Toward Pervasive Computing System to Enhance Safety of Ageing

People in Smart Kitchen

Bessam Abdulrazak, Rami Yared, Thomas Tessier and Philippe Mabilleau

University of Sherbrooke, Quebec, Canada

Keywords: Smart Kitchen, Cooking-Safe, Context-Aware, Ageing People, Assistive Technology, Sensor, Risk, Hazard,

Fire, Burn, Intoxication, Activities of Daily Living.

Abstract: Kitchen is the second place where the majority of domestic accidents occur, and in particular oven presents

the most principal source of fire accidents in residence. Therefore, enabling kitchen safety is a major factor

for ageing people independent living. This paper presents the hardware architecture of our cooking-safe

system that targets enhancing safety of ageing people while cooking. The system is based on insightful

cooking risk analysis that enables to determine the pertinent parameters to be monitored and measured while

cooking. This paper also presents the results of our experimental study that leads us to select the appropriate

sensors to constitute the basic building block of our cooking-safe system. The system is composed of sensor

nodes to monitor events around oven, then the sensory data is transmitted to a computing unit. The system

proactively reacts to hazards in order to prevent cooking associated risks.

1 INTRODUCTION

Cooking is a very important Activity of Daily Living

(ADL). Statistical studies revealed that cooking

enhances survival for ageing people, and can

improve their moral feeling as active people (Chen,

2012). Alas, kitchen is the second place where the

majority of domestic accidents occur, and in

particular oven presents the main source of fire

accidents in the residence (Fire Marshal's Public,

2009; Ahrens, 2008). Studies also revealed that

unattended cooking is the main leading factor

responsible for fire in the kitchen (Ahrens, 2008;

Lushaka, 2014). Therefore, enabling kitchen safety

is a major factor for ageing independent living.

The need of providing safety for ageing people at

home becomes more significant because of the

increasing number of ageing people around the

world, and particularly in developed countries. In

Canada, the proportion of ageing people aged 65

years or over will represent between 23% and 25%

of the population by 2036, and between 24% and

28% by 2061 (Martel, 2011; Hall, 2006). In Japan,

the population of 65 year-old was about 25.1% of

the total population in 2013, and will be 40% in

2050, which is the highest ratio of ageing population

in the world (Toshio, 2013). In the United States, the

number of senior citizens is also on the rise: in 2010,

there were 40.3 million people aged 65 and above,

comprising 13% of the overall population. This

proportion is 12 times higher than it was in 1900,

when this group constituted only 4.1% of the

population. By 2050, projections indicate the

population over 65 will comprise 20.9% of the

population in the United States (Loraine, 2014). In

Europe, by 2025 more than 20% of population will

be 65 or over, with a particularly rapid increase in

the number of over 80s. In the United States, 40% of

women and 19% of men aged 65 years and older,

live alone and do not have anyone in the home to

assist with activities of daily living, provide care

when they are sick, or to assist with home

maintenance (Jacobsen, 2011). In Canada, 92.1% of

ageing people live in private households or

dwellings (Canadian Census, 2011).

Cognitive decline in ageing, such as attention

and memory problems, have severe impacts on

ADL, limiting people to perform cooking. Due to

this decline, ageing people are strongly concerned

by cooking associated risks (We identify the three

major risks during cooking/ in kitchen as fire, burn

or intoxication). As consequences, they are often

forced to stop cooking or completely move to a

nursing home or healthcare facility to prevent

dangerous situations (e.g., a fire may occur when an

17

Abdulrazak B., Yared R., Tessier T. and Mabilleau P..

Toward Pervasive Computing System to Enhance Safety of Ageing People in Smart Kitchen.

DOI: 10.5220/0005538900170028

In Proceedings of the 1st International Conference on Information and Communication Technologies for Ageing Well and e-Health (ICT4AgeingWell-

2015), pages 17-28

ISBN: 978-989-758-102-1

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

ageing person forgets a pot on a burner (Yuan,

2012)). Urgent intervention is required to prevent

risks in ADL, which is driven by the following

motives:

• The vast majority of ageing people live

independently (Gitlin, 2003);

• Most of ageing people wish to remain in their

environment as long as possible (Public Health

agency of Canada, 2006), even if this stay

requires long-term in-home care provision

(Wahl, 2003);

• In addition, about 80% of seniors prefer to die at

home, not at care facilities (Wahl, 2003).

A possible solution for ageing people to stay at

home is to be accompanied by a family member or a

caregiver for cooking activity. However, this

solution is not practical due to independence and

privacy issues. In addition, it has several drawbacks

such as high cost and a shortage of qualified

professionals. It also requires that ageing person

accepts the idea of being not completely autonomous

needing help. These factors negatively affect the

moral situation of ageing people and consequently

complicate the cognitive deficiencies recovery

(Sperling, 2011). Therefore, assistive technology is a

potential alternative to enhance safety at home.

We present in this paper our attempt to provide

ageing people with an assistive technology for safe

cooking environment. Our goal is to establish a

preventive approach for enhancing safety, with a

cooking-safe system that proactively reacts to

hazards in order to prevent cooking associated risks.

We envision a cooking-safe system composed of

sensor nodes that enable monitoring of events

around oven. The sensory data is processed

according to risk prevention algorithms. These

algorithms are based on the results of our

experimental cooking risk analysis. In this paper, we

introduce the hardware architecture of our cooking-

safe system. We mainly discuss the selection of the

sensors that has been inferred from our risk analysis

and experiential studies. We also present the results

of our experimental study including testing sensors

in real word environment.

The rest of the paper is organized as follows.

Section 2 highlights the terminology used in this

paper. Section 3 presents the related existing work.

Section 4 introduces our cooking-safe system.

Section 5 summarizes the results of our risk analysis

and assessment. Section 6 presents the hardware

architecture of our cooking-safe system. In addition,

it discusses the selected sensors that constitute the

basic building block of the system, and sensors

positioning in the cooking environment. Section 7

discusses the results of the sensors testing. Finally,

Section 8 concludes the paper and presents future

work.

2 “RISK” VS. “HAZARD”

There is a need for a clear understanding of the

meaning of terms “Risk” and “Hazard” since they

are generally used interchangeably in the literature.

Risk is defined as “the probability that a negative

consequence (e.g. loss) can occur in a given period

of time following a specific adverse event”

(Marzocchi, 2012). Hazard is defined as “a source of

danger” and risk is the “possibility of loss or injury”

and the “degree of probability of such loss. Hazard,

therefore, simply exists as a source. Risk includes

the likelihood of conversion of that source into

actual delivery of loss, injury, or some form of

damage” (Kaplan, 1981). We distinguish between

risk and hazard. We define Risk as the potential of

occurrence of an event that yields unwanted results,

and we define Hazard as a reason that causes a risk.

As an example, let us consider this scenario for an

elderly person performing ADL. She/he is cooking a

meal, puts a pot on burner and goes to watch TV.

After a period of time, a fire occurs in the kitchen.

The hazard in this example is unattended cooking,

and the risk is fire. Fire occurs and causes unwanted

results such as home destruction, losing valuable

objects, or death of the person.

3 RELATED WORK

We identified the three major risks during cooking/

in kitchen as fire, burn or intoxication. Our study of

the literature reveals that existing research often

addresses only one particular risk in cooking (mainly

fire), and there is no global solution for kitchen

safety. In addition, no research work provides

solutions to prevent burn or intoxication.

A basic existing solution to handle fire risk at

home is installing fire alarms. The main concern of

fire alarms is to detect fire occurrence quickly, so

fire rescue agents can intervene in time. However,

fire alarms have several drawbacks, particularly for

ageing people. These people usually forget replacing

alarm batteries regularly. In addition, fire alarms

generate false alarms (e.g., in the presence of a small

quantity of smock generated by regular cooking).

This situation disturbs them, which increases their

tendency to uninstall fire alarms at their homes.

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

18

Lushaka et al. (Lushaka, 2014) established a more

elaborated system that relies on existing smoke

alarms to detect a potential fire risk, and

consequently, reacts by switching off oven power

supply. The system considers only fire risk and

depends on existing smoke alarms.

Doman et al. establish a system for assisting

ageing people in kitchen through video and audio

(Doman, 2011). This system reminds user to follow

the correct steps when performing a cooking task, so

it can possibly avoid cooking hazards, but it does not

react when a dangerous situation occurs. Other

intelligent assistive technologies are designed for

people with cognitive deficiencies: Li et al. (Li,

2013) propose a design for a smart kitchen

environment to assist ageing people suffering from

dementia in cooking process. Using the system,

caregivers remotely instruct users according to a

cooking workflow. In addition, a visual surveillance

system with multiple cameras enables to observe

cooking conditions, and track user activities and

object movement. This system is not completely

automatic, since it requires observer intervention and

it is based on visual monitoring by cameras, which

may be considered intrusive. Sanchez et al. establish

a system that assists people in the kitchen and reacts

when a potentially dangerous situation is detected

(Sanchez, 2013). The system detects rapid variations

in temperature and smoke in kitchen, and sends a

notification (with camera shots) to the fire

department and caregivers. In addition, the system

activates exhaust fans and a fire extinguishing

suppression system. A number of studies mention

oven monitoring as a part of larger systems to track

ADL: Alwan et al., (Alwan, 2006) measure oven

usage and Wai et al., (Wai, 2011) propose detecting

unsafe usage of the oven. Both systems use

embedded temperature sensors to measure the

burner status, ultrasonic sensors to detect the

presence of a pot and electric current sensors to

detect the usage of oven and levels of abnormality in

the kitchen. Chen et al. (Chen, 2010) propose a

system that detects food ingredients based on

visible-light cameras during cooking activities to

ensure the healthy eating habits. The three discussed

systems either require modifications to oven to

install sensors, or use visible-light cameras (may be

considered intrusive). Yuan et al. (Yuan, 2012)

developed an automated top oven monitoring system

based on thermal camera to detect dangerous

situations. The system alerts user or caregiver when

a dangerous situation occurs. The system does not

require modifications to oven, so it fits any existing

oven and respects user privacy, because it is based

on thermal imaging instead of visible-light camera.

Since the thermal camera does not process regular

images, user privacy is preserved. However, the

thermal camera has significant limitations since it is

sensitive to cooking heat and smoke.

Few electrical cooking devices equipped with

limited safety features are available in the market.

For example, Electrolux INSPIRO oven contains

programmable cooking modes. According to the

selected cooking mode, the oven calculates cooking

time and temperature. TMIO society commercializes

ovens with tactile screen, and network connection to

be remotely controlled. Numerous manufactures

integrate LEDs to indicate that an oven surface is hot

to prevent burn. However, the concentration of

ageing people is on the cooking task itself and

she/he may not notice the lightening LED. Generally

speaking, safety measures are partially considered in

the existing commercial cooking devices.

StoveGuard, SafeCook and HomeSensor propose a

timer system to switch off an oven if there is no

attendance after certain programmed time. Still,

risks may occur within this period of time.

To summarize, existing systems propose

numerous interesting features to manage risks at

home. However, they have several limitations: they

focus on aid for only one specific risk situation, they

need to be programmed for each type of use and

each time they are used, and they provide elevated

risks in the case of cognitive deficiencies.

4 COOKING-SAFE SYSTEM

Our proposition to address cooking safety issues for

ageing people independent living is to offer

pervasive computing support. The system is based

on a smart environment infrastructure, especially

sensors and actuators distributed in the kitchen area.

The system allows sensing cooking activities and

offering appropriate interventions.

• Sensors are installed around oven to perform

contextual information acquisition. They allow

the system to infer the situation during cooking,

or detect changes in the surrounding environment

(e.g., smoke, burner temperature, utensil

temperature, and presence of utensil on burner).

• Actuators are distributed in the residence to

ubiquitously alert user of a cooking risk

situation. They provide feedback through

screens, speakers, or flashing lights, and control

appliances in the kitchen (such as switch off

oven power).

TowardPervasiveComputingSystemtoEnhanceSafetyofAgeingPeopleinSmartKitchen

19

Sensory data fusion and ambient intelligence

techniques enable detection of risk situations with

enhanced accuracy and efficiency. Moreover,

actuators provide a wide range of possibilities for

human-machine interaction including appropriate

intervention for each detected risk situation, and an

adapted reaction according to user needs.

Building a robust sensor-based cooking-safe

environment requires insightful risk analysis. In

addition, adequate sensor selection and testing is a

significant factor for building a robust system.

Therefore, we performed experiments on cooking

several kinds of food in normal and risk situations,

in order to extract the relevant parameters to monitor

and measure to prevent cooking related risks

(Section 5). After analyzing risks, we discuss the

sensors selected based on risk analysis to build the

cooking-safe system (Section 6). Then, we illustrate

sensors testing results in order to study the behavior

and precision of sensors in real world cooking

environment (Section 7).

5 RISK ANALYSIS AND

ASSESSMENT

We performed risk analysis and assessment in two

phases. First, we reviewed literature to study the

characteristics of existing solutions. We also

extracted the pertinent parameters of cooking risks.

As results of this phase, we identified the most

frequent hazards that lead to risk situations as

follows:

1. Unattended cooking,

2. Forgetting a pot on a burner;

3. User turning on a burner, but forgetting to cover

it with a pot;

4. User turning on a burner, but placing the pot on

an incorrect burner,

5. Burners are at dangerous temperatures and oven

is left unattended;

6. A pot is removed from oven but user forgets to

turn it off.

This phase also enabled us to identify the major risks

during cooking activities as: fire, burn, and

intoxication.

Second, we built an experimental setup to study

these three major identified risks. We present a

summary of our experimental results (the complete

study with comprehensive results is presented in

another paper).

5.1 Experimental Setup

We investigated several hazardous situations during

cooking in order to extract pertinent parameters

related to cooking risks. We performed series of

experiments that reflect the real world cooking

scenarios with varieties of cooking materials. The

goal is to establish the relation between the

parameters and triggering risks. In order to focus

only on sources of risks, independently from oven

characteristics (e.g., gas factors related to gas oven),

we used an electrical oven. Following are a

summary of the studied parameters for each risk:

Fire: we observed the parameters: Volatile

Organic Compound (VOC), Alcohol, and

CO gases concentrations in the cooking

smoke gas.

Burn: For burn risk by splash and by contacting

hot objects, we observed the following

parameters: relative humidity, utensils

temperatures, burner temperature, and

presence of object over burner.

Intoxication: we observed the concentration of CO

gas in the cooking smoke.

5.2 Fire Risk Analysis

We observed cooking several types of food, i.e.,

fish, meat, onion, peppers, and spaghetti. Also, we

experiment heated oil (i.e., 50ml of canola oil) in a

frying pan for 8 minutes until oil starts to shudder.

As a summary of our results, there is a correlation

between fire triggering and the concentrations of

certain chemical components in the cooking smoke,

so detection of fire would be possible. Our

experimentations lead us to determine the pertinent

parameters to be monitored in order to detect fire

triggering in early stage i.e., VOC (e.g., aldehydes,

alcohols, acids), hydrocarbons, and inflammable

gases. Our experimentations also revealed that there

are boundaries between normal and dangerous

situations during cooking, with respect to the

concentrations of VOC and Alcohol gases in the

cooking smoke, i.e., if Alcohol or VOC

concentration in the cooking smoke exceeds 170

ppm, then there is a potential fire risk situation.

5.3 Burn Risk Analysis

We distinguish two types of burn linked to cooking:

1

st

by direct contact between skin and hot cooking

utensil and burner; and 2

nd

by splash of hot liquid on

skin. As a summary of our results:

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

20

* For burn by direct contact, detecting the

presence of utensil on a burner is required in order to

start monitoring its temperature. If there is no utensil

on burner, monitoring burner temperature is

required. In addition, we found that there are distinct

thresholds between normal and dangerous situations.

* For burn by splash, we experimented heating

liquid using kettle and saucepan with/without lid for

better understanding of the variations of relative

humidity (%RH) while liquid is boiling. As a

summary of our results: A slight increment in %RH

before water simmers, means that there is a release

of small quantity of steam, and indicates that there is

an object heated on burner. In addition, an increment

of 5%RH indicates that water is simmering so the

global water temperature is around 100°C.

Therefore; rapid variations in relative humidity is an

important indicator of water temperature in a

cooking utensil, and consequently a potential splash

burn risk.

As conclusion, it is feasible to prevent splash

burn risk based on measuring relative humidity,

because it does not change significantly unless a

liquid is being heated. In addition, the

experimentations enabled as to identify the pertinent

parameters to be monitored and measured around

oven in order to prevent burn risk. For burn by

contact with hot object, the parameters are:

temperature of cooking utensils, temperature of

burner, and presence of an object on burner. For

burn by splash, the pertinent parameters are: relative

humidity and presence of an object on burner.

5.4 Intoxication by Gas/Smoke Risk

Analysis

Carbon monoxide (CO) is the most dangerous

component in the cooking smoke. It is an odorless,

tasteless, colorless poisoning gas that may cause

death because of its binding to hemoglobin. It is

produced by the incomplete burning of organic

materials. The concentration of CO becomes

immediately dangerous when it reaches 1200 ppm.

Carbon dioxide (CO

2

) is another gas in the cooking

smoke that is less dangerous for health. It becomes

dangerous if the concentration reaches 40,000 ppm.

Our study reveals that CO is released in the

cooking smoke. Combustion of nutritional elements

is either complete (produces Carbon dioxide CO

2

) or

incomplete (produces CO).

As conclusion for the intoxication risk, CO

concentration is a parameter to be monitored around

oven in order to prevent intoxication by gas/smoke.

There are boundaries between normal and

intoxication risk situations. The normal

concentration of CO in the cooking smoke is around

40 ppm. There is a potential intoxication risk, if CO

concentration exceeds 900 ppm.

6 HARDWARE ARCHITECTURE

AND SENSOR SELECTION

Our cooking-safe system is composed of sensor

nodes to monitor events around oven, and transmit

sensory data to a computing unit. The system

proactively reacts to hazards in order to prevent

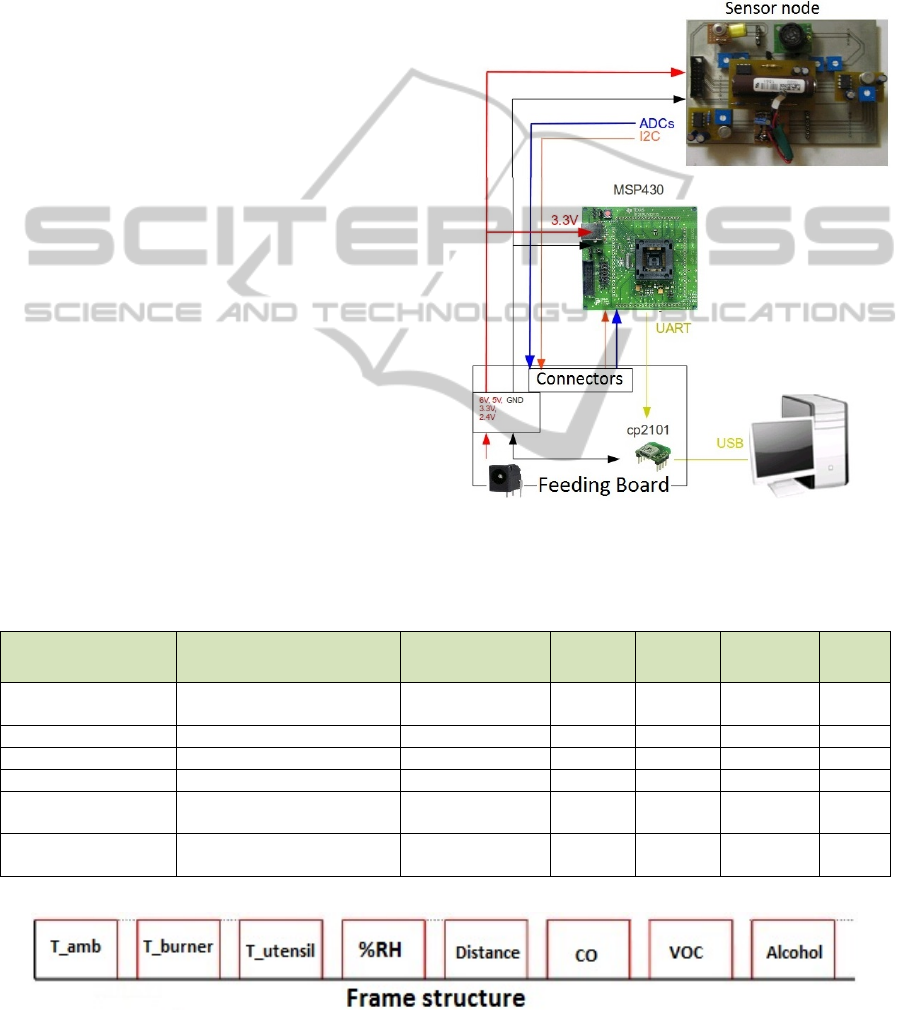

cooking associated risks. Figure 2 illustrates the

hardware architecture of the cooking-safe system

and Figure 1 presents its arrangement in real-world

cooking environment.

Figure 1: Arrangement of the cooking-safe system in the

kitchen.

6.1 Sensor Selection

The selection of sensors is based on the results of

our risk analysis (Section 5). Each sensor is selected

to monitor one of the identified parameters (The

selected sensors are illustrated in Table 1). Our

selection is also based on real-world integration

requirements, which can be summarized as follows:

• Integration requirements: In order to integrate

sensor nodes in the cooking environment,

sensors must be non-intrusive. The selected

sensor technologies (i.e., based on

electrochemical, metal-oxide-semi-conductor,

infrared, ultrasonic, and resistive hygrometer)

do not require contact to operate, and can be

installed around the cooking activity without

interfering with user movement.

• Practicability requirements: Analogue output

signals of the selected sensors are easy to

acquire. For resistive and metal-oxide-semi-

conductor sensors, resistance variations are

TowardPervasiveComputingSystemtoEnhanceSafetyofAgeingPeopleinSmartKitchen

21

translated to voltage. For electrochemical

sensors electric current is transformed into

voltage, which can be easily interfaced with

microcontrollers.

In addition, there are other factors that motivate

our selection of sensors (e.g., price and appropriate

response time).

6.2 Sensor Electrical Feeding

The selected sensors require different electric

feeding voltages, so a “feeding board” is designed to

meet this requirement (illustrated in Figure 2).

Electrical power is taken from the sector through a

transformer, which delivers 12V/1A as output. The

four required electrical voltages (2.4V, 3.3V, 5V,

and 6V) are obtained due to power regulators.

6.3 Microcontroller

The selected microcontroller is MSP430 by Texas

Instruments, because it has the following features:

Analog to Digital Conversion (ADC), multiple

input/output, and two communication ports (UART,

I2C or SPI).

Sensory data is transmitted through cables ADC

(5) and I2C (1), from sensor nodes to MSP430

microcontroller via the feeding board and then from

the MSP430 microcontroller to the computing unit

by one serial frame. The frame is routed to the

computing unit via the cp2101 module, which

converts serial frame to USB frame. The

composition of the frame is illustrated in Figure

3.

Since environment variations are slow, the sampling

period is one second. The frame is composed of the

following attributes: ambient temperature, burner

temperature, utensil temperature, relative humidity,

distance between presence detection sensor and

utensil (used to determine whether utensil is on

burner or not), CO concentration, VOC

concentration, and Alcohol concentration.

Figure 2: Hardware architecture of the cooking-safe

system.

Table 1: Summary of the selected sensors and their technical specifications.

Sensor Monitored information Technology Unit

Operating

voltage

Power

consumption

Response

Time

Melexis MLX 90614

Ambient temperature and

object temperature

Thermopile and

infrared

(°C) V

cc

= 3.3 V 3 mW 100ms

SRF02 Object presence Ultrasonic cm V

cc

= 5 V 72ms

Honeywell H1H1 5030 Humidity Resistive % RH V

cc

= 3.3 V 1.65 mW 5s

Figaro TGS 5042 CO Carbone Monoxide Electro-chemical ppm 60s

Figaro TGS 2620 Alcohol

Metal-Oxide semi-

conductor

ppm

V

h

= V

ref

=

5V

210 mW 20s

e2V MICS 5521

Volatile Organic Compounds

(VOC)

Metal-Oxide semi-

conductor

ppm

V

h

=V

ref

=

3.3V

80 mW 10s

Figure 3: Frame composed of sensory data from MSP430 to computing unit via serial port.

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

22

6.4 System Building

The cooking-safe system experimental kit has been

built based on the following properties and features:

• Flexibility: possibility of adding new sensors if

required. The sensor node is designed such that

adding/removing sensors is easily performed.

• Simple physical installation: The sensors are

integrated on a node such that the node can be

placed in an alternative location if required.

However in this case, longer cables and

appropriate sensor direction (for presence

detection sensor (SRF02) and temperature

sensor (MLX90614)) are required.

• Non-intrusiveness: as the oven surface is free

and the components of the system are placed in

adequate positions to monitor hazards and

prevent risk situations. However, for the

experimentation purpose two sensors are placed

in the workspace in addition to the

microcontroller and a computing unit.

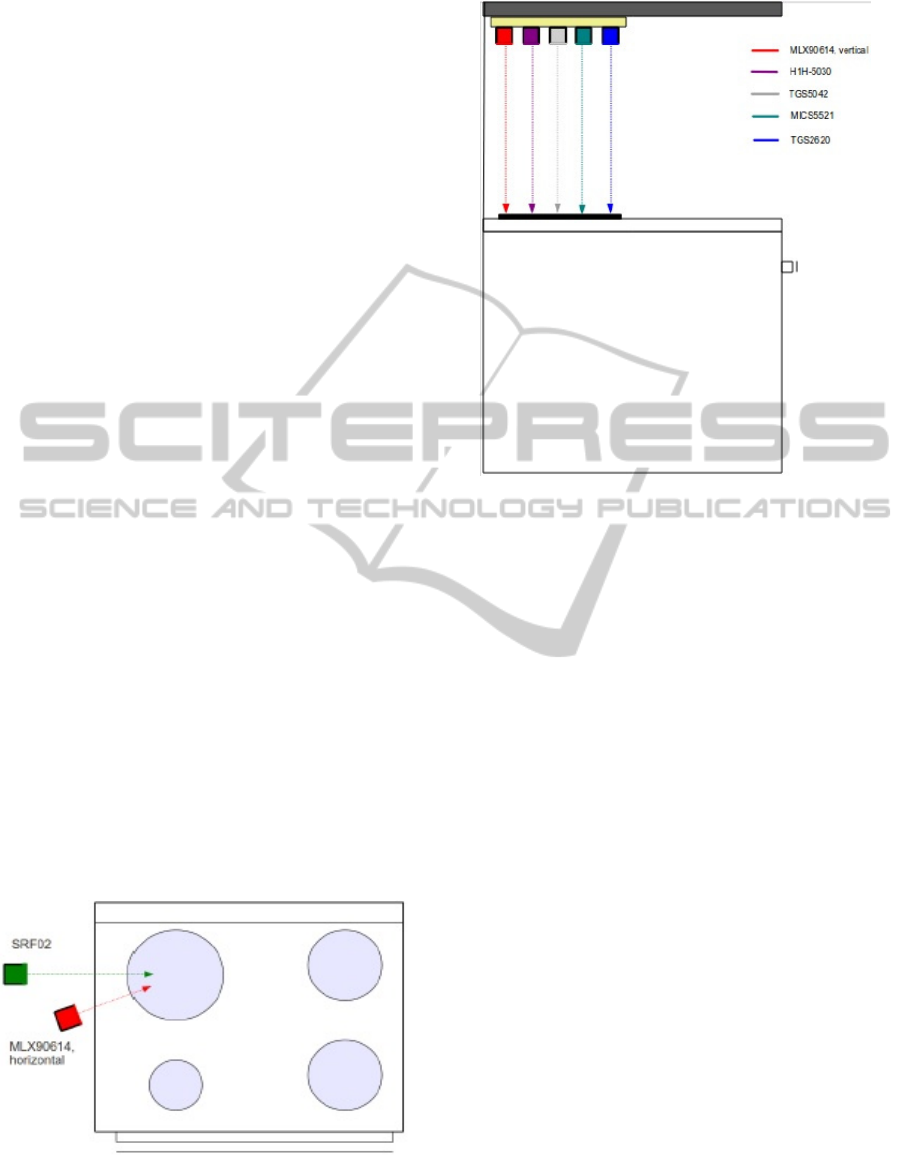

6.5 Sensors Positioning

The output voltage of a sensor varies according to its

position. Therefore, an appropriate sensor

positioning around the oven is required, to acquire

precise sensor measurements and to satisfy the

integration constraints presented in subsection 6.4,

we investigated several configurations and following

is our solution (Figure 4, Figure 5): We placed on

the oven hood level as illustrated in Figure 5 the

following sensors: humidity sensor (H1H-5030),

VOC sensor (MICS5521), Alcohol sensor

(TGS2620), CO sensor (TGS5042), and temperature

sensor (MLX90614) to measure burner temperature.

We placed on the workspace as illustrated in Figure

4 the following sensors: presence detection sensor

Figure 4: Positioning on workspace (20 cm to the left side

of burner) of SRF02 sensor for detecting presence of

utensil on burner and MLX90614 sensor for measuring

utensil temperature.

Figure 5: Positioning of sensors on level of oven hood.

The temperature sensor MLX90614 is to measuring burner

temperature.

(SRF02) for detecting presence of utensil on burner

and temperature sensor (MLX90614) to measure

utensil temperature.

This positioning configuration is non-intrusive as

possible, in order not to disturb user movement and

cooking habits. In addition, positioning sensors at

the level of oven hood allows adequately monitoring

the required parameters.

In addition, the distance between oven hood and

cooking utensils is adequate for acquiring precise

measurements from sensors based on the results of

test for each sensor (Section 7). The motivation

behind positioning SRF02 on workspace for

detecting presence of utensil on burner is that the

distance (20 cm) is appropriate for this sensor

measurements and the positioning on workspace can

avoid cooking heat if it is placed on the level of oven

hood. We placed MLX90614 sensor on workspace

for measuring utensil temperature (20 cm to the left

side of burner) because of the low infrared

emissivity of utensil’s metal which obstructs its

temperature measurment.

7 SYSTEM TESTING

A series of tests has been performed for each

selected sensor. The objective is to investigate the

behavior of each sensor in real world, and thus

TowardPervasiveComputingSystemtoEnhanceSafetyofAgeingPeopleinSmartKitchen

23

determine its limitations. To illustrate the

importance of the test let examine the following

cases. Temperature, humidity, and gases change

frequently around the oven. Furthermore, there is no

single method of cooking in real-world. These

factors may affect sensing data (e.g., putting a small

utensil on a large burner, may affect the

measurements of the presence detection sensor).

Thus, various cooking behaviors have to be

considered to obtain correct and precise

measurements. Measurements of sensors are also

affected by the position and orientation of sensors

(e.g., the temperature sensor does not give the exact

temperature if placed far from the monitored object).

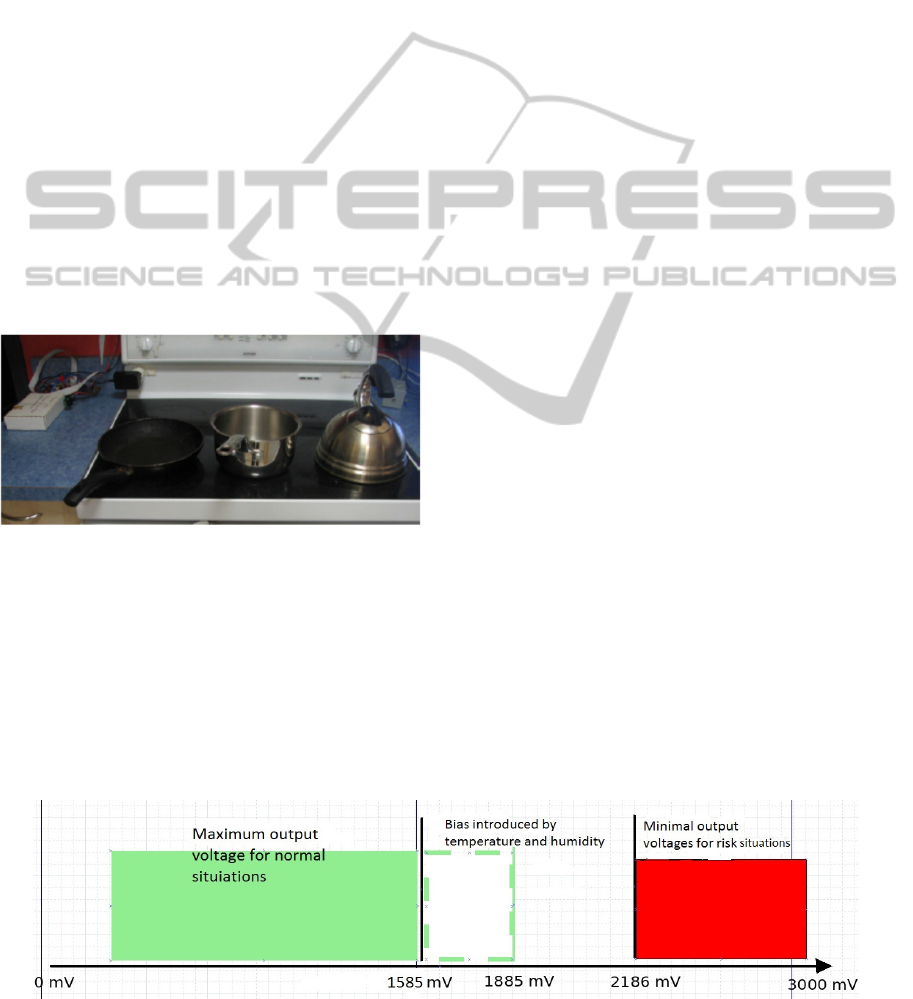

7.1 Test Settings

The first test series was performed using one burner

of the oven, using neither ventilation nor light above

the oven because prior experiments revealed that

sensory date are changing with oven ventilation

and/or light. Utensils used are: saucepan, kettle

(brilliant metal), pan (opaque metal) illustrated in

Figure 6

, for this series of the tests.

Figure 6: Cooking utensils used for testing sensors.

The saucepan is smaller than the burner in order

to study non-ideal situations. These cooking tools

are selected to study the infrared emissivity between

different metals, and explain different behaviors of

an infrared sensor. We also experiment cooking

several kinds of food: fish, meat, onion, peppers, and

spaghetti. Also, we experiment heated oil (50ml of

canola oil) in a frying pan for 8 minutes until oil

starts to shudder.

7.2 Test Results

Following we present the results of tests performed

on the selected sensors.

7.2.1 Results of VOC and Alcohol Sensors

We illustrate in

Figure 7

the distinct boundaries

between normal and risk situations according to

output voltages of the VOC and Alcohol sensors,

while cooking several kinds of food. The output

voltages of VOC and Alcohol sensors in normal

situations are as follows:

• In case of cooking hotdogs in a frying pan

(Figure 8), the maximal output voltages for

normal situation are around 1500 mV.

• In case of cooking fish, onion and peppers in a

frying pan (Figure 9), the maximal output

voltages for normal situation are near 1000

mV.

• In case of heating oil in a frying pan (e.g., for 8

minutes) (Figure 10), the maximal output

voltages for normal situation are near 2000 mV

because heated oil releases more VOC and

Alcohol in the cooking smoke compared to

cooking red meat, which releases more VOC

and Alcohol than cooking fish and vegetables.

Therefore, output voltages of VOC and Alcohol

sensors allow determining fire risk. If output

voltages are greater than 2000 mV, then there is a

potential fire risk.

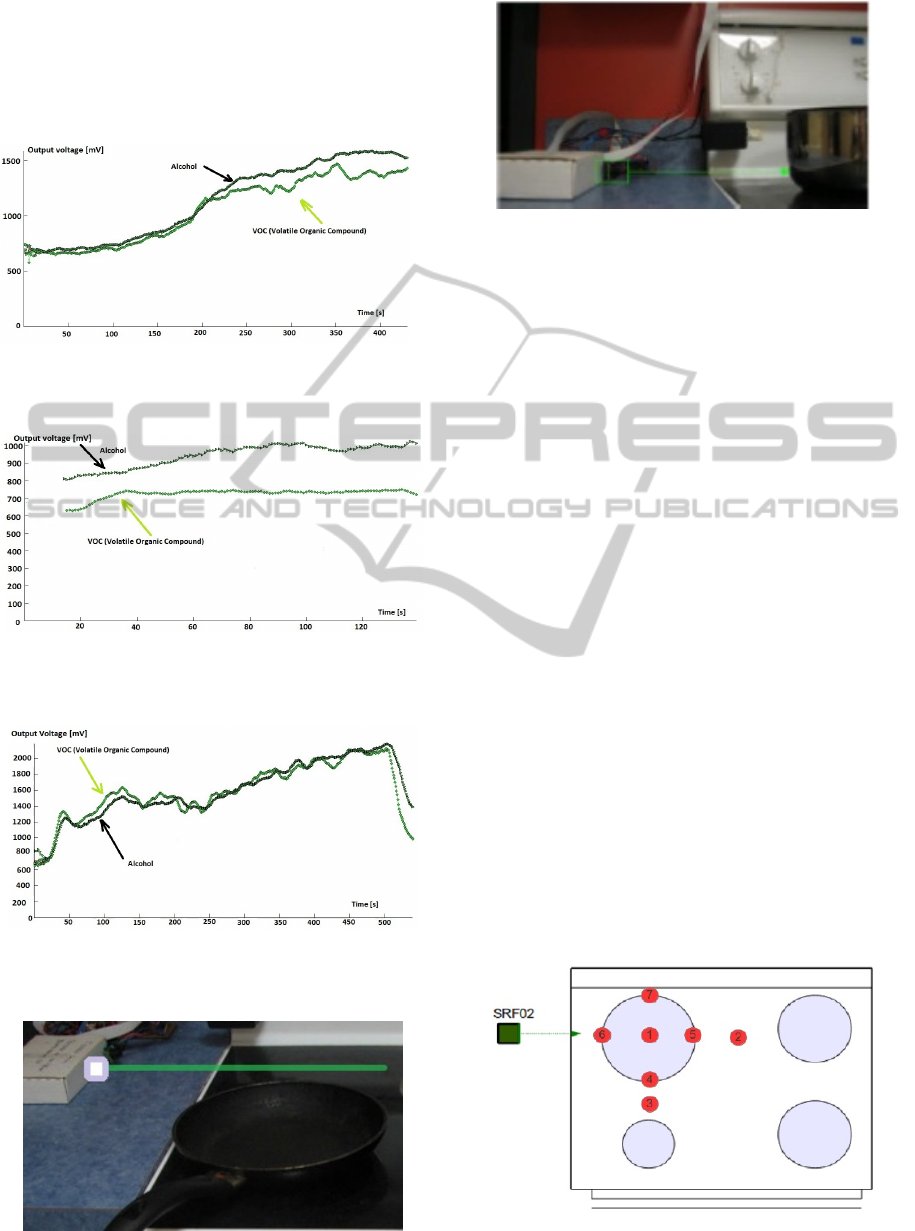

7.2.2 Results of Presence Detection Sensor

SRF02 is an ultrasonic sensor used to detect

presence of utensil on burner, based on measuring

the distance between the sensor and the utensil.

Sonar wave propagation depends on the propagation

medium, so air variable conditions affect wave

propagation. Ultrasonic sensor must compensate

these effects in a variable environment. However,

this sensor does not integrate such compensations.

So, it has to be placed where the air is the most

stable as possible; otherwise measurements will not

Figure 7: Output voltages of Alcohol (TGS2620) and VOC (MICS5521) sensors in normal and risk situations.

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

24

be precise. We excluded certain places such as the

oven hood (hot air, cooking gases, and evaporated

water) and the control panel because the temperature

will be very high. Therefore; we positioned the

presence sensor on the workspace around 20 cm to

the left of the burner as illustrated in Figure 11.

Figure 8: Output voltages of MICS5521 VOC and

TGS2620 Alcohol sensors when cooking hotdogs in a

frying pan.

Figure 9: Output voltages of MICS5521 VOC and

TGS2620 Alcohol sensors when cooking fish in a frying

pan.

Figure 10: Output voltages of MICS5521 VOC and

TGS2620 Alcohol sensors when frying oil during 8

minutes.

Figure 11: SRF02 sensor horizontal position.

Figure 12: SRF02 sensor vertical position (2 cm) above

workspace.

We found that the appropriate vertical

positioning of the SRF02 sensor is around 2 cm

above workspace (Figure 12). This vertical location

allows detecting the presence of utensils with little

height, like frying pan. If the sensor is vertically

located lower than 2 cm then parasite may affect its

measurements.

We tested SRF02 sensor by changing oven state

(on/off), utensil type, utensil volume, and position of

cooking utensil on burner. The goal of changing the

position of cooking utensil on burner is to study the

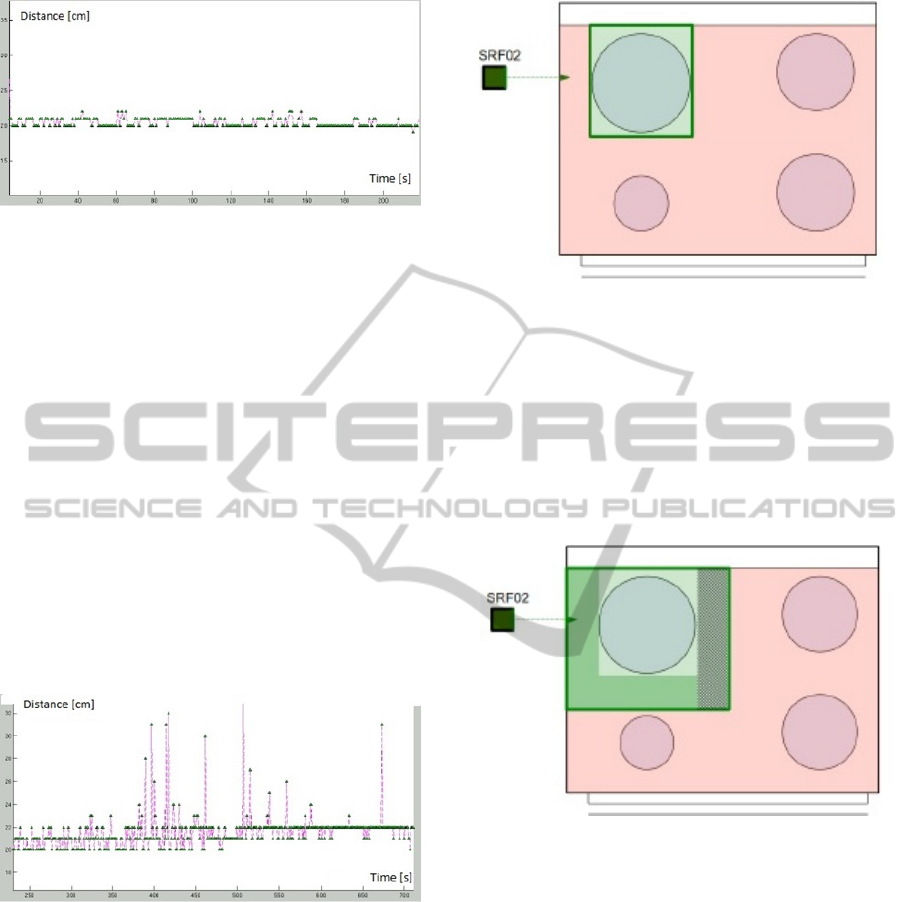

effect of heat on distance measurement. Figure 13

shows 7 different positions of the center of utensil.

A series of measurements was performed, and

yielded the following results:

• The very low position of the sensor is

appropriate because this does not cause

reflections. However; it must be horizontally

oriented.

• To maintain the stable state of the sensor, a

carton box covered it. Without these

precautions, parasitic reflections appear.

• The measured values would be aberrant, if a

cooking utensil was placed further than 30 cm

from the sensor.

• The experimental results show that the form and

volume of a cooking utensil has no impact on

distance measurement using SRF02 ultrasonic

sensor.

Figure 13: Positions of the center of utensil on burner for

testing SRF02 sensor.

TowardPervasiveComputingSystemtoEnhanceSafetyofAgeingPeopleinSmartKitchen

25

Figure 14: Distance measurements [cm] by SRF02 sensor

while cooking meat in a frying pan placed in the middle of

burner.

The obtained results prove that ultrasonic wave

propagation varies with surrounding air temperature.

Each time there is hot air between sensor and object,

the measurements becomes less reliable. This is the

case when the cooking utensil is not placed in the

center of burner, or the case when the cooking

utensil is smaller than the burner.

Figure 14 shows

distance measurements while cooking meat in a

frying pan which is larger than the burner and placed

in its center. The flow of hot air between the sensor

and the pan is minimal and hence measurements of

distance are reliable. Figure 15 shows variable

distance measurements while heating water in the

saucepan which is smaller than burner and placed in

its center. The reason for unreliable measurements is

that the exterior of the burner heats the surrounding

air between the sensor and the cooking utensil.

Figure 15: Distance measurements [cm] by SRF02 sensor

while heating water in a saucepan placed in the middle of

burner.

The previous results reveal that it is possible to

detect that an object is on burner. Variations in

distance measurements according to the position of

utensil allow us to determine a confidence zone,

such that, if an object is placed in the interior of this

zone, it is considered to be on the burner. The

confidence zone is illustrated in

Figure 16 and Figure

17.

Detecting that an object is on burner is

performed by comparing the distance returned by the

sensor with threshold values.

Figure 16: The ideal situation: if utensil is located inside

the rectangle (green zone), then it is on burner, otherwise

(pink zone) it is not.

7.2.3 Results of Humidity Sensor

As described in the sensors positioning section,

humidity sensor is placed at the oven hood’s level.

Steam is transported by the smoke released while

cooking process. The smoke rises up towards the

oven hood.

Figure 17: The actual situation: the inner rectangle (light

green zone) represents the real “on-burner” zone. A utensil

inside this zone is detected by SRF02. The outer rectangle

(dark green) zone represents the false positive zone of

SRF02 sensor where a utensil is detected as “on-burner”

and in reality it is outside burner. The shaded zone

represents the dead zone of the sensor.

This series of tests focuses on heating water using

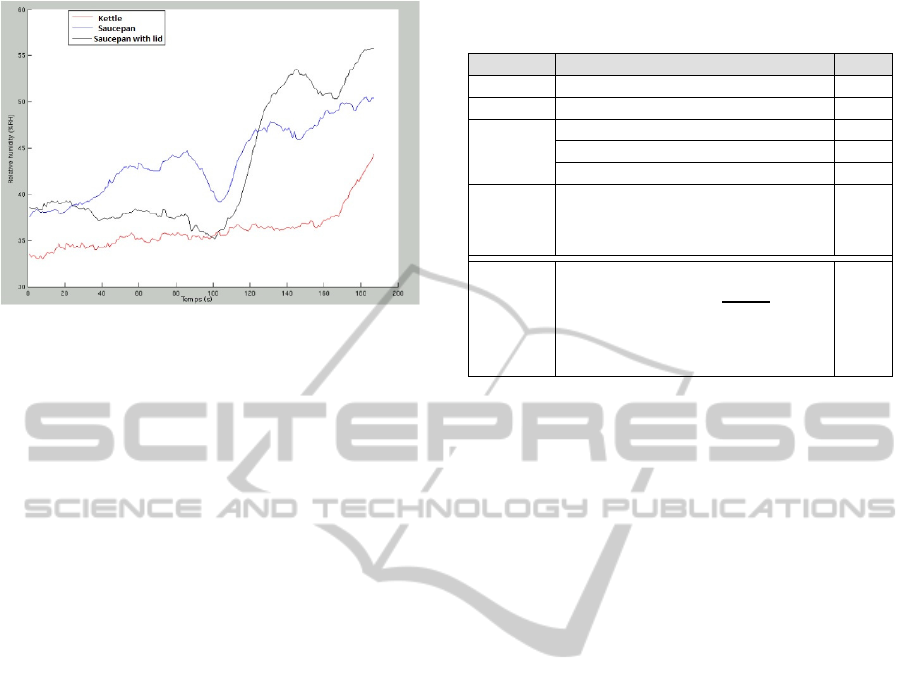

kettle, saucepan, and saucepan with lid. The

experiments were performed with a cooking utensil

half-filled with water.

Figure 18 illustrates the

obtained results.

As expected, variations in humidity depend on the

quantity of steam released. While a lid covers the

saucepan, steam cannot be ejected. The hygrometer

starts and reacts immediately when steam is ejected.

The saucepan without a lid carries more knowledge

about boiling phenomena. Before water simmers, we

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

26

Figure 18: Relative humidity when water boils in: kettle,

saucepan, and saucepan with lid.

observe increment in relative humidity %RH, which

means that a small quantity of steam is released.

This indicates an object is heated on a burner. Then,

another increment of 5%RH indicates that water is

simmering so the global water temperature is around

100°C. It is important to notice the difference in

water temperature on the surface and in the bottom

of the saucepan. When steam is released, the

temperature of water molecules in the bottom of the

utensil becomes around 100°C, and these molecules

rise to the surface. The temperature of molecules on

the surface is lower. Therefore, rapid variation in the

humidity is an important indicator of water

temperature in a cooking utensil.

To conclude, previous tests show that it is

feasible to prevent splash burn risk based on relative

humidity, because it does not change significantly

unless a liquid is being heated. Tests also revealed

that there are clear thresholds which enables to

separate between normal and risk situations.

Therefore, an algorithm of splash burn prevention

can be established.

7.2.4 Results of Temperature Sensor

Hot objects during cooking are utensils and burner.

We performed 12 experimentations to measure the

temperature of cooking utensils when water boils:

three with a kettle, three with a frying pan, and six

with a saucepan. In addition, we investigated

dangerous situations by heating empty frying pan

and saucepan. These experiments cover the majority

of daily cooking situations. The motivation behind

experimenting with boiled water is to overcome the

measurements imprecision of the infrared sensor

used to measure the temperature of cooking

equipment since water boils at a known temperature

(100°C). The results are presented in

Table 2.

Table 2: Experimental results of the measured utensil

temperature when water boils.

Utensil Experiment configuration °C

Kettle middle of burner 40°C

Frying pan middle of burner 65°C

Saucepan

Bottom left corner of burner 58°C

Middle of burner of burner 80°C

Up right corner of burner 110°C

Saucepan,

Frying pan

,

Kettle

All utensils in the middle of burner,

which is preheated.

111°C

67°C

45°C

Frying pan

Kettle

Saucepan

Saucepan

Saucepan

All utensils are placed in the middle

of burner and heated empty (hazard

situation) during 5 minutes.

Bottom left corner of burner

Up right corner of burner

113°C

69°C

100°C

64°C

150°C

The imprecisions in measurement of utensil

temperature are due to the low infrared emissivity of

metals and to the heat of cooking that disturb the

measurements of this infrared sensor.

8 CONCLUSIONS

Enabling kitchen safety is a major factor in

independent living for ageing people. We present in

this paper our cooking-safe system and illustrated in

details the selected sensors that constitute the basic

building block of the system. We have started

building the system by performing an insightful

cooking risk analysis and assessment. As a result,

we identified the major risks during cooking as: fire,

burn (by contact or splash), and intoxication (by gas

or smoke). We also presented this paper our

experimental study to determine the pertinent

parameters to monitor in order to prevent the three

major risks. As results the parameters are: the

concentration of VOC, Alcohol, CO gases in the

cooking smoke, ambient temperature, temperature of

utensil, temperature of burner, relative humidity, and

presence of an object on burner. In addition, we

presented the significant experimental results used to

select the appropriate sensors to measure the

pertinent parameters. The presented results are the

foundation of our work on designing algorithms to

prevent fire, burn, and intoxication by gas/smoke

risks, which will be presented in other papers.

REFERENCES

Ahrens, M. 2008. Home Smoke Alarms: The Data as

Context for Decision. Fire Technology, 44(1), pp.313–

327.

TowardPervasiveComputingSystemtoEnhanceSafetyofAgeingPeopleinSmartKitchen

27

Alwan, M., Dalal, S., Mack, D., Kell, B., Turner, J.,

Leachtenauer and Felder. 2006. Impact of monitoring

technology in assisted living: outcome pilot. IEEE

Trans. Inf. Technol. Biomed., 10: 192–198.

Chen, J., Chi, P., Chu, Chen and Huang. 2010. A Smart

Kitchen for Nutrition-Aware Cooking. IEEE Pervasive

Computing.

Chen, Y., Lee, S., Chang, Y., and Wahlqvist, L. 2012.

Cooking frequency may enhance survival in

Taiwanese ageing. Public health nutrition, 15(07),

pp.1142-1149.

Doman, K., Kuai, Y., Takahashi, T., Ide, I., Murase, H.

2011. Video CooKing: Towards the synthesis of

multimedia cooking recipes. Lecture Notes in

Computer Science.

Gitlin, N. 2003. Conducting research on home

environments: Lessons learned and new directions.

The Gerontologist, 43(5), pp.628-637.

Hall. 2006. Home cooking fire patterns and trends.

National Fire Incident Reporting System (NFIRS).

Jacobsen, A., Kent, M., Lee, M., Mather, M. 2011.

America’s aging population. Population Bulletin,

66(1), pp. 1-20.

Kaplan, S., and Garrick, J., 1981. on the quantitative

definition of risk. Risk Analysis, 1(1).

Li, Y., Asghar, Z, Pulii, P. 2013. Visually-aided smart

kitchen environment for senior citizens suffering from

dementia. In proceedings of the IEEE International

Joint Conference on: Awareness Science and

Technology and Ubi-Media Computing (iCAST-

UMEDIA), pp. 584-590.

Loraine, Cole, Samantha, Daniel, Wan. 2014. 65+ in the

United States, U.S. Census Bureau, Government

Printing Office, Washington, DC.

Lushaka, B., and Zalok, E. 2014. Development of a

sensing device to reduce the risk from kitchen fires.

Fire technology, 50(3), pp.791-803.

Martel, L. and Menard, F. 2011. Statistics Canada,

Canadian Census, Demography Division.

Marzocchi, W., Garcia-Aristizabal, A., Gasparini, P.,

Mastellone, L., and Di Ruocco, A. 2012. Basic

principles of multi-risk assessment: a case study in

Italy. Natural hazards, 62(2), pp.551-573.

Public Health agency of Canada. 2006. Healthy Aging in

Canada: A new Vision, From Evidence to Action.

Reducing stovetop fire. Fire Marshal's Public, 2009.

Sanchez, A., Burnell, L. 2013. Intelligent and Adaptive

Educational-Learning, Springer. Intelligent and

Adaptive Educational-Learning Systems Smart

Innovation, Systems and Technologies, vol. 17,

pp.293-314.

Sperling, Reisa. 2011. Toward defining the preclinical

stages of Alzheimer’s disease: Recommendations from

the National Institute on Aging-Alzheimer's

Association workgroups on diagnostic guidelines for

Alzheimer's disease. Alzheimer's and Dementia,

pp.280-292.

Toshio, O., and N. Iwasaki. 2013. Innovative applications

and strategy on ICT applications for aging society:

case study of Japan for silver ICT innovations. In

Proceedings of the 7th ACM International Conference

on Theory and Practice of Electronic Governance.

Wahl, W., and Gitlin, N. 2003. Future developments in

living environments for older people in the U.S. and

Germany: Potential and constraints. In Aging

independently: Living arrangements and mobility. pp.

281–301. New York: Springer.

Wai, A. Shanthini D., Biswas, J. and Panda, S. 2011.

Pervasive intelligence system to enable safety and

assistance in kitchen for home-alone ageing. Toward

Useful Services for Ageing and People with

Disabilities, Berlin: Springer, pp.276-280.

Yuan, J., Green, R., Goubran. 2012. Thermal Imaging for

Assisted Living At Home: Improving Kitchen Safety.

Journal of Med. Biol. Eng.

ICT4AgeingWell2015-InternationalConferenceonInformationandCommunicationTechnologiesforAgeingWelland

e-Health

28