Using Ontologies to Support Model-based Exploration of the

Dependencies between Causes and Consequences of Hazards

Abigail Parisaca Vargas and Robin Bloomfield

Centre for Software Reliability, City University, London, U.K.

Keywords:

Preliminary Hazard Analysis, Hazard Analysis, Hazard Identification, Ontologies, Railway.

Abstract:

Hazard identification and hazard analysis are difficult and essential parts of safety engineering. These ac-

tivities are very demanding and mostly manual. There is an increasing need for improved analysis tools and

techniques. In this paper we report research that focuses on supporting the early stages of hazard identification.

A state-based hazard analysis process is presented to explore dependencies between causes and consequences

of hazards. The process can be used to automate the analysis of preliminary hazard worksheets with the aims

of making them more precise, disambiguating causal relationships, and supporting the proper definition of

system boundaries. An application example is presented for a railway system.

1 INTRODUCTION

Hazard identification and hazard analysis are difficult

and essential parts of safety engineering. These activ-

ities are very demanding and mostly manual. There

is an increasing need for improved analysis tools and

techniques. In this paper we report research that fo-

cuses on supporting the early stages of hazard identifi-

cation. Hazard analysis is the identification of hazards

and their initiating causes (International Organization

for Standardization, 2000). It can be thought of as the

process of investigating an accident before it actually

occurs. Its aim is to exhaustively identify all possible

causes of accidents, so that they can be eliminated or

controlled before they occur (Leveson, 2011). Hazard

analysis is extremely important, and lack of complete-

ness in the analysis can have serious consequences.

A hazard is a potential source of harm. The term

includes danger to persons arising within a short time

scale, for example, fire and explosion, and also those

that have a long-term effect on a person’s health, such

as release of a toxic substance (ISO, 1999). Harm is

a physical injury or damage to the health of people or

damage to property or the environment (ISO, 1999).

Hazard identification (HazID) is one of the most

important parts of the hazard analysis, as it forms the

basis of the activities carried out to design a safe sys-

tem. By looking at the system from a safety per-

spective, safety analysts check important aspects of

the system and try to identify hazards that could have

been accidentally overlooked. Common methods for

identifying hazards at the early stages of system de-

sign are checklists, HAZOPs (Hazard and Operabil-

ity Studies) and PHA (Preliminary Hazard Analy-

sis) (Kletz, 2001).

Various studies asserted that the most significant

flaws in hazard analysis techniques applied at the

early stages of system design are often related to

the omission of hazards and hazard causes (Hardy,

2010). One reason for this could be that most haz-

ard analysis techniques rely on the manual analysis

of information recorded in text format using differ-

ent spreadsheet representations, called hazard identi-

fication worksheets. The most basic description of a

worksheet would be a table of three columns, where

the first column describes a hazard, the second col-

umn describes the cause or causes of that hazard, and

the third column describes the consequences of the

hazard occurring. Different examples of this basic de-

scription will be discussed further in this paper.

Data and facts are usually abundant in hazard

analysis worksheets. Because of this, for complex

systems, there is always a good chance that even ex-

pert analysts could accidentally miss something, and

therefore draw conclusions on the basis of incom-

plete information. A mechanised process for system-

atic exploration of the dependencies between hazards,

causes and consequences of hazards would therefore

be a convenient way of supporting experts during the

analysis.

Various initiatives in the safety sectors are explor-

ing the use of ontologies as a means to mechanise

316

Vargas, A. and Bloomfield, R..

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards.

In Proceedings of the 7th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2015) - Volume 2: KEOD, pages 316-327

ISBN: 978-989-758-158-8

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the analysis of causal dependencies in hazard analysis

techniques. The aims of these initiatives are generally

to capture consensual knowledge, reuse it and share

it across different application domains and different

teams (Corcho et al., 2003). For example, in (Mayer

et al., 2008), an ontology is described for representing

risk and risk assessment processes, as well as con-

cepts such as hazards and threats. Others have ex-

plored the use of ontologies to support standard haz-

ard analysis techniques, such as Job Hazard Analy-

sis (e.g., see (Wang and Boukamp, 2009)), HAZOP

(e.g., see (Stralhane et al., 2010; Daramola et al.,

2011)), and FMEA (e.g., see (LEE, 2001)), or other

hazard analysis techniques targeted to industrial sec-

tors like construction, food supply (Letia and Groza,

2010; Yang et al., 2012), geology (Liu et al., 2010),

and many others.

Despite all the examples above, little attention has

been devoted to using ontologies for the analysis of

preliminary hazard worksheets generated at the early

stages of system design. Being able to analyse these

preliminary worksheets is highly desirable, as issues

can be resolved earlier in the development process,

when it is easier and cheaper to fix problems. The

present work aims to address this gap.

Contribution. In this paper we present an approach

to facilitate the analysis of preliminary hazard work-

sheets generated at the early stages of system de-

sign. The approach facilitates the resolution of weak-

nesses in the hazard identification process. In our ap-

proach, an ontology is used to review preliminary haz-

ard worksheets using a mechanised process based on

a set of inference rules. Our approach allows one to

check well-formedness of hazards, their causes, and

consequences, as well as to discover new relation-

ships between hazards, causes and consequences, if

these were accidentally omitted in the hazard work-

sheets. The final result obtained using our approach is

therefore an improved version of preliminary hazard

worksheets, with disambiguated hazards and polished

causal relationships.

Organisation. The paper is organised as follows. In

Section 2, we contrast and compare our work with

related work. In Section 3, we introduce our ontology.

Then, in Section 4, we explain our proposed method,

its steps, and the reasoning we used. In Section 5,

we illustrate the method on a case study. Finally, in

Section 6, we briefly conclude, summarise the results,

and discuss future work.

2 RELATED WORK

A number of different hazard analysis techniques

have been created over the last fifty years, and they

are currently widely used by safety-critical industries.

There are different examples of their use in com-

plex systems (Leach, 2010; Zhang et al., 2010; Cen-

ter for Devices and Radiological Health, US FDA,

2010). There are also examples of adaptations of stan-

dard hazard analysis techniques for identifying secu-

rity hazards (Winther et al., 2001).

Despite the wide use of the standard hazard anal-

ysis techniques mentioned above, there is also strong

criticism of them. New techniques are, in fact, being

proposed that are specifically designed for the anal-

ysis of hazards in today’s complex socio-technical

systems. For example, Nancy Leveson describes a

new approach to hazard analysis, STPA (System-

Theoretic Process Analysis) (Leveson, 2011), based

on the STAMP causality model. Another example

is the Ontological Hazard Analysis (OHA) (Ladkin,

2005; Ladkin, 2010) proposed by Peter Ladkin for the

analysis and maintenance of safety hazard lists using

a refinement approach.

Differently from the efforts cited above, we do

not aim to introduce a novel hazard analysis tech-

nique. Rather, we propose a mechanised method that

can improve the analysis of results obtained at the

early stages of system design. In the method pre-

sented in this paper, we start from preliminary haz-

ard worksheets, and use an ontology to check consis-

tency and well-formedness of information contained

in these preliminary documents.

Finally, in his book called HAZOP and

HAZAN (Kletz, 2001), Trevor Kletz discusses

the feasibility of the automation of HAZOPs, for

example, applying techniques from Artificial Intel-

ligence, and whether these techniques could replace

the safety analyst. Kletz concludes it is impossible.

He gives two important objections to the automation

of HAZOPs:

1. Artificial intelligence techniques can manipulate

logical rules, but logic is just one aspect of hu-

man intelligence. For example, most of the scien-

tists who have recounted how they came to make

an important discovery or to achieve a significant

breakthrough have stressed that when they found

the answer to the crucial problem they intuitively

recognised it to be right, and only subsequently

went back and worked out why it was right (Kletz,

2001).

2. Knowledge used in HAZOPs is broad and deep,

while expert systems are suitable only for narrow

and deep knowledge (Kletz, 2001).

Logic is not able to represent all the knowledge

and expertise of the safety analyst. We do not aim

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

317

to represent this; instead, we want to represent the

knowledge already captured by hazard identification

techniques, usually in worksheets. We want to be

able to find logical relationships, which could have

not been seen, and point out the relevant information

that might have been hidden because of the quantity

of information represented.

3 DEVELOPING THE

ONTOLOGY PROTOTYPE

Ontologies, or explicit representations of domain

concepts, provide the basic structure or frame-

work around which knowledge bases can be

built (Devedzi

´

c, 2002; Swartout and Tate, 1999). On-

tologies are specific, high-level models of knowledge

underlying all things, concepts, and phenomena. As

with other models, ontologies do not represent the en-

tire world of interest. Rather, ontology designers se-

lect aspects of reality relevant to their tasks (Devedzi

´

c,

2002; Valente et al., 1999).

During the design of the ontology prototype, we

used a UML-like modelling language. It has been

argued that UML can be used to model ontolo-

gies (Cranefield and Purvis, 1999), yet there are re-

cent, more specialised modelling languages, like On-

toUML (Benevides et al., 2010).

We decided to use the ontology engineering en-

vironment Prot

´

eg

´

e because it provides an integrated

environment for the ontology development and it has

different features supporting different tasks during

the ontology life cycle. The knowledge representa-

tion language of choice was OWL-DL because it is

the most used by the ontology development commu-

nity (Simperl et al., 2009), and because OWL-DL and

SWRL offer a number of sophisticated reasoning ca-

pabilities.

3.1 Ontology Domains

When developing an ontology, we aim to formally

and explicitly describe concepts in a domain, as well

as their properties. Describing the concepts involves

defining classes for these concepts and arranging

them in a hierarchy.

The first domain we work on is the HazID work-

sheets HI, which consist of different hazards with

multiple causes and where different consequences

might exist.

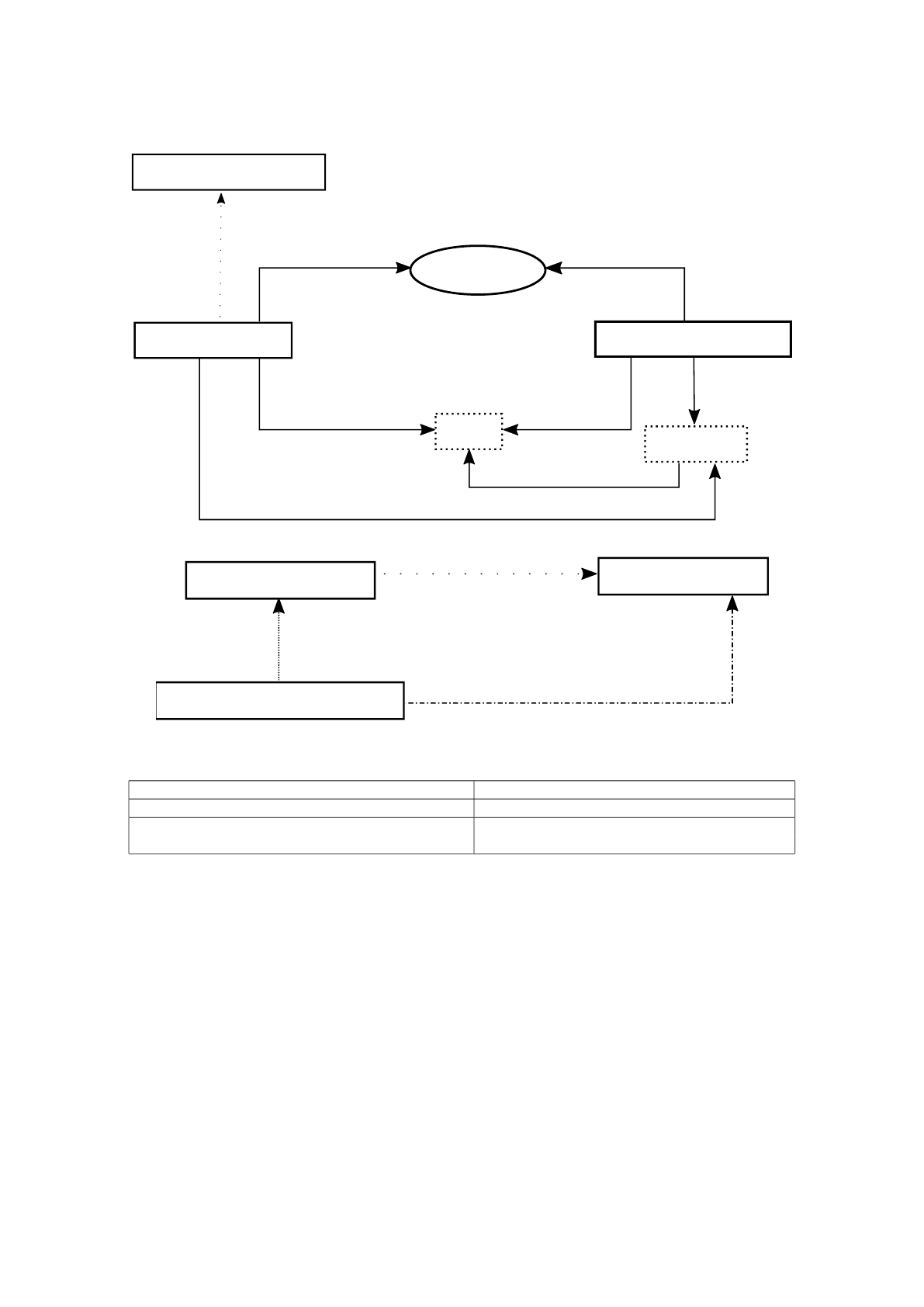

Table 1 shows a basic example of the main

part of a HazID worksheet. The example is taken

from (Evans and Associates, 2006). The hazard de-

scription for hazards A − 5 is Toxic gases in tunnel.

Consequence

Cause Hazard

Situation

isCauseOfHazard

isHazardForCause

isConseqOfHazard

isHazardWithConsequence

1..*

1..*

1..*

1..*

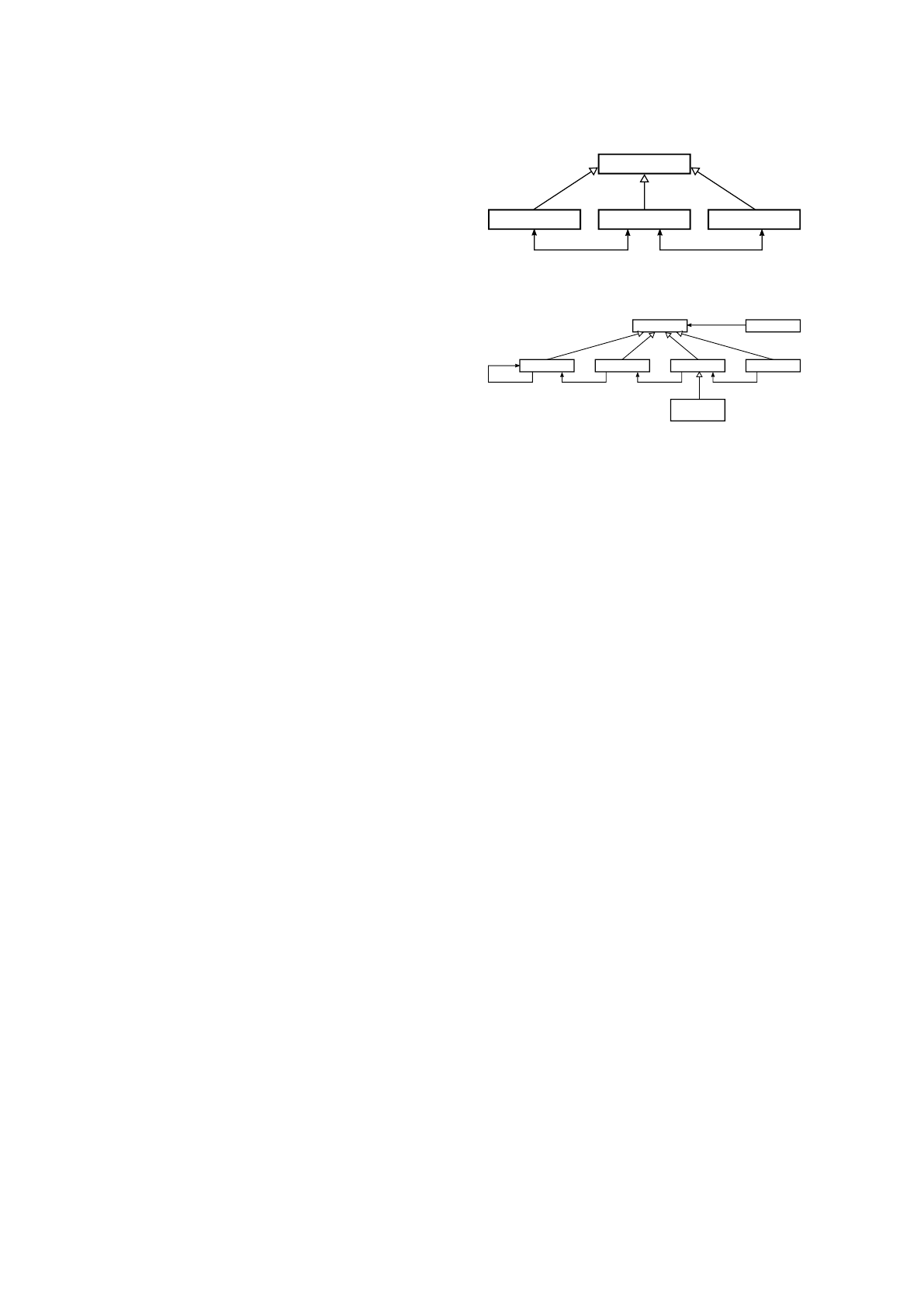

Figure 1: Examples of concepts that are part of our ontol-

ogy.

Process

Object

Component

Part

System

Subsytem

Common

Driver

isMemberOf isMemberOf

isMemberOf

isMemberOf

processInvolves

1..*

1..*

1

1

1

11

1

1

1

Figure 2: Part of Ontology.

The cause of this hazard is Toxic gases enter in tun-

nel from alignment or station. The alignment in the

context of a railway is the ground plan of the railway,

as well as the path that the train follows. The con-

sequences for hazard A − 5 are injury, death or ser-

vice disruption. Another cause of hazard Toxic gases

in tunnel is Maintenance personnel release toxic gas

while performing work.

Figure 1 shows the concepts of Hazard, Cause,

and Consequence represented in our ontology and the

relationships among them. Boxes in the figure repre-

sent the concepts, arrows with triangular heads rep-

resent inheritance, and arrows with two heads repre-

sent the relationships. The concepts can be used to

define a set of hazards, H, consisting of h

1

. . . h

n

indi-

vidual hazards; a set of causes, consisting of c

1

. . . c

n

individual causes; a set of consequences, consisting

of q

1

. . . q

n

individual consequences. Figure 1 shows

the relationships among these concepts. The rela-

tionships cause-hazard and hazard-consequence are

many-to-many. That is, a cause might occur on differ-

ent hazards, and a consequence might occur on sev-

eral hazards. In the hierarchy of types, Situation is a

higher node and the super type for Hazard, Cause and

Consequence.

Hazard identification is performed within a sys-

tem and its boundaries. In order to represent our ba-

sic ontology, we need to define two core concepts

to represent the characteristics of a system and its

behaviour. We chose Object Process Methodology

(OPM) (Crawley and Dori, 2011) because it is geared

towards modelling systems in general. From an on-

tological perspective, OPM’s building blocks are ob-

jects and processes. We use these concepts in order

to represent the initial design of the system and its

behaviour. An object can be a system, subsystem,

component or a part of the system. The object can be

KEOD 2015 - 7th International Conference on Knowledge Engineering and Ontology Development

318

Table 1: Basic example of HazID worksheet.

Hazard Cause Consequence

A − 5 Toxic gases enter in tunnel from alignment or station Injury, death,

Toxic gases in tunnel Maintenance personnel release toxic gas while performing work service disruption

in a particular state. Processes transform objects by

generating, consuming, or changing their state (Craw-

ley and Dori, 2011). A process can be decomposed

into sub-processes. Figure 7 shows an example of

OPM’s building blocks, where Transporting is a pro-

cess. This process involves the objects Tracks, Align-

ment, LRV, Platform and Station.

”System”, is an important concept we need to

represent in our ontology. The physical domain of

the system is composed of subsystems. Subsystems,

in turn, are composed of components, and compo-

nents are composed of parts. From the CLIOS for-

malism (Sussman et al., 2009), we take the notion

of Common drivers, which are shared components

among subsystems of a system.

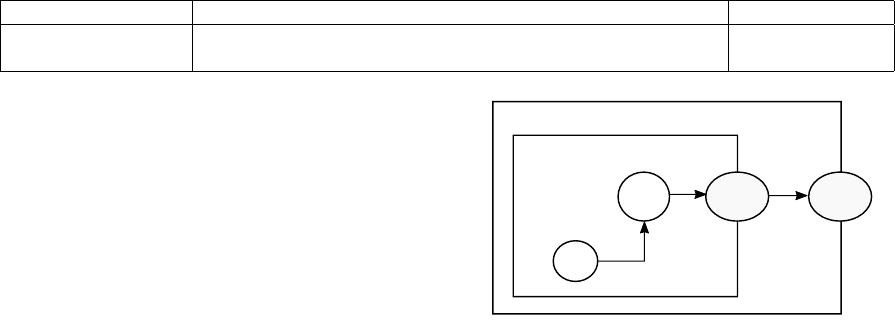

Figure 2 shows the concepts of Object, Process,

System, Subsystem, Component, Common Driver

and Part Modelled. The initial design of a system S,

consists of different natural divisions such as subsys-

tem B, component M, part P. We identify a set of sub-

systems, B, consisting of b

1

. . . b

n

individual subsys-

tems; a set of components, M, consisting of m

1

. . . m

n

individual components; and finally, a set of parts, P,

consisting of individual parts p

1

. . . p

n

. A part might

occur within a component, so then the relationship is

one-to-one. Similarly, the relationship between com-

ponent and subsystem and between subsystem and

system is one-to-one. In addition, a system has a re-

cursive relationship, where a system can be part of an-

other system, and the relationship will again be one-

to-one.

The behavioural description of the system is de-

scribed as the set of objects, O, consisting of o

1

. . . o

n

individual objects; the set of processes, C, consisting

of c

1

. . . c

n

individual processes. An object may par-

ticipate in different processes and a process may oc-

cur in different objects, so the relationship is many-

to-many.

Figure 3 shows that subsystem A is a member of

system B. They have different system boundaries and,

as a result, concentrate on different hazards. System

B provides the environment for subsystem A. A haz-

ard, normally, is described with respect to its system

boundary, so it is a relative term.

Figure 5 shows fundamental concepts of the ba-

sic ontology. ”Thing” is a generalisation of objects,

processes and situations; it represents the class of all

things, or the abstract objects that can be described

by the criteria for being something. This concept is

Subsystem A

System B

Hazard A Hazard B

Figure 3: Hazard in Systems. Based on (Railtrack, 2001).

taken from class-defined ontologies. In addition, Fig-

ure 6 shows four new relationships that we need to

discuss. The hazard information within the ontology

needs to include information such as the scope and lo-

cation of the hazards. When we talk about the scope

of a hazard, we refer to what affects the hazard di-

rectly; we therefore refer to two kind of scopes: be-

havioralScope and physicalScope. If a hazard affects

a determined system, that system will be the scope of

the hazard. When we refer to the physicalScope we

refer to the boundary of the hazard. For example, if

subsystem A is a member of system B, then system B

is the scope of subsystem A. When we talk about loca-

tion, we refer to where the hazard is located in terms

of objects and also in terms of processes; the relation-

ships that we will use will be called physicalLocation

and behaviouralLocation.

Hazards, causes and consequences could be inter-

linked by any of these characteristics. This kind of

knowledge is already known by the safety analyst or

it can be deduced by reading the HazID description.

The idea is that information provided by these rela-

tionships (object properties in Prot

´

eg

´

e) offer a natu-

ral way to establish associations among hazard mean-

ing, or senses, in a certain HazID process. This can

be profitably used during the processing of the haz-

ard worksheets, e.g., to disambiguate the process. For

example, the hazard virus affecting the system, when

referring to an infusion pump medical device, is am-

biguous between its Biology and Computer Science

senses and, therefore, the system boundary of the haz-

ard, can be disambiguated by assigning the correct do-

mains to the contexts where it actually occurs.

3.2 Extended Ontology

In this subsection we explain in detail the extended

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

319

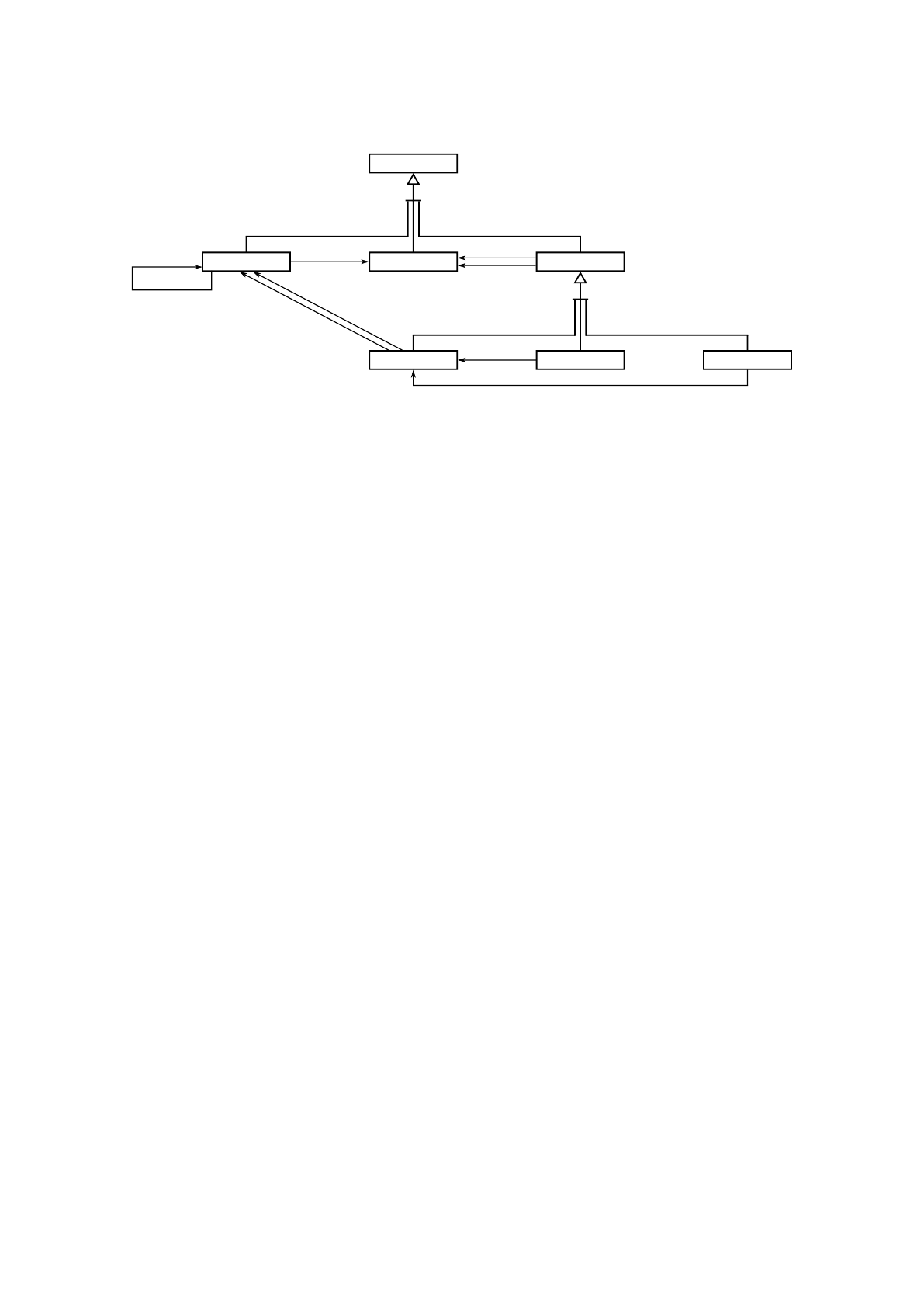

Figure 4: Class hierarchy of complete ontology.

ontology. The extended ontology is formed using

more specific types, i.e., lower nodes in the hierar-

chy. This provides a more granular organisation of

the hazards, causes and consequences, and relation-

ships between them. Figure 4 shows a more detailed

hierarchy of the classes in our ontology.

Hazards have a scope. In order to generate a hi-

erarchy to hazards according to their scope, we cre-

ate equivalent classes called PartHazard, Componen-

tHazard, SubsystemHazard and SystemHazard. When

editing the ontology, the analyst can decide which of

the SystemHazards belong to the HighPriorityHaz-

ards. These are the hazards that are deemed the most

important for analysis by the safety analyst. The class

GenericHazards is useful to handle worksheets with

generic hazards identified using, e.g., a Preliminary

Hazard Analysis.

The class ConsequenceHazard is a subclass of

class Hazard. The classes Consequence and Cause-

Hazard are subclasses of Hazards and Cause.

4 THE METHOD

We developed an ontology to capture domain in-

formation related to hazards, systems, and hazards

within a system. The ontology is designed to help

the analysts in the task of hazard identification using

the knowledge already gathered, and the relationships

that already exist. An ontology provides the means

to structure information by classes, property descrip-

tions and relationships between classes and individ-

uals. Analysts can use the ontology for reasoning

HazID

worksheets

Initial design

of the system

Ontology description

and

inference rules

Input A Input B

knowledge base

End

Populate ontology with

Input A and Input B

Finding relationships among

hazards, causes and

consequences

Reviewed

HazID

Amended

system design

Does it

need more

processing?

Figure 5: Control flow diagram of our method.

about missing relationships between hazards, causes

and consequences. Figure 5 shows the steps of our

method:

1. We start from an initial Preliminary Hazard Anal-

ysis, an initial design of the system, an ontol-

ogy description of the domains, and a set of rules

for reasoning about our domains. The ontology

description models the data from the inputs il-

lustrated above, including property descriptions

and relationships between classes and individu-

als. We used the open-source editor and frame-

work Prot

´

eg

´

e 5.0 (Stanford Center for Biomedi-

cal Informatics Research, 2015). The output is

our knowledge base.

2. The next step is to find possible indirect causal

and overlooked relationships. This is ilustrated

in Sections 5.1 and 5.2. The intention is to use

the structured and automated reasoning provided

by tools for the analysis of ontologies, such as

Prot

´

eg

´

e’s built-in reasoner, Pellet.

KEOD 2015 - 7th International Conference on Knowledge Engineering and Ontology Development

320

ConsequenceHazard Cause

SituationObject

Thing

isConsequenceOf

isCauseOf

physicalLocation

physicalScope

behaviouralLocation

behaviouralScope

involves

Process

isSubproessOf

Figure 6: Core classes of the ontology.

3. The initial results are used to review the HazID

worksheet, and perhaps modify the System De-

sign model. Yet more could be done after the first

amendment, and our knowledge base could still

be reviewed and amended further.

4.1 Reasoning using the Ontology

In this subsection we will explain some concepts that

are needed to understand the reasoning approach im-

plemented with the ontology. The approach will also

be illustrated with concrete examples.

4.1.1 Direct and Indirect Causality

In (Leveson, 2011) Leveson argues that current haz-

ard analysis techniques are event chain models of the

form: ”if event A had not occurred, then the following

event B would not have occurred”. This type of model

supports limited notions of direct causality, and it is

sometimes impossible to incorporate indirect relation-

ships. For example, consider the following statement:

“Smoking causes lung cancer”. It is argued (Leveson,

2011) that in current models such a statement would

not be allowed; however, it is widely accepted that

there is a relationship between the two, even though

the relationship is complex and indirect.

4.1.2 Synonymy, Entailment and Non-direct

Causality

Hazard identification is a demanding task and relies

on detailed descriptions. It is difficult to remember

each and every hazard and cause in a hazard analysis

and, as a consequence, the worksheets may refer to

hazards, causes and consequences in different written

forms. Sometimes this reflects real differences that

should be captured, while in other situations the dif-

ferences are only artificial, and should therefore be

amended. For example, when analysing a road sys-

tem, we could have the following hazards: H − 1 Ve-

hicle drives on the wrong lane; H − 2 Vehicle passes

through the wrong lane; H − 3 Vehicle on the wrong

lane. H − 1 and H − 3 could have the same mean-

ing, or H − 3 could mean that the vehicle actually

stopped on the wrong lane. H − 1 and H − 2 could

also have the same meaning if each just means that

a vehicle temporarily drives on the wrong lane. An

ontology could help the analyst to find and identify

these hazards, as well as to disambiguate them, when

needed, by means of logical rules applied to the struc-

tured knowledge.

When two situations (hazards, causes, conse-

quences) have the same meaning, we will call them

synonyms. Using only inference rules, we cannot de-

termine whether a hazard is a synonym of another

hazard, cause or consequence. To resolve the prob-

lem, we rely on different relationships established be-

tween situations that are part of the HazID entry. For

example, two synonym hazards might have the same

physical location, physical scope, behavioural loca-

tion, or behavioural scope. Therefore, using rules to

find hazards where multiple similar relationships oc-

cur can help to spot synonyms. In addition, a syn-

onym is not the only kind of relationship that can be

spotted. For example, let us consider hazard H − 4

Train on fire. The cause of this hazard is Ca − 1 Train

stopped adjacent to a wayside fire. A train circulates

around different places in a railway system; it also can

stop at different places. For example, it can stop at the

platform, which can be on fire. Following this rea-

soning, there might be a relationship between a haz-

ard called H − 5 Fire on station platform and Ca − 1

Train stopped adjacent to a wayside fire. Therefore,

there might be a nonlinear (indirect) causal relation-

ship between H − 5 Fire on station platform and H − 4

Train on fire.

In logic, entailment (Fellbaum, 1990), or strict

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

321

Transporting

Station

Passenger

Platform

Alignment

Tracks

LRV

waits at

travels on

built on

Figure 7: Top level representation of our initial system de-

sign in OPM.

implication, is properly defined for propositions; a

proposition P entails a proposition Q if and only if

there is no conceivable state of affairs that could make

P true and Q false. Entailment is a semantic relation-

ship because it involves reference to the states of af-

fairs that P and Q represent. We generalise the term

in order to talk about hazards. For us, in the context

of the hazard descriptions for a certain system, entail-

ment refers to the special relationship between two

hazards, where a hazard, H1, of a more general haz-

ard, H2, also entails H2. In addition, if H1 entails

H2, then it can not be the case that H2 entails H1.

In order to explain this, we introduce a brief exam-

ple. We mentioned before that the alignment in the

context of a railway is the ground plan of the railway,

as well as the path that the train follows. The cross-

ing is the crossroad between the train path and the

motor road. Hazards H − 6 Motor vehicle on align-

ment and H − 7 Road vehicle drives around cross-

ing gate refer to a motor vehicle inside the train path.

Because the crossing is part of the path of the train,

H − 7 entails H − 6, because while a motor vehicle

drives around the crossing gate, the motor vehicle is

on the alignment. In addition, H − 6 does not entail

H − 7 because Motor vehicle on alignment does not

necessarily mean that the vehicle is driving around the

alignment. Using inference rules and a reasoner could

therefore help the safety analyst to disambiguate the

meaning of those hazards and also to find hazards in-

terlinked by the causation relationships. The follow-

ing section will exemplify some of these rules and

their application using a case study based on a rail-

way system.

5 CASE STUDY

We now introduce a case study that we use to illus-

trate the method: the West Corridor Light Rail Tran-

sit (LRT) System. Figure 7 shows a representation of

the system in Object Process Modelling (OPM). The

hazard analysis that we use is the Preliminary Hazard

Analysis (PHA) for the West Corridor LRT Project

Design Phase (Evans and Associates, 2006). The de-

scription of the system was inferred from the PHA

document and from terminology in rail transport and

railways (www.allenrailroad.com, 2014; Transport

Canada, 2014; www.railway-technical.com, 2014;

www.trafficsigns.us, 2014; www.railsigns.uk, 2014).

We succinctly describe the system:

• Alignment provides a path and physical infras-

tructure, such as tunnels and crossrails.

• Track is the structure consisting of the rails, fas-

teners, sleepers, and ballast, plus the underlying

subgrade. The track provides the physical struc-

ture by which the Light Rail Vehicle (LRV) circu-

lates.

• A station is a railway facility where trains reg-

ularly stop to load or unload passengers and/or

freight.

• A control system provides help in controlling the

train to prevent accidents and to improve circu-

lation. The service provided can be concisely

described as: train separation or collision avoid-

ance, line speed enforcement, enforcing tempo-

rary speed restrictions, enabling rail worker way-

side safety.

• An Overhead Catenary System (OCS) comprises

different components, such as wires suspended

between poles, bridges supporting overhead con-

tact wires which are normally energised with elec-

tricity, etc. The OCS powers the LRV.

• The LRV is the vehicle that circulates along the

railway and transports passengers.

Figure 7 represents only the top level of the pro-

cess representation. The process Transporting is re-

lated to the objects by the relationship processIn-

volves. In this case, the process involves the objects

LRV, Alignment, Tunnel, Track and Platform. Sub-

processes of Transporting are: Carrying passengers,

Circulating, Grade crossing management, Guiding

LRV, Loading and unloading passengers, and Trans-

mitting power. All these processes are related to ob-

jects and have subprocesses as well. We will mention

some of the processes while developing our examples

in the sections below.

5.1 Example with Non-direct Causality

Let us start from a small subset of the PHA per-

formed. Below, we define the rule that helps us to

find non-direct or indirect causality between hazards

and causes. The property representing this relation-

ship is isIndirectCauseOf.

KEOD 2015 - 7th International Conference on Knowledge Engineering and Ontology Development

322

LRV stopped adjacent to a wayside fire

Circulating

Fire on station platform

Platform

LRV fire

Fire on Alignment

Fire in tunnel

Railway system

Tunnel

LRV

Alignment

physicalLocationOf

physicalLocationOf

physicalLocationOf

physicalLocationOf

physicalLocationOf

processInvolves

processInvolves

processInvolves

processInvolves

Station

isMemberOf

isMemberOf

isMemberOf

isMemberOf

isMemberOf

isCauseOf

Figure 8: Relationships among individuals, exemplifying the relationships that are used in example 5.1.

LRV stopped adjacent to a wayside fire

LRV fire

isCauseOf

Fire on station platform

mightRelateTo

isIndirectCauseOf

Figure 9: Example of non-direct casualty.

physicalLocationOf(?q, ?o),

behaviouralLocationOf(?p, ?a),

Object(?o),

Situation(?p),

processInvolves(?a, ?o),

physicalLocationOf(?p, ?o1),

isMemberOf(?o, ?o1),

Situation(?q),

Process(?a)

→ mightRelate(?p, ?q)

(1)

This rule is explained as follows. Every situa-

tion happens within some object (based on the bound-

ary of hazards). The property representing this is

physicalLocationOf (a, b). We need to represent this

property since any situation, that could affect the be-

haviour of the system, depends on where this situation

occurs. In our ontology, the behaviour of the system is

described via processes; a process may involve vari-

ous objects (processInvolves(e, f ) property). We need

also to record which process(es) could be directly af-

fected by a situation, and we do this using the property

behaviouralLocationOf (c, d).

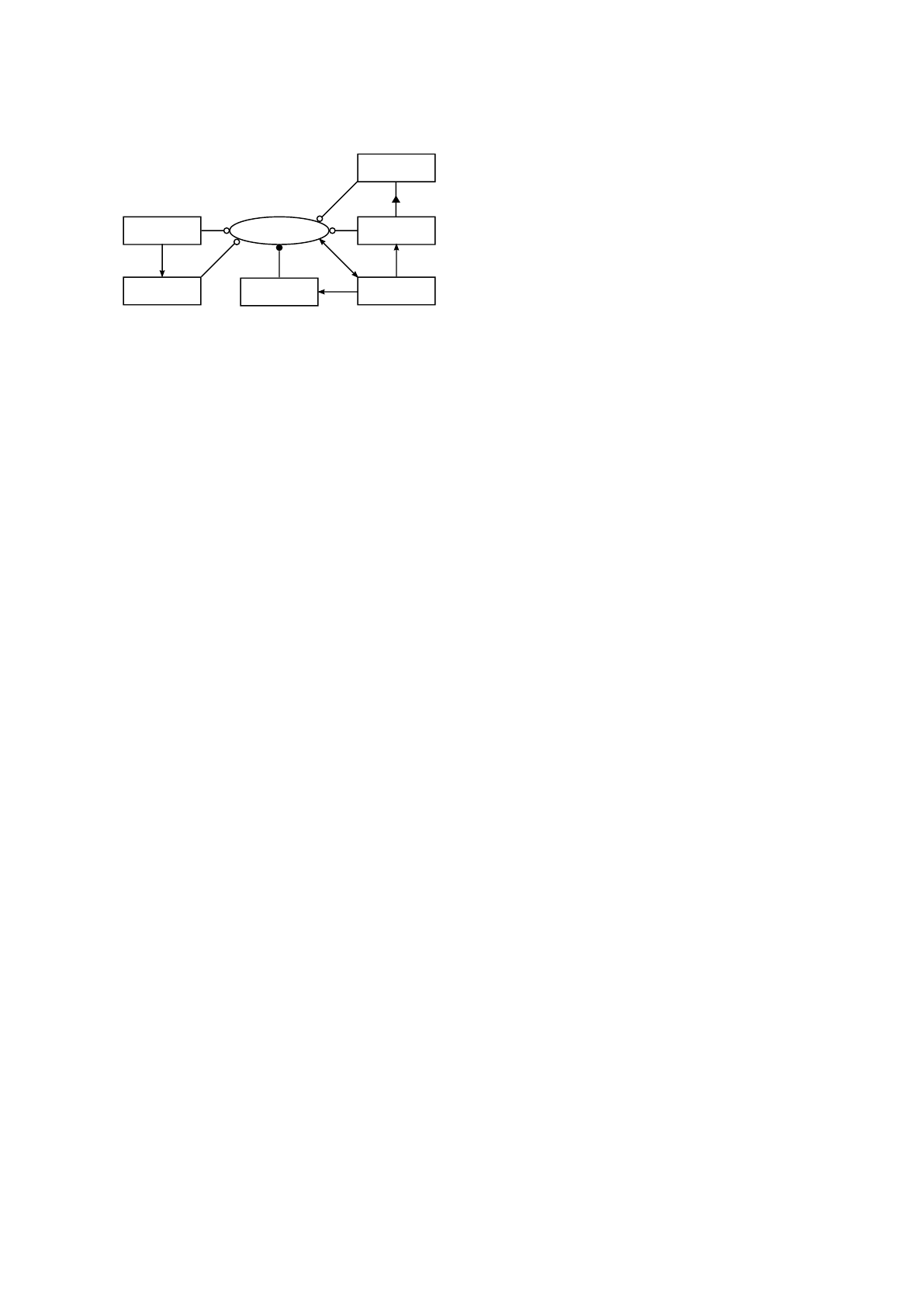

Figure 8 helps us to understand better how it is

going to happen. We can see three kinds of things

(Objects, Situations and Processes) and different re-

lationships among them, and that all are related by

the process Circulating. This process describes the

actions of the LRV passing directly through different

objects. Therefore, the Circulating process involves

objects such as tunnel, alignment, platform at a sta-

tion and railway crossings. The situation LRV stopped

adjacent to a wayside fire refers to anywhere within

the Railway system. This situation affects the process

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

323

Table 2: Table representing a small subset of the PHA for the case study (Evans and Associates, 2006).

Hazard Cause

A − 1 LRV fire Ca − 1 LRV stopped adjacent to a wayside fire

A − 2 Fire/smoke on station platform Ca − 2 Electrical wiring fault

A − 3 Fire/smoke on alignment Ca − 3 Fire on station

Ca − 4 Fire on wayside building or brush

A − 4 Fire/smoke on station platform Ca − 4 Electrical wiring fault

Circulating. Also, there exists a relationship among

the situations Fire on station platform, Fire in tunnel

andFire on alignment because the physical locations

of all these situations are involved with the process

Circulating. Last, the physical locations of all those

different situations are related by a transitive, hierar-

chical relationship MemberOf.

Rule 1, in our example, returns as an answer that

Cause LRV stopped adjacent to a wayside fire might

relate to (mightRelate) hazards Fire on station plat-

form, Fire on tunnel, Fire on Alignment and LRV fire.

It is not a reflexive relationship. LRV stopped adja-

cent to a wayside fire is definitely related to LRV fire

because the former is a direct cause of the latter. What

we could conclude is that any of those hazards could

be indirect causes of LRV fire. Figure 9 illustrates this,

and we can add this relationship (isIndirectCauseOf )

to our knowledge base.

5.2 Another Example on Non-direct

Causality

Let us examine another example. We will first give

some definitions related to railways. A grade cross-

ing is an intersection where a road passes across a line

of railway at a grade. A grade is a part of a railway

or road that slopes upwards or downwards. A grade

crossing warning system consist of all of the elements

or warning devices such as signals, signs, lights and

horns that automatically alert the public that a train is

approaching. Figure 10 illustrates that Grade cross-

ing warning system is part of Crossing in a railway.

This object has a clear functionality, which is process

Warning at crossing. Situations TC − 6 and Ca − 8

both happened within object Grade crossing warning

system and refer to the behaviour of process Warn-

ing at crossing. In addition, the physical scope of

both situations is the wider object Crossing (Grade

crossing warning system is part of Crossing). Rule 2,

below, helps us to discover this possible relationship.

The property physicalScope refers to the boundary of

the hazard. As explained earlier, if a hazard affects a

determined system, that system will be the scope of

the hazard. The property isSubProcessOf exemplifies

that a process can be decomposed into subprocesses.

The rest of the properties have been explained while

describing Rule 1.

physicalLocationOf(?h, ?l2),

behaviouralLocationOf(?s, ?p1),

behaviouralLocationOf(?h, ?p2),

physicalScopeOf(?h, ?c),

physicalLocationOf(?s, ?l1),

physicalScopeOf(?s, ?c),

isSubProcessOf(?p1, ?p3),

Situation(?s),

isSubProcessOf(?p2, ?p3),

Situation(?h)

→ possibleEntailment(?s, ?h)

(2)

Using Rule 2, we can discover a relationships

between cause Insufficient warning before gate de-

scends and hazard Grade crossing warning system

failed, or not visible or audible. They might not be

synonyms but there is a possible entailment relation

between them. The final decision about this relation-

ship is left to the analyst. What we can conclude is

that there is a causality relationship between hazard

Grade crossing warning system failed, or not visible

or audible and hazard Road vehicle breaks gate arm

and fouls track as shown in Figure 11. In the next sec-

tion we draw the conclusions and discuss future work.

6 DISCUSSION AND

CONCLUSION

In this paper we defined a state-based hazard process

for model-based exploration of the dependencies be-

tween causes and consequences of hazards. In addi-

tion, we showed how ontologies can be used to reason

about these dependencies. This method can be used

to automate the analysis of preliminary hazard work-

sheets with the aims of making them more precise,

disambiguating causal relationships, and supporting

the proper definition of system boundaries. Our anal-

ysis process is supported by an ontology that can

help analysts to find nonlinear causal relationships,

and to disambiguate identified hazards and causes. A

KEOD 2015 - 7th International Conference on Knowledge Engineering and Ontology Development

324

Road vehicle breaks gate arm

and fouls track

Warning at crossing

Insuficient warning

before gates descends

Grade crossing warning system

failed or not visible or audible

Crossing

Grade crossing

warning system

physicalLocationOf

physicalLocationOf

isMemberOf

isCauseOf

behaviouralLocationOf

behaviouralLocationOf

physicalScopeOf

physicalScopeOf

Figure 10: Relationships among individuals, exemplifying the relations that are used in example 5.2.

Insuficient warning before

gates descends

isCauseOf

possibleEntailment

isIndirectCauseOf

Road vehicle breaks

gate arms and fouls track

Grade crossing warning system failed,

not visible or audible

Figure 11: Possible causality relationship.

Table 3: Table that represents another small subset of the PHA for the case study (Evans and Associates, 2006).

Hazard Cause

TC − 8 Road vehicle breaks gate arm and fouls track Ca − 8 Insufficient warning before gate descends

TC − 6 Grade crossing warning system failed, Ca − 6 Equipment malfunction

or not visible or audible

demonstration of the approach was given using an in-

dustrial example, the PHA of the West Corridor LRT

System (Evans and Associates, 2006).

A thorough validation of our ontology is in

progress. We are currently working on two exam-

ples related to medical infusion pumps and an e-

voting system. This will allow us to instantiate the

ontology for real world situations, and check that

the ontology is truly capturing the domain concep-

tualisation. This is a well grounded evaluation pro-

cess (de Almeida Falbo, 2014).

Specialised tools are needed to better support our

analysis process. We believe that for a safety analyst

using Protege 5.0 might add more work to their tasks.

Our idea is that there should be a front-end tool that

interacts with the analyst and with the ontology. This

way, the input of data will be more user-friendly to the

safety analyst and the results could also be presented

in a more understandable way to the user.

REFERENCES

Benevides, A. B., Guizzardi, G., Braga, B. F. B., and

Almeida, J. P. A. (2010). Validating modal aspects of

ontouml conceptual models using automatically gen-

erated visual world structures. J. UCS, 16(20):2904–

2933.

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

325

Center for Devices and Radiological Health, US FDA

(2010). Total product life cycle: infusion pump – pre-

market notification [510(k)] submissions.

Corcho, O., Fern

´

andez-L

´

opez, M., and G

´

omez-P

´

erez, A.

(2003). Methodologies, tools and languages for build-

ing ontologies: Where is their meeting point? Data

Knowl. Eng., 46(1):41–64.

Cranefield, S. and Purvis, M. (1999). Uml as an ontology

modelling language. In In Proceedings of the Work-

shop on Intelligent Information Integration, 16th In-

ternational Joint Conference on Artificial Intelligence

(IJCAI-99, pages 46–53.

Crawley, E. and Dori, D. (2011). Object-Process Method-

ology: A Holistic Systems Paradigm. Springer Berlin

Heidelberg.

Daramola, O., Stralhane, T., Sindre, G., and Omoronyia, I.

(2011). Enabling hazard identification from require-

ments and reuse-oriented hazop analysis. In Manag-

ing Requirements Knowledge (MARK), 2011 Fourth

International Workshop on.

de Almeida Falbo, R. (2014). Sabio: Systematic approach

for building ontologies. In Proceedings of the 1st

Joint Workshop ONTO.COM / ODISE on Ontologies

in Conceptual Modeling and Information Systems En-

gineering co-located with 8th International Confer-

ence on Formal Ontology in Information Systems,

ONTO.COM/ODISE@FOIS 2014, Rio de Janeiro,

Brazil, September 21, 2014.

Devedzi

´

c, V. (2002). Understanding ontological engineer-

ing. Commun. ACM, 45(4):136–144.

Evans, D. and Associates, I. (2006). West corridor

LRT project final engineering design phase pre-

liminary hazard analysis draft revision 0. http://

www.rtd-fastracks.com/media/uploads/wc/

WC Risk Assessment Draft 06-06.pdf.

Fellbaum, C. (1990). English verbs as a semantic net. In-

ternational Journal of Lexicography, 3(4):278–301.

Hardy, T. (2010). Using accident reports to improve the haz-

ard identification process. 28th International System

Safety Conference.

International Organization for Standardization (2000). ISO

14971: medical devices - application of risk manage-

ment to medical devices. ISO.

ISO (1999). ISO/IEC GUIDE 51:1999(E): Safety Aspects

- Guidelines for Their Inclusion in Standards. Aus-

tralian Standards.

Kletz, T. (2001). Hazop and Hazan: Identifying and As-

sessing Process Industry Hazards. The Institution of

Chemical Engineers.

Ladkin, P. B. (2005). Ontological analysis. Safety Systems,

14(3).

Ladkin, P. B. (2010). Ontological hazard analysis of a com-

munication bus system. Technical report, Causalis

Limited.

Leach, K. (2010). A Demonstration of the Applicability of

HAZOP to Voting Systems. New Castle University.

LEE, B. H. (2001). Using fmea models and ontologies to

build diagnostic models. AI EDAM, 15:281–293.

Letia, I. and Groza, A. (2010). Developing hazard ontology

for supporting haccp systems in food supply chains. In

Intelligent Systems and Informatics (SISY), 2010 8th

International Symposium on, pages 57–62.

Leveson, N. G. (2011). Engineering a safer world: Systems

thinking applied to safety. MIT Press.

Liu, G., Wang, Y., and Wu, C. (2010). Research and ap-

plication of geological hazard domain ontology. In

Geoinformatics, 2010 18th International Conference

on, pages 1–6.

Mayer, R., Plank, C., Bohner, A., Kollarits, S., Corsini,

A., Ronchetti, F., Siegel, H., Noessing, L., Mair, V.,

Sulzenbacher, U., Tosoni, D., Cimarosto, S., Zanco,

A., Todorov, S., Krastev, L., Wergles, N., Gasperl,

W., Mayerl, M., Toli, T., Haradalia, H., Koutsias, N.,

Kreuzer, S., Liehr, C., Rachoy, C., Papez, J., and Jin-

dra, P. (2008). Monitor: Hazard monitoring for risk

assessment and risk communication. Georisk: Assess-

ment and Management of Risk for Engineered Systems

and Geohazards, 2(4):195–222.

Railtrack (2001). Engineering Safety Management, volume

1 and 2. Railtrack.

Simperl, E., Mochol, M., B

¨

urger, T., and Popov, I. O.

(2009). Achieving maturity: The state of practice

in ontology engineering in 2009. In Proceedings of

the Confederated International Conferences, CoopIS,

DOA, IS, and ODBASE 2009 on On the Move to

Meaningful Internet Systems: Part II, OTM ’09, pages

983–991, Berlin, Heidelberg. Springer-Verlag.

Stanford Center for Biomedical Informatics Research, S.

U. S. o. M. (2015). Protege 5.0 beta version.

http://protege.stanford.edu/.

Stralhane, T., Omoronyia, I., and Reicenbach, F. (2010).

Ontology-guided requirements and safety analysis. In

6th International Conference on Safety of Industrial

Automated Systems.

Sussman, J., Dodder, R. S., McConnel, J. B., Mostashari,

A., and Sgouridis, S. (2009). The clios process

a user’s guide. https://esd.mit.edu/Faculty Pages/

sussman/CLIOS-PROCESS.pdf.

Swartout, W. and Tate, A. (1999). Guest editors’ introduc-

tion: Ontologies. IEEE Intelligent Systems, 14(1):18–

19.

Transport Canada (2014). Rail transportation. http://

www.tc.gc.ca/eng/rail-menu.htm.

Valente, A., Russ, T., MacGregor, R., and Swartout, W.

(1999). Building and (re)using an ontology of air cam-

paign planning. IEEE Intelligent Systems, 14(1):27–

36.

Wang, H.-H. and Boukamp, F. (2009). Ontology-Based Job

Hazard Analysis Support, chapter 66, pages 676–685.

American Society of Civil Engineers.

Winther, R., Johnsen, O.-A., and Gran, B. (2001). Secu-

rity assessments of safety critical systems using ha-

zops. In Computer Safety, Reliability and Security,

volume 2187 of Lecture Notes in Computer Science,

pages 14–24. Springer-Verlag.

www.allenrailroad.com (2014). Railroad glossary and

definitions. http://www.allenrailroad.com/consulting/

Railroad Glossary.htm.

www.railsigns.uk (2014). Rail signs and signals of great

britain. http://www.railsigns.uk.

KEOD 2015 - 7th International Conference on Knowledge Engineering and Ontology Development

326

www.railway-technical.com (2014). Railway technical web

pages. http://www.railway-technical.com.

www.trafficsigns.us (2014). Manual of traffic signs.

http://www.trafficsign.us/railsign.html.

Yang, X., Gao, R., Han, Z., and Sui, X. (2012). Ontology-

based hazard information extraction from chinese

food complaint documents. In Tan, Y., Shi, Y., and Ji,

Z., editors, Advances in Swarm Intelligence, volume

7332 of Lecture Notes in Computer Science, pages

155–163. Springer Berlin Heidelberg.

Zhang, Y., Jones, P. L., and Jetley, R. (2010). A hazard

analysis for a generic insulin infusion pump. Journal

of diabetes science and technology, 4(2):263.

Using Ontologies to Support Model-based Exploration of the Dependencies between Causes and Consequences of Hazards

327