A Methodology for the Design of Fuzzy Fractional PID Controllers

Ramiro S. Barbosa and Isabel S. Jesus

GECAD - Knowledge Engineering and Decision Support Research Center, ISEP/IPP - School of Engineering,

Polytechnic Institute of Porto,

Rua Dr. Antonio Bernardino de Almeida, 431, Porto, Portugal

Keywords:

Fuzzy Control, PID Controller, Fractional Calculus, Fractional PID Control, Fuzzy Fractional PID Control.

Abstract:

This paper proposes two novel fuzzy fractional PID structures. The tuning of the fuzzy fractional controllers

is based on the prior knowledge of fractional-order control tuning rules. The digital implementation of these

controllers is also investigated. The effectiveness and robustness of the proposed tuning methodology is illus-

trated through its application on a fractional-order plant. The simulations results show that the control system

performance is better than that of conventional fractional PID control.

1 INTRODUCTION

In recent years, the fractional-order PID (FO-PID)

controllers have been a fruitful field of research (Pod-

lubny, 1999a; Podlubny, 1999b). However, no effec-

tive and simple tuning rules still exist for these con-

trollers as those given for the integer PID controllers

(Astrom and Hagglund, 1995). It is well known that

the FO-PID extends the capabilities of the classical

counterpart and, thus, have a wider domain of appli-

cation, such as in suspension systems, robotics, sig-

nal processing, control and diffusion (Oldham and

Spanier, 1974; Podlubny, 1999a; Podlubny, 1999b).

On the other hand, the fuzzy logic controllers (FLC)

have also been successfully applied in the control of

many physical systems, particularly those with un-

certainty, unmodelled, disturbed and/or nonlinear dy-

namics (Lee, 1990; Li and Gatland, 1996; Carvajal

et al., 2000).

In this paper, we combine the features of fuzzy

controllers with those of fractional controllers of PID-

type. The resulting fuzzy fractional PID (FF-PID)

controller is investigated in terms of its digital imple-

mentation and robustness. The combined advantages

of the two controllers results in a better controller with

superior robustness and wider domain of application.

The tuning methodology of these controllers is based

on the prior knowledge of fractional-order control.

First, a fractional-order controller is built and tuned

(or used one already implemented). Then, we replace

it with a linear fuzzy fractional controller displaying

exactly the same step response. After, we make the

controller nonlinear and fine tune it in order to get

better control of the system. The fuzzy fractional con-

troller will give, at least, the same performance of its

linear counterpart.

The paper is organized as follows. Section 2

presents the basic ideas of continuous and discrete

fractional PID controllers. Section 3 outlines a pro-

cedure for the design of FF-PID controllers. In sec-

tion 4, we test the proposed fuzzy fractional con-

trollers and assess their applicability and robustness

on a fractional-order plant. Finally, section 5 draws

the main conclusions and addresses perspectives to

future developments.

2 FRACTIONAL PID

CONTROLLERS

The fractional-order controller of PID-type, usually

named PI

λ

D

µ

controller, may be given as (Podlubny,

1999b; Barbosa et al., 2010):

C(s) =

U (s)

E (s)

= K

p

+

K

i

s

λ

+ K

d

s

µ

(1)

where K

p

, K

i

and K

d

are the proportional, inte-

gral and derivative gains, and usually the fractional

orders (λ, µ) ∈ [0, 1]. Clearly, taking (λ, µ) ≡

{(1, 1), (1, 0), (0, 1), (0, 0)} we get the classical

{PID, PI, PD, P}-controllers, respectively. The

PI

λ

D

µ

-controller is more flexible and gives the possi-

bility of adjusting more carefully the dynamical pro-

prieties of a control system (Podlubny, 1999b).

276

S. Barbosa R. and S. Jesus I..

A Methodology for the Design of Fuzzy Fractional PID Controllers.

DOI: 10.5220/0004586702760281

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 276-281

ISBN: 978-989-8565-70-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

The time domain equation of the PI

λ

D

µ

controller

is:

u(t) = K

p

e(t)+ K

i

D

−λ

e(t)+ K

d

D

µ

e(t) (2)

where D

(∗)

(≡

0

D

α

t

) denotes the differential operator

of integration and differentiation (differintegral) to a

fractional-order α = {−λ, µ} ∈ ℜ.

The two most commonly used definitions for the

differintegral are the Riemann-Liouville definition

and the Gr¨unwald-Letnikov definition. For our pur-

pose we use the Gr¨unwald-Letnikov definition, which

can be written as (α ∈ ℜ):

D

α

f (t) = lim

h→0

1

h

α

[t

/

h]

∑

j=0

(−1)

j

α

j

f (t − jh) (3a)

α

j

=

Γ(α + 1)

Γ( j+ 1)Γ(α− j + 1)

(3b)

where f(t) is the applied function, Γ(·) is the Gamma

function, h is the time increment, and [·] means the

integer part.

From a control and signal processing perspective,

approach (3) seems to be the most useful and intu-

itive, particularly for a discrete-time implementation

(Barbosa et al., 2006; Machado, 1997). In fact, using

(3), a discrete fractional PI

λ

D

µ

control equation can

be obtained from (2) as (h ≈ T, T is the sampling

period):

u(k) = K

p

e(k) + K

i

D

−λ

e(k) + K

d

D

µ

e(k) (4)

with

D

α

e(k) ≈

1

T

α

k

∑

j=0

(−1)

j

α

j

e(k − j) (5)

The difference control equation (4) is then given

by:

u(k) = K

p

e(k) +

K

i

T

−λ

k

∑

j=0

(−1)

j

−λ

j

e(k − j)

+

K

d

T

µ

k

∑

j=0

(−1)

j

µ

j

e(k − j) (6)

Eq. (6) shows that the current value of control sig-

nal u(k) depends on all previous values of error e(k),

making the computation too heavy as time increases

and so unsuitable for a practical implementation of

these algorithms. This fact illustrates the global char-

acter (i.e., unlimited memory) of the fractional-order

operators. For practical implementation of fractional

integral and derivative (5) we often apply the short

memory principle (Podlubny, 1999a), resulting in ex-

pression:

u(k) = K

p

e(k) +

K

i

T

−λ

k

∑

j=v

c

(−λ)

j

e(k − j)

+

K

d

T

µ

k

∑

j=v

c

(µ)

j

e(k − j) (7)

where v = 0 for k < L

T or v = k−L

T for k > L

T;

L is the memory length and c

(α)

j

= (−1)

j

α

j

are

the binomial coefficients which may be calculated re-

cursively as:

c

(α)

0

= 1; c

(α)

j

=

1−

1+ α

j

c

(α)

j−1

, j = 1, 2, ···

(8)

Note that (7) is given in the form of a FIR filter.

Other discrete-time approximations in the form of IIR

filters are also possible (Vinagre et al., 2003; Barbosa

et al., 2006; Chen et al., 2004).

3 DESIGN OF FUZZY

FRACTIONAL PID

CONTROLLERS

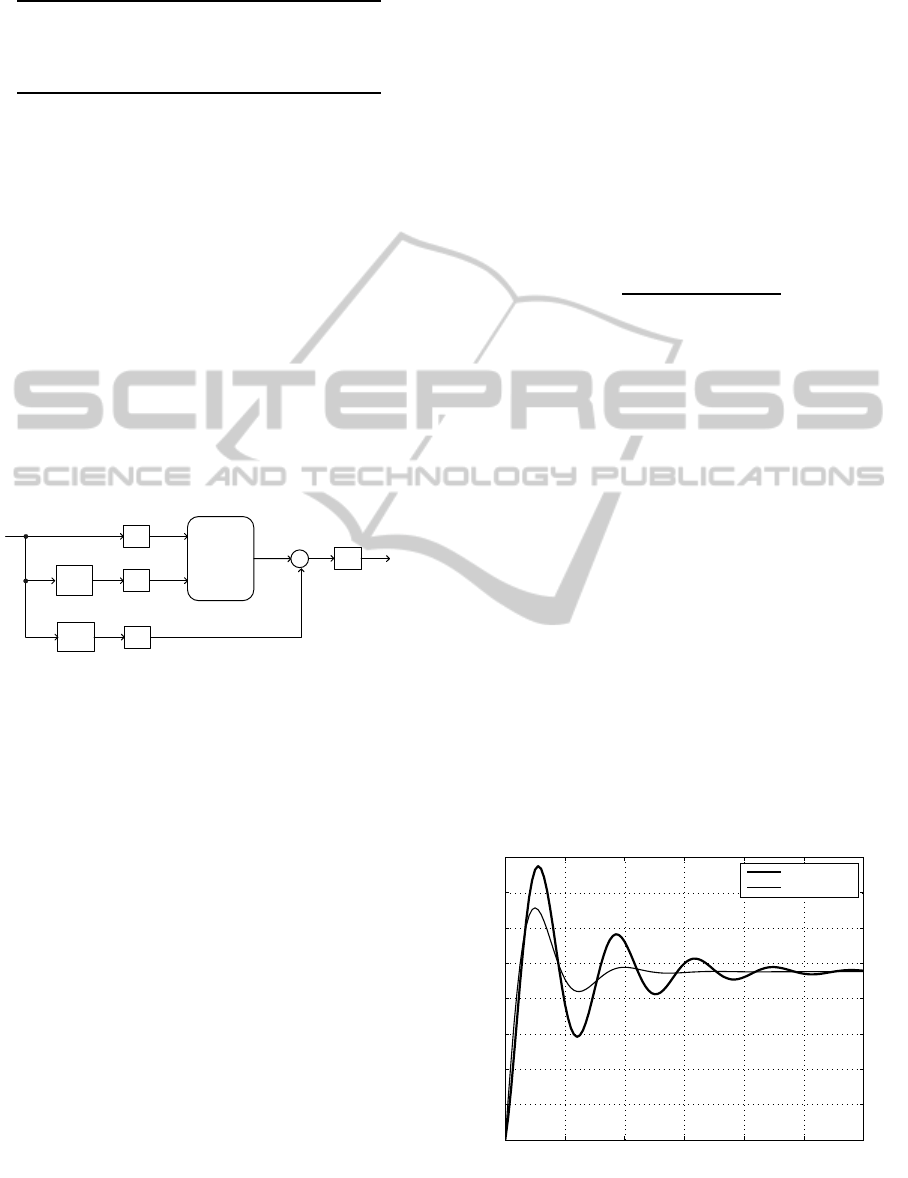

Despite of variety of possible fuzzy controller struc-

tures, the controller is usually arranged in cascade

with the system being controlled. This type of ar-

rangement is shown in Fig. 1 and will be used in this

study.

The main idea here is to explore the fact that the

FLC, under certain conditions, is equivalent to a PID

controller (Mizumoto, 1995; Li and Gatland, 1996;

Jantzen, 2007). In a certain sense, the fuzzy PID con-

trollers are a special case of the more general FF-PID

controllers, in which are involved two extra tuning

parameters: the fractional orders (λ, µ) of controller

equation (4).

The basic form of a fuzzy controller is illustrated

in Fig. 2 (Passino and Yurkovich, 1998). In gen-

eral, the mapping between the inputs and the outputs

−

+

G(s)

Fuzzy

Fractional

Controller

r(t) y(t)

u(t)

e(t)

l(t)

+

+

Figure 1: Fuzzy fractional PID controlled system.

AMethodologyfortheDesignofFuzzyFractionalPIDControllers

277

Rule Base

Fuzzy

inference

Fuzzification

Defuzzification

Input Output

Figure 2: Structure of a fuzzy controller.

of a fuzzy system is nonlinear (Galichet and Foulloy,

1995; Jantzen, 2007). However, it is possible to con-

struct a rule base with a linear input-output mapping

(Mizumoto, 1995; Jantzen, 2007). For that, the fol-

lowing conditions must be fulfilled:

• Use triangular input sets that cross at the member-

ship value 0.5;

• The rule base must be complete AND combina-

tion (cartesian product) of all input families;

• Use the algebraic product (*) for the AND con-

nective;

• Use output singletons, positioned at the sum of the

peak positions of the input sets;

• Use sum-accumulation and centre of gravity for

singletons (COGS) defuzzification.

It seems reasonable to start with the design of

a conventional integer/fractional PID controller and

from there to proceed to a fuzzy control design. In

this way, the linear fuzzy controller may be used in a

design procedure based on integer/fractionalPID con-

trol, as follows (Jantzen, 2007; Barbosa et al., 2010;

Barbosa, 2010):

1. Build and tune an integer/fractional PID con-

troller;

2. Replace it with an equivalent linear fuzzy con-

troller;

3. Make the fuzzy controller nonlinear;

4. Fine-tune it.

With the above procedure, the design of fuzzy

fractional PID controllers will be greatly simplified,

particularly if the controller was already implemented

and it is desirable to enhance its performance. More-

over, this new type of controllers extends the poten-

tialities of both fuzzy and fractional controllers and

performs, at least, as well as its linear fractional coun-

terpart (Jantzen, 2007; Barbosa et al., 2010; Barbosa,

2010).

3.1 Fuzzy Fractional PD Controller

The time-domain equation of a fractional PD

µ

-

controller is given by (K

i

= 0 in (2)):

u(t) = K

p

e(t) + K

d

D

µ

e(t) (9)

The corresponding discrete-time fractional PD

µ

-

controller is:

u(k) = K

p

e(k) + K

d

D

µ

e(k) (10)

Fig. 3 illustrates the block diagram of the fuzzy

fractional PD

µ

(FF-PD

µ

) controller. As can be seen,

the controller acts on the error, E = K

e

e(k), and on

the fractional change of error, FE = K

fe

D

µ

e(k). The

control signal is U = K

u

u. The controller has three

tuning gains, K

e

and K

fe

, corresponding to the inputs

and K

u

to the output.

The control signalU is generally a nonlinear func-

tion of E and FE:

U = f(E, FE)K

u

= f (K

e

e, K

fe

D

µ

e)K

u

(11)

With a proper choice of design, a linear approxi-

mation can be obtained as:

f (K

e

e(k), K

fe

D

µ

e(k)) ≈ K

e

e(k)+K

fe

D

µ

e(k) (12)

and

U (k) = (K

e

e(k) + K

fe

D

µ

e(k))K

u

= K

e

K

u

e(k) + K

fe

K

u

D

µ

e(k) (13)

Comparing (13) with (10), it yields the relation for

the gains of the two controllers:

K

e

K

u

= K

p

K

fe

K

u

= K

d

(14)

The linear FF-PD

µ

-controller provides all the

advantages of the conventional fractional PD

µ

-

controller.

For an equivalent linear FF-PD

µ

-controller, the

conclusion universe should be the sum of the premise

universes and the input-output mapping should be lin-

ear. Table 1 lists a linear rule base for the FF-PD

µ

controller composed of four rules. There are only

two fuzzy labels (Negative and Positive) used for the

fuzzy input variables and three fuzzy labels (Negative,

Zero and Positive) for the fuzzy output variable. This

rule base should satisfy conditions mentioned above

in order to provide a linear mapping.

FF-PD

µ

Rule base

E

FE

Uu

e

u

K

fe

K

e

K

µ

D

Figure 3: Fuzzy fractional PD

µ

-controller.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

278

Table 1: Rule base for the FF-PD

µ

controller.

Rule 1 If E is N and FE is N then u is N

Rule 2 If E is N and FE is P then u is Z

Rule 3 If E is P and FE is N then u is Z

Rule 4 If E is P and FE is P then u is P

Scaling the input gains may be necessary to pre-

serve the linearity of the fuzzy controller. However,

that should be made without affectingthe tuning (Bar-

bosa et al., 2010; Barbosa, 2010). This scaling has

some advantages, as it will avoid saturation and will

provide a simpler design, since the universes ranges

of inputs and outputs are normalized to a prescribed

interval, say percentage of full scale [−100, 100].

3.2 Fuzzy Fractional PID Controller

The inclusion of an integral action is necessary when-

ever the closed-loop system exhibits a steady-state er-

ror. The fuzzy fractional PD

µ

+I

λ

(FF-PD

µ

+I

λ

) con-

troller combine the fractional-order integral action

with a fuzzy PD

µ

-controller, as illustrated in Fig. 4.

FF-PD

µ

Rule base

E

FE

U

u

e

u

K

fe

K

e

K

µ

D

fie

K

FIE

+

+

λ−

D

Figure 4: Fuzzy fractional PD

µ

+ I

λ

controller.

The control signalU is generally a nonlinear func-

tion of error E, fractional change of error FE, and

fractional integral of error FIE:

U = ( f (E, FE) + FIE) K

u

=

f (K

e

e(k) + K

fe

D

µ

e(k)) + K

fie

D

−λ

e(k)

K

u

(15)

Adopting the linear approximation (12) yields the

control action:

U (k) ≈

K

e

e(k) + K

fe

D

µ

e(k) + K

fie

D

−λ

e(k)

K

u

= K

u

K

e

e(k) + K

u

K

fe

D

µ

e(k) + K

u

K

fie

D

−λ

e(k) (16)

Comparing (16) with the discrete fractional PI

λ

D

µ

-

controller (4), it yields the relation for the gains of

the two controllers:

K

e

K

u

= K

p

K

fie

K

u

= K

i

K

fe

K

u

= K

d

(17)

The linear FF-PD

µ

+I

λ

controller provides all the

advantages of the conventional fractional PI

λ

D

µ

-

controller.

4 ILLUSTRATIVE EXAMPLE

Many real dynamical processes are modeled by

fractional-order transfer functions (Podlubny, 1999a;

Oldham and Spanier, 1974). Here we consider

the fractional-order plant model given in (Podlubny,

1999b):

G(s) =

1

0.8s

2.2

+ 0.5s

0.9

+ 1

(18)

An integer-order PD controller and a fractional-

order PD

µ

-controller were designed in (Podlubny,

1999b):

C

PD

(s) = 20.5+ 2.7343s (19)

C

PD

µ

(s) = 20.5+ 3.7343s

1.15

(20)

Fig. 5 shows the unit-step response of the closed-

loop fractional-order system with the conventional

PD-controller and with the PD

µ

-controller. The com-

parison shows that for satisfactory feedback con-

trol of the fractional-order system is better to use a

fractional-order controller. Note, however, that the

control system presents a steady-state error, since no

integral action is employed.

Let us now design an equivalent linear FF-PD

µ

controller. By configuring the fuzzy inference system

(FIS) and selecting three scaling factors, we obtain a

FF-PD

µ

-controller that reproduces the exact control

performance as the fractional PD

µ

-controller. We first

fix K

e

= 100, since the error universe is chosen to be

0 1 2 3 4 5 6

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

Time [s]

Plant output

PD−controller

PD

µ

−controller

Figure 5: Unit-step responses of the fractional-order control

system with the PD and PD

µ

-controllers.

AMethodologyfortheDesignofFuzzyFractionalPIDControllers

279

−100

0

100

−100

0

100

−200

0

200

E

FE

u

−100 0 100

0

0.2

0.4

0.6

0.8

1

Input family: Neg and Pos

Degree of membership

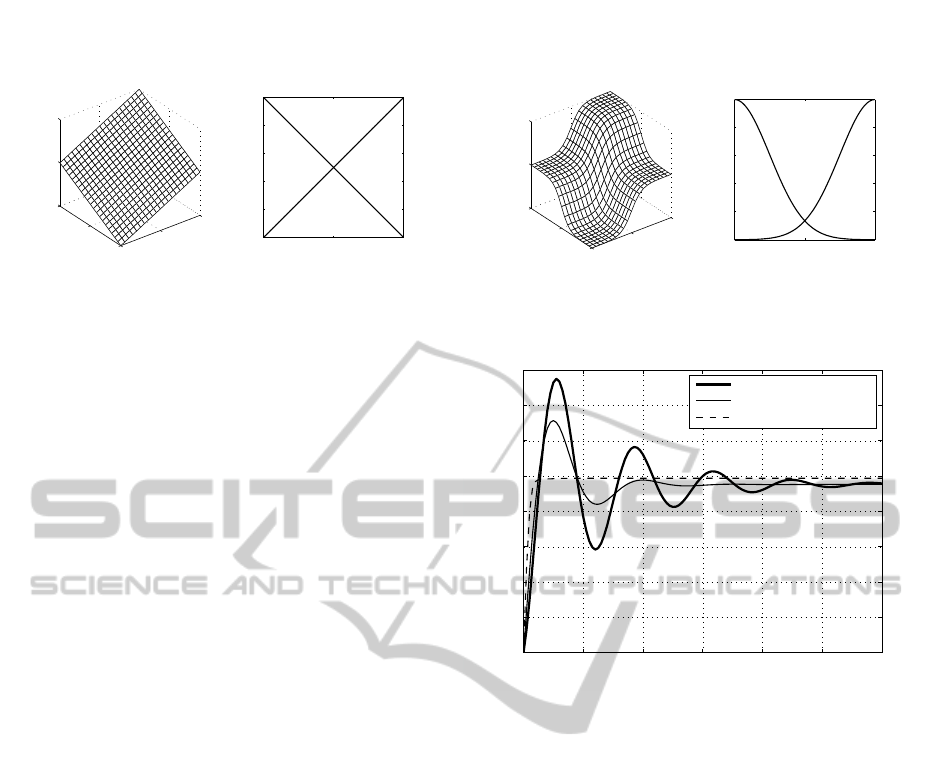

Figure 6: Linear surface with the corresponding input fam-

ilies.

percentage of full scale [−100, 100], and the maxi-

mum error to a unit step is 1. The values of K

fe

and

K

u

are obtained using expressions (14). Fig. 6 shows

the input families and the linear control surface ob-

tained by using the rule base of Table 1 while satis-

fying conditions outlined in section 3. Note that this

result represents the step 2 – replace the conventional

controller with an equivalent linear fuzzy controller –

of the design procedure. In order to enhance the per-

formance of the control system we proceed to step 3

and 4 of the design – make the fuzzy controller non-

linear and fine-tune it.

Thus, after verifying that the linear FF-PD

µ

-

controller is properly designed, we may adjust the FIS

settings such as its style, membership functions and

rule base to obtain a desired nonlinear control sur-

face. In our example, we choose Gaussian member-

ship functions for the inputs, as illustrated in Fig. 7

with the corresponding nonlinear control surface.

In Fig. 8, the comparison of the unit-step response

of the closed-loop system with plant model (18) con-

trolled by the linear PD and FF-PD

µ

-controllers, and

with the nonlinear FF-PD

µ

-controller is given. The

simulation parameters are: absolute memory compu-

tation of approximation (5), fractional-order µ=1.15,

scale factor M = 0.4 and T = 0.05 s. As can be seen,

making the controller nonlinear improved the control

system performance, namely the overshoot, rise time,

settling time, and steady-state error, when compared

with the linear fuzzy controller. The fuzzy fractional

controller provides greater flexibility than the frac-

tional controller and can be used to better adjust the

dynamical properties of a control system.

Now, let us consider the FF-PD

µ

+I

λ

-controller. In

order to test the robustness of the fuzzy controller, we

introduce a load disturbance of amplitude l = 2 after

7 seconds in system of Fig. 1. We use the same (K

p

,

K

d

) parameters of the linear FF-PD

µ

-controller and

tuned the (K

i

, λ) for a satisfactory control response.

The final tuned parameters are (K

i

, λ) = (10, −0.8).

With K

e

= 100, and using (17) we obtain K

fe

, K

u

, and

K

fie

of the fuzzy controller.

−100

0

100

−100

0

100

−200

0

200

E

FE

u

−100 0 100

0

0.2

0.4

0.6

0.8

1

Input family: Neg and Pos

Degree of membership

Figure 7: Nonlinear control surface with the corresponding

input families.

0 1 2 3 4 5 6

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

Time [s]

Plant output

PD−controller

FF−PD

µ

−controller

Nonlinear FF−PD

µ

−controller

Figure 8: Unit-step responses of the fractional control sys-

tem with the linear PD and FF-PD

µ

-controllers, and with

the nonlinear FF-PD

µ

-controller.

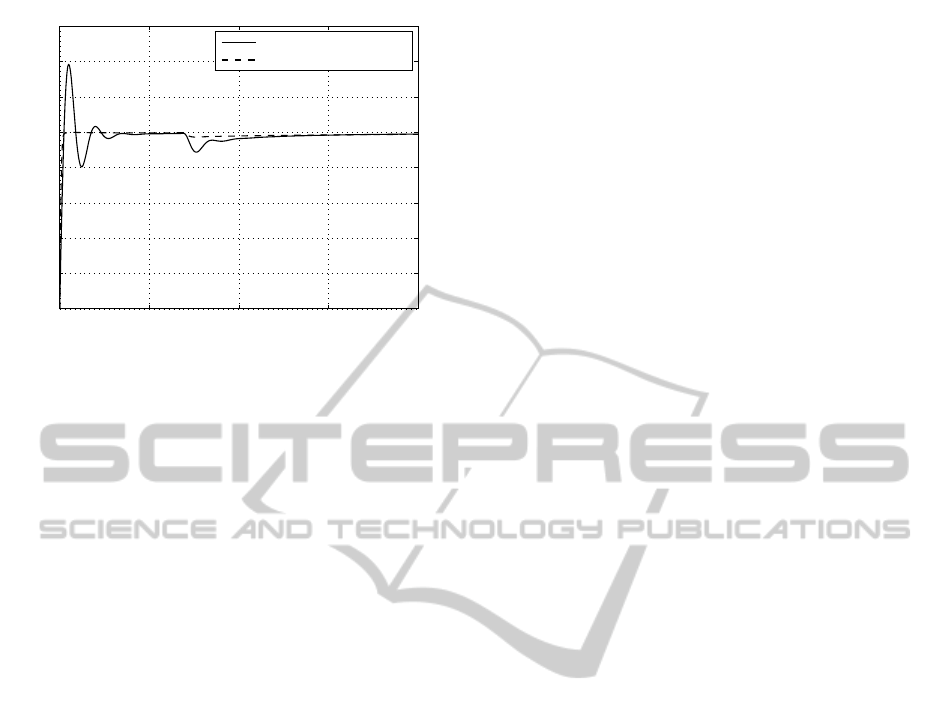

In this experiment, the simulation parameters are:

absolute memory computation of approximation (5),

scale factor M = 0.1 and T = 0.05 s. Fig. 9 shows the

step and load responses of closed-loop system with

FF-PD

µ

+I

λ

controller, (µ, λ)=(1.15, −0.8), for the lin-

ear and nonlinear control surfaces. We observe the

better response of the fuzzy controller to the reference

and disturbance inputs with the nonlinear rule base

compared to their linear counterpart. Once more, we

demonstrate the robustness and effectiveness of this

type of controller.

5 CONCLUSIONS

This paper introduced two novel fuzzy fractional PID

structures: the FF-PD

µ

and FF-PD

µ

+I

λ

controllers. It

was demonstrated that these controllers are equiva-

lent to the conventional fractional PD and PID con-

trollers by using a linear input-output mapping of the

rule base of the fuzzy fractional controller. Moreover,

by making the controller nonlinear, the performance

of the control system proves to be, in most systems,

better than its linear counterpart. A methodology for

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

280

0 5 10 15 20

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

Time [s]

Plant output

Linear FF−PD

µ

+I

λ

controller

Nonlinear FF−PD

µ

+I

λ

controller

Figure 9: Unit-step and load responses of the fractional con-

trol system with the linear and nonlinear FF-PD

µ

+I

λ

con-

trollers.

tuning the nonlinear fuzzy fractional PID controllers

is also presented. This methodology is simple and

effective and can be used to replace an existent frac-

tional/integer PID controller in order to get better per-

formance of the control system. In this perspective,

future research on this topic includes the application

of the proposed fuzzy fractional PID controllers and

tuning methodology in other types of linear and non-

linear plants of integer and/or fractional-order. We

expect that the incorporation of fuzzy reasoning into

fractional-order controllers will increase the applica-

bility of these controllers.

ACKNOWLEDGEMENTS

This work is supported by FEDER Funds through

the ”Programa Operacional Factores de Competitivi-

dade - COMPETE” program and by National Funds

through FCT ”Fundac¸˜ao para a Ciˆencia e a Tecnolo-

gia”.

REFERENCES

Astrom, K. J. and Hagglund, T. (1995). PID Controllers:

Theory, Design, and Tuning. Instrument Society of

America, USA.

Barbosa, R. S., , Jesus, I. S., and Silva, M. F. (2010). Fuzzy

reasoning in fractional-order PD controllers. In Pro-

ceedings of AIC’10, 10th WSEAS International Con-

ference on Applied Informatics and Communications,

pages 252–257, August 20-22, Taipei, Taiwan.

Barbosa, R. S. (2010). On linear fuzzy fractional pd and

pd+i controllers. In Proceedings of FDA’10, 4th IFAC

Workshop Fractional Differentiation and its Applica-

tions, pages 1–6, October 18-20, Badajoz, Spain.

Barbosa, R. S., Machado, J. A. T., and Silva, M. F. (2006).

Time domain design of fractional differintegrators

uing least-squares. Signal Processing, 86:2567–2581.

Carvajal, J., Chen, G., and Ogmen, H. (2000). Fuzzy

PID controller: Design, performance evaluation, and

stability analysis. Journal of Information Science,

123:249–270.

Chen, Y. Q., Vinagre, B. M., and Podlubny, I. (2004).

Continued fraction expansion approaches to discretiz-

ing fractional order derivatives-an expository review.

Nonlinear Dynamics, 38:155–170.

Galichet, S. and Foulloy, L. (1995). Fuzzy controllers: Syn-

thesis and equivalences. IEEE Transactions on Fuzzy

Systems, 3(2):140–148.

Jantzen, J. (2007). Foundations of Fuzzy Control. Wiley

and Sons, Chichester, England.

Lee, C. C. (1990). Fuzzy logic in control systems: fuzzy

logic controller-Part I and II. IEEE Transactions on

System Man, and Cybernetics-Part B: Cybernetics,

20(2):404–435.

Li, H.-H. and Gatland, H. B. (1996). Conventional fuzzy

control and its enhancement. IEEE Transactions on

System Man, and Cybernetics-Part B: Cybernetics,

26(5):791–797.

Machado, J. A. T. (1997). Analysis and design of fractional-

order digital control systems. SAMS Journal of Sys-

tems Analysis, Modelling and Simulation, 27:107–

122.

Mizumoto, M. (1995). Realization of PID control by fuzzy

control methods. Fuzzy Sets and Systems, 70:171–

182.

Oldham, K. B. and Spanier, J. (1974). The Fractional Cal-

culus. Academic Press, New York.

Passino, K. M. and Yurkovich, S. (1998). Fuzzy Control.

Addison-Wesley, Menlo Park, California.

Podlubny, I. (1999a). Fractional Differential Equations.

Academic Press, San Diego.

Podlubny, I. (1999b). Fractional-order systems and PI

λ

D

µ

-

controllers. IEEE Transactions on Automatic Control,

44(1):208–214.

Vinagre, B. M., Chen, Y. Q., and Petras, I. (2003). Two di-

rect tustin discretization methods for fractional-order

differentiator/integrator. Journal of the Franklin Insti-

tute, 340:349–362.

AMethodologyfortheDesignofFuzzyFractionalPIDControllers

281