Processing of Browncoal from Kutai Kertanegara: East Kalimantan

as Adsorbent Media

Alwathan and Dedi Irawan

Department of Chemical Engineering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Activation, Activated Carbon, Adsorbent, Brown Coal, H

3

PO

4

-NaHCO

3

Activator.

Abstract: East Kalimantan is one of the provinces in Indonesia that produces the largest coal. Brown coal or known as

lignite has less economic value, this is because of its poor quality, low heating value and high sulfur and ash

content, so it is not suitable for use as an energy source. However, lignite coal has the potential to be used as

activated carbon which is an absorbent medium because it has a fixed carbon content of 25-30%. As activated

carbon, low rank coal will be very useful for absorbing impurities such as color and dissolved metals. The

purpose of this study was to determine the adsorption of browncoal from East Kalimantan from the Kutai

Kertanegara area which was activated using the H3PO4-NaHCO3 activator on the quality of the activated

carbon produced. Coal is sifted with a size of -100+120 mesh and then carbonized at 600

o

C for 3 hours. After

that, 20 grams of charcoal was activated using 2.5M H

3

PO

4

-NaHCO

3

2.5M with time variations of 2 hours, 4

hours, 6 hours, 8 hours and 12 hours, then washed to a neutral pH and then physically activated at 700

o

C for

2 hours. The best results were obtained with chemical activation for 6 hours with a water content of 3.5%;

volatile matter content 9.81%; ash content 14.91%; fixed carbon content 71.78% and iodine absorption

505.072 mg/g.

1 INTRODUCTION

East Kalimantan is one of the provinces in Indonesia

that produces the largest coal. Production in 2017 was

86,101,658.68 tons (EMR Department, 2018). Low

rank coal is the type that produces the most, which is

50% even though it has a low heat. Subbituminous

and bituminous coal produced 36.6% while anthracite

11.6% (Geological Agency, 2016).

Lignite or brown coal is usually soft and has a

brownish color that often contains plant parts that are

easily recognizable from their cell structure. Brown

Coal so far has not been utilized optimally even

though the potential is quite large in the Kutai

Kertanegara area of East Kalimantan, this is because

the calorific value is low so that the combustion

efficiency produced is low due to the high water

content.

Lignite coal or brown coal has less economic

value due to high transportation and storage costs and

high sulfur content and ash content. Lignite coal has

a calorific value composition of less than 7500 Btu/lb

(5250 cal/g), 25-45% water content, 24-32% volatile

matter content, 25-30% fixed carbon content and 3-

15% ash content (Heriyanto et al., 2014). Based on

the fixed carbon content of the coal, lignite coal has

the potential to be used as activated carbon.

Activated carbon is an adsorbent that is needed in

industrial processes, including the pharmaceutical

industry, food, beverages, water treatment (water

purification) and others (Rahim and Indriyani, 2010

and Kusdarini et al., 2017). The application of the use

of adsorbents is usually in adsorption technology,

which is a process or phenomenon of accumulation of

substances on the surface of other substances, such

events are usually referred to as absorption of

adsorbate molecules. to the adsorbent surface.

(Treybal) , 1981) There are 2 types of adsorption

consist of 1. Physical Adsorption Van Der Walls

Adsorption Physical adsorption process is an

adsorption process which is the result of

intermolecular attractive forces between solid

molecules and substances. does not penetrate into the

crystal screen of the adsorbent and does not dissolve

in it, but completely on the surface of the adsorbent.

In highly porous solids containing many capillaries,

adsorbed substances will enter these crevices when

the adsorbate soaks the solid, (Treybal, 1981). 2.

Chemical adsorbent or active adsorbent is the result

of the interaction between solids and adsorbed

510

Alwathan, . and Irawan, D.

Processing of Browncoal from Kutai Kertanegara: East Kalimantan as Adsorbent Media.

DOI: 10.5220/0010948300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 510-513

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

substances. Chemical absorbers are often not

reversible and the desorption of substances is often

found to have undergone chemical changes, (Treybal,

1981).

Adsorbents are solid substances that can adsorb

certain components of a fluid phase, One of the

adsorbants is activated carbon which is amorphous

carbon which has a large surface area and internal

volume so that it has a high adsorption capacity (Ali

I et al., 2012). Activated carbon was a material that

has many very small pores (Liu et al., 2019). These

many pores will be able to make activated carbon

have the ability to adsorp various other substances

that are close to it. the wider the surface of the

activated carbon, in principle, the more pores it has to

increase the surface area, then a number of materials

containing activated carbon will be present (Jawad et

al., 2019 ; Lilibeth, et al., 1996). There were at least

2 ways that can be done for activation, the first is a

physical process, namely by using a high temperature,

and the second is through a chemical process, namely

using certain chemicals that can be in the form of

acids or bases, or even a combination of both (Han et

al., 2018 ; Yan et al., 2020).

Research using lignite coal or browncoal has

been carried out by Rahim and Indriyani (2010),

obtained the best conditions for physical activation,

namely a temperature of 800

o

C while chemical

activation using 5% NaOH for 2 hours. moisture

content is 8.05%, ash content is 16.70%, volatile

matter content is 9.92% and iodine adsorption is

24.88%. Another study used a temperature of 600

0

C

carbonization time and physical activation at a

temperature of 800

0

C, the best results were at 150

minutes with the results of water content, ash content,

volatile matter and absorption of iodine as follows:

0.64%; 13.74%; 12.42% and 46.75%.

In this study, H

3

PO

4

-NaHCO3 activator was used,

the use of this activator will produce H

2

CO

3

and

Na

3

PO

4

compounds where Na

3

PO

4

can reduce ash

because it can bind calcium magnesium and silica

(Saragih, 2009) while H

2

CO

3

can dissolve calcium

(Tahriri, et al, 2009). The results to be achieved from

this study are focused on the effect of chemical

activation time on brown coal using H

3

PO

4

-NaHCO

3

activator on the quality of activated carbon in order to

increase the economic value of brown coal which is

abundant in East Kalimantan as an alternative raw

material for making activated carbon.

2 METHODOLOGY

First, the brown coal is reduced to -100+120 mesh,

then carbonized at T=600

0

C for 3 hours, then

chemical activation of the carbonized brown coal is

soaked using 2.5 M H

3

PO

4

solution - 2.5 M NaHCO

3

with a variation of immersion time of 2 hours, 4

hours, 6 hours, 8 hours, 12 hours. The immersion

results obtained were then washed with distilled water

until the pH was neutral and then placed in an oven to

remove the water content at a temperature of 105

0

C

and physical activation was carried out by heating at

T=700

0

C for 2 hours. remove it and let it cool in a

desiccator then perform proximate testing including

analysis of inherent moisture, ash content, volatile

matter, fixed carbon, and iodine absorption test,

The proximate analysis to determine the content

contained in brown coal activated carbon includes

water content analysis using the ASTM D-3173 test

method, ASTM D-3174 ash content, ASTM D-3175

volatile matter content and ASTM D-3175 iodine

adsorption.

3 RESULT AND DISCUSSION

The coal used in this study is lignite or brown coal

The calorific value test of brown coal obtained the

result that the calorific value of the coal used was

3665 cal , The results obtained were analyzed after the

carbonization process was carried out to determine the

effect of carbonization on brown coal and used as the

basis for the initial conditions of brown coal before

further activation, proximate analysis includes

analysis of water content, ash content, volatile matter

content and iodine absorption. like table 1 below

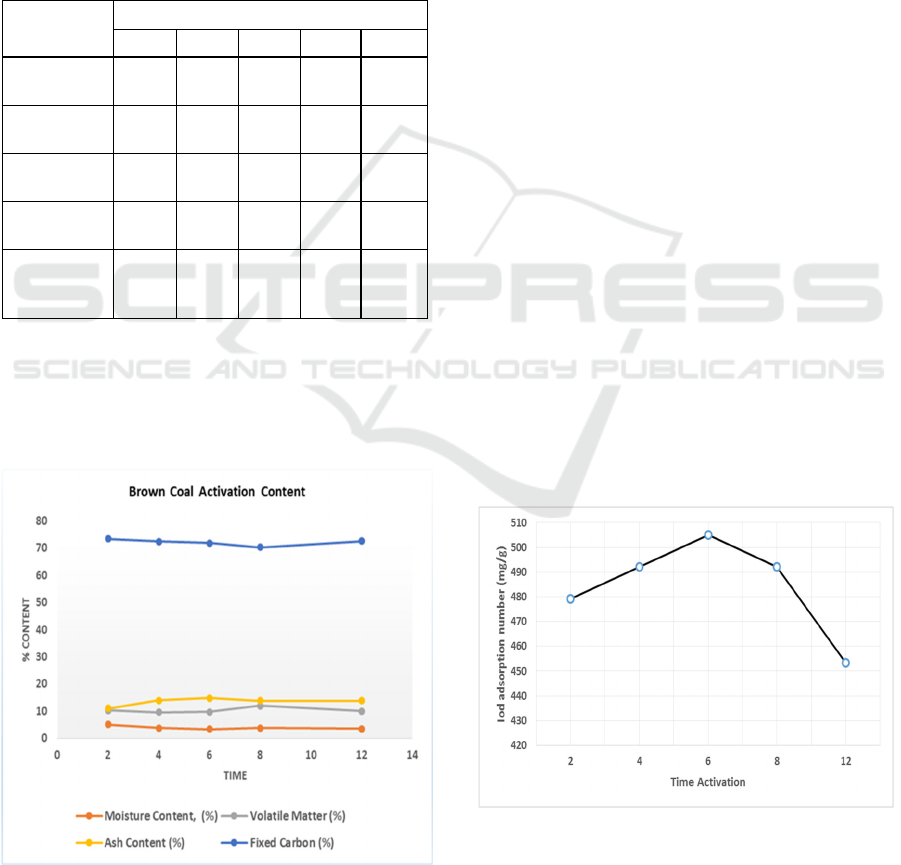

Table 1: The effect of carbonization brown coal analyzed.

Brown Coal Before

carbonization

After

Carbonizatio

Moisture Content, (%) 37.86 0.68

Volatile Matter (%) 5.53 34.25

Ash Content (%) 25.06 20.80

Fixed Carbon (%) 31.55 44.27

Iod Absorption (mg/g) 215.73 279.18

The characteristics of brown coal that have been

carbonized are affected by high temperatures causing

the surface area of brown coal to open but it is not

significant to become activated carbon, obtained

water content of 0.68%, volatile matter content

Processing of Browncoal from Kutai Kertanegara: East Kalimantan as Adsorbent Media

511

34.28%, fixed carbon content 44.27%, ash content

20.80% and iodine adsorption 279.18 mg/g. The

value of iodine adsorption has a correlation with the

surface area of activated carbon, the greater the iodine

number, the greater its ability to adsorb adsorbate or

solutes.

the carbonization process has a significant

effect due to the decomposition of organic

compounds that make up the structure of the material

to form methanol, vapor, tar, and hydrocarbons, this

is characterized by reduced volatile matter and

increased moisture content when carbonization is

carried out.

Table 2: The effect of Time Activation.

Parameter Time activation ( h)

2 4 6 8 12

Moisture

Content,

(

%

)

5.15 3.89 3.5 3.83 3.62

Volatile

Matter (%)

10.36 9.71 9.81 12.03 10.08

Ash Content

(%)

11.07 13.98 14.91 13.89 13.85

Fixed Carbon

(

%

)

73.42 72.42 71.78 70.25 72.45

Iod

Adsorption

(

m

g

/

g)

479.17 492.12 505.07 492.12 453.28

Table 2 shows how the effect of activation time

on brown coal, the activation carried out includes

chemical and physical activation. The following

graph below shows the effect of activation based on

variations in activation time.

Figure 1: The time effect of brown coal activation.

Figure 1 The water content tends to decrease with

the duration of activation, this is because the longer

the activation time, the water trapped in the cavities

of the activated carbon will be more dehydrated by

the activating agent which results in more water being

taken up by the activator because Na

3

PO

4

is a

compound that is a dehydrating agent.

The increase in ash content was due to the fact that

the water content in activated charcoal was much

reduced when heated, but the inorganic compounds

which were the components of the ash remained

relatively constant so that the percentage of ash

content would increase. The activator substance

succeeded in reducing the ash content from 20.80%

to 11.07%-14.91% after chemical activation because

the ash component was soluble in the activator

substance.

The decrease in volatile matter levels is because

the volatile compounds dissolve with the activator

and evaporate during physical activation at a

temperature of 700

o

C. The compound H

2

CO

3

breaks

down into H

2

O and CO

2

. CO

2

trapped in activated

carbon can increase volatile matter levels

Fixed carbon content is determined by the content

of other impurities such as water content, ash content

and volatile matter. The higher the water content, ash

content and volatile matter, the lower the fixed carbon

value. From the results of the study, it can be seen that

the increase in fixed carbon content was caused by a

decrease in water content and volatile matter content,

while the ash content did not significantly contribute

to the increase in fixed carbon content.

Another important parameter is the iodine number,

as shown in the figure below which shows a

significant increase in iodine adsorption after

activation.

Figure 2: The effect time activation for iodin adsorption

number.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

512

Based on Figure 2, shows an increase in iodine

absorption at each time variation when compared to

before activation, of course there is a very significant

difference, the iodine adsorption before activation is

at 279.18 mg/g and after activation was in the range

of 453.28 mg/g - 505.07 mg/g. The use of chemical

compounds in the activation process causes the

activating mineral elements to enter between the

hexagon plates of the crystallites and separate the

initially closed surface and break the carbon chain of

organic compounds, contact time or immersion time

has a significant impact on the activation process.

When physical activation is carried out by heating at

high temperatures, the contaminant compounds that

are in the pores become more easily released. This

causes the active surface area to increase and

increases the adsorption of brown coal activated

carbon.

4 CONCLUSIONS

The best results in the process of making activated

charcoal from browncoal from Kutai Kertanegara,

East Kalimantan based on variations in activation

time using the H

3

PO4-NaHCO

3

activator, the best

conditions were obtained at 6 hours of activation with

a water content of 3.5%; volatile matter content

9.81%; ash content 14.91%; fixed carbon content

71.78% and iodine adsorption 505.072 mg/g.

ACKNOWLEDGEMENTS

The author would like to thank the Research and

Development Center in the Samarinda State

Polytechnic for funding this research, and also thanks

to the Chemical Engineering Laboratory of the

Samarinda State Polytechnic as the place for the

research.

REFERENCES

AH Jawad, K Ismail, MAM Ishak, LD Wilson (2019).

Conversion of Malaysian low-rank coal to mesoporous

activated carbon: structure characterization and

adsorption properties. Chinese Journal of Chemical

Engineering 27 (7), 1716-1727.

Kusdarini, et al, (2017). Production of Activated Carbon

from Bituminous Coal with H3PO4 Single Activation,

Combination of H3PO4-NH4HCO3, and Thermal.

Adhi Tama Institute of Technology Surabaya. Mining

Engineering.

Lilibeth l, Shigehisa I, Yuji I, Toshimitsu M (1996)

Research and Development of Carbon Compositesfrom

Wood Charcoal for Environmental Clean-up and their

Applications. Wood research Journal 83: 43-46.

Liu, J., Zhang, Q., Liang, L., & Huang, W. (2019). Study

on the Catalytic Pyrolysis Mechanism of Lignite by

Using Extracts as Model Compounds. Catalysts, 9(11).

doi:10.3390/catal9110953

Patmawati, Y and Kurniawan, A. (2017). Utilization of East

Kalimantan Lignite Coal into Activated Carbon.

Samarinda State Polytechnic. Chemical Engineering.

Rahim, M and Indriyani, O.S. (2010). Production of

Activated Carbon from Low Rank Coal. Journal of

Perspective Media Technology. Thing. 40-44.

Saragih, R. (2009). Determination of Phosphate Levels in

Recovery Boiler Feed Water by UV-VIS spectrometry

method at PT Toba Pulp Lestari, Tbk- Porsea.

University of Northern Sumatra. Medan.

Tahrini, W et al. (2009). Effect of Carbonic Acid (H2CO3)

on the impact strength of limestone aggregates.

Udayana University. Denpasar.

Treybal, R. E. (1981), Mass Transfer Operation.

SingaporeMcGraw-Hill Book Company

Yan, J., Liu, M., Feng, Z., Bai, Z., Shui, H., Li, Z., Yan, H

(2020). Study on the pyrolysis kinetics of low-medium

rank coals with distributed activation energy model.

Fuel, 261. doi:10.1016/j.fuel.2019.116359

Processing of Browncoal from Kutai Kertanegara: East Kalimantan as Adsorbent Media

513