Surface-Graph-Based 6DoF Object-Pose Estimation for

Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots

Taiki Yano

1

a

, Nobutaka Kimura

2 b

and Kiyoto Ito

1 c

1

Research & Development Group, Hitachi, Ltd., Kokubunji, Tokyo, Japan

2

Research & Development Division, Hitachi America, Holland, Michigan, U.S.A.

Keywords:

Object Recognition, 6DoF Pose Estimation, Depalletizing, Shrink-Wrapped Item.

Abstract:

We developed an object-recognition method that enables six degrees of freedom (6DoF) pose and size esti-

mation of shrink-wrapped items for use with a mixed depalletizing robot. Shrink-wrapped items consist of

multiple products wrapped in transparent plastic wrap, the boundaries of which are unclear, making it difficult

to identify the area of a single item to be picked. To solve this problem, we propose a surface-graph-based

6DoF object-pose estimation method. This method constructs a surface graph representing the connection of

products by using their surfaces as graph nodes and determines the boundary of each shrink-wrapped item

by detecting the homogeneity of the edge length, which corresponds to the distance between the centers of

the products. We also developed a recognition-process fl ow that can be applied to various objects by appro-

priately switching between conventional box-shape object recognition and shrink-wrapped object recognition.

We conducted an experiment to evaluation the proposed method, and the results indicate that the proposed

method can achieve an average recognition rate of more than 90%, which is higher than that with a conven-

tional object-recognition method in a depalletizing work environment that i ncludes shrink-wrapped items.

1 INTRODUCTION

Mixed depalletizing is the process of unloading mul-

tiple types of items that are stacked on pallets or

in cage s, and there is a great need to automate this

heavy workload process using robots. Many re-

searchers have p roposed various system s and meth-

ods to achieve robot automation (Nakamoto et al.,

2016; Eto et al., 2019; Do liotis et al., 2016; Aleotti

et al., 2021; Stoyanov et al., 2016; Katsou la s and Kos-

mopoulos, 2001; Katsoulas et al., 2002; Kirchheim

et al., 20 08; Kimura et al., 2016). Size an d six de-

grees of freed (6DoF) objec t-pose estimation, which

accurately determines the size, position, and orienta-

tion of an object, plays an essential role in e nabling

robots to unload a variety of items (Poss e t al., 2019;

Mitash et al., 202 0; Monica et al., 202 0; Fuji et al.,

2015; Ya no e t al., 2022).

One of the challenges in size and 6DoF object-

pose estimation for mixed depalletization is estimat-

ing the boundaries of shrink-wrapped items. Shrink-

wrapped items, often seen in depalletizing operations,

a

https://orcid.org/0000-0001-9433-0569

b

https://orcid.org/0000-0001-5248-5108

c

https://orcid.org/0000-0002-2243-5756

consist of multiple products such as plastic bo ttles

wrapped tog ether in a transparent wra p. Because it is

difficult to measure this wrap area with a distance sen-

sor, only the top sur face of e ach produc t in the shr ink-

wrapped item can be measured, makin g it difficult to

identify the boun daries of the e ntire shrink-wrapped

item. Since the size and arrange ment of each item is

generally not known in advance in mixed depalletiz-

ing operations, it is difficult to corre c tly estimate the

6DoF pose of ea ch shrink-w rapped item, espe cially

when such items are placed adjacent to each oth er.

This incorrect recognition mu st be avoided because it

may lead to incorrect grasping, such as picking two

items at the same time.

To achieve shrink-wrapped item recognition, we

propose a surface-graph- based object-pose recogni-

tion method that estimates the 6Do F pose and size

of each shrink-wra pped item (Fig.1). Focusing on

the fact that the same type of pr oducts are packed

closely together in a shrink-wrappe d item and the dis-

tance between them is almost constant, we detect the

boundaries of the shrink-wrapped items by construct-

ing a sur face graph, where the product sur faces are

nodes and the distances be twe en their cente rs are the

edge lengths. Since there are usually gaps or mis-

Yano, T., Kimura, N. and Ito, K.

Surface-Graph-Based 6DoF Object-Pose Estimation for Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots.

DOI: 10.5220/0011635000003417

In Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2023) - Volume 5: VISAPP, pages

503-511

ISBN: 978-989-758-634-7; ISSN: 2184-4321

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

503

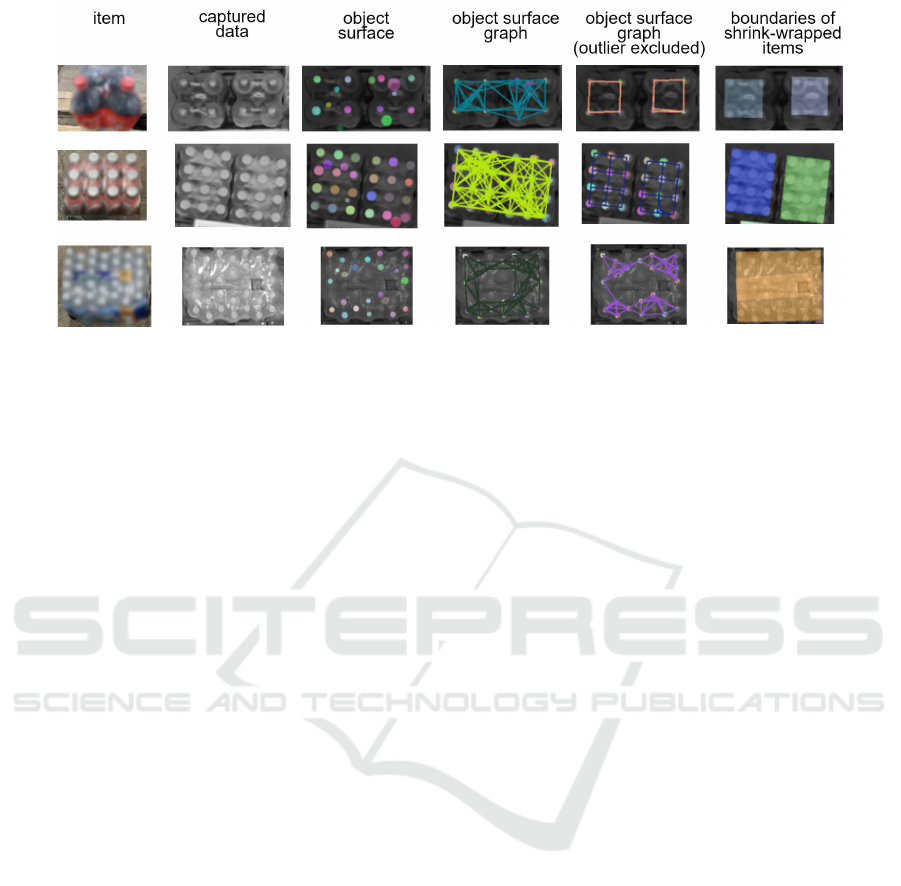

Figure 1: Surface graph-based 6DoF object-pose estimation for shrink-wrapped items. Columns show results of each pro-

cessing stage in estimating boundaries of shrink-wrapped items ( w ith each image blurred). Focusing on fact t hat same type of

products are packed closely together in shrink-wrapped item and distance between them is nearly constant, proposed method

constructs surface graph representing connection of products, and estimates region of each shrink-wrapped item by deter-

mining homogeneity of edge length, which corresponds to distance between centers of products. This makes it possible to

correctly estimate boundaries of variety of shrink-wrapped i tems.

alignments between the shrink-wrapped items, there

will be a difference between the distances among

the products ”within” one shrink-wrapped item and

the distances among the products ”between” multi-

ple shrink-wrapped items. There fore, the boundaries

of shrink-wrapped items can be estimated from the

differences in the edge length of this surface graph.

We also developed a recognition-process flow th a t can

be applied to various objects by appropriately switch-

ing between using a conventional edge-based object-

recogn ition method for boxed items and the proposed

method for shrink-wrapped items.

To compare the performance of the pro posed

method with a conventional edge-b a sed object-

recogn ition method, we c onducted exper iments to

simulate a mixed depalletizing process using a robot

arm. The results indicate that the proposed m ethod

could correctly recognize 6DoF poses of both boxed

and shrink-wrapped items and achieve an average

recogn ition rate of more than 90%, which is higher

than that of th e only the conventional method. This

recogn ition ac curacy validates the applicability of the

proposed method to mixed depalletizing robots that

handle shrink-wrapped items.

2 RELATED WORK

There has been much research on 6DoF object-p ose

estimation for depalletization. Before we describe

the proposed method, we discuss conventional object-

recogn ition methods. These methods are categorized

as local feature matching, deep-learning-based object

recogn ition, and edge-based bou ndary detectio n.

Local Feature Matching. One of the most c om-

monly used methods for rec ognizing the 6DoF pose

of an object is a local-feature-matching method (Tang

et al., 2012; Lowe, 2004). Such a method ge ner-

ates and ma tc hes local features representing pattern

informa tion between a three-dimensional (3D) objec t

model created in advance and captured images and

has high recognition performance for objects with

patterns. However, it is not suitable for cases in which

it is difficult to create a 3D obje c t model in advance,

such a s in mixed depalletizing operations. When

the same pattern is seen repeatedly, as with shrink-

wrapped items, local features from the 3D model an d

captured images obtained at d ifferent locations can

potentially be matched, which may result in incorrect

6DoF pose estimation. It is also difficult to recognize

items without patterns, such as car dboard boxes.

Deep-learning-based Object Recognition. Curre nt

object-recognition methods using deep learning can

automatically learn useful features for estimating the

boundaries and/or 6DoF pose of items on the basis

of a large amount of data prepared in advance ( X iang

et al., 2018; Kehl et al., 2017; He et al., 2020; Wan g

et al., 2019; Mitash et al., 2020; Yang et al., 2022;

Gou et al., 2021). However, when handling new items

that differ significantly in appearance from those used

for training, a large amount of tra ining data must be

prepare d a gain, and this learning cost is an issue in

the field of logistics, where products are frequently

replaced.

Edge-based Boundary Detection. Conventiona lly,

edge-b a sed boundary detection has b een wid ely used

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

504

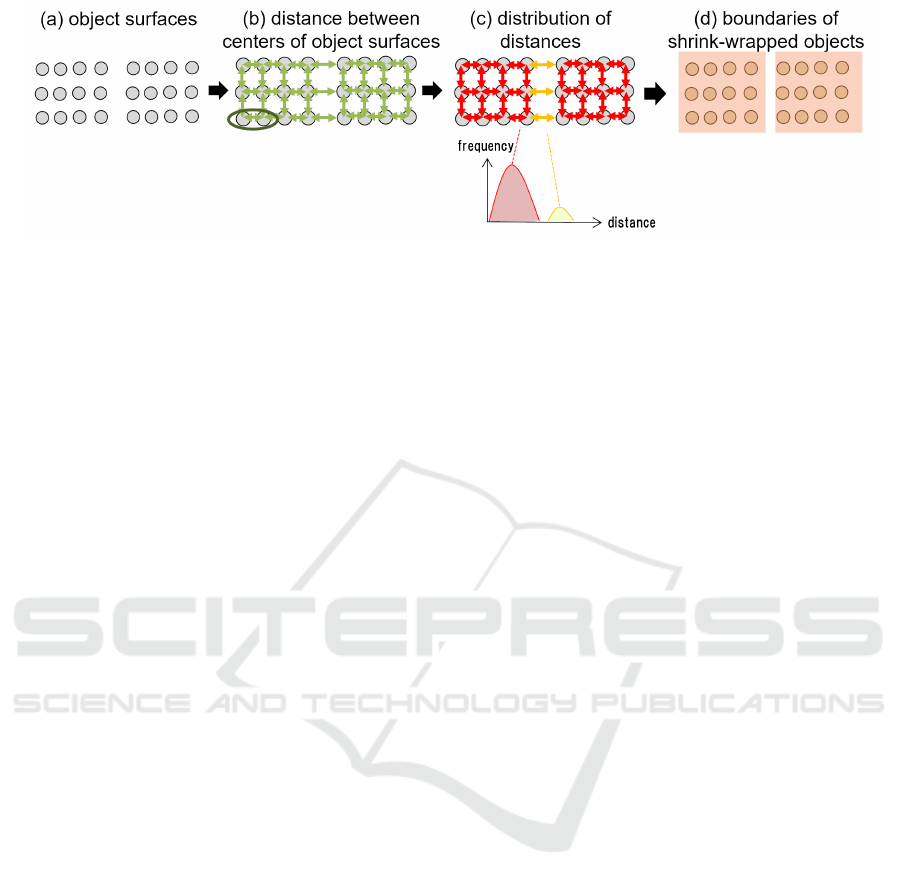

Figure 2: Boundary-detection procedure for shrink-wrapped items. Fir st, graph connecting each detected surface and distri-

bution of distances between surface centers are obtained, and edges corresponding to infrequent center-to-center distances are

excluded from graph. This enables estimating boundaries of shrink-wrapped items.

as 6Do F object-pose estimation for boxed items (Kat-

soulas and Kosmopoulos, 2001; Katsoulas et al.,

2002; Monica et al., 2020; N a umann et al., 2020;

Stein et al., 2014). By estimating the edges on the

basis of the lu minance gradient or degree of change

in the normal direction, it is possible to recog nize the

boundary of each item and estimate the 6DoF pose.

However, due to th e difficulty in detecting the edges

of wraps that cannot be measured, there is a risk of

detecting not each shrink-wrapped item but its inter-

nal products as a single item. The pr oposed method

is similar to this type of method, but differs in that it

estimates the boundar ie s of shrink-wrapped items on

the basis of the regularity of distances between prod-

ucts.

3 METHODS

3.1 Surface-Graph-Based 6DoF

Object-Pose Estimation for

Shrink-Wrapped Items

This section describes the proposed method for recog-

nizing shrink-wrapped items (Fig. 2). As mentioned

in 1, when a shrink-wrapped item is captured with a

distance sensor, on ly the top surface of each product

in the shrink-wrapped item is measured, making it dif-

ficult to determine the bound ary of each shrink- w rap

item. Therefor e , the proposed method constructs a

surface graph that represents the connection of each

product in shrink wrapped items and u ses this graph

to estimate the boundaries of shrink-wrapped items

and their 6DoF poses and sizes.

After extracting the product surfaces by the pro-

cess d e scribed in 3.2.1, we connect the surfaces that

are with in a certain d istance, forming a surface g raph

that represents each surface as a node and its connec-

tions a s edges (Fig.2(b)). We associate the distance

between the centers of the surfaces (referred to a s

the center-to-center distance) with the corresponding

edges. We then obtain the distribution of the center-

to-center distances on the basis of all this infor mation

(Fig. 2(c)). In this distribution, cente r-to-center dis-

tances with high frequency are considered edges con-

necting products within shrink-wrapped items, while

center-to-center distances with low frequency are

considered edges connecting products from different

shrink-wrapped items. Ther e fore, we exclude edges

correspo nding to low-frequency center-to-center dis-

tances from the grap h and identify the su bgraphs that

represent shrink-wrapped items to detect the bound-

aries between shrink-wrapped items (Fig. 2(d)). We

exclude edges cor responding to ce nter-to-center dis-

tances that are more than a certain distance from the

median of the distribution. Finally, fo r the group of

surfaces within th e estimated shrink-wrapped-item re-

gion, we carry out plane fitting using random sam-

ple consensus (RANSAC) ( Fisch le r and Bolles, 1981;

Holz et al., 2015) and estimate the 6DoF pose and size

of the bounding r ectangle surrounding the region.

When the wrap is translucent and partially mea-

sured, many noisy surfaces are included other than

the surface corresponding to the product, and the reg-

ularity of the center-to-cente r distance is buried in the

noise. This has a significant negative impact on the

boundary-detection procedure described above (Fig.

3). To avoid this problem, we carry out plane fitting

using RANSAC for the surface nodes belonging to

the graph formed in Fig. 2(b) and exclude nodes that

are more than a certa in distance from the plane in ad-

vance.

3.2 Developed Recognition-Process

Flow for both Boxed and

Shrink-Wrapped Items

This section describes our developed recognition-

process flow for recogniz ing items in various pack-

Surface-Graph-Based 6DoF Object-Pose Estimation for Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots

505

Figure 3: N oise reduction i n boundary-detection procedure. Carrying out plane fitting on surfaces and excluding surfaces that

are more than certain distance from the plane reduce impact of noise on regularity of center-to-center distance.

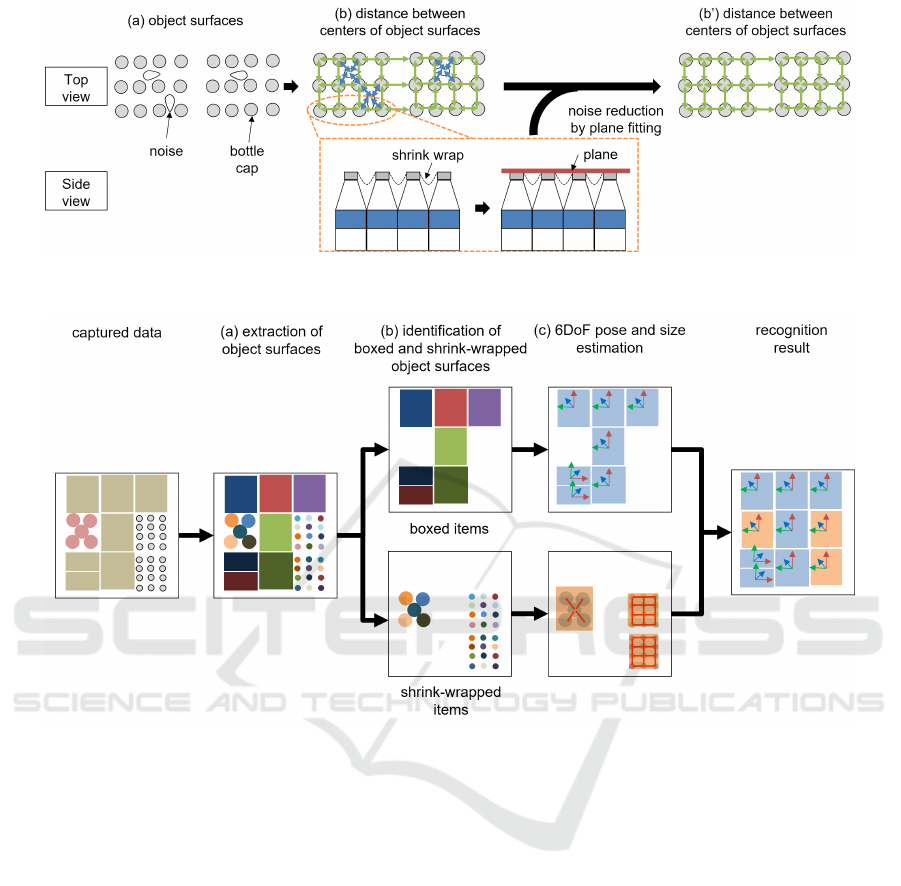

Figure 4: Developed recognition-process flow. Given scene image and point cloud, our recognition-process flow first estimates

whether each region obtained by segmentation is surface of boxed or shrink-wrapped item. Then, for boxed item, its size and

6DoF pose are estimated, and for shrink-wrapped item, its boundary, size, and 6DoF pose are estimated.

aging forms. This flow first estimates whether the ex-

tracted surfaces are boxed or shrink -wrapped items,

respectively. If it is a boxed item, its size and 6DoF

pose are obtained with the same procedure as a c on-

ventional method, and if it is a shrink-wrapped item,

its size and 6DoF po se are obtained with th e proposed

method on the basis of the regularity of the distance

between th e items. These processes mainly follow the

three steps shown in Fig. 4.

3.2.1 Extrac tion o f Object Surfaces

The surface of each item is first extracted by dividing

the captured image into regions (Fig. 4(a)). Note that

for shrink-w rapped items, th e surface of each p roduct

inside the shrink-wrapped item is extracted at this step

rather than the surface of the entire shrink-wr a pped

item. Since the distance and brightness information

changes significantly at th e boundar y of the surface of

each item, it is effective to use this information to seg-

ment the area. However, wh en items are densely piled

up, the distance between the gaps of the item s ma y

not be measured correctly; thus, multiple items may

be recognized as one object surface. If there is a pat-

tern on the item, the lum inance gradient near the pat-

tern also increases, making it difficult to distinguish

between the pattern and object boundar y. Therefore,

we estimate an edge region via the following values v

that emphasizes the boundary by combining the mag-

nitudes of bo th types of inform ation,

v

i j

= l

2α

i j

∗ c

2(1−α)

i j

(1)

where i, j are the x and y coordinates o f the pixel, l is

the magnitude of the vector consisting of luminanc e

gradients in the x and y directions, c is the value of

curvature at each pixel, and α is a parameter that ad-

justs the ratio between the luminance gradient and

curvature. We then apply the watershed algorithm

(Vincent et al., 1991) o n the region bounded by the

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

506

identified edges to obtain segmented regions, which

are regarded as the object surfaces.

3.2.2 Identification of Boxed and

Shrink-Wrapped Object Surfa c es

Next, we identify whether each o f the extracted sur-

faces mentio ned in 3.2.1 is the surface of a boxed item

or that of each product in a shrink-wrapped item (Fig.

4(b)). While most items are large rectangular shapes

and can be r ecognized with conventional me thods,

shrink-wrapped items con ta ining plastic bottles or

cans, which have sm a ll circular top surfaces, are dif-

ficult to be re cognized with such metho ds. Therefore,

the extracted surfaces larger than th e threshold are

identified as th e surfaces of boxed items, and those

smaller than the threshold are identified as th e sur-

faces of the prod ucts in shrink-wrapped items. The

circle extraction proc ess proposed in (Yuen et al.,

1990) is fur ther applied to the surfaces that belong to

products in a shrink-wrapped item, and only the area

overlapping the detected circle area is considered as

its surface area. This proce ss elimin ates small noise

areas.

3.2.3 6DoF Pose and Size Estimation

In this step, we obtain the 6DoF poses and sizes

of boxed and shrink-wrapped items. Surfaces be-

longing to products in the shrink- w rapped item men-

tioned in 3.2.2 are estimated for their 6DoF p oses

and sizes using the method d escribed in 3.1. Since

there is no need to obtain a surface graph for boxed

items, we carry out planar fitting d irectly on each

surface that belongs to a boxed item, as mentione d

in 3.2.2, to obtain its 6DoF pose and size. In this

study, we calculated the 6DoF poses of all items ex-

cept shrink-wrapped items using planar fitting, but it

is also possible to estimate the 6DoF pose by apply-

ing the RANSAC algorithm assuming cylindrical or

conical shap es.

4 EXPERIMENTS AND RESULTS

4.1 Dataset

We co nducted an experiment to evaluate the perfor-

mance of the proposed method. The experiments

were conducted under the assumption of recognition

in a mixed-depalletizing operation, as shown in the

left figure of Fig. 5. We used TVS4.0, a 3D vision

head with 2 cameras and an industrial projector, with

a resolution of 1280 x 1024. An example of an actual

image is sh own in the right figure.

Figure 5: Experimental setup. Left figure shows experi-

mental environment and right figure shows example scene

image (with each image blurred).

We evaluated th e recognition rate of the proposed

method for a total of 175 scenes, which were cap-

tured by chang ing the set of items in the ca ptured

image. The 25 typ es of items to be recognized are

shown in Fig. 6 . There existed overlap betwe en

boxed and shrink-wrapped items, i.e., on e item can

belong to both categories. Since the purpose of this

experiment was to evaluate the recognition accuracy

of the size, position, and or ie ntation of each item,

we did not evaluate the category-identification accu-

racy. The depth distance between the camera and top

surface of the item was 2.4–3.2 m. We compared

the proposed method with a conventional edge-based

boundary-detection method.

4.2 Definition of Success Rate

We defined a successful recognition as the corre c t es-

timation of the 6DoF pose of an item without occlu-

sion (i.e., par t of the item is hidden by other items and

cannot be seen) and used the ratio of scenes in which

the item was successfully recognized as the recogni-

tion rate. The success or failure of the 6DoF pose was

evaluated in accordance with the evaluation method

(Hodaˇn et al., 2016) and defined as suc c ess when the

intersection over un ion sco re (IoU) of the 2D bound-

ing rectangle of the estimated 6DoF pose projection

was 0.5 or mo re.

4.3 Results and Discussion

Figure 7 shows the recognition results of the proposed

method. The p roposed method correctly extracted

each surface area ( Fig. 7(a)) a nd correctly classified

the area into either boxed item or sh rink-wrapped item

in accordance with its size (Fig. 7(b)). The surfaces

that were reco gnized as shrink-wra p items were cor-

rectly divided into two shrink-wrapped- item ar e as on

the basis of the distribution of the center-to-center dis-

tances (Fig. 7(c)). For the surfaces that were recog-

nized boxed items, the correct 6DoF pose of each item

was successfully estimated by fitting a plane to a set

Surface-Graph-Based 6DoF Object-Pose Estimation for Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots

507

Figure 6: Target items. Each item is classified into eight categories, and corresponding item is shown in each column.

Figure 7: Results of proposed method. Each image shows result of each processing stage with proposed method (wi th each

image blurred). Proposed method recognized items in variety of packaging forms by dividing the items into boxed and

shrink-wrapped and applying diffrent methods. It also correctly recognized boundaries of shrink-wrapped items even when

such items of the same type were adjacent to each other by estimating boundaries on basis of regularity of distances between

products.

of points corresponding to the estimated item area, as

with the conventional method (Fig. 7(c)).

Table 1 shows the recogn ition rate for each item

shown in Fig. 6 using the evaluation criteria defined

in 4.2. The convention al method had a high reco g-

nition rate for boxed items, while the recognition rate

for objects with complex shapes such as bottles signif-

icantly decreased. The proposed method had a high

recogn ition rate for boxed items as well as bottles,

with an average recognition rate of more than 90%,

which is higher than that of the conventional method.

This shows that the proposed method is ca pable of

recogn izing both boxed an d shrink-wrapped items.

Figure 8 shows the results of failed recognition

with the proposed m ethod. When the shrink-wrapp e d

items were closely aligned without any misalignment,

there was insignificant difference in the distance be-

tween the products within the shrink- w rap items and

between the shrink-wr ap items. Therefore, the pro-

posed method recognized two shrink-wrapped items

as one large shrink-wra pped item. When the bound-

ary of the shrink-wrapped items cannot be determined

by only the distance between products, it is neces-

sary for the robotic system to grasp the edge of the

shrink-wrapped item and shift it to create a gap then

recogn ize the boundary again in the scene where the

boundary is clear.

The selected pa rameters can affect the perfor-

mance of the propo sed method. Fig ure 9 shows the

difference in recognition results when recognition is

executed with two different parameters in the recog-

nition p rocess. The parameter that correctly detects

the boundary of a large boxed item and the param-

eter that detects a very small area, such as a plastic

bottle cap, are often different. Th erefore, there are

potentially cases in which one fixed set of the pa-

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

508

Table 1: Recognition rate.

object

Edge-based bou ndary detection

Proposed method

(Convention al method)

Case 97.0% (32 / 33) 97.0% (32 / 33)

Box

88.1% (214 / 243) 87.7% (213 / 243)

Boxes

71.0% (233 / 328) 70.4% (231 / 328)

Grains

97.7% (208 / 213) 97.7% (208 / 213 )

Packs

95.4% (313 / 328) 95.4% (313 / 328)

Paper rolls

97.4% (150 / 154) 97.4% (150 / 154)

Cylinders 95.7% (400 / 418) 95.7% (400 / 418)

Bottles

67.6% (294 / 435) 91.3% (397 / 435)

All 85.7% (1844 / 2152) 90.3% (1944 / 2152)

Figure 8: Results of proposed method (failure case). Columns show results of each processing stage in estimating boundaries

of shrink-wrapped items. (with each image blurred). When shrink-wrapped items are closely aligned w ithout misalignment,

it is difficult to estimate boundaries of shrink-wrapped items on basis of regularity of distances between products alone.

rameters cannot be utilized to recognize all types of

items simultaneously. However, we believe that such

a pro blem can be solved by incorporating an a uto-

matic loc al-parameter adjustmen t process that selects

locally optimal parameters for each detected surface.

5 CONCLUSION

We proposed a sur face-graph-based 6Do F object-

pose estimation method that enables 6DoF pose and

size estimation o f shrink-wrapped items for m ixed

depalletizing processes. The proposed me thod con-

structs graphs that connect the product surfaces cor re-

sponding to each shrin k-wrapp ed item on the basis of

the d istribution of the center-to-cente r distan ce of the

products in the shrink-wrapped item, enabling accu-

rate boundary detection of shrink-wrapped items and

the estimation of their sizes and 6DoF poses, which

are difficult when u sin g conventional object recogni-

tion methods. To corre ctly recognize each item even

in an environment where boxed and shrink-wrapped

items are mixed, we also developed a recognition-

process flow that switches between a n edge-based

boundary-detection method for boxed items and the

proposed method for shrink-wra pped items depend-

ing on the size of the item surface.

In the experiment that simulated mixed depal-

letizing operations, we co nfirmed that the propo sed

method could correctly recognize 6Do F poses of both

boxed a nd shrink-w rapped items and achieve an av-

erage recognition rate of over 90%, which is higher

than that o f a conventional method.

By applying the proposed method to r ecognize in-

dividual items then having the robot pick and unload

them, an effective rob ot-picking system can be im-

plemented in a depalletizing work environment even

when boxed and shr ink-wrapped items are mixed.

Our future work will include incorp orating a

robot- a ssisted object-displacement process for cases

in which shrink-wrapped items are in close contact

with each other, which makes it difficult to distinguish

the boundary of each item. We also aim to improve

the recogn ition accuracy of the proposed method by

selecting locally optimal parameters for each item in

the scene.

ACKNOWLEDGEMENTS

We are grateful to Mr. Takaha ru Matsui fo r his useful

discussions with us. We are also grate ful to Mr. Kento

Sekiya and Mr. Koichi Kato for their cooperation in

implementing the software for the proposed method.

Surface-Graph-Based 6DoF Object-Pose Estimation for Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots

509

Figure 9: Difference in recognition performance due to parameter setting. Each image is recognition result for same scene but

with different parameters (with each image blurred). Parameters that correctly capture boundaries of large boxed items and

those that detect very small areas, such as plastic bottle caps, often differ, and there are cases in which it is not possible to set

parameters that allow all objects to be recognized simultaneously.

We are also gratefu l to Mr. Daisuke K a tsumata and

Mr. Tsubasa Watanabe for their cooperation in ob-

taining the experimental d a ta .

REFERENCES

Aleotti, J., Baldassarri, A., Bonf`e, M., Carr icato, M., Chiar-

avalli, D., Di Leva, R., Fantuzzi, C., Farsoni, S., In-

nero, G., Rizzini, D. L., Melchiorri, C., Monica, R.,

Palli, G., Rizzi, J., Sabattini, L., Sampietro, G., and

Zaccaria, F. (2021). Toward future automatic ware-

houses: An autonomous depalletizing system based

on mobile manipulation and 3d perception. Applied

Sciences (Switzerland), 11(13).

Doliotis, P., McMurrough, C. D., Criswell, A., Middleton,

M. B., and Rajan, S. T. (2016). A 3D perception-based

robotic manipulation system for automated truck un-

loading. IEEE International Conference on Automa-

tion Science and Engineering, 2016-Novem:262–267.

Eto, H., Nakamoto, H., Sonoura, T., Tanaka, J., and Ogawa,

A. (2019). Development of automated high-speed de-

palletizing system for complex stacking on roll box

pallets. Journal of Advanced Mechanical Design, Sys-

tems and Manufacturing, 13(3):1–12.

Fischler, M. A. and Bolles, R. C. (1981). Random sample

consensus: a paradigm for model fitting with appli-

cations to image analysis and automated cartography.

Communications of the ACM, 24(6):381–395.

Fuji, T., Kimura, N., and Ito, K. (2015). Architecture for

recognizing stacked box objects for automated ware-

housing robot system. In Proceedings of the 17th Irish

Machine Vision and Image Processing conference.

Gou, L., Wu, S., Yang, J., Yu, H., Lin, C., Li, X., and Deng,

C. (2021). Carton dataset synthesis method for do-

main shift based on foreground texture decoupling and

replacement. arXiv preprint arXiv:2103.10738, (Xi-

aoping Li).

He, Y., Sun, W., Huang, H., Li u, J., Fan, H., and Sun, J.

(2020). PVN3D: A deep point-wise 3D keypoints vot-

ing network for 6DoF pose estimation. Proceedings of

the IEEE Computer Society Conference on Computer

Vision and Pattern Recognition, pages 11629–11638.

Hodaˇn, T., Matas, J., and Obdrˇz´alek,

ˇ

S. (2016). On evalu-

ation of 6d object pose estimation. In European Con-

ference on Computer Vision, pages 606–619. Springer.

Holz, D., Ichim, A. E., Tombari, F., Rusu, R. B., and

Behnke, S. (2015). Registration with the point cloud

library: A modular fr amework for aligning in 3-d.

IEEE Robotics & Automation Magazine, 22(4):110–

124.

Katsoulas, D., Bergen, L., and Tassakos, L. (2002). A versa-

tile depalletizer of boxes based on range imagery. Pro-

ceedings - IEEE International Conference on Robotics

and Automation, 4(May):4313–4319.

Katsoulas, D. K. and Kosmopoulos, D. I. (2001). An ef-

ficient depalletizing system based on 2D range im-

agery. Proceedings - IEEE International Conference

on Robotics and Automation, 1:305–312.

Kehl, W., Manhardt, F., Tombari, F., Ilic, S., and Navab, N.

(2017). SSD-6D: Making RGB-Based 3D Detection

and 6D Pose Estimation Great Again. Proceedings of

the IEEE International Conference on Computer Vi-

sion, 2017-October:1530–1538.

Kimura, N., I to, K., Fuji, T., Fujimoto, K., Esaki, K.,

Beniyama, F., and Moriya, T. (2016). Mobile dual-

arm robot for automated order picking system in ware-

house containing various kinds of products. 2015

IEEE/SICE International Symposium on System Inte-

gration, SII 2015, pages 332–338.

Kirchheim, A ., Burwinkel, M., and Echelmeyer, W. (2008).

Automatic unloading of heavy sacks from contain-

ers. Proceedings of the IEEE International Con-

ference on Automation and Logistics, ICAL 2008,

(September):946–951.

Lowe, D. G. (2004). Distinctive image features from scale-

invariant keypoints. International Journal of Com-

puter Vision, 60(2):91–110.

Mitash, C., Wen, B., Bekris, K., and Boularias, A. (2020).

Scene-level pose estimation for multiple instances of

densely packed objects. In Conference on Robot

Learning, pages 1133–1145. PMLR.

VISAPP 2023 - 18th International Conference on Computer Vision Theory and Applications

510

Monica, R., Aleotti , J., and Rizzini, D. L. (2020). Detec-

tion of Parcel Boxes for Pallet Unloading Using a 3D

Time-of-Flight Industrial Sensor. Proceedings - 4th

IEEE International Conference on Robotic Comput-

ing, IRC 2020, pages 314–318.

Nakamoto, H., Eto, H., Sonoura, T., Tanaka, J., and Ogawa,

A. ( 2016). High-speed and compact depalletizing

robot capable of handling packages stacked compli-

catedly. IEEE International Conference on Intelligent

Robots and Systems, 2016-Novem:344–349.

Naumann, A., Dorr, L ., Ole Salscheider, N., and Furmans,

K. (2020). Refined Plane Segmentation for Cuboid-

Shaped Objects by Leveraging Edge Detection. Pro-

ceedings - 19th IEEE International Conference on

Machine Learning and Applications, ICMLA 2020,

pages 432–437.

Poss, C., Ibragimov, O., Indreswaran, A., Gutsche, N.,

Irrenhauser, T., Prueglmeier, M., and Goehring, D.

(2019). Application of open Source Deep Neural

Networks for Object Detection in Industrial Environ-

ments. Proceedings - 17th IEEE International Confer-

ence on Machine Learning and Applications, ICMLA

2018, pages 231–236.

Stein, S. C., Schoeler, M., Papon, J., and Worgotter, F.

(2014). O bject partitioning using local convexity.

Proceedings of the IEEE Computer Society Confer-

ence on Computer Vision and Pattern Recognition,

(June):304–311.

Stoyanov, T., Vaskevicius, N., Mueller, C. A., Fromm, T.,

Krug, R., Tincani, V., Mojtahedzadeh, R., Kunaschk,

S., Mortensen Ernits, R., Canelhas, D. R ., Bonilla, M.,

Schwertfeger, S., Bonini, M., Halfar, H., Pathak, K.,

Rohde, M., Fantoni, G., Bicchi, A., Birk, A., Lilien-

thal, A. J., and Echelmeyer, W. (2016). No More

Heavy L ifting: Robotic Solutions to the Container

Unloading Pr oblem. IEEE Robotics and Automation

Magazine, 23(4):94–106.

Tang, J., Miller, S., Singh, A., and Abbeel, P. (2012). A

Textured Object Recognition Pipeline for Color and

Depth Image Data. 2012 IEEE International Confer-

ence on Robotics and Automation, pages 3467–3474.

Vincent, L., Vincent, L., and Soille, P. (1991). Watersheds

in Digital Spaces: An Efficient Algorithm Based on

Immersion Simulations. IEEE Transactions on Pat-

tern Analysis and Machine Intelligence, 13(6):583–

598.

Wang, H., Sridhar, S., Huang, J., Valentin, J., Song, S., and

Guibas, L. J. (2019). Normalized object coordinate

space for category-level 6d object pose and size esti-

mation. In Proceedings of the IEEE/CVF Conference

on Computer Vision and Pattern Recognition, pages

2642–2651.

Xiang, Y., Schmidt, T., Narayanan, V., and Fox, D. (2018).

PoseCNN: A Convolutional Neural Network for 6D

Object Pose Estimation in Cluttered S cenes. arXiv

preprint arXiv:1711.00199.

Yang, J., Wu, S., Gou, L., Yu, H., Lin, C., Wang, J., Wang,

P., Li, M., and Li, X. (2022). SCD: A Stacked Car-

ton Dataset for Detection and S egmentation. Sensors,

22(10).

Yano, T., Hagihara, D., Kimura, N., Chihara, N., and Ito,

K. (2022). Parameterized B-rep-Based Surface Corre-

spondence Estimation for Category-Level 3D Object

Matching Applicable to Multi-Part Items. In 2022

IEEE 18th International Conference on Automation

Science and Engineering, pages 607–614.

Yuen, H., Princen, J., Illingworth, J., and Kit tler, J. (1990).

Comparative study of hough transform methods for

circle finding. Image and vision computing, 8(1):71–

77.

Surface-Graph-Based 6DoF Object-Pose Estimation for Shrink-Wrapped Items Applicable to Mixed Depalletizing Robots

511