Screen-printed Biochemical Sensors for Detection of Ammonia Levels

in Sweat – Towards Integration with Vital Parameter Monitoring

Sports Gear

Susanne Oertel

1

, Michael P. M. Jank

1

, Lothar Frey

1

, Christian Hofmann

2

,

Nadine

Lang

2

and Matthias Struck

2

1

Fraunhofer Institute for Integrated Systems and Device Technology IISB, Schottkystr. 10, 91058 Erlangen, Germany

2

Fraunhofer Institute for Integrated Circuits IIS, Am Wolfsmantel 33, 91058 Erlangen, Germany

Keywords: Screen-printed, Biosensor, Biomedical Sensor, Sweat, Ammonia, Exercise, Ion-selective Electrode,

Wearable Device.

Abstract: The fabrication of fully screen-printed biochemical sensors employing planar integrated solid state

electrodes is described. The sensors are developed to fit wearable devices and target the monitoring of

ammonia respectively ammonium levels in sweat. Increased ammonium levels in sweat correlate to physical

overstrain of muscles, indicated by the breakdown of proteins in muscle cells. The sensor on flexible foil

uses an ion-selective working electrode and a reference electrode for potentiometric measurements of the

electromotoric force, EMF. For the ammonium ion-selective electrode a cocktail of nonactin was deposited.

The printed sensors were calibrated with ammonium standard solutions at a working range between 10

-5

M

to 0.1 M which corresponds to the range of physiological levels of ammonium in sweat before and during

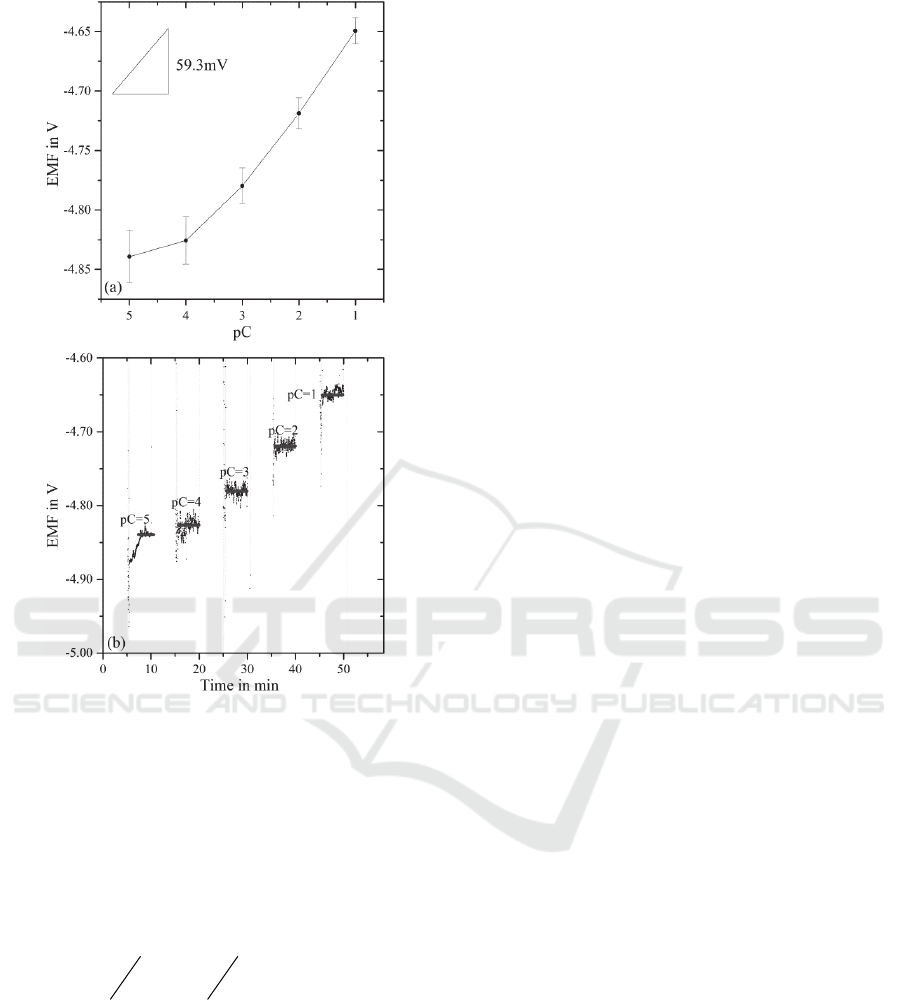

physical strain. The potentiometric characterization of the ion-selective sensor shows a linear behaviour of

the EMF versus pC values with a Nernstian slope of 59.3 mV ± 11.2 mV. The combination of low-cost

printed sensors, potentiometric sensing, and the integration with textiles represents a very attractive

approach for non-invasive monitoring of individual sports performance to prevent overload during physical

training.

1 INTRODUCTION

The monitoring of fitness status for identification of

the ideal workout conditions or the prevention of

muscular overstress is usually performed by logging

vital data during physical exercise and sequential

externally analysis by medical labs.

Direct analysis of body metabolism during

physical strain can be performed in sports medicine

laboratories using body fluids, e.g. blood and, more

and more common, also sweat. Generally, blood is

used to analyze the workout condition in

combination with the registration of vital parameters

like heart rate and respiratory gases. Analysis of

blood withdrawals during physical strain are

invasive, very much time-consuming, and costly and

can only be achieved in cooperation with a sports

medicine laboratory

Mobile fitness and health related data acquisition

becomes more and more common and is the first

success story for a range of wearable technologies.

Motion trackers that count the steps and estimate the

energy/calories consumption of the user have been

in the market for years. Vital parameters such as

respiration effort as well as heart rate and heart rate

variabilities derived from the electrocardiogram

(ECG), deliver more reliable information sources for

assessing training success and cardiovascular health.

Thus those systems are under research for

integration in future wearable systems (Tantinger et

al., 2012; Tobola et al., 2015). An even more

detailed picture of health and fitness status can be

derived with simultaneous monitoring of metabolic

parameters. Non-invasive approaches, e.g. detection

of relevant electrolyte concentrations are preferred

against blood analysis. The appropriate sensing units

along with challenging textile sensor adaptation and

biosignal processing methods that can cope with

motion artefacts have to be developed.

Generally, the body fluid sweat is only used for

medical analysis for diseases or for analysis for drug

160

Oertel, S., Jank, M., Frey, L., Hofmann, C., Lang, N. and Struck, M.

Screen-printed Biochemical Sensors for Detection of Ammonia Levels in Sweat – Towards Integration with Vital Parameter Monitoring Sports Gear.

DOI: 10.5220/0005691501600165

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 160-165

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

levels inside the body (Heikenfeld, 2014).

Sweat is an electrolyte solution that mostly

consists of water with sodium, potassium, and

bicarbonate. Additional inorganic compounds such

as urea, pyruvate, lactate, as well as proteins,

peptides, amines, amino acids, and ammonia are

contained in sweat. Furthermore, metal ions,

inhibitors, antigens, antibodies, and a variety of

xenobiotics such as drugs, cosmetics, and ethanol

have been found in sweat (Sato et al., 1989; Mena-

Bravo and Luque de Castro 2014).

Next to these physical species, ammonia content

in sweat is known for some decades to be a key

parameter for sports performance diagnostics

(Ament et al., 1997). The correlation of muscular

overstrain to production of ammonia is known since

last century. Ammonia and ammonium in blood are

mostly a result of metabolic degradation of proteins

(Schulz and Heck, 2001).

Czarnowski et al., (1992) published the

mechanism of the ammonia transport from muscle

cells into sweat. As ammonia generally is a

cytotoxin, the human body tends to minimize the

ammonia content (Czarnowski et al., 1992). The

difference between the pH value of sweat (4.0-6.8)

and blood (7.35-7.45) forms a pH gradient.

Ammonia diffuses from a higher to a lower pH

value, i.e. from blood to sweat. The size of ammonia

molecules is similar to water molecules. As such

they are permeable through cell membrane.

Some 20 years ago, investigations verified the

mechanism published by Czarnowski et al., (1992)

and therefore the correlation between physical strain

and sweat ammonia. Ament et al., (1997) published

the evaluation of ammonia in blood and sweat in

correlation to physical strain. This study was

performed utilizing an incremental cycle ergometer

exercise. During physical strain the content of

ammonia in sweat is in the range of millimol

whereas it is only in the µmol range in blood at the

same time.

Further publications from Alvear-Ordenes et al.,

(2005) and Meyer et al., (2007) show a direct

correlation between muscle overload of rugby

players during physical workout and also a gender

effect of ammonia content in sweat. All ammonia

diagnostics were done by analyzing sweat collected

with gauze pads (Alvear-Ordenes et al., 2005; Meyer

et al., 2007). One of the major challenges in

monitoring ion concentrations in sweat is the sample

recording. Extraction from human skin is time-

consuming, complex, and subject to errors, e.g. in

analyte concentration due to evaporation of solvent

or contamination of the sweat sample. This explains

also the low number of publications on sports related

sweat diagnostics.

For these reasons, direct monitoring of sweat

composition on the skin before and during physical

strain is a very attractive alternative. Bandodkar et

al. (2013), Wang et al., (2010), and Guinovart et al.,

(2013) developed skin applicable microfluidic

devices for sweat extraction and integrated pH

monitoring as well as flexible screen-printed

electrodes for application to skin-wearable devices.

Rose et al., (2013) published a sodium-selective

sensor in combination with a RFID chip.

Ion-selective electrodes are the most

fundamental features of sensors for analysis of

activity of ions in physiological fluids. In the last

century they mostly were electrochemical glass

electrodes an automated apparatus (Schulz and

Heck, 2001; Czarnowski et al., 1992; Ament et al.,

1997; Alvear-Ordenes et al., 2005; Meyer et al.,

2007).

Koncki et al., (1999) and Tymecki et al., (2006)

published screen-printed and planar electrodes

designed from printed silver, carbon and insulating

inks on flexible substrates. The potentiometric

measurements were taken against commercially

acquired reference electrodes.

In the last years, several potentiometric sweat

electrolyte measurements were published using

planar ion-selective sensors directly on skin (Yang et

al., 2010; Guinovart et al., 2013; Rose et al., 2014).

Koncki et al., (1999); Tymecki et al., (2006) and

Guinovart et al. (2013) developed ammonium-

selective electrodes by means of screen printing on

flexible foils.

Guinovart et al. (2013) developed a

potentiometric tattoo style ammonium sensor

including the reference electrode that can be directly

stuck to the skin.

Our present work combines the previously

reported sensor designs of Koncki et al., (1999) and

Guinovart et al., (2013). A flexible screen-printed

sensor is prepared combining an ammonium-

selective electrode based on nonactin ionophore with

an integrated reference electrode. Screen-printing

technology enables the deposition of thick layers,

short fabrication time, and precise sensor patterns

with a resolution of few hundreds of microns leading

to the fabrication of cheap and disposable

electrochemical sensors. The ion-selective

biomedical sensor published in this paper shows a

promising approach. The fully-printed biomedical

sensor shows a sensitivity or Nernstian slope of over

2 orders of magnitude (0.001 M to 0.1 M).

Furthermore, this work presents an outlook towards

Screen-printed Biochemical Sensors for Detection of Ammonia Levels in Sweat – Towards Integration with Vital Parameter Monitoring

Sports Gear

161

the sensor integration in textiles to extent a

functional sport shirt with low-power appliance for

various electrolyte monitoring tasks (Tantinger et

al., 2012; Tobola et al., 2015).

2 EXPERIMENTAL

2.1 Materials and Reagents

Silver-based (125-13), silver-silver chloride with a

ratio of 65:35 (125-21) and carbon filled (120-24)

pastes for screen printing were acquired from

Creative Materials (Ayer, MA, USA).

The pastes were printed on flexible polyester

(Hewlett Packard ink jet foil, 125µm) and polyimide

(Kapton HN, 125µm, Müller GmbH) foils.

Analytical grade salts of ammonium chloride and

sodium chloride were purchased from Bernd Kraft

for standard calibration solutions.

Sodium chloride (NaCl, ≥ 99.5%, BioXtra),

methanol 99.8% anhydrous) and polyvinyl butyral

(PVB, Butvar® B-98) were purchased from Sigma

Aldrich and used for an insulating layer on top of the

reference electrode (Guinovart et al., 2013).

Ammonium ionophore (nonactin in Cocktail A,

Fluka) was obtained from Sigma Aldrich for

fabrication of the ion-selective electrode. Cocktail A

consisted of Nonactin (6.9 wt%), 2-Nitrophenyl

octyl ether (92.40 wt% NPOE) as plasticizer and

potassium tetrakis(4-chlorophenyl)borate (0.7 wt%

KTClPB).

For the insulating layer, a Barium titanate (PE-

BT 101) paste from Conductive Compounds was

used. All screen printing pastes offered annealing

temperatures below 200°C. This is essential for

sensor application on flexible foil substrates.

2.2 Equipment

An automated screen- and pattern printer from Ekra

(series X1) was utilized to produce the printed

electrodes. Polyester screen (110 µm mesh - 34 µm

wire thickness x 22.5° cover angle, 10 µm -15 µm

emulsion over mesh, EOM) was used for silver-

silver chloride paste and a stainless steel screen (VA

270-0.036x22.5°, 5-10µm EOM) for silver- and

carbon-filled paste.

The printed layers on foils were annealed at

150°C for different times (5 minutes up to

15 minutes) on a hot plate (PZ 28-2 EZ, Harry

Gestigkeit). For potentiometric measurements a

2636B Sourcemeter from Keithley instruments

(Cleveland, OH, USA) was used.

2.3 Screen-printing for Sensor

Fabrication

The sensor design was adopted from two sensor

layouts published by Koncki et al., (1999) and

Guinovart et al., (2013). The schematic and a picture

of the screen-printed sensor electrodes are shown in

Figure 1. The layout of the sensor involves several

steps and consists of a bielectrode system that

combines silver working electrodes with silver-silver

chloride electrodes as the reference electrode.

At first the conductive layer with silver-based

paste (84% silver) was printed and afterwards the

silver-silver chloride electrode. Koncki et al., (1999)

proposed an additional carbon layer as a chemically

inert layer between the ion-selective layer and the

silver electrode. Guided by the same considerations

we choose to realize the reference electrode both by

a carbon/silver-based system as well as a pure silver-

silver chloride electrode.

Finally, printing the insulating paste with contact

openings for electrical contacts and opening at the

active area with ion-selective membrane was done as

fourth and last screen printing step.

The squeegee speeds during screen-printing of

pastes were between 50 mm/s and 80 mm/s. After

each printing step the flexible foil substrates were

annealed at 150°C on a hotplate with annealing

times between 5 minutes and 15 minutes. At the end

of the printing process, the sensors were cut for

further individual use.

For preparation of the measurements the

reference electrode was covered with a mixture of

PVB, methanol, and NaCl as was published by

Guinovart et al., (2013). This process was done by

dispensing the liquid by hand and letting the layer

dry for a minimum of 12 hours. The final

preparation step was the insertion of the ion-

selective membrane. The cocktail of ammonium

ionophore was drop-cast onto the inner circle

(insulator opening, layer 4 in Figure 1a) with

amounts of 20 µl and also dried overnight. The

finished ammonium-selective biomedical sensor is

shown in Figure 1b.

The additional silver electrodes shown left and

right next to the sensor in Figure 1a can be used for

conductivity measurements. The line gap was 100

µm (right) and 200 µm (left). The first generation of

screen-printed ammonium-selective sensors had a

dimension of 20 mm in width and 40 mm in length.

The resolution pattern of the ink allows for shrinking

the sensor size in future layouts.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

162

(a)

(b)

Figure 1: (a) Schematic and (b) photograph of screen-

printed ammonium selective potentiometric sensor (1)

silver-silver chloride reference electrode, (2) silver

electrodes, (3) carbon-filled electrode, (4) insulating layer

and (5) ion-selective area with ammonium ionophore.

2.4 Measurements

Calibration curves were obtained by standard

solutions with different activities of the analyst ion.

Potentiometric measurements were recorded using

the high-impedance voltage measurement mode of

the 2636B sourcemeter that delivers 10

14

ohms of

internal resistance, i.e. the measurement is current-

less minimizing the feedback on the built-up

potential difference at the electrodes. Data points

were acquired with time intervals of 200

milliseconds (ms) or 500 ms respectively in a

continuous data collection cycles of up to 1 hour in

duration. The measurement schematic is depicted in

Figure 2. The connection between flexible sensor

and measurement equipment was realized via a

flexible flat cable (FFC) connector with a 0.1 in.

pitch.

Figure 2: Schematic of cabling of potentiometric ion-

sensitive sensor for measurement ammonium levels.

The ammonium ionophore, Nonactin, extracts its

preferred cation, NH

4

+

, out of the solution into the

membrane. The potential difference measured at the

device inputs is the sum of the potentials built-up at

all interfaces: solid-solid, solid-liquid and liquid-

liquid. In ideal case, all potentials except the

potential at the ionophore membrane can be

considered to be constant. The electromotive force,

EMF is forming across the membrane when both

reference and working electrodes are in contact with

the solution. This potential over the ammonium-

selective membrane depends on the NH

4

+

ion

activity (Spichiger, 1998).

Potassium, K

+

, is a critical interfered ion due to

the same ionic diameter as of ammonium. The

sensor selectivity will be tested in further work.

3 RESULTS AND DISCUSSION

3.1 Characterization of the Sensor

The potentiometric measurements of the

ammonium-selective sensor were conducted by

recording the voltage response upon modification of

activity of the ammonium by exchanging standard

solutions of concentrations from 0.1 mol/l (pC=1) up

to 0.0001 mol/l (pC=4). The negative of the

logarithm of base 10 of the ion activity (a

NH4+

) is pC.

A calibration of the sensor was realized by recording

the potential deviation (electromotive force, EMF)

versus the time and changing the activity of

ammonium ions by adding drops of solutions on top

of the sensor electrodes. After a delay time of

5 minutes, the first standard solution with pC=4 was

added and measured for further 5 minutes.

Afterwards the sensor was purged with deionized

water and dried using nitrogen flow. This procedure

was repeated for all standard solutions from pC=4

up to pC=1.

The range of the calibration concentrations from

0.00001 mol/l up to 0.1 mol/l covers the typical

ammonium level in sweat with and without physical

strain (Czarnowski et al., 1992; Guinovart et al.,

2013). The curve progression of lower

concentrations (pC values of 5 to 3 in Figure 3) is

nonlinear. Between pC values of 3 and 1 the sensor

shows a linear calibration function, that correlates

with published calibration graphs of other groups

(Koncki et al., 1999). The Nernstian slope in the

linear range from pC values of 3 (0.001 M) to 1

(0.1 M) is 59.3 mV/pC ± 11.2 mV/pC.

Screen-printed Biochemical Sensors for Detection of Ammonia Levels in Sweat – Towards Integration with Vital Parameter Monitoring

Sports Gear

163

Figure 3: (a) Calibration graph and (b) potentiometric

measurement (potential deviation, EMF in mV vs. changes

of ion activity, -log(a

NH4+)

) of screen-printed ammonium-

selective biosensor with integrated screen-printed

reference electrode.

The slope of an ideal electrode for the

selectively-measured ion is given by the Nernstian

equation:

(1)

(2)

with E

0

being the reference potential, s being the

Nernstian slope, a

i

the activity of the ion i, R the

universal gas constant, T the temperature, F the

Faraday constant, and z

i

the valency of the ion i.

The performance of the sensor was achieved

after considerable efford towards optimization of the

integrity of the ion-selective membrane on the

working electrode. Frequent defects include

delamination, cracks or insufficient drying behavior

and lead to dramatically changed sensing

characteristics. Guinovart et al., (2013) fabricated an

ammonium-selective sensor in a style of a skin

tattoo with integrated PVB-based reference

electrode. The range of the calibration

concentrations from 0.00001 mol/l up to 0.1 mol/l is

also used and the calculated Nernstian slope was

59.2 mV. Our approach of integrating the nonactin

ionophor in a polymeric matrix lowers dramatically

the consumption of the ionophor which is by far the

most expensive ingredient of the sensor system.

However we could show that the performance is

kept at the same level.

In comparison to this work and the sensors

published by Guinovart et al., (2013), Koncki et al.

(1999) fabricated a screen-printed sensor which is

measured against an external calomel reference

electrode. The Nernstian slope of 53mV/pC was

calculated in a range of the calibration

concentrations from 0.00001 mol/l up to 0.01 mol/l.

However the non-planar approach is less flexible

with respect to sensor processing and system

integration.

Our fastly and cheaply fabricated ammonium-

selective screen-printed sensors show a high

potential for analysis of physiological electrolytes as

sweat in sports applications. In further work, the

layout of the sensor will be shrinked. The resolution

of the screen-printed silver pastes was better than

200 µm. The size minimization will on the one hand

increase the amount of sensors yielded by one

fabrication cycle as well as the spatial options for

integration with functional sport textiles and will

also reduce the materials and fabrication costs per

sensor.

3.2 Integration with LokVitalTag

The printed sensor circuit will be attached to a

multifunctional electronics box. The so called

LokVitalTag combines various electronic modules

that acquire data from the physiological sensor front

ends (ECG-electrodes, respiration-band, ammonia-

sensitive sensor front-end) and also tracks

movement information from an inertial sensor. The

gathered data will be processed and stored locally.

Further on, the calculated values can be transmitted

wirelessly. In addition the LokVitalTag carries

electronics for the real-time-localization technology

RedFIR 2.0, so localization information and vital

parameters can be analysed in combination.

Under real conditions, in sweat, also interfering

ions interact with the ionophore membrane. The

effect on the overall potential can be related to the

concentration of the analyte by applying the

modified Nernstian equation, the so-called Nicolsky

i

asEE log

0

C25atmV

Fz

59.16

Fz

RT

2.303s

ii

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

164

equation. In further work, the selectivity factor will

be calculated by this evaluation. The experimental

selectivity coefficients in sweat are dependent on the

method of determination, e.g. separate solution

(SSM) or fixed interference method (FIM).

4 CONCLUSIONS

A facile route to the fabrication of planar, solid-

state, ion-selective sensors for ammonium ions using

screen-printing technology is presented. The

performance of the fully-printed ion-selective sensor

allows for the detection of ammonium ion

concentration in the physiological levels of human

sweat.

The results shown in this paper give the base for

further research into especially the potentiometric

analysis, the optimization of the sensor layout and

area consumption, and the integration with textiles

for wearable functional sport clothing.

ACKNOWLEDGEMENTS

This contribution was supported by the Bavarian

Ministry of Economic Affairs and Media, Energy

and Technology as a part of the Bavarian project

”Leistungszentrum Elektroniksysteme (LZE)”.

REFERENCES

Heikenfeld, J. 2014. Your sweat may bring medical

diagnostics to Fitbits and Fuelbands. IEEE Spectrum,

Nov. issue, 47-63.

Sato, K., Kang, W. H., Saga, K., Sato, K. T. 1989. Biology

of sweat glands and their disorders.I. Normal sweat

gland function, J. Am. Acad. Dermatol., 20(4), 537–

563.

Mena-Bravo, A., Luque de Castro, M. D. 2014. Sweat: A

sample with limited present applications and

promising future in metabolomics, J. Pharm. Biomed.

Anal. 90, 139– 147.

Schulz, H. & Heck, H. 2001. Ammoniak in der

Leistungsdiagnostik. Deutsche Zeitschrift für

Sportmedizin, 52(3), 107-108.

Czarnowski, D., Gorski, J., Jozwiuk, J. and Boron-

Kaczmarska, A. 1992. Plasma ammonia is the

principal source of ammonia in sweat. Eur. J. Appl.

Physiol., 65, 135-137.

Ament, W., Huizengau, J. R., Mook, G. A., Gips, C. H.,

Verkerke, G. J. 1997. Lactate and ammonia

concentration in blood and sweat during incremental

cycle ergometer exercise. Int. J. Sports Med., 18, 35-

39.

Alvear-Ordenes, I., Garcia-Lopez, D., De Paz, J.,

Gonzalez-Gallego, J. 2005. Sweat lactate, ammonia,

and urea in rugby players. Int. J. Sports Med., 26, 632-

637.

Meyer, F., Laitano, O., Bar-Or, O., Mc Dougall, D.,

Heigenhauser, G. J. F. 2007. Effect of age and gender

on sweat lactate and ammonia concentrations during

exercise in the heat. Braz. J. Med. Biol. Res., 40(1),

135-143.

Bandodkar,A. J., Hung, V. W. S., Jia, W., Valdés-

Ramírez, G., Windmiller, J. R., Martinez, A. G.,

Ramírez, J., Chan, G., Kerman, K. and Wang, J. 2013.

Tattoo-based potentiometric ion-selective sensors for

epidermal pH monitoring. Analyst, 138, 123-128 .

Yang, Y.-L., Chuang, M.-C., Lou, S.-L., Wang, J. (2010).

Thick-film textile-based amperometric sensors and

biosensors. Analyst, 135, 1230-1234 .

Guinovart, T., Bandokar, A. J., Windmiller, J. R.,

Andrade, F. J., Wang, J. 2013. A potentiometric tattoo

sensor for monitoring ammonium in sweat. Analyst,

138, 7031-7038.

Rose, D.P., Rattermann, M., Griffin, D. K., Hou., L.,

Kelley-Loughnane, N., Naik, R. R., Hagen, J. A.,

Papausky, I., Heikenfeld, J. 2014. Adhesive RFID

Sensor Patch for Monitoring of sweat electrolytes.

IEEE Transc. Biomed. Eng., 0018-9294, 1-9.

Koncki, R., Glab, S., Dziwulska, J., Palchetti, I., Mascini,

M. 1999. Disposable strip potentiometric electrodes

with solvent-polymeric ion-selective membranes

fabricated using screen-printing technology. Anal.

Chim. Acta, 385, 451-549.

Tymecki, L., Glab, S., Koncki, R. 2006. Miniaturized,

planar ion-selective electrodes fabricated by means of

thick-film technology. Sensors, 6, 390-396.

Tantinger D, Feilner S, Schmitz D, Weigand C, Hofmann

C, Struck M. 2012. Evaluation of QRS detection

algorithm implemented for mobile applications based

on ECG data acquired from sensorized garments.

Biomed Eng Biomed Tech ,57(1), 635-368.

Tobola, A., Espig, C., Streit, F. J., Korpok, O., Schmitz,

B., Hofmann, C. 2015. Scalable ECG hardware and

algorithms for extended runtime of wearable sensors.

Medical Measurements and Applications (MeMeA),

IEEE International Symposium. 255–60. 209.

Spichiger-Keller, U. E., 1998. Chemical Sensors and

Biosensors for Medical and Biological Applications.

Wiley-VCH, Weinheim.

Screen-printed Biochemical Sensors for Detection of Ammonia Levels in Sweat – Towards Integration with Vital Parameter Monitoring

Sports Gear

165