Numerical Comparison between a Modern Surfboard and an Alaia

Board using Computational Fluid Dynamics (CFD)

Luca Oggiano

Norwegian University of Science and Technology – SIAT (Senter for Idrettsanlegg og Teknologi),

K. Hejes Vei 2b 7042, Trondheim, Norway

IFE -Institutt for Energiteknikk, Instituttveien 18a, 2007, Kjeller, Norway

Keywords: Hydrodynamics, CFD, Surfboard Design.

Abstract: Surfboard design is traditionally considered more as an art than an engineering process. However, in the

past decade, the use of computers is becoming the standard in the shaping process. In the design part the use

of computer-aid-design (CAD) software, has simplified the design process allowing shapers to save time

and consistently modify or reproduce similar designs. At the same time, the improvement of computer-

numerical-controlled (CNC) machines is slowly replacing the traditional hand shaping techniques with more

controlled and reproducible manufacturing process. Another considerable advantage about having a 3D

CAD model of the surfboard is that the model can be imported in Computational Fluid Dynamics (CFD)

programs and its performances can be studied and evaluated highlighting details that would be otherwise

impossible to identify from a field test. The present paper aims to show the potential of CFD solvers for

surfboard design and its applicability by comparing a modern surfboard with a traditional ancient surfboard

design (alaia). The performances of the modern surfboard are evaluated and compared with the alaia board,

represented by an equivalent flat plate which is also used for validation. The commercial CFD code STAR-

CCM+ is used in the present work. An Unsteady Reynolds Navier Stokes (URANS) approach is used, the

volume of fluid (VOF) method is chosen as free surface discretization method and the turbulence model

chosen to allow the numerical closure of the RANS equations is the k-ɷ-SST proposed by Menter. The

model validation on an alaia board, represented as a flat plate shows good agreement with previous studies

and the comparison between the surfboard and the alaia addresses the superiority of the modern surfboard

design in terms of stability.

1 INTRODUCTION

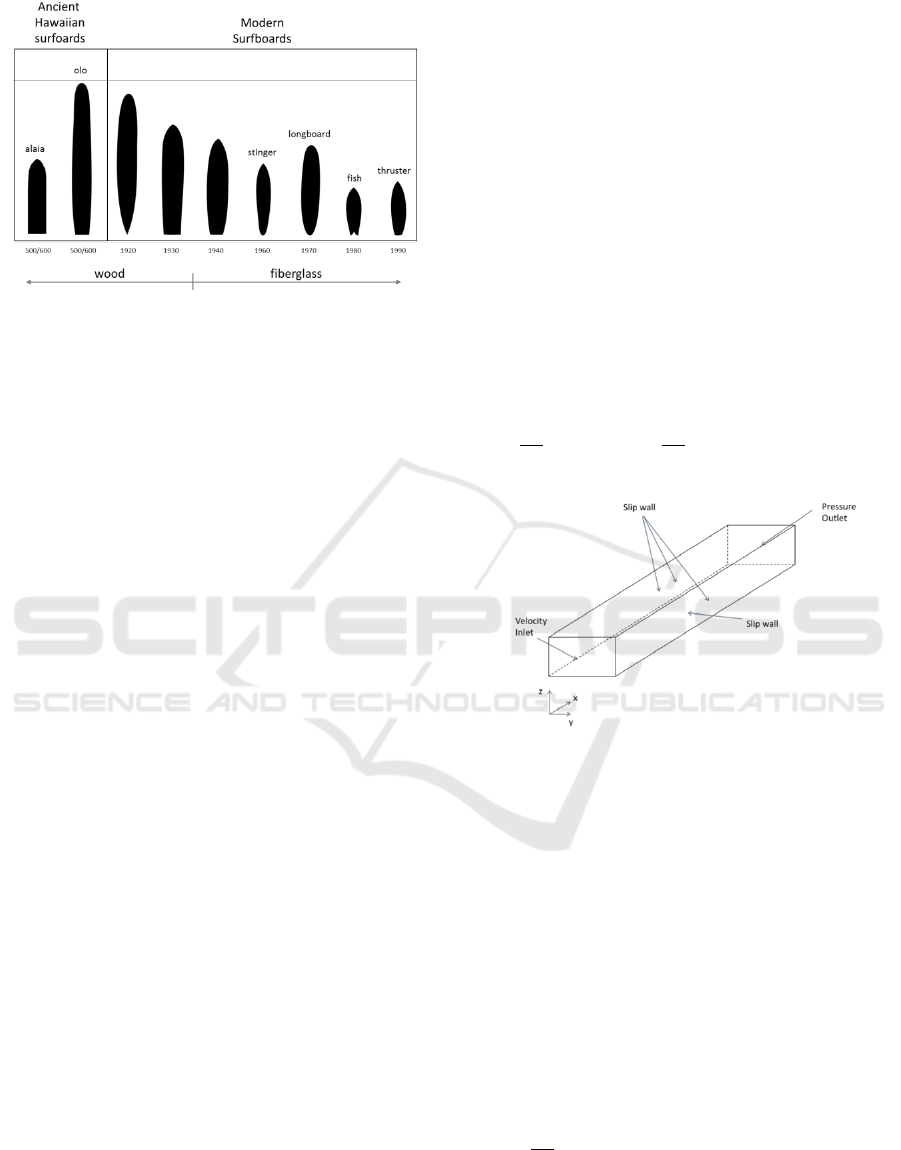

Surfboards firstly appeared in the 5

th

-6

th

century in

Hawaii and they were used monarchs and villagers

alike. At that time, three types of surfboards were

available: the paipo (used by children) the olo (long,

thick and heavy boards that could weight up to

100kg) and the alaia. Surfing as we know it

(standing up and riding curing waves) was

developed and discovered thanks to the alaia boards.

The alaia boards are middle sized boards, simple in

shape, made in wood and finless, they can be

resembled to flat plates with a rounded nose. The

board paddles well enough to catch unbroken swells

still allows manoeuvres and curves on the waves

face and it is responsive to the surfer commands. For

centuries, surfing and surfboard design was confined

to Hawaii and no evolutions in the shape of the

boards were made since modern times. For the first

time, in 1930’s balsa wood (much lighter than

normal wodd) was introduced, the tail of the boards

were tapered to have a more hydrodynamic design

and increase manoeuvrability and fins were firstly

introduced to increase stability . The main change in

construction and materials didn’t appear since the

late 1940’s, where fiberglass was introduced,

allowing more complex shaping and finally driving

the design to the modern surfboard design

(Warshaw, 2010, Heimann, 2010). During this

period of time, boards became lighter, smaller and

their shape constantly evolved. However, the

surfboard design and shaping is still seen as a form

of art more than an engineering task.

Surfboards can be considered as 3D planing

surfaces similar to planing boats, velles, and surface

effect ship (SES) (Doctors, 2009). The main

Oggiano L.

Numerical Comparison between a Modern Surfboard and an Alaia Board using Computational Fluid Dynamics (CFD).

DOI: 10.5220/0006488400750082

In Proceedings of the 5th International Congress on Sport Sciences Research and Technology Support (icSPORTS 2017), pages 75-82

ISBN: 978-989-758-269-1

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Evolution of surfboard design throughout the

years.

difference between a planing vessel and a traditional

one is that in planing vessels (and also in

surfboards), the hydrodynamic lift is typically used

to support a majority of the vessel displacement,

whereas hydrostatic forces constitute the main

contribution for displacement vessels. In order to

generate the necessary amount of lift, surfboards

need to reach a certain speed, however, in order to

reach the high speed needed, they should first

operate at a lower speed and successively accelerate

in order to be able to support the surfer. The

acceleration is usually obtained in two steps, in the

first step the surfer paddles, accelerating in order to

catch the wave and then uses the wave behaviour by

pitching the board to sharply increase the speed

reaching planing conditions. While the studies on

surfboards are limited, the studies on planing

surfaces are present in the literature and CFD proved

to a useful tool to study the physics of the

phenomenon. In particular Kramer (Kramer et al.,

2013) studied with CFD at 2D flat plate similar in

size of a alaia board.

The present paper aims to compare the planing

characteristics of a modern surfboard with an alaia

board with the same aspect ratio, pointing at

differences and proving the efficiency of CFD as

design tool for surfboards.

2 METHODS

A fully non-linear CFD approach will used

throughout the paper.

2.1 Numerical Setup

The VOF (Volume of Fluid) method originally

proposed by (Hirt and Nichols, 1981) included in

STAR-CCM+ was used in the current simulations.

The interface capturing routine is implemented in

the solver with a high-resolution compressive

differencing scheme described in (Ubbink, 1997,

Ferziger and Peric, 2001).

The k-turbulence model proposed by Menter

(Menter, 1994) was used as closure model to solve a

time dependent version of the Reynolds Averaged

Navier Stokes. The k- Menter SST model was

chosen due to its capabilities to capture the vortex

structures developing in the wake region and its

superior performances in highly separated flows

(Zaïdi et al., 2010, Wilcox, 2006).

The governing equations used in the discretised

model can be generally expressed as:

(1)

(2)

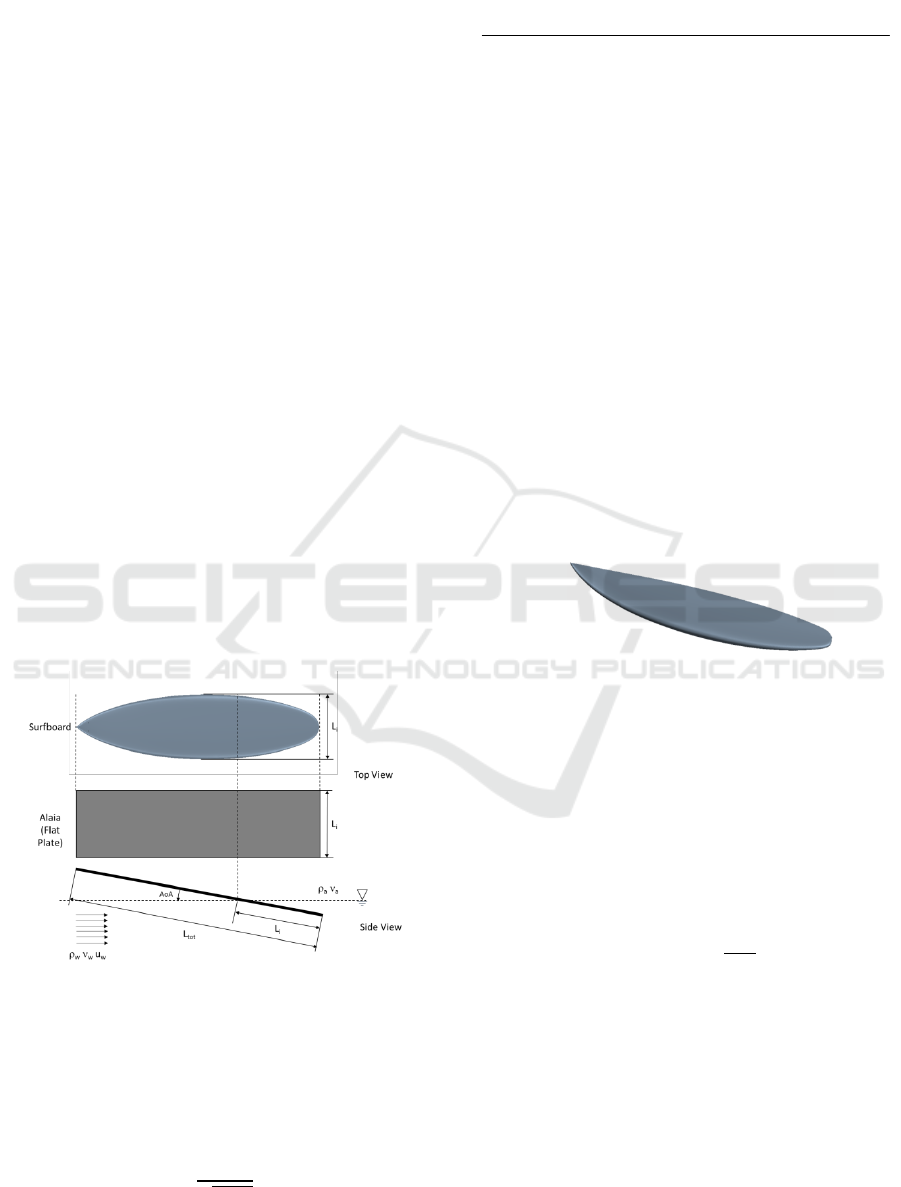

Figure 2: Numerical basin with boundary conditions

applied at each boundary.

Where Eq. 1 represents the conservation of mass

and Eq.2 represents the conservation of momentum.

In the VOF representation, the density

, and the

viscosity,

, are specified in terms of the water

volume fraction,

(3)

(4)

When solving the equations, the water volume

fraction

, once the velocity field is known, is

advanced in time by the transport equation:

(5)

Per each time step, the forces on the model are

calculated by pressure integration on the pressure on

the wetted surface area.

(6)

The domain width is 30m, the depth is 10m and

the length is 200m. The boundary conditions used in

the simulation are shown in Figure 2: slip wall

condition was used at the bottom, symmetry

boundary conditions were used at the sides and top

and a p boundary condition was used at the outlet. A

relaxation area, consisting of an added damping

domain with a flat bottom, 200m long and

discretized with stretched cells in the x-direction was

added at the end of the domain in order to reduce

numerical reflection from the outlet.

2.2 Geometrical Models Used

A surfboard and a flat plate (representing the alaia)

models are used in the present study, both with an

initial immersed length Li=0.5m and oriented with

an angle of attack AoA from the calm-water free-

surface. The model is assumed to travel at a constant

forward speed U on the water surface, which is

assumed to be an incompressible fluid of density ρ

w

and kinematic viscosity ν

w

and it represents the

liquid phase of the mixture. The traveling velocity is

modelled by imposing a velocity inlet boundary

condition at the inlet boundary, where the velocity

u

w

=U is here prescribed to each of the boundary

cells included in the liquid phase of the mixture.

Figure 3: Side and top view of the surfboard and alaia (flat

plate) models used in the simulations.

The second phase of the mixture is assumed to

be air and it is modelled as an incompressible gas of

density ρ

a

and kinematic viscosity ν

a

and u

a

=0.

Defining the Froude Number as

(7)

Table 1: Physical quantities.

Where u

w

is the flow velocity of the water mixture, g

is the gravity and Li is the immersed length, two

different flow velocities, U=4m/s and U=8m/s

corresponding to Fr=1.28 and Fr=2.55 were

simulated. The flow velocities are chosen in order to

be representative for paddling speed (U=4m/s) and

cruising speed (U=8m/s).

2.2.1 Surfboard

The surfboard model used is designed with

Akkushape. The model does not include fins and it

has a length of 1.65m and a width of 0.5m The tail

geometry is a squash tail.

Figure 4: 3D representation of the surfboard model.

2.2.2 Alaia

The alaia model used in the simulations has the same

length and width of the surfboard (length=1.65m,

width= 0.5m). For simplification and in order to

have comparable data available, the alaia design

chosen for the simulations was a simple flat plate

and its dimensions were chosen in order to have the

same aspect ratio as the surfboard where:

(8)

2.3 Grid Topology and Grid

Dependence Study

A trimmed meshing technique was chosen in order

to correctly model the water free surface in the

numerical basin. Different levels of grid refinements

were used in order correctly reproduce the

perturbations to the free surface induced by the

models.

Item

Symbol Value Units

Water density ρ

w

1000 kg/m3

Air density ρ

a

1.19 kg/m3

Water kinematic viscosity ν

w

1.0048∙10

-6

m

2

/s

Air kinematic viscosity ν

a

1.4604∙10

-5

m

2

/s

Immersed length L

i

0.5 m

Gravitational acceleration

g 9.81 m/s

2

Total length

L

tot

1.65 m

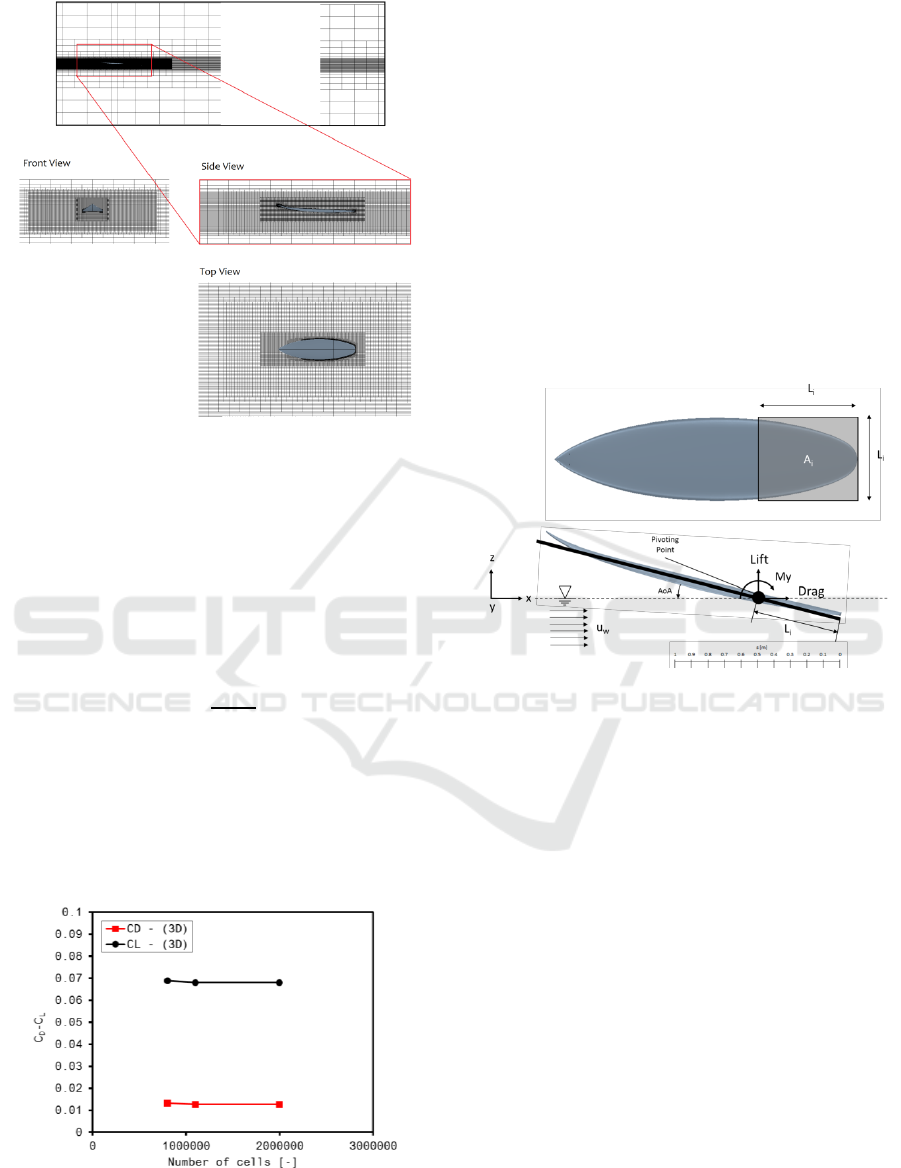

Figure 5: Mesh topology.

The surface mesh was created using 100points

per curvature and a prismatic mesh consisting of 10

layers growing with a growing factor of 1.5 was

created on top of the surface in order to correctly

capture the boundary layer. The first cell height was

chosen so that the wall y+ was kept lower than 5 on

the whole surface. Defining the convective Courant

number as

(9)

Where u

w

is the water flow velocity, Δt is the

time step and Δx is the cell with in the x direction,

the time step was chosen so that CCN=0.5 in the

finer portion of the grid, which is the necessary

condtion for the numerical stability of the VOF

model.

Figure 6: Grid convergence for c

L

and c

D

at Fr.1.1, AoA=4

deg for the surfboard.

A preliminary dependency study was carried out

for AoA=4 deg and Fr=1.1 in order to ensure

numerical convergence and a grid independent

solution. The results are plotted in Figure 6. The plot

shows a clear grid convergence with minimal

differences between the middle refined grid

consisting of 1.2million cells and the fine grid which

consists of 2.1millions cells. The fine grid,

consisting of a total number of cells of 2.1millions

was used in the simulations.

2.4 Model Validation

A preliminary study on a 2D fixed flat plate was

carried out in order to validate the model against

previous work.

Figure 7: Surfboard parameters and coordinate system.

The problem of a two-dimensional planing flat

plate studied using a nonlinear CFD solver for

varying Froude number and angle of studied by

Kramer (Kramer et al., 2013) was chosen for the

comparative study. In Kramer’s work a quasi-steady

CFD approach using inviscid flow was used and

potential-flow assumptions that either assume linear

free-surface and body boundary conditions or ignore

gravitational effects were also addressed. As a

reference case, the test case with Fr=1.1 and

AoA=10deg was chosen. In the present

computations, a fully turbulent approach is used and

both a 2D and 3D computations were carried out and

compared with the previous computations carried

out by Kramer.

The non dimensional coefficients for lift and

drag were chosen to be relative to the direction of

motion with the drag being along the x-axis and

parallel to u

w

and the lift in the y-axis and

perpendicular to the velocity u

w.

The pivoting point

around which the models rotate was placed at

s=0.5m.

The nondimensional coefficients for lift and drag

force can be expressed as follows:

(10)

(11)

With A

i

[m

2

] being the submerged area and being

0.25m and 0.182m respectively for the flat plate

representing the alaia and for the surfboard.

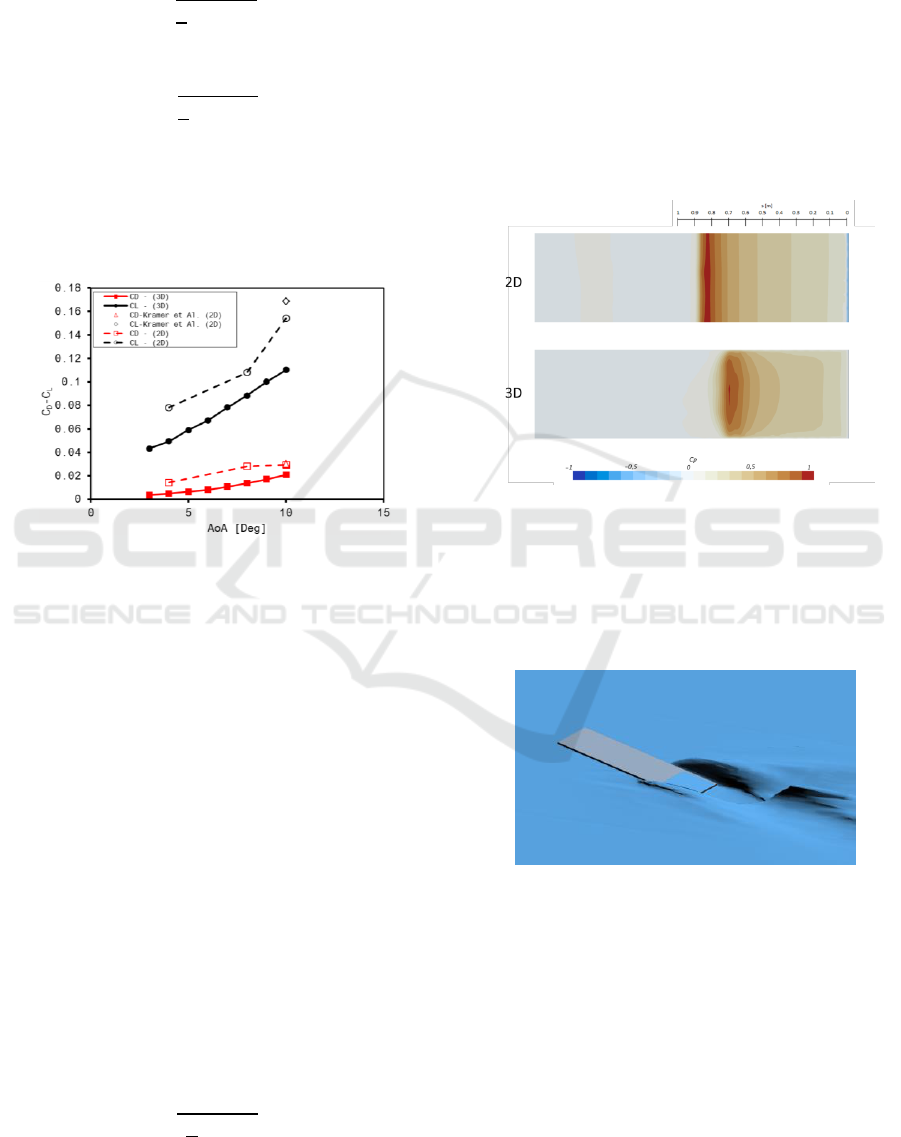

The results from the computations for both 2D and

3D cases are plotten in Figure 8.

Figure 8: C

D

and C

L

for a 2D and 3D flat plate and

comparison with previous work (Kramer et al., 2013).

A good agreement between the Kramer compu-

tations and the present one can be seen for both lift

and a drag coefficient values for the 2D case. When

comparing the 3D simulations with the 2D

simulations, a clear decrease in drag and lift

coefficient can be seen in Figure 8. This is due to the

influence of the downwash from the extremity

vortices resulting in reduced lift for finite aspect-

ratio plates. This is a known phenomenon and it is

widely addressed in the classical theory for flat

plates aerodynamics (Taira and Colonius, 2009) but

also in the theory for planing flat plates with

different aspect ratios (Perry, 1952) and in the

classical aerodynamics theory (White, 2016). The

drag and lift difference due to extremity vortices can

also be seen when analysing the pressure coefficient

contour plots for the 2D and 3D flat plate from the

simulations at AoA=10deg and Fr=1.1 (Figure 9). In

the plots the pressure has been normalized with the

flow velocity

(12)

The contour plots from the 2D simulations show

that the stagnation point is located at 0.85m from the

trailing edge, which is in line with previous

simulations while for the 3D simulations the

stagnation pint is located further back in the plate at

0.7m from the trailing edge. While in the 2D

simulations the iso-pressure lines are almost parallel,

in the 3D simulations, a pressure drop near the sides

is present. The overall lower pressure experienced

by the 3D plate when compared with the 2D plate,

results leads to a lower drag force but in particular a

lower lift force.

Figure 9: Iso-pressure coefficient contours on the 2D and

3D flat plate.

In Figure 10 the iso-surface representing the free

water surface is shown. Here, the flow detaching

from the flat plate sides that leads to a lower overall

drag on the 3D flat plate is clearly visible.

Figure 10: Free surface snapscho of the flow behind a 3D

flat plate for AoA=10 and Fr=1.1.

3 RESULTS AND DISCUSSION

In the present section, the results from the

simulations are evaluated and the key performances

of the surfboard and the alaia board are compared.

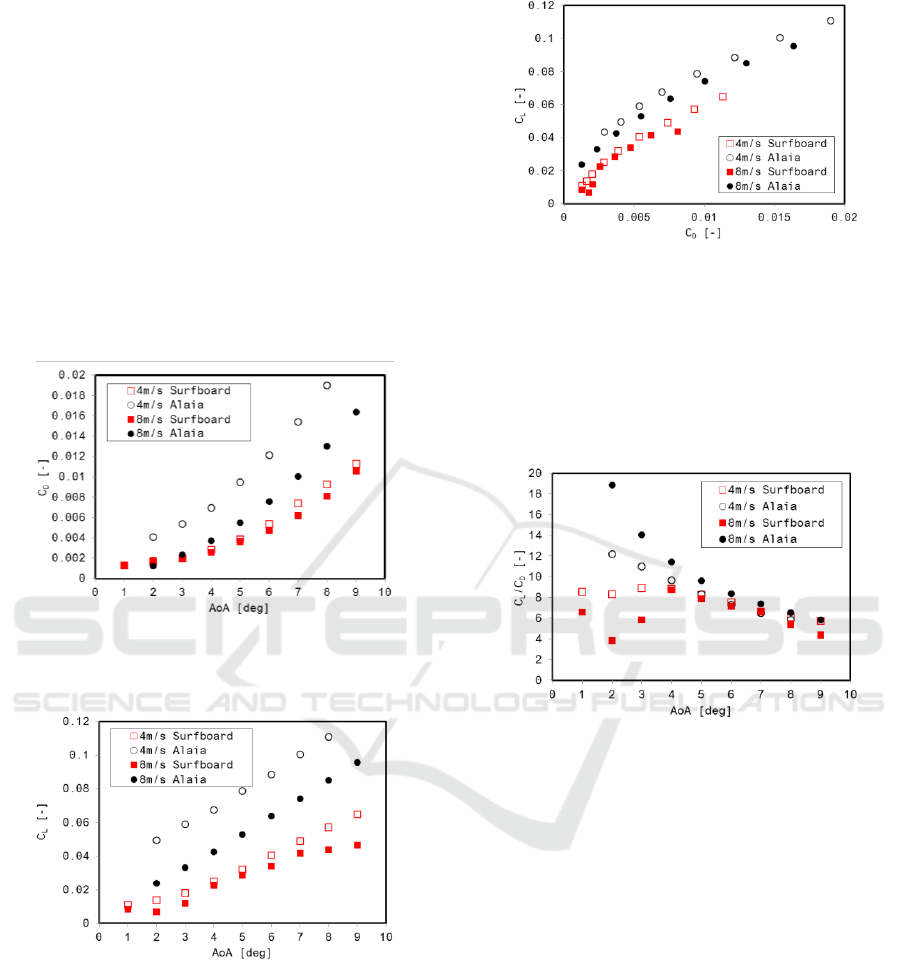

From Figure 11 it is clearly visible the alaia has

a larger drag than the surfboard. This is due to a

number of factors but two main design differences

causing this behaviour can be addressed. The bottom

of the boards is different with the surfboard having a

curved bottom surface to deliberately reduce the

drag and increase the speed. The tail shape between

the two boards is also different, with the surfboard

having a tapered shape (introduced in late 1920’s) to

allow for better performances and in particular to

reduce the drag generated by the extremity vortices

detachment. It is also clearly visible that the

surfboard’s c

D

is stable with increasing speeds while

a steep decrease in c

D

happens in in the alaia. This

leads to the need of continuous and more prominent

adjustments from the rider in order to compensate

for the difference in drag generated by the board and

allow the surfer a smooth ride.

Figure 11: Drag coefficient c

D

versus Angle of Attack AoA

for alaia and surfboard at 4m/s and 8m/s. Surfboard in red

(■) and alaia in black (●).

Figure 12: Lift coefficient c

L

versus Angle of Attack AoA

for alaia and surfboard at 4m/s and 8m/s. Surfboard in red

(■) and alaia in black (●).

The alaia also generates a greater lift than the

surfboard due to the topology of its bottom deck

when compared with the surfboard.

A flatter bottom like the one found in the alaia

leads to a larger wetted area and thus larger forces

both in the horizontal and vertical direction. This

also explains the fact that alaias require considerable

smaller volumes to be able to plane.

Figure 13: Lift coefficient c

L

versus drag coefficient c

D

for

alaia and surfboard at 4m/s and 8m/s. Surfboard in red (■)

and alaia in black (●).

Similar conclusions can be drawn when plotting

the polar curve (c

L

vs. c

D

) for both surfboard and

alaia with the latter one generating higher lift for the

same levels of drag when compared with the

surfboard.

Figure 14: Efficiency (c

L

/c

D

) versus Angle of Attack AoA

for alaia and surfboard at 4m/s and 8m/s. Surfboard in red

(■) and alaia in black (●).

When plotting the efficiency (c

L

/c

D

) against the

angle of attack (Figure 14), a different behaviour

between the alaia and the surfboard can be noticed,

with the latter having a lower efficiency at low

angles of attack but a more constant efficiency than

the former. The higher lift generated by the alaia at

low angles of attack is due to the different pressure

distribution that the alaia experiences when

compared with the surfboard in the tail region

(Figure 15). This high pressure in the tail region

generates a negative moment that the surfer will

have compensate by moving his weight on his back

foot and changing the AoA in order to keep the board

stable. In general then the high efficiency at low

angles of attack for the alaia is generated by an

unstable pressure distribution and requires

continuous adjustments from the surfer in order to

compensate the lift generated in the tail area of the

board.

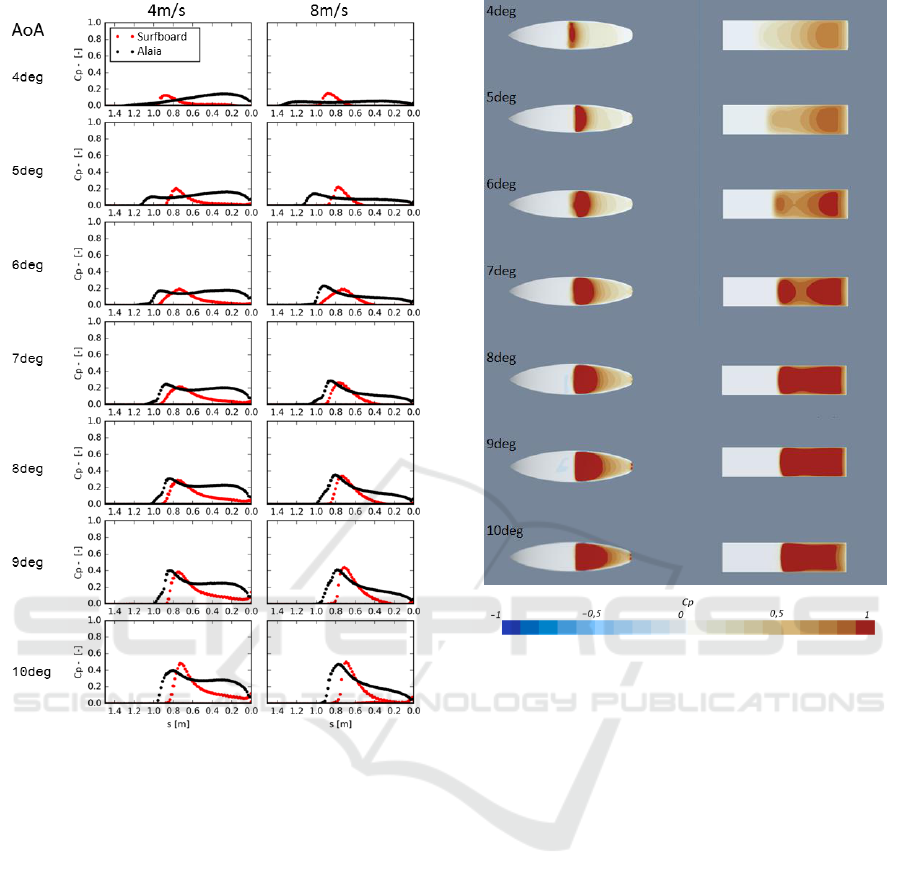

Figure 15: Pressure coefficient plots at the middle section

of the models: surfboard in red (●) and alaia in black (●).

Figure 15 shows how the pressure distribution

varies at different angles of attack on the alaia and

on the surfboard. Due to the increased curvature of

the bottom, the peak in pressure distribution on the

surfboard is constantly placed at ca. s=0.7m, close to

the front foot placement thus allowing the surfer to

always feel the same behaviour of the board under

his feet. It is also important to notice that the

pressure distribution at 4m/s and 8m/s is similar and

thus almost speed independent. The pressure

distribution of the alaia, on the other hand, varies

both with AoA and with speed, forcing the surfer to

apply continuous corrections in order to keep the

board balanced. It is also clearly noticeable that the

alaia has a larger wetted area, which directly reflects

on higher forces and higher pressure on the bottom

deck, resulting then in higher lift and drag.

Figure 16: Pressure distribution on the surfboard (left) and

alaia (right) at U=8m/s.

When analysing the 3D pressure contour plots on

the surfboard and on the alaia for 8m/s plotted in

Figure 16, the same behaviour noticeable in the

pressure distributions plots in Figure 15 can be

highlighted, with the surfboard keeping the

maximum pressure close to where the front foot is

placed and thus allowing a smoother ride to the

surfer without constant corrections. When

comparing the wakes generated by the surfboard and

the alaia (Figure 17) the wake generated by the

surfboard results clearly smaller than the wake

generated by the alaia, directly leading to a lower

drag. This is again due to the different tail shape and

bottom shape between the the two boards with the

alaia needing to move more water in order to be able

to travel at the same speed of the surfboard and thus

generating a wider and deeper wake.

Figure 17: Free and wake development on the surfboard

(left) and alaia (right) at U=8m/s.

4 CONCLUSIONS

CFD simulations proved to be a useful tool and to

evaluate and compare the performances of a

surfboard against an alaia with the same aspect ratio.

The fixed model approach has is however only

useful if used for qualitative comparisons or design

since it does not take into consideration buoyancy

and trimming. Overall the performances of the

surfboard showed a clear superiority in longitudinal

stability when compared with the alaia while the

alaia, mostly due to the flat bottom inducing a larger

wetted area resulted to have higher drag but also

higher lift, however, the strong dependency of the

generated lift to speed and AoA and the placement of

the pressure on the bottom deck, lead to continuous

adjustments needed in order to stabilize the board.

ACKNOWLEDGMENTS

The author would like to thank Max Leinenbach for

providing the surfboard CAD model.

REFERENCES

Ferziger, J. H. & Peric, M. 2001. Computational Methods

for Fluid Dynamics, Springer - London.

Heimann, J. 2010. Surfing.

Hirt, C. W. & Nichols, B. D. 1981. Volume of Fluid (Vof)

Method for the Dynamics of Free Boundaries. Journal

of Computational Physics, 39, 201-225.

Kramer, M. R., Maki, M. J. & Young, Y. L. 2013.

Numerical Prediction of the Flow Past A 2-D Planing

Plate At Low Froude Number. Ocean Engineering, 70,

110–117.

Menter, F. R. 1994. Two-Equation Eddy-Viscosity

Turbulence Models for Engineering Applications.

Aiaa Journal, 32, 1598–1605.

Perry, B. 1952. The Effect of Aspect Ratio on the Lift of

Flat Planing Surfaces. Pasadena: Hydrodynamics

Laboratory California Insitute of Technology.

Taira, K. & Colonius, T. 2009. Three-Dimensional Flows

Around Low-Aspect-Ratio Flat-Plate Wings At Low

Reynolds Numbers. J. Fluid Mech., 623, 187–207.

Ubbink, O. 1997. Numerical Prediction of Two Fluid

Systems With Sharp Interfaces, Phd Thesis Submitted

To The University of London and Diploma of Imperial

College.

Warshaw, M. 2010. The History of Surfing.

White, F. M. 2016. Fluid Mechanics (8th Eidition),

Mcgraw-Hill Book Co, New York, USA.

Wilcox, D. C. 2006. Turbulence Modelling for Cfd, La

Canada, California, USA.

Zaïdi, H., Fohanno, S., Taïar, R. & Polidori, G. 2010.

Turbulence Model Choice For The Calculation of

Drag Forces When Using The Cfd Method. Journal of

Biomechanics, 10, 405-11.