A Product Development System using Knowledge-intensive

Support Approach

Janus S. Liang

1

, Kuo-Ming Chao

2

and Paul Ivey

3

1

Department of Vehicle Engineering, Yung-Ta Institute of Technology and Commerce,

316 Chungshan Road, Linlo, PingTung, 909, Taiwan

2

Department of Computing, Faculty of Engineering and Computing, Coventry University,

Priory Street, Coventry, CV1 5FB, U.K.

3

Faculty of Engineering and Computing, Coventry University, Priory Street, Coventry, CV1 5FB, U.K.

Keywords: Product Development, Knowledge Support, Fuzzy Assessment Model, DFMEA.

Abstract: The author is carrying out research studies to explore the applicability of knowledge-based system

technologies to today’s competitive product design and development, with an emphasis on the design of

high quality products at the design stage. A framework of knowledge-intensive support approach for new

product concepts is proposed in this paper. Based on the proposed approach and methodologies, a prototype

system named KB@Pds, which can assist inexperienced users to perform the process in design and

knowledge management. KB@Pds integrates the intelligent design process and knowledge management.

This paper presents the underlying concepts of the development and shows the practical application with the

prototype system with a case study.

1 INTRODUCTION

The new product development task is a highly

iterative process which involves a substantial

heuristic knowledge component about areas of

customer requirements, product design

specifications, production and tooling requirements,

etc. Product designers are required to possess a high

standard of specific knowledge and experience

because design decisions require intensive

knowledge and interaction between different

parameters. Product design does not result from a

sole quantitative analysis but comes within a range

of design procedures and decision makings.

Individual components of the design may be opened

to quantitative analysis, but these do not help the

designer to establish the overall aspect of the design,

particularly in the conceptual design stage in which

the design details are not yet available. The general

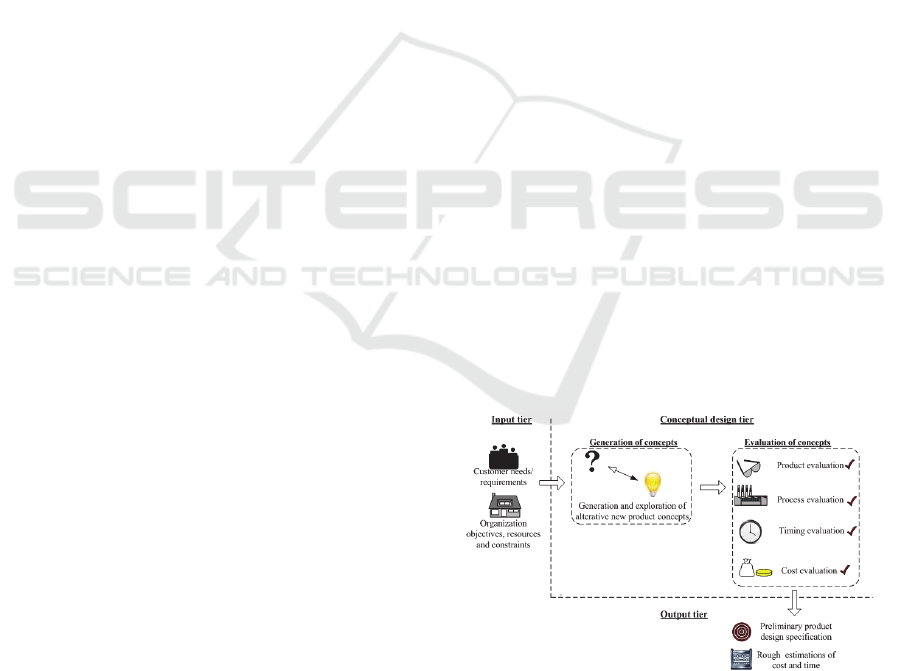

decision making process required at the conceptual

design stage (as shown in Figure 1) for a new

product development project.

The aim of this paper is to discuss knowledge

support methodologies and technologies for product

design. An integrated modular product design

process with knowledge support is explored. This

Figure 1: Decision makings in conceptual product design.

process includes customer requirements modeling,

product architecture modeling, product platform

establishment, and product assessment. The

followings present a knowledge-based assisted

product design system, KB@Pds, to support

inexperienced users to perform the product analysis

and making evaluation decision at the conceptual

product design stage. The organization of this paper

is as follows. Section 2 describes an analysis of the

product design process based on the product

designer’s perspective. Section 3 outlines the

framework of a knowledge-based assisted product

design system. Section 4 addresses the relevant

25

S. Liang J., Chao K. and Ivey P..

A Product Development System using Knowledge-intensive Support Approach.

DOI: 10.5220/0004122800250033

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2012), pages 25-33

ISBN: 978-989-8565-30-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

issues and technologies for implementing the

knowledge-intensive support approach for product

design. Section 5 summarizes the paper and point

out the future work.

2 REQUIREMENTS OF THE

PRODUCT DESIGN PROCESS

To develop a good product design process, an

analysis of ‘what they have’ and ‘what they want’

needs to be performed. First of all, what they have:

(1) the customer’s requirements for the product. This

includes the detailed geometry and dimension

requirements of the product; (2) an existing product

design library. This library covers the standard or

previously designed components and assemblies of

the product design; (3) n expert knowledge in

product design. Expert knowledge for product

design is obtained mainly from experienced product

designers. Such knowledge includes material

selection, geometry suggestion, alternative design

evaluation and others. What they want: (1) an

intelligent and interactive product design

environment. Product design is often composed of a

series of design procedures. These procedures

usually require certain parts to be created and

existing parts to be assembled. An intelligent and

interactive environment will be a good choice to

integrate some useful automation algorithms,

heuristic knowledge and on-line interaction by the

experienced product designer; (2) standard/previous

designed components/assemblies (product-

independent parts) management. Apart from the

parts that are similar in structure and geometrical

shape that can be used in other product designs.

These parts are independent of the products. They

are mostly standard components that can be reused

in different product designs; (3) useful tools

(including solid design and analysis calculation) in

product-dependent parts design. Geometrical shapes

and the sizes of the component system are

determined directly by the product. All components

in such a system are product dependent. Also, these

parts are the critical components in the product

design. Their geometrical requirements may be

complicated. Thus, some tools developed to design

the component based on partial automation and

partial interaction can be quite useful; (4) design for

assembly. In conventional CAD/CAM systems,

components are represented and stored as a complete

geometric and topological solid model. However,

this form is not appropriate for tasks that require

decision-making based on high-level information

about product geometric entities and their

relationships. Product designers prefer a design for

assembly environment instead of a simple solid

model environment (Desai and Mital, 2010); (5) a

design for manufacture. A complete product design

development can be composed of the design and

manufacturing process. To integrate CAD/CAM into

the product design, the manufacturing features on

the component should be abstracted and analysed for

the specific fabrication.

Based on the above analysis, the research focus

is to develop techniques to represent ‘what they

have’ and ‘what they want’. Representing ‘what they

want’ is actually the representation of the knowledge

and product object. Developing ‘what they want’

means to integrate the representation with intelligent

and interactive tools for the product design into a

completed design environment. Therefore, a

KB@Pds is proposed for product designers to

realize the above two requirements.

3 FRAMEWORK OF PRODUCT

DESIGN

3.1 Knowledge Support Scheme

and Key Items

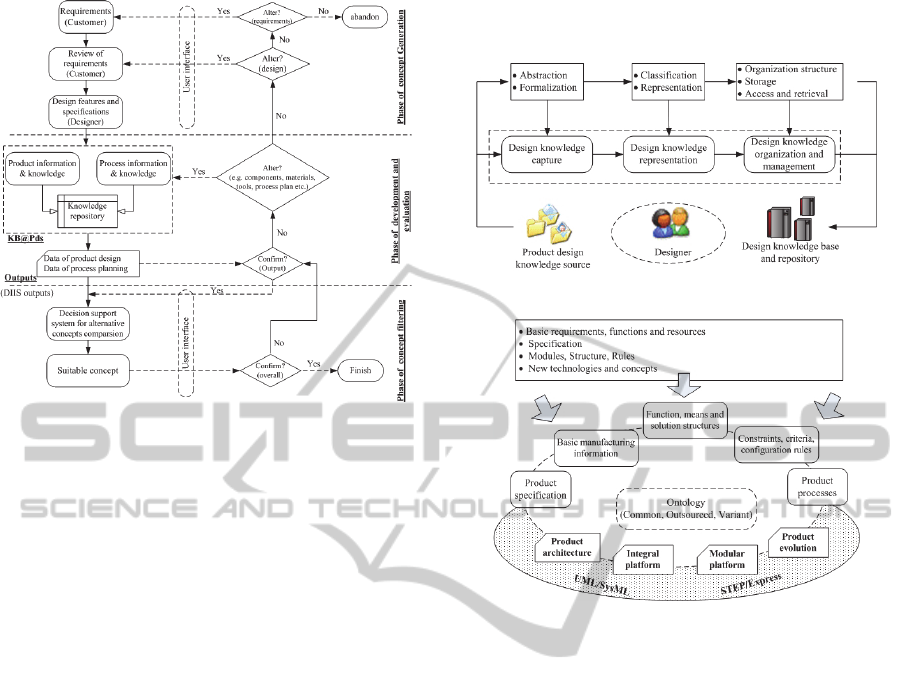

Figure 2 shows the process of product concept

development, which is composed of several phases –

generation of concept, development and evaluation,

as well as concepts filtering. Knowledge-based

assisted systems are proposed to support decision-

making throughout the whole process of concept

development. In the phase of concept generation, a

customer requirements review is conducted based on

customer inputs. After confirming the customer

requirements, the design features and specifications

will be formulated as the inputs to the next step of

conceptual development process. In the phase of

development and evaluation, two knowledge-based

modules are proposed. A knowledge-based system

of product information determines the most

appropriate elements, e.g. components, material, and

tool, etc., based on the product concept and

requirements. Another knowledge-based system of

process planning decides the process plan for the

product in manufacturing. With these outputs, the

alternative product concepts will be compared with

the aid of a decision support system to confirm the

most suitable option.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

26

Figure 2: Framework of proposed product development

system.

3.2 Product Design Knowledge

Modelling and Support

According to the above knowledge support scheme,

the implementation of knowledge-based assisted

product design can be achieved through two steps:

(1) knowledge modeling; (2) the knowledge support

process, which are described in this section.

3.2.1 Product Design Knowledge Modeling

Fig. 3(a) illustrates the aspects related to product

design knowledge modeling, which include design

knowledge capture, classification, representation,

organization and management. The approach to

modeling information and knowledge for product

architecture and platform in terms of the semantics

used in platform product development is shown in

Fig. 4(b). The product structure and components of

the generic information platform are represented in

the physical domain of axiomatic design and

configuration rules and mappings are represented as

criteria and mappings between the functional,

physical, and process domains. It contains modeling

constructs for representing alternatives,

configuration rules and many other aspects of

product platforms. The purpose to adapt the

conceptual model to a standard: (1) provide

functionally and detailed information models; (2)

support the exchange of information between

applications and users (Sivard, 2001; Zheng, 2006).

With assistance of the product platform, customers’

requirements are satisfied either by standard models

or customer models configured from standard or

custom modules and/or components in knowledge-

based configuration systems.

Figure 3(a): Knowledge modeling in product design.

Figure 3(b): Generic platform information model.

3.2.2 Knowledge Modelling and

Representation for Product Design

Following the requirements of designing product

with a high degree of commonality around reusable

components, there are two main items of the

architecture are: (1) generic product specifications

and (2) reusable solution libraries. Product

architectures and component architecture are treated

in a similar way, enabling a hierarchical structure of

structures. Thus, components may be selected from

the solution library and integrated into the

framework.

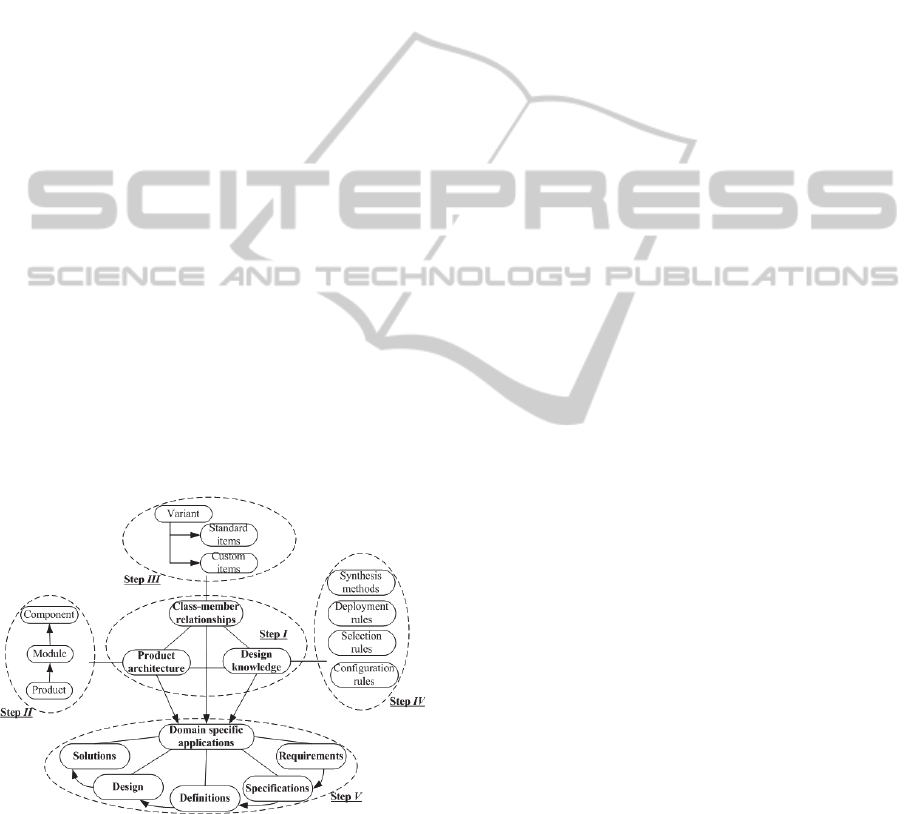

Figure 4 shows the construction process of

product platform (Step I – Step IV) and the reuse

for domain-specific applications (Step V). Hence, a

multi-level hybrid representation schema, e.g. meta

tier, conceptual tier, instance tier, geometric tier, is

adopted to represent the product design process

knowledge in different design stages at different

tiers, based on a combination of elements of

semantic relationships with the object-oriented data

model. To effectively manage and utilize design

knowledge, a generalized design knowledge matrix

is proposed, in which all tasks in the design process

are listed in column while all information and design

AProductDevelopmentSystemusingKnowledge-intensiveSupportApproach

27

knowledge is categorized in rows. The contents of

design knowledge for each task are recorded in the

corresponding cell of the matrix with appropriate

representations. Meanwhile, the object-oriented

knowledge representation is based on a mixed

representation method and object-oriented

programming techniques (Liang, 2010), and allows

designers to look at the design problem as a

collection of objects or sub-problems linked together

by rules. If a designer can break the design problem

into the form of well-defined, clearly manipulative

chunks with their own self-containing information,

which is interrelated through a series of rules and

constraints, then the problem can be easily solved.

The class of an object and its instances are depicted

by the module structure. An object-oriented module

is composed of several kinds of clusters: attribute,

relation, method, and rule: (i) Cluster attribute is

used for depicting the static attributes (parameters)

of design object; (ii) Cluster relation is applied for

expressing the static relations among objects.

According to the relation of classification, the design

object can be defined as a hierarchical structure. The

hierarchical structure of object-oriented knowledge

representation is formed; (iii) Cluster method is

defined for storing the methods of design, sending

messages and performing procedural control and

numerical calculation; (iv) Cluster rule is used for

keeping sets of production rules. The rules can be

categorized in accordance with the differences

among objects being treated and stored respectively.

Figure 4: Diagram for product platform construction

process.

The integrated knowledge representation scheme

realizes the advantages of both object-oriented

representation and rule-based representation. For

example, an object-oriented representation instance

for 3D polarized glasses suit and its parameterized

module information (e.g. bond and hinge modules)

are described. The modular design is proposed

(Liang, 2010), i.e., it is a collection of

interchangeable modules that can be assembled into

many different types and configurations. The model

presented above is being incorporated and fit into

the core product model (Szykman and Sriram, 2006)

developed recently at US National Institute of

Standards and Technology. In this connection, we

define a platform product represented by Class

Platform_Product in the Package Platform.

Information about differences between the product

members can be used for the development of an

extensible architecture of the common core assets,

and two processes may be involved:

platform/component construction and

platform/component evolution. CCM_Product

(component construction model) and CEM_Product

(component evolution model) are subclass of

Platform_Product and Product, representing

product platform (component) to be constructed and

evolved. These packages can support component

design for customization.

3.2.3 Knowledge Support Process for

Module Product Design

Once the design knowledge repository is built up,

the user or designer can utilize the knowledge in it to

solve problems in product design. Product variety

can be implemented at different layers within the

product architecture. A modular architecture has

clearly benefits in the areas of cost, product

performance and development.

Consequently, the procedure for developing a

modular product design can be outlined as follows:

(i) decompose products into their representative

functions; (ii) build modules with correspondence

with functions; (iii) organize common functional

modules into a product platform; and (iv)

standardize interfaces to facilitate addition, removal

and substitution of modules. The fundamental issues

underlying the product design include product

information modeling, product component

architecture, product platform and variety,

modularity and commonality, product generation,

and product assessment and customization.

Incorporating the above stages, the whole

knowledge supported modular product design

process can be fulfilled.

The knowledge support process in product

design evaluation for customization experiences the

elimination of unacceptable alternatives, the

evaluation of candidates, and the final decision-

making under the customers’ requirements and

design constraints (Mohamed and Celik, 2002). The

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

28

knowledge resources utilized in the process include

differentiating features, customers’ requirements,

assimilability, manufacturability, and heuristic

knowledge (e.g. production rules), etc. In applying

the above knowledge support scheme for modular

product design, the following should be noted: (i)

The first step, system requirement modeling and

analysis, should be considered in development of a

modular product design; (ii) A system and structured

approach is a mandatory for development of a

modular product design; (iii) A new product is

developed through functional analysis, rather than

modifying existing ones; (iv) Complex products or

systems have a considerable amount of constraints

that limit the product design.

3.2.4 Assessment of Product Design

Figure 5 illustrates an overall view of the proposed

fuzzy assessment model with design failure mode and

effective analysis (DFMEA), in which there are three

major stages to implement the assessment:

fuzzification, rule evaluation, and defuzzification

(Diaz-Hermida et al., 2005; Li et al., 2005). The

model firstly uses linguistic variables to depict the

severity, frequency of occurrence, and detectability of

the failure. These inputs are then fuzzified to

determine the degree of membership in each input

group. The resulting ‘fuzzy inputs’ are evaluated

using a linguistic rule base and fuzzy logic operations

to create a classification of the riskiness of the failure

mode and an associated degree of membership in the

risk group. This ‘fuzzy output’ is then defuzzified to

give the prioritization level for the failure mode. The

fuzzification process, using crisp gradings, converts

the severity, occurrence, and detectability inputs into

the fuzzy representations that can then be matched

with the premises of the rules in the rule base (Diaz-

Hermida et al., 2005; Li et al., 2005). The rule base

depicts the riskiness of each combination of input

variables. It is composed of the expert knowledge

about the interactions between various failure modes

and effect that is represented in the form of fuzzy ‘IF-

THEN’ rules. There are two parts included: an

antecedent that is compared to the inputs and a

consequence that is the result. For example, ‘IF t is P

THEN u is Q’ where P and Q are linguistic values

defined by fuzzy sets on the ranges t and u

respectively. The portion IF of the rule ‘t is P’ is

called the antecedent or premise, while the portion

THEN of the rule ‘u is Q’ is called the consequence or

conclusion. The antecedent is an interpretation that

returns a single number between 0 and 1, whereas the

consequence is an assignment that assigns the entire

fuzzy set Q to output variable u.

Figure 5: Diagram of a fuzzy criticality assessment model.

The importance of fuzzy ‘IF-THEN’ rules stems

from the fact that human expertise and knowledge

can often be represented in the form of fuzzy rules.

For the fuzzy criticality analysis, the system

expresses the seriousness of a failure through its

severity, the failure probability through its

occurrence and how easy a failure can be detected

through its detectability. The fuzzy inference process

uses min-max inferencing to estimate the rule

conclusions base on the system input values

(Ladneer et al., 2003). The result of this process is

called the fuzzy conclusion. The applicability of a

rule is determined from the conjunction of the rule

antecedents. The defuzzification process builds a

crisp grading from the fuzzy conclusion set to

express the riskiness of the design so that corrective

actions and design revisions can be prioritized. The

defuzzification process is required to figure out the

meaning of the fuzzy conclusions and their

membership values, and resolve conflicts between

different results, which may have been triggered

during the rule evaluation. Several defuzzification

algorithms have been developed (Li et al., 2005;

Roychowdhury and Pedrycz, 2001). One of the

widely used algorithms, center of gravity, is applied

as it gives the average, weighted by their degree of

truth, of the support values at which all the

membership functions that apply reach their

maximum value.

The design decision support subsystem (DIIS)

consists of several main units: attributes input,

criticality assessment, exploring and grading, and

graphical user interaction. These units are supported

by a knowledge base and a material database. The

operational procedure is described in the following

with reference to Figure 6(a). The initiatory lists

AProductDevelopmentSystemusingKnowledge-intensiveSupportApproach

29

created in a product analytical hierarchical structure

from the design requirement review (as illustrated in

Figure 6(b)), is input into the DIIS. Then, DIIS will

conduct the fuzzy criticality assessment on the

proposed components. The subsystem applies

linguistic variables to depict the severity, frequency

of occurrence, and detectability of the failure. All

these information in design failure mode effective

analysis can be represented by the commonly used

triangular membership function (Novák, 2005). The

evaluation criteria and fuzzy set definitions for

severity, occurrence, detectability, and risk are

shown in Table 1(a), 1(b), 1(c), and 1(d)

respectively. DIIS finally generates the risk priority

numbers to prioritize the risk of each component.

The results will be screened out for components

(materials) selection.

Figure 6(a): The architecture of design support decision.

Figure 6(b): Check list of product and its components

design review.

DIIS will then search appropriate components

(materials) based on the input information. Utilizing

the searching algorithm, the appropriate components

(materials) are listed with grading by scores. The

Table 1(a): Evaluation criteria of 3D polarized glasses suit

– severity.

Grade

Severit

y

effect

Description

1 none No effect.

2 low

Fit / tighten item does not conform.

Defect noticed by most customers.

Item operable, but

comfort/convenience item(s) operable

at reduced level of performance.

Customer experiences some

dissatisfaction.

3

moder

ate

Item operable, but

comfort/convenience item(s)

inoperable. Customer experiences

discomfort.

4 high

Item operable, but at reduced level of

performance.

Customer dissatisfied.

5

very

high

Item operable, with loss of primary

function.

Table 1(b): Evaluation criteria of 3D polarized glasses suit

– frequency of occurrence.

Grade Occurrence Description

Probability

(%)

Process

capability

1 seldom Unlikely

0

≧2.00

2 low Few 10

≧1.58

3 moderate Occasional 25

≧1.00

4 high Repeated 30

≧0.75

5 very high Inevitable

≧

50

≧0.51

Table 1(c): Evaluation criteria of 3D polarized glasses suit

– detectability.

Grade Detectability Description

1 definite

A potential cause is definitely

detected.

2 high

A potential cause is detected

in high chance.

3 moderate

A potential cause is detected

in moderate chance.

4 low

A potential cause is detected

in low chance.

5 none

A potential cause cannot be

detected, or

There is no design control.

Table 1(d): Evaluation criteria of 3D polarized glasses suit

– risk.

Grade Risk

Description (to take the

subsequent actions)

1 not important It’s not important

2 low It’s low priority

3 moderate Moderate priority

4 important It’s important

5

very

important

It’s very important

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

30

objective of the grading is to prioritize alternative

materials, relative to the order of importance of their

attributes to the designers. A quantitative scoring

system is applied for the grading process.

R

st

= C

rs

+C

cs

+C

re

R

st

: the summation of risk, cost and reliability of

component (material)

C

rs

: risk of the component (material)

in which the risk is rated from 0 to 5 with 0 is equal

to ‘not important’ and 5 is equal to ‘very important’

that is determined in the fuzzy criticality assessment

stage.

C

cs

: score of cost of component (material)

that the score of cost is rated from 0 to 5 with 0 is

equal to the most expensive and 5 is equal to the

most inexpensive.

C

re

: score of reliability of the component (material)

in which the score of reliability is rated from 0 to 1

with 0 is equal to the lowest reliability and 1 is equal

to the highest reliability.

The appropriate component (materials) can then be

selected by the product designer based on this

information. Finally, a proposed bill of material can

be created after all the components (materials) have

been selected and reviewed.

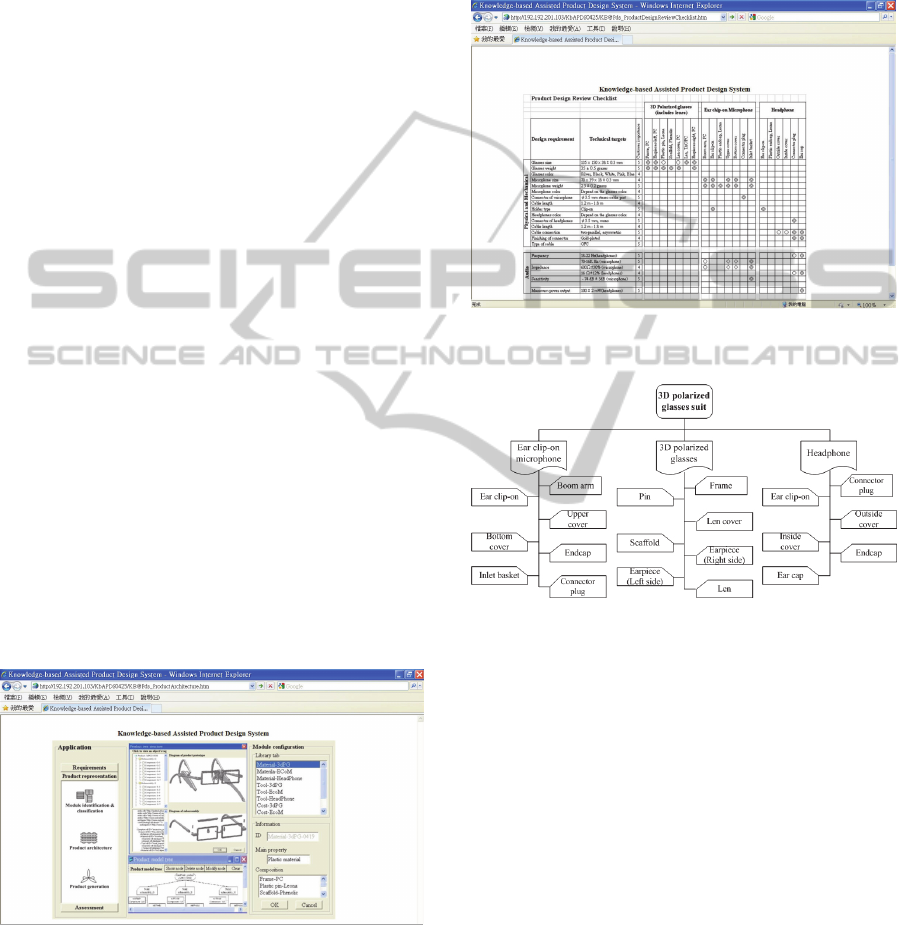

4 PROTOTYPE SYSTEM

To demonstrate the operations of the prototype

system, a case study on a 3D polarized glasses suit

for commercial entertainment application has been

conducted by using KB@Pds. Figure 7 gives a

screen snapshot of the prototype system used for

product design.

Figure 7: Screen snapshot of knowledge-based assisted

product design system.

The 3D polarized glasses suit is applied to watch

the 3D films, view 3D photos, play 3D interactive

games. After input the qualitative customer

requirements and product features to the phase of

concept generation (Chin et al., 2005), the initiatory

list was generated in design requirement review as

shown in Figure 8(a). According to the initiatory

list, the model type of the 3D polarized glasses suit

was proposed to be in 3dPG215EM and the level of

the product hierarchy structure was also constructed

as illustrated in Figure 8(b).

Figure 8(a): Output table of design requirement review

checklist.

Figure 8(b): Hierarchical structure of 3D polarized glasses

suit in model (No. 3dPG215EM).

The product designer determined the initiatory

list of the proposed 3D polarized glasses suit and

triggered the option boxes which next to the item list

of components by processing the graphical user

interface. After pressing the ‘Import’ button, the

value of severity, occurrence and detectability of

each component was shown on the DFMEA

inferencing interface, the product design then

adjusted the these values to get a more accurate

input. The next step is to prioritize the risk of each

component by DFMEA inferencing process with

fuzzy logic grading approach. To assist the fuzzy

DFMEA evaluation, a rule base is generated in the

form of rule matrix of the riskiness for DFMEA

analysis, is built in the prototype system (KB@Pds).

The graphical user interface of DIIS was as

illustrated in Figure 9(a). In the DFMEA inferencing

process, the risk of each component was prioritized

automatically with fuzzy logic grading algorithm

AProductDevelopmentSystemusingKnowledge-intensiveSupportApproach

31

according to the potential failure, effect, cause, and

the grading of severity, occurrence and detectiability

of each component. Finally, the bill of components

of the robustness product design was generated after

completing the alternative components selection by

means of DIIS through press the ‘Finish’ button. It is

shown in the form of a spreadsheet in Figure 9(b).

Figure 9(a): Fuzzy DFMEA assessment of 3D polarized

glasses suit.

Figure 9(b): Recommended bill of components for

proposed 3D polarized glasses suit.

5 CONCLUSIONS

This paper has proposed a knowledge-intensive

support approach and framework for knowledge-

based assisted product design and development. An

integrated modular platform-based product design

scheme is presented with knowledge assistance for

customer requirements’ modeling, product

architecture modeling, product platform

establishment, product generation, and product

variant assessment. The developed approach and

framework can be applied for capturing,

representing, and managing product design

knowledge and provide support in the design

process. Finally, the issues related to the

implementation of the knowledge support

framework are addressed.

The system is expected to help to optimize

product quality and reliability and costs and to

reduce the iterations of redesign so as to shorten the

development lead time. On the basis of the current

decision-making models used in the industry, the

KB@Pds has a modular structure to facilitate access

to the knowledge bases and to ensure its future

development and extension. A case study on a 3D

polarized glasses suit has been conducted by using

KB@Pds to illustrate the feasibility of the proposed

system. However, the current system only focuses

on the generation of simple product or component

design. For complex product, the framework could

be modified to cater the assembly operations.

ACKNOWLEDGEMENTS

This research is supported in part by the National

Science Council in Taiwan under contract number

NSC 101-2918-I-132-001, NSC 100-2511-S-132-

002-MY2 and NSC 101-2631-S-132-001-CC3.

Important parts of the system, especially the user

interface and programming, were developed by the

student Wang Cong-Jie.

REFERENCES

Chin, K. S., Lam, J., Chan, J. K. F., Poon, P. K. K., &

Yang, J. B. (2005). A CIM-OSA presentation of an

integrated product design review framework.

International Journal of Computer Integrated

Manufacturing, 84, 4, 260-278.

Desai, A. A., & Mital, A. (2010). Facilitating design for

assembly through the adoption of a proactive design

methodology. International Journal of Industrial

Engineering: Theory, Applications and Practice, 17, 2.

Diaz-Hermida, F., Losada, D. E., Bugarin, A., & Barro, S.

(2005). A probabilistic quantifier fuzzification

mechanism: the model and its evaluation for

information retrieval. IEEE Transactions on Fuzzy

Systems, 13, 5, 688-700.

Ladneer, R., Petry, F. E., & Cobb, M. A. (2003). Fuzzy set

approaches to spatial data mining of association rules.

Transactions in GIS, 7, 1, 123-138.

Li, D. C., Wu, C. S., & Chang F. M. M. (2005). Using

data-fuzzification technology in small data set learning

to improve FMS scheduling accuracy. International

Journal of Advanced Manufacturing Technology, 27,

3-4, 321-328.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

32

Liang, S. J. (2010). A web-based collaborative design

architecture for developing immersive VR driving

platform. International Journal of Computer

Integrated Manufacturing, 23, 10, 876-892.

Mohamed, A, & Celik, T. (2002). Knowledge-based for

alternative design, cost estimating and scheduling.

Knowledge-Based Systems, 15, 1, 177-188.

Roychowdhury, S., & Pedrycz, W. (2001). A survey of

defuzzification strategies. International Journal of

Intelligent Systems, 16, 6, 679-695.

Sivard, G. (2001). A generic information platform for

product families. Doctoral Thesis, Royal Institute of

Technology, Sweden, 2001.

Szykman, S., & Sriram R. D. (2006). Design and

implementation of the web-enabled NIST design

repository. ACM Transactions on Internet Technology,

6, 1, 85-116.

Zheng, J. (2006). General information platform of ITS

based on web service. IEEE International Conference

on Systems, Man and Cybernetics, Taipei, Taiwan, 8-

10 October, 4620-4624.

AProductDevelopmentSystemusingKnowledge-intensiveSupportApproach

33