Application of Bio-inspired Algorithm of Structural Optimization to

Automated Design

Mirosław Mrzygłód

Institute of Rail Vehicles, Cracow University of Technology, Al. Jana Pawla II 37, Cracow, Poland

Keywords: Structural Optimization, Bio-inspired Algorithm, Automated Design.

Abstract: The article presents the concept of methodology of automated design based on bio-inspired algorithm of

structural optimization. For the purposes of the automatic design, the constant criterion surface algorithm

(CCSA) is used The algorithm shapes the structure under constant constraint surface rule and gives

possibility to start optimization from a minimum volume arrangement. The automated design schema

considers a minimum effort of the designer that is limited to defining the loads and boundary conditions. To

ensure a high reliability of the automated design process, the CCSA algorithm was enriched by a procedure

of the structure continuity control. As illustrated in the chair example, the application of bio-inspired

algorithm in the automated design framework allows to obtain efficient solution.

1 INTRODUCTION

The high robustness of biological structures and

their mechanism of auto-elimination of weak

solutions can be taken as a direction of research on

the modern design methodology. In order to obtain

the optimum solutions fast it is necessary to

eliminate the restrictions of human mind.

The article presents a concept of methodology of

automated design based on bio-inspired algorithm of

structural optimization. The assumption of such

methodology is to reduce the contribution of the

designer in the designing process only to defining

loads and boundary conditions. For the purposes of

the automatic design, the constant criterion surface

algorithm (CCSA) will be used (Mrzyglod, 2012).

The algorithm belongs to generative evolutionary

design methods (Bentley, 1999) and use indirect

representation similar to the cellular automaton (CA)

algorithm (Tovar et al., 2006). However, the CA

algorithm uses local rules to modify the structure.

The CCSA algorithm is based on the principles

of constant stress surface rule. This idea was first

formulated by Mattheck and Burkhardt (1990) and

states that all biological structures follow the rule of

a constant stress at the surface. Though, the

condition of constant energy density at the free

surface of the optimized structure was first derived

by Wasiutyński (1960).

The CCSA algorithm gives the possibility to do

optimization with various constraints as well as to

solve multi-constraint problems. Moreover, it is also

possible to start the optimization procedure from a

minimum volume layout (unfeasible solution) and

growth structure to its optimum topology. To ensure

high reliability of the automated design process, the

algorithm was enriched by a procedure of the

structure continuity control. The procedure is based

on the intelligent strategy of void identification

(ISOVI) (Mrzyglod, 2011).

2 THE CONSTANT CRITERION

SURFACE ALGORITHM

The optimization problem can be formulated as

follows:

)(min

f

(1)

the constraints are:

jj

gxg

, j = [ 1,2, …, K ]

(2)

where:

= [

1

,

2

,…

N

] is a vector of design

variables defined as

i

i

i

and

are

respectively, intermediate and real material Young’s

modules; g

j

(x) are the criterion parameters;

j

g

are

302

Mrzygłód M..

Application of Bio-inspired Algorithm of Structural Optimization to Automated Design.

DOI: 10.5220/0004157803020305

In Proceedings of the 4th International Joint Conference on Computational Intelligence (ECTA-2012), pages 302-305

ISBN: 978-989-8565-33-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

the upper bounds of constraints. The N design

variables represent a pseudo-density (stiffness

parameter) of each finite element of the structures

that vary between

min

and 1. The lower boundary of

pseudo-density

min

is

introduced to prevent

singularity of the equilibrium problem.

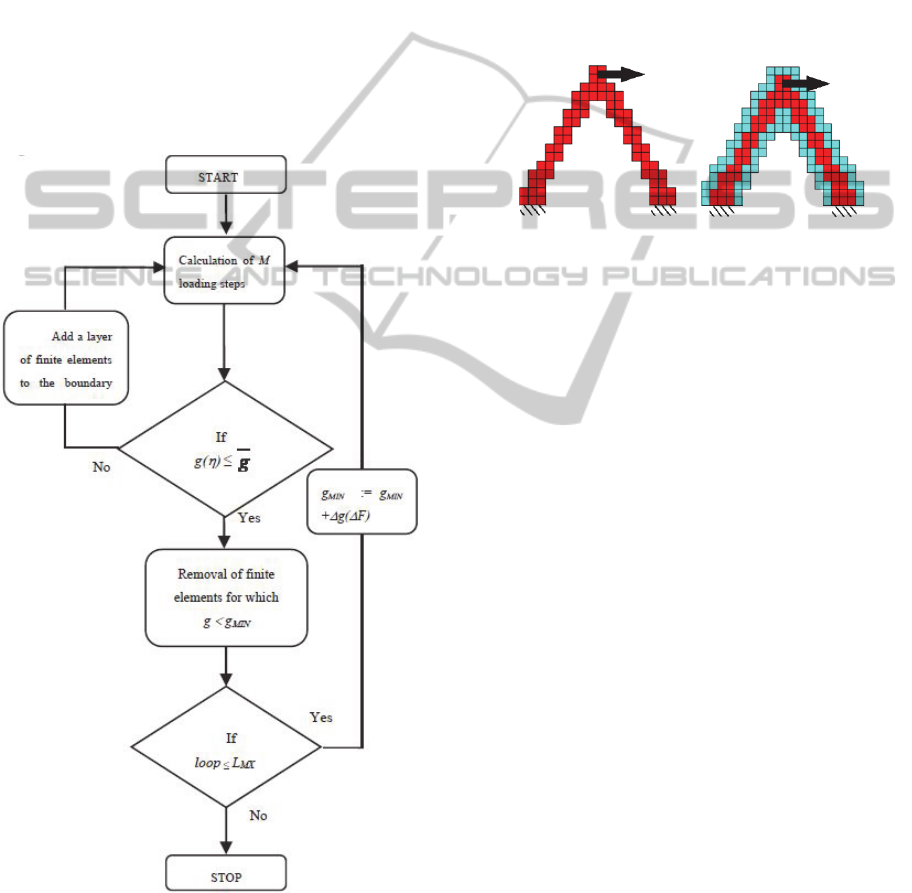

The CSSA algorithm consists of procedure of the

removal and adding procedure of FE elements (see

Fig. 1). The removal procedure of FE elements with

low values of constraint criterion parameters g is

similar to Evolutionary Structural Optimization

(ESO) approach introduced by Xie and Steven

(1993). However, in the CSSA algorithm the volume

value of optimized structure is not assumed a priori

what makes an important difference between those

algorithms.

Figure 1: The constant criterion surface algorithm.

The elimination procedure is controlled by a

F

parameter of volume percentage reduction. To select

the constant value of

F (usually 1%), a constraint

criterion increasing parameter

g at every volume

decreasing iteration is calculated. The FE elements

with values of constraint criterion parameters g

below the g

MIN

limit are eliminated from the

structure. For the volume increasing iteration, there

is no removal operation.

The stress-constrained topology optimization

procedure can give premature results when it is

stuck in point of high values of the state parameter.

In the CCSA algorithm when criterion function

is over the limit, a layer of finite elements is added

to the entire boundary of the structure (see Fig. 1,2).

(a) b)

Figure 2: The layer expansion algorithm: a structure

before (a) and after operation of adding a layer of finite

elements to the structure boundary (b).

The procedure of increasing the volume of the

structure is continued until the criterion parameter g

returns to admissible values. By increasing and

decreasing the structure volume, the algorithm

obtains better solutions after every ‘breakdown’.

This scheme is analogous to the simulated annealing

(SA) (Kirkpatrick et al., 1983).

Furthermore, to ensure reliability of the

optimization process, the continuity control

procedure has been added to the CCSA algorithm. It

prevents the optimization process from being

stopped because of FE solver error. For the

discontinuities detection, the ISOVI procedure based

on automatic pattern recognition is employed

(Mrzyglod, 2011). When the ISOVI procedure

detects a loss of structural continuity, the layer

expansion procedure is turned on. This procedure

will work until the structure returns to the continuity.

This can be treated as self-healing scheme of the

optimization procedure.

The CCSA method to take into account forces

that act in an asynchronous way on the structure, a

‘compare and save maximum’ procedure of

summation of constrain criterion values is proposed

(Mrzyglod, 2010). The procedure assumes, that

during each iteration for every finite element only

the maximum values of the constraint criterion of all

load cases will be written to the equivalent design

space.

ApplicationofBio-inspiredAlgorithmofStructuralOptimizationtoAutomatedDesign

303

The constraint values of final equivalent design

space are used by the constant criterion surface

algorithm of topology optimization.

For multi-constrained topology optimization

problems normalized constraints are introduced

(Mrzyglod, 2012).

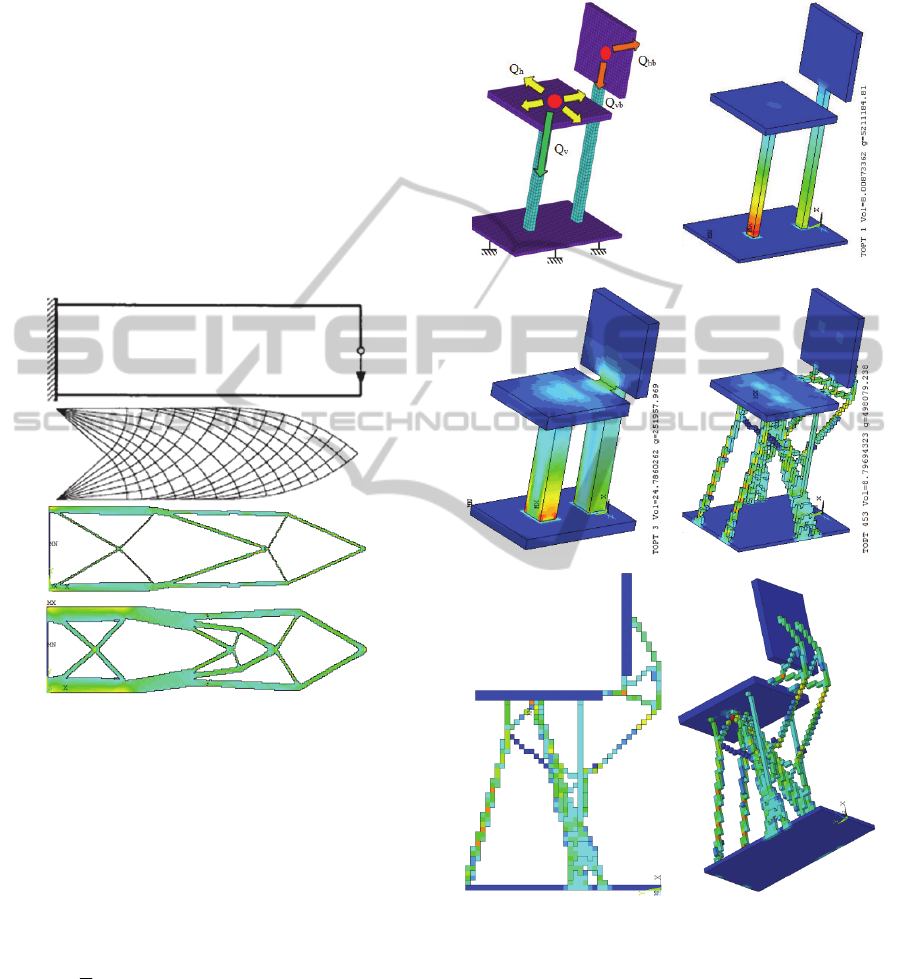

To test the convergence of the algorithm, the

benchmark problem of optimizing truss topology

was selected (Rozvany, 1998) (see Fig. 3a-b). In the

Fig. 3c-d the result of the tests are presented. The

obtained numerical solution is consistent with data

published in the literature for the compliance and

stress constraints (Bendsoe and Sigmund, 2003).

From the example, we can see clear dependency

of final solution on applied load values (see Fig. 3c-

d).

a)

b)

c)

d)

Figure 3: Benchmark problem (Rozvany, 1998): problem

description (a), analytical solution (b), numerical solution

for load Q (c), numerical solution for load 2 x Q (d).

3 EXAMPLE OF AUTOMATED

DESIGN

The chair structure was selected as the example of

automated design. In the example, the mass of the

structure is optimized with the von Mises stress

constraint (

g

= 0.5 MPa,

j = 1

).

The structure is subjected to complex and

asynchronous loading schema: a vertical force Q

v

that is acting on the seat of the chair; horizontal

forces Q

h

= 1/3 Q

v

that are acting in four directions

on the seat; a superposition of forces Q

vb

+ Q

hb

that

are acting on the back of the chair (Q

vb

= Q

hb

= ¼

Q

v

) (see Fig. 4a). The chair FE model with boundary

and results of automated design procedure of the

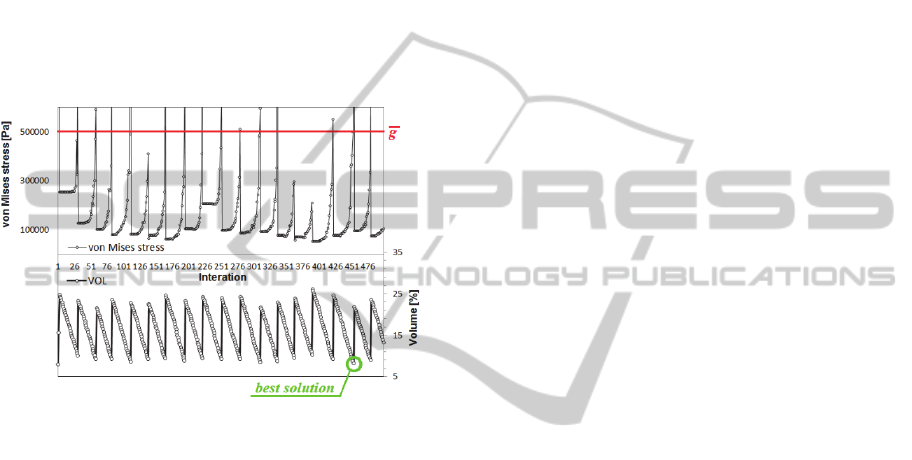

chair example are presented in Fig. 4a-f. The

history

of searching for a solution is shown

in the Fig. 5.

a) b)

c) d)

e) f)

Figure 4: Example of automated design: FE model with

boundary conditions (a); starting solution (unfeasible)

Vol=8.0% (Vol - percent of volume of the design space N

= 64400) (b); first feasible solution Vol=24.8% (c) best

solution Vol=8.8% (d, e, f).

4 CONCLUSIONS

In the article, the design methodology based on bio-

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

304

inspired algorithm is presented. In the algorithm

CCSA, the bio-inspired procedure of shaping the

structure in the form of constant criterion surface has

been joined with local minima avoidance scheme

based on simulated annealing. This ensure achieving

the high efficiency of optimal solution searching.

With the introduction of additional structure

continuity control, the optimization procedure has

been enriched by the possibility of self-repair which

significantly increases the reliability of the

optimization process. As illustrated in the example,

the application of the automated design framework

allowed to obtain efficient solution with minimum

effort of the designer.

Figure 5: Example of automated design: History of

searching for a solution (L

max

= 500).

REFERENCES

Bentley P. J. (Ed.), 1999. Evolutionary design by

computers, Morgan Kaufmann Publishers, San

Francisco, CA.

Bendsoe M. P., Sigmund O., 2003. Topology

Optimization. Theory, Methods, and Applications,

Springer Verlag, New York.

Mattheck C., Burkhardt S., 1990. A new method of

structural shape optimisation based on biological

growth, Int. J. Fatigue, 12(3), 185-190.

Mrzyglod, M., 2010. Two-stage optimization method with

fatigue constraints for thin-walled structures, Journal

of Theoretical and Applied Mechanics, 48(3), 567-

578.

Mrzyglod, M., 2011. A Method of Voids Size

Identification for 2D and 3D Topology. The 2nd

International Conference on Inverse Problems in

Mechanics, IPM2011 ECCOMAS Thematic

Conference, Rzeszow University of Technology, 73–

74.

Mrzyglod M., 2012. Multi-constrained topology

optimization using constant criterion surface

algorithm, Bulletin of the Polish Academy of Sciences

- Technical Sciences, 60(2), 229-236.

Kirkpatrick S., Gelatt C.D., Vecchi M. P., 1983.

Optimization by Simulated Annealing, Science, 220,

671-680.

Rozvany G. I. N., 1998. Exact analytical solutions for

some popular benchmark problems in topology

optimization, Struct Optim 15, 42–48.

Tovar A., Patel N. M., Niebur G. L., Sen M., Renaud J. E.,

2006. Topology Optimization Using a Hybrid Cellular

Automaton Method with Local Control Rules, ASME

Journal of Mechanical Design, 128(6), 1205-1216.

Wasiutyński Z., 1960. On the congruency of the forming

according to the minimum potential energy with that

according to equal strength, Bull. De L’Academie

Polonaise des Sciences, Serie des Sciences

Techniques, 8(6), 259-268.

Xie Y. M., Steven G. P., 1993. A simple evolutionary

procedure for structural optimization, Comput. Struct.,

49, 885-896.

ApplicationofBio-inspiredAlgorithmofStructuralOptimizationtoAutomatedDesign

305