Two-dimensional Numerical Simulation Method for Convective Flow

Structure Induced by Chemical Concentration Waves

Atsushi Nomura

1

, Tatsunari Sakurai

2

and Hidetoshi Miike

3

1

Faculty of Education, Yamaguchi University, Yoshida 1677-1, Yamaguchi 753-8513, Japan

2

Graduate School of Science, Chiba University, Inageku Yayoicho 1-33, Chiba 263-8522, Japan

3

Organization for Research Initiatives, Yamaguchi University, Tokiwadai 2-16-1, Ube 755-8611, Japan

Keywords:

Belousov-Zhabotinsky (BZ) reaction, elastic surface, Marangoni effect, Navier-Stokes equation.

Abstract:

This paper presents a two-dimensional numerical simulation method for modeling a convective flow struc-

ture induced by chemical concentration waves of Belousov-Zhabotinsky (BZ) reaction in a two-dimensional

rectangular domain of horizontal space and vertical depth. The method assumes a scenario in which an air-

liquid interface of the BZ chemical solution has an elastic property and the Marangoni effect drives the surface

motion of the interface. As a result of the surface motion, a convective flow is organized in the bulk of the

chemical solution. The bulk flow of the chemical solution is described with the Navier-Stokes equations, and

the chemical reaction is described with the Oregonator model. Thus, we couple the three systems of the bulk

flow, the chemical reaction and the surface motion described with an elastic equation in the numerical simula-

tion method. Results of several numerical simulations performed with the method show that a single chemical

concentration wave propagates with a broad convective flow structure and a chemical concentration wave train

propagates with a global flow structure. These flow structures are similar to those observed in real laboratory

experiments.

1 INTRODUCTION

Pattern dynamics have been observed in a solution

layer of the Belousov-Zhabotinsky (BZ) reaction sys-

tem (Zaikin and Zhabotinsky, 1970). A reaction-

diffusion model such as the Oregonator model de-

scribes the dynamics organizingthe spatial patterns of

chemical concentration distributions. The model rep-

resents an assembly of nonlinear chemical oscillators

coupled with the diffusion of molecules (Field et al.,

1972; Keener and Tyson, 1986; Jahnke et al., 1989).

Thus, the target patterns and spiral waves of chemi-

cal pattern dynamics are understood within the frame

work of chemical reaction and molecular diffusion.

Pattern dynamics of flow will arise with propagat-

ing chemical waves. For example, oscillatory flow

and flow waves appear in spiral chemical waves, and

a strong flow velocity of convection appears in a sin-

gle chemical wave with accelerating propagation. In

contrast to the reaction-diffusion system, only a few

studies for modeling and numerical simulation have

examined the problem of self-organized flow struc-

tures in the BZ solution.

There are several evidences showing that a chem-

ical wave train or a single chemical wave induces a

convective flow in a shallow layer of the chemical

solution (Miike et al., 2010). There is a correlation

between the two temporal changes of surface flow

velocity and chemical concentration in the chemical

wave train (Miike et al., 1988); a global surface flow

structure having a circular or spiral shape travels with

a chemical wave train (Matthiessen and M¨uller, 1995;

Sakurai et al., 1997; Sakurai et al., 2003). Surface

flow velocity at the center of a petri dish begins to

change just after triggering a single chemical wave at

an edge of the dish; the direction of the surface flow

velocity changes from anti-parallel to parallel to the

traveling direction of the chemical wave at the pas-

sage of the chemical wave (Miike et al., 1993).

There are two effects that induce flow in a chem-

ical solution: the gravity effect induced by a density

gradient and the Marangoni effect induced by a sur-

face tension gradient. Matthiessen et al. (1996) pro-

posed a model that takes account of both the grav-

ity and Marangoni effects due to the concentration

distributions of chemical species, and performed nu-

merical simulation of organized flow structure. By

quantitatively comparing the flow structure obtained

613

Nomura A., Sakurai T. and Miike H..

Two-dimensional Numerical Simulation Method for Convective Flow Structure Induced by Chemical Concentration Waves.

DOI: 10.5220/0005108506130618

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 613-618

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

through their numerical simulation with that obtained

in laboratory experiments, they concluded that the

Marangoni effect due to a chemical concentration

gradient is more dominant than the gravity effect in

a single chemical wave (Matthiessen et al., 1996).

Yoshikawa et al. (Yoshikawa et al., 1993) and In-

omoto et al. (Inomoto et al., 2000) measured the de-

pendence of surface tension on the concentrations of

chemical species in the BZ solution; these experi-

mental results support the results of Matthiessen et

al. (1996).

More recently, Rossi et al. found chemical con-

centration waves segmented in the BZ reaction sys-

tem (Rossi and Liveri, 2009), and performed its nu-

merical simulation with the gravity and Marangoni

effects (Rossi et al., 2012). They explored how the

chemical concentration distributions and flow struc-

ture change with a thickness of the chemical solution

layer and excitability of the chemical reaction. As re-

sults, they found that the segmented waves are caused

in a thick chemical solution and with high excitabil-

ity, and in that case the gravity effect is more effec-

tive than the Marangoni one in the segmented waves.

Rongy et al. focused on the front of a chemical con-

centration wave propagating in a shallow layer of a

chemical solution, and performed its numerical simu-

lation with the solutal Marangoni effect under a vari-

ety of thickness of the solution layer without the grav-

ity effect (Rongy and De Wit, 2007). They confirmed

the dependence of a traveling speed on the thickness;

the speed increases with the thickness of the solu-

tion. These results of numerical simulation were per-

formed on the situation of propagating chemical reac-

tion wave(s) in a thick solution layer more than 1 mm.

Nomura et al. (2004) assumed that the air-liquid

interface of the chemical solution has an elastic prop-

erty. Then, they proposed a one-dimensional model

that consists of the Oregonator model and an elas-

tic equation driven by the Marangoni effect. The

one-dimensional model reproduced the global surface

flow structure observed in a chemical wave train, and

the surface flow velocity induced in far from a single

chemical wave.

This paper presents a two-dimensional numeri-

cal simulation method for modeling convective flow

structures induced by chemical concentration waves

of BZ reaction in a two-dimensional rectangular do-

main of horizontal space and vertical depth. Accord-

ing to the result of Nomura et al. (2004), we assume

that the air-liquid interface of the chemical solution

is governed by the elastic equation; the bulk flow of

the solution is governed by the Navier-Stokes equa-

tions. Although deformation of the interface was ob-

served in previous laboratory experiments (Sakurai

Displacement

Chemical solution

x

Elastic surface

d(x,t)

F(x,t)

Figure 1: One-dimensional model for the air-liquid inter-

face of a chemical solution. The model assumes that the

surface has an elastic property. The surface tension gra-

dient of the Marangoni effect induces a force F(x,t) [see

Eq. (5)], which induces surface displacement d(x,t) of the

elastic surface [see Eq. (3)].

et al., 2004), we do not consider the deformation in

this paper. Thus, by coupling the three systems of

the bulk flow, the chemical reaction and the surface

motion, we carry out numerical simulation of the two

dimensional system. Simulation results show that a

broad convective flow structure is organized with a

single chemical propagation wave and a global flow

structure is organized with a chemical wave train.

2 MODELING AND NUMERICAL

SIMULATION METHOD

2.1 Modeling Study

In the BZ reaction system, concentration distributions

of chemical species u and v are governed by a set

of reaction-diffusionequationswith convection terms,

as follows:

∂u

∂t

= D

u

∇

2

u+ R

u

(u,v) − V· ∇u,

∂v

∂t

= D

v

∇

2

v+ R

v

(u,v) − V· ∇v, (1)

in which t denotes time, D

u

and D

v

are the diffusion

coefficients of ∇

2

u and ∇

2

v, and V· ∇u and V· ∇v are

convection terms. The functions R

u

(u,v) and R

v

(u,v)

are the nonlinear chemical reaction terms, which are

described by

R

u

(u,v) =

1

ε

u(1− u) − fv

u− q

u+ q

,

R

v

(u,v) = u− v, (2)

in the Oregonator model with positive constants of

f and q and a positive small constant ε (Keener and

Tyson, 1986; Jahnke et al., 1989).

According to the scenario proposed by (Nomura

et al., 2004), we also assume that the air-liquid inter-

face of the chemical solution has an elastic property,

and the Marangoni effect induces horizontal surface

displacement, as shown in Fig. 1. An elastic equation

defined in space x and time t describes surface dis-

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

614

placement d(x,t) induced by a force F(x,t), as fol-

lows:

∂

2

d

∂t

2

+ a

∂d

∂t

= D

d

∇

2

d + F(x,t), (3)

in which a and D

d

are constants. A temporal change

of surface displacement d brings about the surface

flow velocity of

V

s

=

∂d

∂t

. (4)

The function F(x,t) represents the force induced by

the surface tension gradient of the Marangoni effect.

If we assume that the distribution of the chemical

species v(x,t) primarily induces the surface tension

gradient (Matthiessen et al., 1996; Yoshikawa et al.,

1993), the force F(x,t) becomes

F(x,t) = b

∂v

∂x

, (5)

with a coefficient b. Thus, the previous model pro-

posed by Nomura et al. (Nomura et al., 2004) con-

nects the Oregonator type reaction-diffusion model

[Eqs. (1) and (2)] and the elastic equation [Eq. (3)]

through the Marangoni effect of Eq. (5) and the con-

vection terms.

The Navier-Stokes equations describe a flow field

in the bulk of the BZ chemical solution. We considera

rectangular domain consisting of the horizontal space

x and a vertical depth z. The Navier-Stokes equa-

tions defined in the two dimensional space (x, z) can

be converted into two equations governing a stream

function ϕ and a vorticity function ω, as shown in

∇

2

ϕ = −ω,

∂ω

∂t

+

∂ϕ

∂z

∂ω

∂x

−

∂ϕ

∂x

∂ω

∂z

= µ∇

2

ω, (6)

in which V = (V

x

,V

z

) = (∂ϕ/∂z, −∂ϕ/∂x) represents

two-dimensional flow velocity and µ represents the

kinematic viscosity of the chemical solution. We do

not take account of the gravity effect due to the den-

sity distribution, as suggested by (Matthiessen et al.,

1996).

In the bulk of the chemical solution, the Orego-

nator model of Eqs. (1) and (2) defined in the two-

dimensional space (x,z) describes the chemical con-

centration distributions of u(x,z,t) and v(x,z,t).

The model proposed here couples the Navier-

Stokes equations of Eq. (6) with the Oregona-

tor model of Eqs. (1) and (2), through the one-

dimensional elastic equation of Eq. (3). The elastic

equation describes the displacement of the air-liquid

interface of the chemical solution. Surface flow ve-

locity or surface displacement induces a convective

flow in the bulk of the chemical solution. Thus, we

make use of the surface flow velocity V

s

obtained by

the elastic equation as the boundary condition of V

x

in

the Navier-Stokes equations.

Elastic surface

+ Navier-Stokes equations

Oregonator model

x

z

L

x

L

z

A B

CD

Figure 2: Rectangular domain utilized for modeling the

two-dimensional flow field of a chemical solution. The

Navier-Stokes equations describe a flow field in the bulk of

the chemical solution [see Eq. (6)]; the Oregonator model

with convection terms describes the chemical reaction in the

domain [see Eq. (1)]. The elastic equation given in Eq. (3)

governs the displacement of the air-liquid interface (A–B)

of the domain. The right wall (B–C), the bottom (C–D), and

the left wall (D–A) are rigid. See Eq. (7) for the boundary

conditions. The rectangular domain consists of a horizontal

axis x (space) and a vertical axis z (depth); L

x

represents the

width of the rectangular domain and L

z

represents its depth.

2.2 NUMERICAL SIMULATION

METHOD

We discretize the model equations of Eqs. (1), (3) and

(6) with a finite difference method, in which spatial

differences discretizing horizontal space and vertical

depth are denoted by δx and δz and a temporal differ-

ence is denoted by δt.

On the one-dimensional elastic equation govern-

ing the air-liquid interface, we discretized the Lapla-

cian operator ∇

2

in Eq. (3) with the three-point

centered difference formula and the Crank-Nicolson

scheme. Then, we solve a set of linear equations by

the LDU decomposition method.

In the bulk of the chemical solution, we explicitly

discretized the Laplacian operator ∇

2

in Eqs. (1) and

(6) with the five-point centered difference formula.

We discretized the convection terms of Eq. (1) with

the two-point upwind scheme. We solved the set of

linear equations obtained from ∇

2

ϕ = −ω by the suc-

cessive overrelaxation (SOR) method.

The initial conditions are u = v = d = ϕ = ω = 0

over the one- or two-dimensional space. A single

chemical wave can be generated by setting the distri-

bution u(x, z,t = 0) as u = 1.0 in a local area. A wave

train, namely, a series of chemical waves is generated

at a time interval λ.

The Direchlet boundary condition governs both

ends of the surface displacement (d = 0). The Neu-

mann boundary condition governs the four sides of

the two-dimensional rectangular domain of the two

distributions u and v (∂u/∂x = ∂u/∂z = ∂v/∂x =

∂v/∂z = 0).

On the Navier-Stokes equations, the stream func-

tion ϕ is zero along the four sides, and the vorticity

function ω along the four sides: A–B, B–C, C–D and

Two-dimensionalNumericalSimulationMethodforConvectiveFlowStructureInducedbyChemicalConcentrationWaves

615

D–A are governed by

A–B: ω(iδx,0) = −2[V

s

δz− ϕ(iδx, δz)]/δz

2

,

B–C: ω((I − 1)δx, jδz) = −2ϕ((I − 2)δx, jδz)/δx

2

,

C–D: ω(iδx,(J − 1)δz) = −2ϕ(iδx,(J − 2)δz)/δz

2

,

D–A: ω(0, jδz) = −2ϕ(0, jδz)/δx

2

, (7)

in which V

s

represents the surface flow velocity of

Eq. (4); the grid point (iδx, jδz) represents the dis-

crete position of (x,z). Let L

x

× L

z

be the size of the

two-dimensional space considered here as shown in

Fig. 2. Then, in the boundary conditions of Eq. (7)

I = [L

x

/δx] and J = [L

z

/δz] represent the total num-

bers of grid points in space x and depth z.

In the following numerical simulations, finite dif-

ferences in space, depth and time were fixed at δx =

δz = 1/5 and δt = 1/10000. The parameter settings

were fixed at D

u

= 1.0,D

v

= 0.6, q = 2.0× 10

−3

,ε =

0.01, and µ = 6.7 (Jahnke et al., 1989).

3 NUMERICAL SIMULATION

RESULTS

A previous model (Matthiessen et al., 1996; Diewald

et al., 1996) connects the Oregonator model of

Eqs. (1) and (2) with the Navier-Stokes equations

given in Eq. (6) through the Marangoni effect due

to a chemical concentration gradient of v along the

air-liquid interface. The model takes account of the

Marangoni effect as the boundary condition of the

surface flow velocity V

x

along the air-liquid interface,

as follows:

∂V

x

∂z

= M

a

∂v

∂x

, (8)

in which M

a

is a constant. The boundary condi-

tions on ω for the side walls and bottom of the two-

dimensional domain, and those on u, v and ϕ for the

four sides of the domain are the same as those of the

proposed model. The initial conditions of u, v, ϕ and

ω are the same as those of the proposed model. The

previous model does not takes account of the grav-

ity effect. The discretization methods utilized in the

previous model are the same as those in the proposed

model.

In order to compare the proposed model with the

previous model mentioned above, we carried out two-

dimensional numerical experiments on a single chem-

ical wave. Figure 3(a) shows the result of the pro-

posed model; the single chemical wave triggered at

the left end travels in the horizontal position approx-

imately x = 220 towards the right end. The surface

flow velocity anti-parallel to the traveling direction

of the chemical wave induces a flow structure with

a counter-clockwise direction in the bulk; this flow

structure has some spatial extent in front of the chem-

ical wave. Figure 3(b) shows the result of the previ-

ous model (Matthiessen et al., 1996; Diewald et al.,

1996). While the single chemical wave is traveling in

a similar horizontal position (x = 220), a flow struc-

ture exists in the vicinity of the chemical wave. There

is no spatial extent of the flow structure in front of the

chemical wave.

Results of previous laboratory experiments show

that some spatial extent of a flow structure exists in

front of the single chemical wave. Therefore, we sug-

gest that the proposed model is able to reproduce a

more plausible flow structure than the previous model

for a single chemical wave.

We carried out additional numerical experiments

on a wave train in a two-dimensional domain, in

which chemical waves triggered at the left end trav-

eled in the two-dimensional domain towards the right

end. Figure 4(a) shows the result of the proposed

model. A particular chemical wave organizesa pair of

small convection rolls having clockwise and counter-

clockwise directions.

Around the middle of the horizontal position in

the two-dimensional domain, particular pairs of the

convection rolls are almost symmetrical and most of

them have similar strength of convection. Compared

with these pairs traveling in the middle, those on the

left side of the domain lack symmetry and have dif-

ferent strengths. The asymmetrical convection rolls

with different strengths induces a global flow struc-

ture. In comparison with the results of the proposed

model, the result of the previous model do not show

such the global flow structure, as shown in Fig. 4(b).

Uniform pairs of convection rolls travel maintaining

almost uniform strength and symmetry.

In these two-dimensional numerical experiments,

the absolute flow velocity obtained by the proposed

model was small compared with that obtained using

the previous model. Two-dimensional numerical ex-

periments with the proposed model broke down for

large values of b and D

d

, and we therefore had to

choose sufficiently small values of b and D

d

to ob-

tain results. In spite of such small values, the pro-

posed model successfully presented the global flow

structure. The model is a plausible candidate for

simulating the two-dimensional flow structures self-

organized in the systems of a single chemical wave

and of a chemical wave train.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

616

-10

0

10

160 180 200 220 240 260 280

-0.4

0

0.4

V

x

v

V

x v

x

x

z

0 0.15

v

0.05 0.10

-6.0 6.0

ϕ

0-3.0 3.0

(b-1)

(b-3)

(b-2)

-0.04

0

0.04

160 180 200 220 240 260 280

-0.4

0

0.4

V

x

v

V

x

v

x

x

z

0 0.15

v

0.05 0.10

-0.04 0.04

ϕ

0-0.02 0.02

(a-1)

(a-3)

(a-2)

(a) (b)

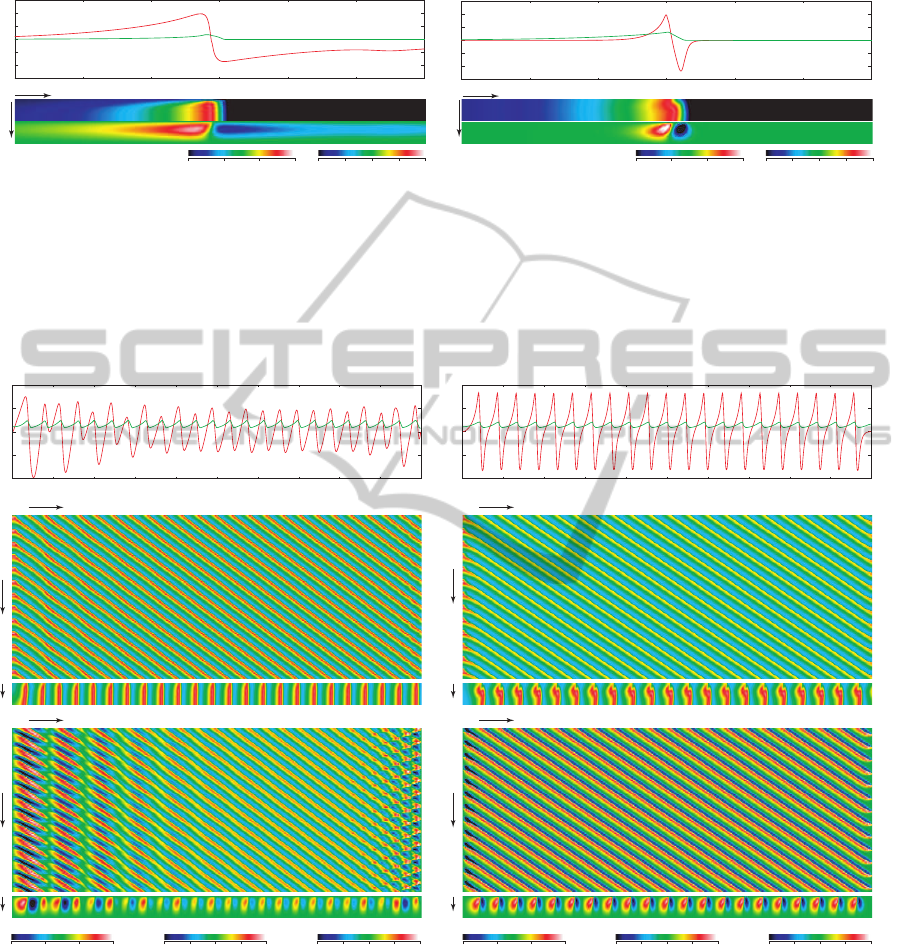

Figure 3: Result of a two-dimensional numerical experiment on a single chemical wave with (a) the proposed model and

(b) the previous model (Matthiessen et al., 1996; Diewald et al., 1996). Figures (a-1) and (b-1) show one-dimensional spatial

distributions of the concentration v and the flow velocity V

x

along the air-liquid interface of the two-dimensional domain in

the range of 160 ≤ x < 280. Figures (a-2) and (b-2) show two-dimensional spatial distributions of v, and Figs. (a-3) and

(b-3) show distributions of the stream function ϕ, in the ranges of 160 ≤ x < 280 and 0 ≤ z < 5. The spatial size of the

two-dimensional domain was (L

x

× L

z

) = (400× 5). All the distributions were obtained at t = 10. The single chemical wave

was triggered at the left-top position at t = 0. The parameter settings of Eqs. (2), (3), (6) and (1) were D

d

= 10

3

, a = 0.5,

b = 100 and f = 2.5; see Section 2.2 for the other parameter settings.

-6.0

-3.0

0

3.0

6.0

0 40 80 120 160 200

-1.0

-0.5

0

0.5

1.0

V

x

v

x

V

x

(10

-4

)

v

x

t

t

180

200

180

200

0 200

x0 200

0 0.3

v

0.1 0.2

-6.0 6.0

V

x

(10

-4

)

0-3.0 3.0

ϕ (10

-4

)

-4.0 4.00-2.0 2.0

(a)

(a-1)

(a-2)

(a-3)

x

t

t

180

200

180

200

0 200

x0 200

x

V

x

v

-10

-5

0

5

10

0 40 80 120 160 200

-1.0

-0.5

0.0

0.5

1.0

V

x

v

0 0.3

v

0.1 0.2

-10 10

V

x

0-5.0 5.0

ϕ

-6.0 6.00-3.0 3.0

z

(b)

(b-1)

(b-2)

(b-3)

z

z

z

Figure 4: Result of a two-dimensional numerical experiment on a chemical wave train with (a) the proposed model and

(b) the previous model (Matthiessen et al., 1996; Diewald et al., 1996). Figures (a-1) and (b-1) show one-dimensional spatial

distributions of the concentration v and the flow velocity V

x

along the air-liquid interface of the two-dimensional domain at

t = 200. Figures (a-2) and (b-2) show spatiotemporal plots of v with their two-dimensional spatial distributions at t = 200.

Figures (a-3) and (b-3) show spatiotemporal plots of V

x

with their two-dimensional spatial distributions of the stream function

ϕ at t = 200. Chemical waves were triggered at the time intervals of λ = 1.55 at the left-top position of the two-dimensional

domain. The spatial size of the two-dimensional domain was (L

x

× L

z

) = (200× 5). The parameter settings of Eqs. (2), (3)

and (5) were f = 1.0, D

d

= 100, a = 1.0 and b = 0.1; see Section 2.2 for the other parameter settings.

Two-dimensionalNumericalSimulationMethodforConvectiveFlowStructureInducedbyChemicalConcentrationWaves

617

4 CONCLUSIONS

This paper presented a numerical simulation method

for explaining convective flow structures induced by

a single chemical wave and a chemical wave train in a

chemical solution layer of the BZ reaction. According

to the previous result by Nomura et al. (Nomura et al.,

2004), the model assumes a scenario in which the

surface of the chemical solution has an elastic prop-

erty. The concentration gradient of a chemical species

along the surface induces a surface tension gradient,

and brings about displacement of the elastic surface

through the Marangoni effect. In addition, the surface

displacement causes a bulk flow of the chemical solu-

tion, which can be described with the Navier-Stokes

equations. Thus, the numerical simulation method

proposed here couples an Oregonator type reaction-

diffusion model with the Navier-Stokes equations via

the elastic equation.

We carried out numerical experiments with the

proposed model on a single chemical wave and a

chemical wave train. The results of these experiments

show that the proposed model reproduces the flow

structures observed in laboratory experiments. That

is, a flow structure induced by a single chemical wave

has some spatial extent in front of the chemical wave;

a flow structure induced by a chemical wave train has

a global flow structure due to asymmetric convection

rolls. A previous model did not predict such the flow

structures in our numerical experiments. These re-

sults suggest that the assumption of the elastic prop-

erty helps us to understand flow structures observed

in the solution layer of the BZ reaction.

REFERENCES

Diewald, M., Matthiessen, K., M¨uller, S. C., and Brand,

H. R. (1996). Oscillatory hydrodynamic flow due to

concentration dependence of surface tension. Physical

Review Letters, 77:4466–4469.

Field, R. J., Koros, E., and Noyes, R. M. (1972). Os-

cillations in chemical systems. II. Thorough analysis

of temporal oscillation in the bromate-cerium-malonic

acid system. Journal of American Chemical Society,

94:8649–8664.

Inomoto, O., Abe, K., Amemiya, T., Yamaguchi, T., and

Kai, S. (2000). Bromomalonic-acid-induced transi-

tion from trigger wave to big wave in the Belousov-

Zhabotinsky reaction. Physical Review E, 61:5326–

5329.

Jahnke, W., Skaggs, W. E., and Winfree, A. T.

(1989). Chemical vortex dynamics in the Belousov-

Zhabotinskii reaction and in the two-variable orego-

nator model. Journal of Physical Chemistry, 93:740–

749.

Keener, J. P. and Tyson, J. J. (1986). Spiral waves in the

Belousov-Zhabotinskii reaction. Physica D, 21:307–

324.

Matthiessen, K. and M¨uller, S. C. (1995). Global flow

waves in chemically induced convection. Physical Re-

view E, 52:492–495.

Matthiessen, K., Wilke, H., and M¨uller, S. C. (1996). In-

fluence of surface tension changes on hydrodynamic

flow induced by traveling chemical waves. Physical

Review E, 53:6056–6060.

Miike, H., Miura, K., Nomura, A., and Sakurai, T. (2010).

Flow waves of hierarchical pattern formation induced

by chemical waves: The birth, growth and death of

hydrodynamic structures. Physica D, 239:808–818.

Miike, H., M¨uller, S. C., and Hess, B. (1988). Oscilla-

tory deformation of chemical waves induced by sur-

face flow. Physical Review Letters, 61:2109–2112.

Miike, H., Yamamoto, H., Kai, S., and M¨uller, S. C. (1993).

Accelerating chemical waves accompanied by travel-

ing hydrodynamic motion and surface deformation.

Physical Review E, 48:R1627–R1630.

Nomura, A., Sakurai, T., Miike, H., and Hano, M. (2004).

Model for the Belousov-Zhabotinsky reaction and sur-

face flow structure induced by chemical concentra-

tion gradients. In Proceedings of 2004 International

Symposium on Nonlinear Theory and its Applications,

pages 363–366, Fukuoka, Japan.

Rongy, L. and De Wit, A. (2007). Marangoni flow around

chemical fronts traveling in thin solution layers: in-

fluence of the liquid depth. Journal of Engineering

Mathematics, 59(2):221–227.

Rossi, F., Budroni, M. A., Marchettini, N., and Carballido-

Landeira, J. (2012). Segmented waves in a reaction-

diffusion-convection system. Chaos, 22(3):037109

(11 pages).

Rossi, F. and Liveri, M. L. T. (2009). Chemical self-

organization in self-assembling biomimetic systems.

Ecological Modelling, 220:1857–1864.

Sakurai, T., Inomoto, O., Miike, H., and Kai, S. (2004).

Structure of surface deformation waves induced in

spiral pattern in the Belousov-Zhabotinsky reaction.

Journal of the Physical Society of Japan, 73:485–490.

Sakurai, T., Miike, H., Okada, K., and M¨uller, S. C. (2003).

Spiral flow wave in a reaction-diffusion-convection

system. Journal of the Physical Society of Japan,

72:2177–2180.

Sakurai, T., Miike, H., Yokoyama, E., and M¨uller, S. C.

(1997). Initiation front and annihilation center of

convection waves developing in spiral structures of

Belousov-Zhabotinsky reaction. Journal of the Physi-

cal Society of Japan, 66:518–521.

Yoshikawa, K., Kusumi, T., Ukitsu, M., and Nakata, S.

(1993). Generation of periodic force with oscillat-

ing chemical reaction. Chemical Physics Letters,

211:211–213.

Zaikin, A. N. and Zhabotinsky, A. M. (1970). Concen-

tration wave propagation in two-dimensional liquid-

phase self-oscillating system. Nature, 225:535–537.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

618