailability of the system. These problems and

others make fueling companies and customers unsatisfied with the FMS.

This paper aims to solve the noted problems by introducing enhanced system

architecture and integrating a Caching System in the FMS architecture to

enhance the performance, reduce system delay and increase the availability of

the system.

After architecture was developed, simulation programs were implemented to

simulate the interactions required to re-fuel and to provide statistics results that

help in evaluating the proposed FMS. The results of simulation programs were

presented as the average service time, number of customers in system, number

of customers in queue, idle probability and other results. The average service

time was reduced and all results obtained emphasize the effectiveness of the

proposed solution.

1 Introduction

FMS consists of equipments and software designed to automate the process of

purchase and sale of any fuel product inside fueling site. Fuel is delivered by the

supplier to the tank at fuel distribution site and then to the customers; when

distributing fuel, some features are required such as accuracy, integrity, and caution of

every person that uses the facility to ensure that the losses is only due to natural

causes such as evaporation. Losses are becoming a great concern for Management and

Accounting departments especially in the public sector [1].

By using FMS many benefits can be gained such as it becomes easy to account for

every liter of fuel purchased and to know where the fuel goes, hence the organization

will avoid fuel theft and misuse [1], also re-fueling becomes easier and faster and

ensuring the proper fuel was delivered for specific vehicle becomes available with the

ability of restricting access to re-fueling until the maintenance is performed [1].

FMS principle is the connection and control of all dispensers to an interface unit

which is connected to the controller computer to control these dispensers by the

software installed on the computer, to enable all fueling operations to be reported,

Ahmed M. and Ali Taha M..

Development of Architecture and Caching System for Improving the Performance of Fuel Management System.

DOI: 10.5220/0003111700030014

In Proceedings of the International Workshop on Semantic Sensor Web (SSW-2010), pages 3-14

ISBN: 978-989-8425-33-1

Copyright

c

2010 SCITEPRESS (Science and Technology Publications, Lda.)

controlled, recorded and customers can easily monitor their vehicle’s fueling

operation [2].

FMS must have the ability to identify users (by using identification method like:

Attend key, Smart cards, Automated Teller Machine (ATM) cards etc...) in order to

enable the system give authorization to the dispenser for fueling. Fueling information

are recorded at the end of the fueling [2]; then it’s transferred automatically to the

central server through an appropriate network connection [3].

As FMS consists of many components (hardware and software) and the system

might be integrated with other systems such as Banking System and/or other sites

through complicated network, the system will be affected with most of networks

problems, so there is a need for techniques to reduce the effect of network problems

to the system. Also the architecture of the automation system and the equipments used

for connecting the dispensers to the system are important to be considered because

any loss or delay of re-fueling data is not acceptable [2]. Therefore, it is vital to stick

to international standards during the design and implementation of these systems [2],

so it is powerful to construct simulation programs to test new systems before

implementing them.

2 FMS Infrastructure

2.1 Fuel Management Sub-Systems

FMS is a complex system, so a good way to deal with the system is to divide it -

according to functionalities - into small subsystems.

The main sub-system in FMS is Pump Controlling System; it connects all fuel

dispensers to the station controller computer resulting in the controlling of these

dispensers by the software installed on the computer [2]. The system operates the fuel

dispenser only to valid customers and vehicles [4].

An optional system is a Head-Office System. It delivers the capability of

programming identification devices. Head-office system sends all the fleet

information to the automation solutions in all stations. The system stores data in the

central database, since all the transactions in the stations are transferred to the head-

office. Information stored in the head-office is later used to generate reports and

submitted to the users [2].

2.2 Fuel Management Identification Equipment

FMS consists of a fuel island controller, software, some types of identification

devices (as shown in Table 1) and the Central Controller that normally communicates

with other sites to exchange the data [1].

4

Table 1. Identification equipment.

Identification

equipment

Description

Smart Chip Key

Contains a microchip that can be programmed and

reprogrammed.

Smart cards

Standard size card with an embedded read/write memory

chip and it works exactly like smart Chip Key.

Credit cards

It allows 24 hour, unattended, self-serve operations for

credit card holders [5].

Vehicle Identification

System

It is a coil ring integrated with electronic chip that

installed at the opening of the fuel tank to enable

collecting data from the vehicle [6].

2.3 Fuel Management System Sensors

A sensor can be defined as "a device that detects (senses) changes in the ambient

conditions or in the state of another device or a system, and conveys or records this

information in a certain manner" [7]. FMS and its subsystems contain many sensors to

monitor system status (i.e. volume, motion, temperature and other sensors) where all

sensors are connected with FMS network through defined protocols. FMS Sensors are

located in station forecourt (to detect vehicle motion), in fuel dispenser (to measure

delivered fuel volume), in station fuel tanks (to measure temperature, viscosity and

other physical parameters) and in the vehicle .All sensors are responsible for the

accuracy and performance of the system.

2.4 Off-line Automation and On-line Automation

Vehicle identification and station automation operate in two different modes [2]:

Off-line automation: All the vehicle information, Black/White List is stored in the

automation systems located at the station. The vehicle approaching the station is

controlled by this automation system and then re-fueled. Daily sales are transferred to

the oil company head-office on a batch transfer. During the batch transfers, the fleet

list definitions are updated [2].

On-line automation: All the vehicle information, Black/White List is stored in the

servers of company head-office or in the servers of the Internet Service Provider (ISP)

that is responsible for central communication and data storage. The vehicle that

approaches the station is detected by the station controller and queried on the head-

office system. Fueling, regional and time limitations of the vehicle are checked from

the head-office [2].

2.5 Payment Methods

Payment methods are an important issue that can be considered when designing FMS.

In general, there are two types of payments, post-paid and pre-paid [2].

5

In the post-paid method the customers will take fuel and can also be provided with

some services and/or products and will pay the money later, so the off-line

automation is suitable for this case.

In the pre-paid method the customers will take fuel and can also be provided with

some services and/or products only if they have sufficient amount defined in the

system, so the on-line automation is suitable for this case.

3 Related Works

This section discusses some FMSs according to the author experience, and then an

ATM network model is highlighted to help in designing the enhanced FMS.

PumpOmat is a forecourt automation system developed by Turpak – Turkish

company- for dispenser automation .When installing and running PumpOmat in

Sudan, the author found that there were some problems in the system. The first

problem is that when the customer presents his identification, the system takes long

time (approximately 40 Sec.) to start the dispenser and the dispenser can not stop at

the target volume or amount exactly. Also the system supports only post-paid

customers.

Another FMS is EasyFuel Plus which is developed by OTI. Also this system has

many problems; the first problem is that when the customer presents his

identification, the system takes long time (approximately 36 Sec.) to start the

dispenser. Another problem is, although the system supports pre-paid customers but

the tag that holds the data must be returned to the fuel company for balance reloading,

so from the author point of view it is not practical.

The author observes that the FMS is similar to the ATM Network in which the

ATMs are owned by different banks, and the customer may use any ATM even it

doesn’t belong to his bank. All ATMs are connected using a main switch which

connects them to the core systems [8]; this scenario has been applied to proposed

FMS for network considerations.

4 Methodology

4.1 Caching System

Caching is a technique aimed at bringing parts of an overall data set closer to its

processing site [9], and can be used in FMS to retrieve customer data from 'outside'

servers to the station computer to enhance the performance.

Caching can improve network performance in two ways. First, when serving

clients locally (customer data), caches hide wide-area network latencies. Second,

temporary unavailability of the network can be hidden from customers, thus making

the network appear to be more reliable [10].

Caching systems eliminate the need to contact the originating server. Thus,

additional network communication can be avoided, so caching systems can save

6

bandwidth, enhance server load balancing, perceived network latency reduction, and

increase content availability [10].

The main drawback of caching system is data inconsistency, and this drawback

does not affect the FMS because the data is retrieved when the customer is in the

station and the update occurs after the customer leaves the station.

4.2 Simulation and Modeling

Simulation is used as a tool to better understand and optimize the performance and

reliability of systems [11]. Modeling and simulation is a valuable tool in the analysis

of large-scale networks and computer systems [12].

Simulation and modeling technique will be used after the development of

architecture and Caching System for FMS to ensure the correctness of the design.

4.3 Queuing Analytical Models

Queuing theory is usually used to define a set of analytical techniques in the form of

mathematical formulas to describe properties of the processes with a random demand

and supply (waiting lines or queues). Queuing formulas are usually applied to a

limited number of pre-determined simplified models of the real processes for which

analytical formulas can be developed [13].

There are three main concepts in queuing theory which are customers, queues, and

servers (service mechanisms). In queuing systems, customers are generated by an

input source according to a statistical distribution that describes their interarrival

times (the times between arrivals of customers). The customers join a queue and

waiting for some event to occur (i.e. take a fuel). At various times, customers are

selected for service by the server (service mechanism). The basis on which the

customers are selected is called the queue discipline which can First-come-first-

served (FCFS) or Last-come-first-served (LCFS) or Random selection or Priority

selection [14] .In some models customers can decide not to join a queue if the queue

length is too long. This phenomenon is called Balking [14].

5 FMS Architecture

This section proposes FMS architecture with discussion of two system scenarios and

suggests a solution for them.

One solution to reduce the waiting time, increase the availability and enhance the

integrity at the fuel station is the 'Caching System' that is to start retrieving the fueling

data while the vehicle/customer in the waiting queues.

When the customer needs re-fueling at fuel station, two situations may occur. The

first situation is that the customer does not find any vehicle in re-fueling process, so

there is no queue and he/she can stop at the fuel dispenser directly. The second

situation is that the customer finds there is a vehicle in re-fueling and/or other

7

vehicles are waiting in the queue for re-fuel, in this case the customer will join a

queue.

In the first situation the customer can use his/her identifier to re-fueling, and the

customer will wait for a few times while the system is retrieving the data.

In the second situation, there is a possibility that the fueling information for the

customer is stored in some server outside the station, a good technique is to retrieve

the fueling information while the customer is waiting in the queue.

When a customer comes to station and joins a queue, he/she will be waiting in the

queue until he/she becomes the first customer in the queue, and then a capturing

device will capture the vehicle plate number and transfer it through the controller to

the station computer. The station computer will establish a communication with other

severs to get the fueling information for this vehicle and store them temporally in the

station computer. When the customer leaves the waiting queue and stops at the

dispenser and uses his/her identifier, the request will be forwarded by the Central

Controller to the station computer and the data will be found in the station computer

because it is prepared while the customer was waiting, so by implementing this

solution the waiting time will be reduced.

5.1 Components

FMS must contain Station Computer (SC) at each station to provide and process data

for station devices.

Since the one fuel company can have more than one fuel station, there is a need

for a centralized server (Fuel Company Server (FCS)) to collect and analyze data

from different stations.

Since there is more than one Fuel Company and the customers need the ability to

take their quantities from any station, there is a need for a common centralized server

(Main Server (MS)) to enable data exchange between different FCSs and SCs. Since

all traffic must pass through the MS it can act as a point of solving conflicts and

coordinating between fueling companies.

In some cases if the customer uses his/her banking card, there is a need for

Banking System (BS).

Also customers can use their computers (Customers Computer (CC)) to manage

and monitor their fleet remotely.

5.2 System Architecture

This section proposes an enhanced system architecture that helps in reducing the

waiting time, increasing the availability and enhancing the integrity of the system.

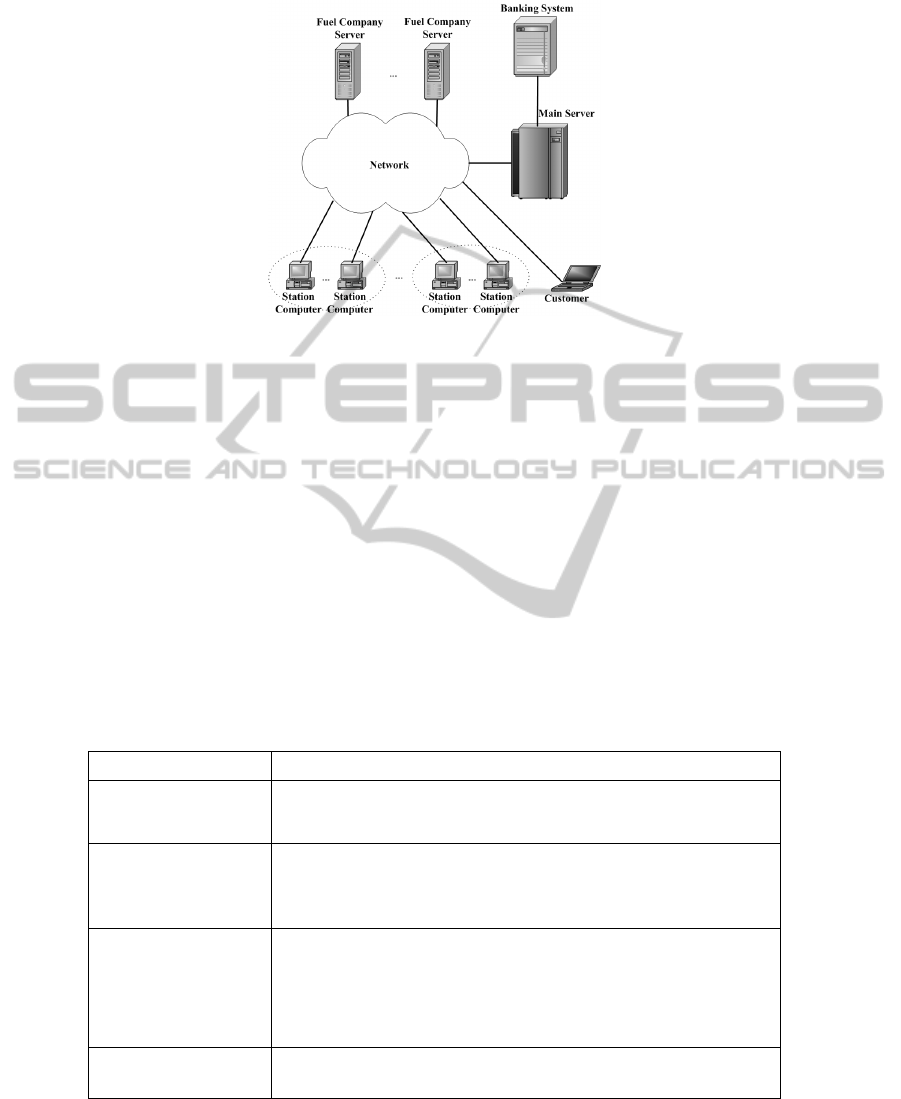

The architecture as shown in Fig. 1 consists of the Main Server, Banking System,

Fuel Company Server, Station Computer and customer Computer.

In this architecture The MS, FCSs and SCs connect through one network, but each

transaction must pass through the MS. Also, the MS is connected with the BS to

provide services to the customers who have banking account.

In general, when the customer needs to re-fuel or needs a service from fuel station,

there are two ways for paying, using FMS identifiers or using banking cards.

8

Fig. 1. The proposed architecture.

The first case, If the customer uses one of FMS identifiers, the SC will request the

MS to retrieve the fueling information from the place where it is stored; the MS

searches in its database to determinate the appropriate FCS and then requesting it to

get the fueling information, the FCS will response to the MS and the response will be

forwarded from the MS to the FCS and then to the SC.

The second case, if the customer uses his/her banking card, the SC will request the

MS to dept the amount of money needed from the BS; the MS requests the BS to dept

the customer account, the BS will search for customer account and the result is sent to

the MS; the MS will forward the result to the SC.

In all cases, after re-fueling the dispensed fuel amount and cost will be processed

and transferred to the FCS and/or other Server(s) and it depends on if the customer

belongs to the fuel company or others.

While availability is an important issue when designing FMS, Table 2 shows the

effect of component and/or link failure to the system.

Table 2. The effect of component or link failure to the system.

Component / Link Effect of component or Link failure to the system

SC / Link between

SC and network

The station is out of service, so customers of this fuel company

and customers of other fuel companies can not use this station.

FCS / Link between

FCS and network

Customers of the fuel company can not fuel at fuel company or

each other station (also if it’s owned by different companies).

But company customers can use their banking card.

MS / Link between

MS and network

Customers of any fuel company can use company fuel stations

only (required to modify the SC logic and became that: if it

detects the failure of the MS, it can connect directly to its FCS).

Since the BS is connected to the MS, the customers are unable

to use their banking cards.

BS / Link between

BS and MS

Customers of any fuel company can not use their banking

cards.

9

As shown above this architecture retrieves the data from the FCS in 6 steps only,

so it reduces the time to retrieve the data and enhances the availability of data as

shown in the case of component or link failure, thus it is a powerful architecture to

implement.

Start

Customer arrive to station

Cash customer YesNo

Found free dispenser ?

Presents identifier ,pre-

paid card or banking card

Join a queue until becoming first

(in queue)

Yes

No

Request the customer to enter the needed

amount

Is the customer allowed to re-fuel ?

Yes

No

Is the amount of fuel

entered allowed ?

System presets the amount in the dispenser and start fueling

and display maintenance information

Display message: No sufficient credit

Yes

After fueling, stop the dispenser and update the

required servers

Customer leave the station

End

Display message: Not allowed

Send

request

to the

Main

Server

Payment type

Send

request

to the

Main

Server

Send request to the Main Server

process

and send

data to

station

Retrieve data from the Fuel Server

and send it to station

Retrieve

data from

the

Banking

system

and send it

to station

Pre - paid

card

FMS

Identifier

Customer data available at Station Computer

The Plate No. Reader captures

and sends plate number to the

Main Server

The Main

Server searches

and sends the

result to the

Station

Computer

Data available in Station

Computer

Yes

Found free dispenser ?

Join a

queue

Re-fuel using the pump attendant key

and pay in cash

Yes

No

No

No

Banking

card

Try other

payment type ?

Yes

No

Fig. 2. FMS Framework.

10

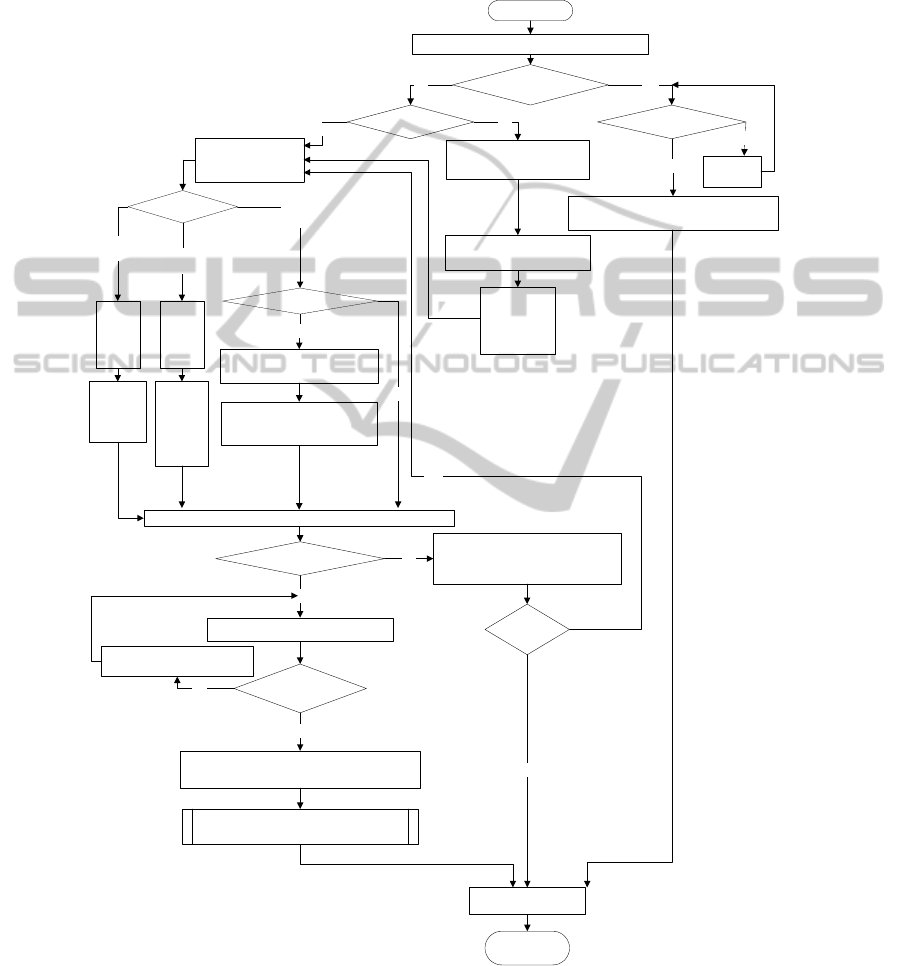

5.3 System Framework

By integrating the station system with other servers, it produces a Comprehensive

FMS that provides several services to customers with 'acceptable' performance. Fig. 2

shows an FMS framework that summarizes the steps required to re-fuel.

6 Results and Discussion

This section is divided into three sub-sections that show and discuss three

implemented FMS simulation programs. The first program is for simulating the

behavior and steps required to re-fuel. The second program is for calculating the

average service time while the third program is about calculating average waiting

time, calculating the number of customers in the system and the number of customers

in the waiting queues and other results.

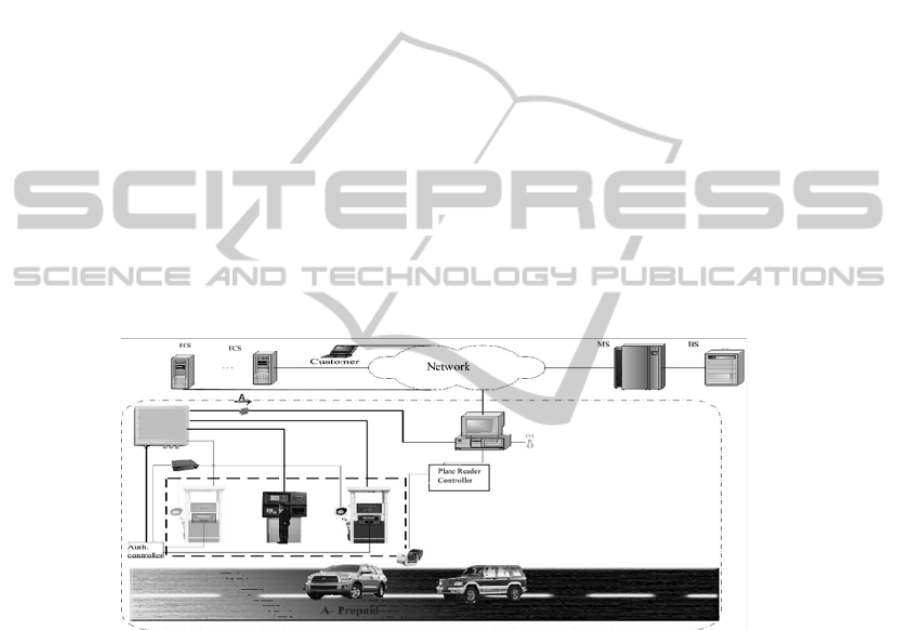

6.1 FMS Behavior Simulation

A simulation program that illustrates all cases and steps for re-fueling using the

proposed architecture is implemented. Fig. 3 shows a screen shot from the simulation

program.

Fig. 3. Screen shot of FMS behavior simulation.

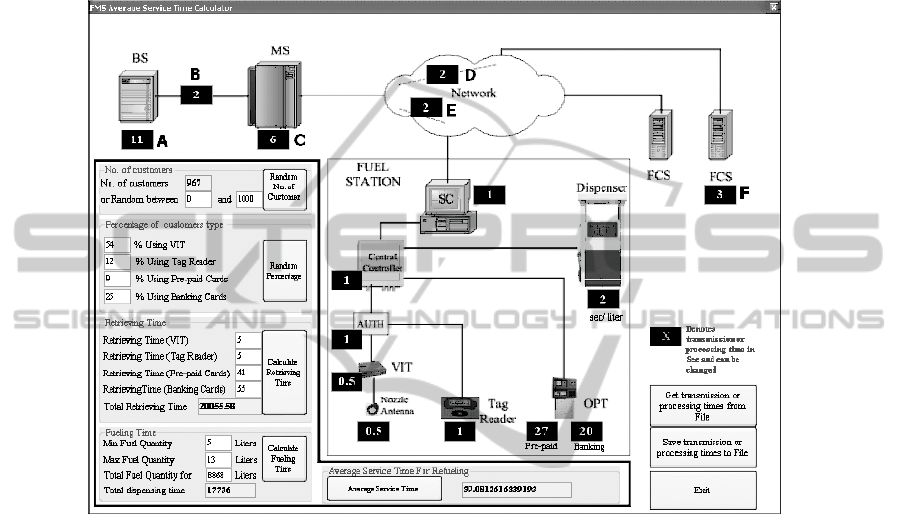

6.2 FMS Average Service Time Calculator

Average service time is a basic parameter that is required in any simulation program.

Since FMS has different customers type (customers with different authentication

methods), and the way to retrieve the data is different from method to other, it is

required to calculate the retrieving time.

Customers come to station to re-fuel in different quantities, and that will affect the

dispensing time (time required to re-fuel the desired quantity).

11

Since the retrieving time and dispensing time mostly compose the service time, then

the average service time for FMS customers is the summation of data retrieving time

and fueling (dispensing) time divided by the number of customers.

As shown in Fig. 4, a simulation program that calculates the average service time

was implemented (values used for transmitting and processing times are approximate

times and can be changed and it determined by author experiments and experience).

Fig. 4. Average Service Time Calculator.

As shown in Fig. 4 above, when using the proposed architecture the Average

Service Time is 39.081.

When integrating Caching System with the proposed architecture (the time

parameters A, B, C, D, E, F, set to zero because the data is available at the Station

Computer) , the Average Service Time will be 30.431Sec.

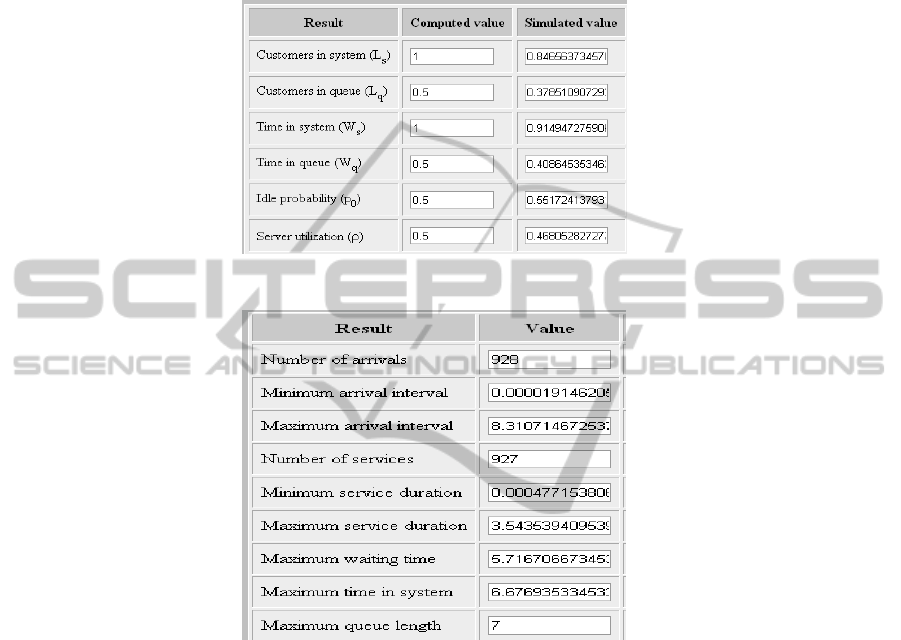

6.3 FMS Statistics Calculator

A simulation program (M/M/1 Solver & Simulator that is available at :

http://staff.um.edu.mt/jskl1/simweb/simmm1.html ) which is developed by Jaroslav

Sklenar was used to get the number of customers in system (Ls), number of

customers in queue (Lq), Time in system (Ws), Time in queue (Wq), Idle probability

(p0), Server utilization (r) and other results.

When using ‘FMS Average Service Time Calculator’ program, the calculated

average service time is (approximately 0.5 Min.). And each customer arrives after

12

(1.0 Min.) from the previous one, the arrival rate will be (1 customer/minute) and the

service rate will be (2 customers/minute). The author assumes that if there is 10

customers in waiting queue the customer will not join the system (buffer size is 10

customers). Fig. 5 and Fig. 6 below show the simulation results.

Fig. 5. Basic simulation results.

Fig. 6. Additional simulation results.

When simulating other systems, a simulation program shows that systems are

unstable because the arrival rate is greater than the service rate. In the proposed

system the architecture helps to improve the service rate by introducing common fuel

servers. Also as shown in Fig. 5 and Fig. 6, the Caching System reduces the average

service time that improves the system.

7 Conclusions

A powerful architecture that connects all fuel stations (for all fueling companies) in

the same network to enable customers to re-fuel at each fuel station regardless of the

station owner is designed to provide a set of services with ‘acceptable’ performance

13

and to reduce system delay and increase the accuracy of fuel volumes taken by

customers. Also the proposed architecture enables customers to re-fuel using various

payments methods.

According to the importance of evaluating the performance of the proposed FMS,

various simulation programs developed to illustrate the interaction scenarios between

different components, and to measure some system statistics such as average service

time, average waiting time and other statistics that considered important for fueling

companies and customers. The results obtained from the simulation programs

reflected the efficiency of the proposed FMS.

References

1. Municipal, Internet: http://www.municipalfuelmanagement.com , [Nov. 3, 2009].

2. TURPAK ELECTROMAGNETIC, Internet: http://www.turpak.com.tr, 2006 [Oct. 11,

2009].

3. Taurus systems Inc, Internet : http://www.Taurus-systems.com , [Sep. 25,2009].

4. Coencorp Inc., Internet: http://www.coencorp.com/e/provsrvover.htm, [Sep. 26, 2009].

5. PFA International Ltd., Internet : http://www.pfainternational.com/products.htm , 2006

[Oct 1,2009].

6. E - Drive Technology Ltd., Internet: http://www.e-drivetech.com, 2004 [Nov. 10, 2009].

7. WebFinance Inc.,"Sensor." Internet: http://www.businessdictionary.com/definition/

sensor.html, 2010 [Jul. 26.2010] .

8. CSFI.,Internet http://www.csfi.com/ezswitch.cfm , 2009 [Jun 13.2010] .

9. M. Baentsch, L. Baum, G. Molter, S. Rothkugel, P. Sturm, "World-Wide Web Caching The

Application level view of the Internet", Internet: http://www.syssoft.uni-trier.de/

systemsoftware/Download/Publications/communic.pdf , 1997 [Jul. 25.2010].

10. Greg Barish, Katia Obraczka , "World Wide Web Caching: Trends and Techniques",

Internet: http://inrg.cse.ucsc.edu/katia-pubs/cache-survey.pdf , Sep. 2009 [Jul. 25,2010] .

11. L. F. Perrone , Y. Yuan , and D. M. Nicol , “Modeling and Simulation Best Practices for

Wireless Ad Hoc Networks” , Proceedings of the 2003 Winter Simulation

Conference,2003, pp. 685 – 693.

12. G. R. Yaun, “Efficient Large-Scale Computer and Network Models using Optimistic

Parallel Simulation “ Ph.D. thesis , Rensselaer Polytechnic Institute , New York, Jun. 2005.

13. A. Kolker , “Queuing Analytic Theory and Discrete Events Simulation for Healthcare:

Right Application for the Right Problem” , Internet :http://www.iienet2.org/uploadedFiles/

SHS_Community/Resources/QueuingAnalyticTheoryandDiscreteEventsSimulation.pdf ,

[Nov. 15,2009].

14. A. Ferrier,“What is Queuing Theory?” , Internet : http:// www.andrewferrier.com/oldpages/

queueing_theory/Andy/what_is_queueing_theory.html, Jun. 1999 [Nov. 15,2009] .

14