Visual Detection of Personal Protective Equipment

and Safety Gear on Industry Workers

Jonathan Karlsson

1

, Fredrik Strand

1

, Josef Bigun

1 a

, Fernando Alonso-Fernandez

1 b

,

Kevin Hernandez-Diaz

1 c

and Felix Nilsson

2

1

School of Information Technology (ITE), Halmstad University, Sweden

2

HMS Industrial Networks AB, Halmstad, Sweden

Keywords:

PPE, PPE Detection, Personal Protective Equipment, Machine Learning, Computer Vision, YOLO.

Abstract:

Workplace injuries are common in today’s society due to a lack of adequately worn safety equipment. A

system that only admits appropriately equipped personnel can be created to improve working conditions. The

goal is thus to develop a system that will improve workers’ safety using a camera that will detect the usage

of Personal Protective Equipment (PPE). To this end, we collected and labeled appropriate data from several

public sources, which have been used to train and evaluate several models based on the popular YOLOv4 ob-

ject detector. Our focus, driven by a collaborating industrial partner, is to implement our system into an entry

control point where workers must present themselves to obtain access to a restricted area. Combined with fa-

cial identity recognition, the system would ensure that only authorized people wearing appropriate equipment

are granted access. A novelty of this work is that we increase the number of classes to five objects (hardhat,

safety vest, safety gloves, safety glasses, and hearing protection), whereas most existing works only focus on

one or two classes, usually hardhats or vests. The AI model developed provides good detection accuracy at

a distance of 3 and 5 meters in the collaborative environment where we aim at operating (mAP of 99/89%,

respectively). The small size of some objects or the potential occlusion by body parts have been identified

as potential factors that are detrimental to accuracy, which we have counteracted via data augmentation and

cropping of the body before applying PPE detection.

1 INTRODUCTION

A study made by the International Labour Office con-

cluded that approximately 350,000 workers die annu-

ally due to workplace accidents. In addition, there

are about 270 million accidents at work leading to ab-

sence for three or more days. A high level of produc-

tivity is associated with good occupational safety, and

health management (ILO, 2005).

The U.S. Bureau of Labor Statistics shows statis-

tics on injury conditions for various industries. The

report concludes that construction has the most con-

siderable fatal injuries. Statistics show that 5,039

American construction workers died between 2016

and 2020 due to a deficiency of personal protective

equipment, safety deficiencies, and other accidents.

This is a high number compared to the occupations

like (BLS, 2021): agriculture, forestry, fishing, and

hunting (2832); mining, quarrying, and oil and gas

a

https://orcid.org/0000-0002-4929-1262

b

https://orcid.org/0000-0002-1400-346X

c

https://orcid.org/0000-0002-9696-7843

Figure 1: Airlock room to separate controlled environ-

ments.

extraction (536); or finance and insurance (129). The

National Institute for Occupational Safety and Health

(NIOSH) has concluded that 25% of all construction

fatalities are caused by traumatic brain injury (TBI)

(Nath et al., 2020), and 84% of these fatal injuries

are due to not wearing hardhats (Ahmed Al Daghan

et al., 2021). Heavy machinery and trucks are stan-

dard within construction sites, and it is essential to

ensure high visibility of the workers to prevent poten-

tially fatal injuries (Ahmed Al Daghan et al., 2021).

Many fatal deaths could potentially be avoided with

Karlsson, J., Strand, F., Bigun, J., Alonso-Fernandez, F., Hernandez-Diaz, K. and Nilsson, F.

Visual Detection of Personal Protective Equipment and Safety Gear on Industry Workers.

DOI: 10.5220/0011693500003411

In Proceedings of the 12th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2023), pages 395-402

ISBN: 978-989-758-626-2; ISSN: 2184-4313

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

395

Figure 2: Left: Examples of images from the Kaggle dataset of hardhats and safety vests with positive examples (rows 1,2)

and negative examples (row 3). Right: Examples of images gathered from Google to complement the safety gloves, safety

glasses, and hearing protection classes. See Section 3.1 for further details.

proper protective equipment, such as vests with re-

flexes increasing visibility.

AI-driven applications are increasingly utilized in

several environments where security and protection

are prioritized. This work aims to develop a sys-

tem that helps enforce Personal Protective Equipment

(PPE) usage. PPE detection could also be combined

with facial recognition to determine whether people

are authorized to access an area of the production

floor, which is the aim of the project that motivates

this research. In the present paper, however, we have

only focused on developing and evaluating PPE de-

tection compliance. Based on the literature review

of the next section, PPE is an occurring topic in ob-

ject detection and is often used as a monitoring sys-

tem. However, the combination of face recognition

and PPE detection is not very common. Also, the

number of PPE classes in existing works is usually

one or two (normally hardhat or vest), but we aim at

detecting five different objects (hardhat, safety vest,

safety gloves, safety glasses, and hearing protection).

The contribution of this work is thus to increase

the number of target classes to five and, in a later

stage, combine facial recognition and PPE object de-

tection. Fast execution and response are important

for a user-friendly system. Therefore, another goal is

to have real-time detection. Combining object detec-

tion with identity recognition via facial analysis can

produce virtual key cards that only allow authorized

staff with the proper gear to enter a restricted area via,

e.g., an airlock room (Figure 1). An airlock room is a

transitional space with two interlocked doors to sepa-

rate a controlled area, where different checks can be

made before granting access. A system like this could

save thousands of lives annually and prevent severe

injuries with object detection and facial recognition

tools. We thus aim ultimately at increasing the safety

of industry workers in hazardous environments.

This project is a collaboration of Halmstad Uni-

versity with HMS Networks AB in Halmstad. HMS

develops and markets products and solutions within

ICT for application in several industrial sectors

(HMS, 2022). They explore emerging technologies,

and one crucial technology is AI, where they want to

examine and showcase different possibilities and ap-

plications of AI and vision technologies, e.g. (Nilsson

et al., 2020), which may be part of future products.

2 RELATED WORKS

Several projects (Nath et al., 2020; Jana et al., 2018;

Protik et al., 2021) use machine learning or deep

learning to detect PPE in different conditions. Ob-

ject detection and facial recognition are also common

topics within machine learning.

In (Protik et al., 2021), the objective is to de-

tect people wearing face masks, face shields, and

gloves in real time. They used the YOLOv4 detec-

tor (Bochkovskiy et al., 2020) with a self-captured

database of 1,392 images gathered from Kaggle and

Google, suggesting that real-time operation is feasible

(a score of 27 frames per second (FPS) was achieved).

The achieved mean average precision (mAP) is 79%.

The authors also implemented a counter function for

objects and record keeping.

In (Ahmed Al Daghan et al., 2021), the authors

developed a system to notify a supervisor when a

worker is not wearing the required PPE (helmet and

vest). It was achieved through object detection with

YOLOv4, and facial recognition with OpenFace (Bal-

tru

ˇ

saitis et al., 2016) that identified the worker and

its gear via CCTV in the construction site. An alert

system notifies the supervisor via SMS and via email

with an attached image of the incident. Supervisors

are also informed if non-authorized personnel enter

the construction site. They used 3,500 images col-

lected from Kaggle, with 2,800 to train the model dur-

ing 8,000 iterations. The attained mAP is 95% (vest),

97% (no vest), 96% (helmet), 92% (no helmet).

Three different approaches are proposed in (Nath

et al., 2020) based on YOLOv3 to verify PPE com-

pliance of hard hats and vests. The first approach de-

tects a worker, hat, and vest separately, and then a

classifier predicts if the equipment is worn correctly.

The second approach detects workers and PPE simul-

ICPRAM 2023 - 12th International Conference on Pattern Recognition Applications and Methods

396

taneously with a single CNN framework. The last ap-

proach first detects the worker and uses the cropped

image as input to a classifier that detects the presence

of PPE. The paper uses ∼1,500 self-obtained and an-

notated images to train the three approaches. The sec-

ond approach achieved the best performance, with a

mAP of 72.3% and 11 FPS on a laptop. The first ap-

proach, although having lower mAP (63.1%), attained

13 FPS.

The paper (Fang et al., 2018) proposed a system

to detect non-hard hat use with deep learning from a

far distance. The exact range was not specified, just

small, medium, and large are mentioned. Faster R-

CNN (Ren et al., 2015) was used due to its ability

to detect small objects. More than 100,000 images

were taken from numerous surveillance recordings at

25 different construction sites. Out of these, 81,000

images were randomly selected for training. Object

detection is outdoors, and the images were captured

at different periods, distances, weather, and postures.

The precision and recall in the majority of conditions

are above 92%. At a short distance, like the one that

we will employ in this work, they achieved a precision

of 98.4% and a recall of 95.9%, although the system

only checks one class (helmet).

In (Zhafran et al., 2019), Faster R-CNN is also

used to detect helmets, masks, vests, and gloves. The

dataset consists of 14,512 images, where 13,000 were

used to train the model. The detection accuracy was

measured at various distances and under lighting but

with a distracting background. Helmet resulted in

100% accuracy, masks 79%, vest 73%, and gloves

68% from a 1-meter distance. Longer distances con-

tributed to poorer results, with detection at a 5-meter

distance or above deemed unfeasible for all classes.

Reduced light intensity was also observed to have a

high impact on the smaller objects (masks, gloves).

The paper (Delhi et al., 2020) developed a frame-

work to detect the use of PPE on construction work-

ers using YOLOv3. They suggested a system where

two objects (hat, jacket) are detected and divided into

four categories: NOT SAFE, SAFE, NoHardHat, and

NoJacket. The dataset contains 2,509 images from

video recordings of construction sites. l. The model

reported an F1 score of 0.96. The paper also devel-

oped an alarm system to bring awareness whenever a

non-safe category was detected.

In (W

´

ojcik et al., 2021), hard hat wearing detec-

tion is carried out based on the separate detection

of people and hard hats, coupled with person head

keypoint localization. Three different models were

tested, ResNet-50, ResNet-101, and ResNeXt-101. A

public dataset of 7,035 images was used. ResNeXt-

101 achieved the best average precision (AP) at 71%

for persons with hardhat detection, but the AP for per-

sons without hard had was 64.1%.

Figure 3: Examples of images from volunteers to be used

as test images of the evaluation phases (see Section 3.3).

3 METHODOLOGY

3.1 Data Acquisition

The five object classes to be detected in this work

include hardhat, safety vest, safety gloves, safety

glasses, and hearing protection. Two data sources

have been used to gather data to train our system.

A dataset from kaggle.com

1

(Figure 2, left) with la-

beled hardhats and safety vests was utilized, contain-

ing 3,541 images, where 2,186 were positive, i.e. with

hardhats, safety vests, or both present. Negative im-

ages are pictures of people in different activities in-

doors and outdoors. An additional 2,700 images were

collected and annotated from Google Images with dif-

ferent keyword searches to complement the remain-

ing classes (Figure 2, right), given the impossibility

of finding a dataset containing all target classes. Pre-

liminary tests showed that, for example, caps could be

predicted as hardhats. This was solved by adding im-

ages of caps as negative samples of the training set to

help the model to learn the difference. The available

data has been augmented with different modifications

(saturation, brightness, contrast, blur, and sharpness)

to increase the amount of training data of some under-

represented classes, as it will be explained during the

presentation of results in Section 3.3.

3.2 System Overview

Several algorithms exist for object detection, e.g.:

RetinaNet (Lin et al., 2020), Single-Shot MultiBox

Detector (SSD) (Liu et al., 2016), and YOLOv3 (Red-

mon and Farhadi, 2018). Comparatively, RetinaNet

usually has a better mean average precision (mAP),

but it is too slow for real-time applications (Tan et al.,

2021). SSD has a mAP between RetinaNet and

YOLOv3. YOLOv3 has the worst mAP but is faster

and suits real-time applications. In addition, it is the

fastest to train, so one can adapt quickly to changes

1

https://www.kaggle.com/datasets/johnsyin97/hardhat-

and-safety-vest-image-for-object-detection

Visual Detection of Personal Protective Equipment and Safety Gear on Industry Workers

397

Table 1: Data variability conditions in the different test phases.

Table 2: Results of the first test phase.

Precision/Recall Training data

Object 3m 5m 7m Occurrences Percentage

Hardhat 98% / 99% 99% / 93% 97% / 98% 3367 33%

Safety vest 100% / 100% 96% / 100% 100% / 100% 2798 27%

Safety gloves 100% / 57% 100% / 41% 100% / 17% 2362 23%

Safety glasses 100% / 18% 100% / 4% 100% / 2% 897 9%

Hearing protection 100% / 44% 100% / 9% 0% / 0% 860 8%

in datasets. YOLOv4 (Bochkovskiy et al., 2020) is an

improvement of YOLOv3, with an increase in mAP

and frames per second of 10% and 12%, respectively.

YOLOv4 was also the newest YOLO version when

this research was conducted, making it the choice of

object detection algorithm for this work.

3.3 Experiments and Results

Our primary focus in this paper is detecting personal

protective equipment (PPE). Four test phases were

made to improve the results iteratively after identify-

ing the drawbacks of the previous phase and making

opportune adjustments in the training and/or test data.

Each phase employs data captured at different condi-

tions in terms of environment, distance, light, people

pose, etc., as reported in Table 1. Different YOLO

models have been trained with the indicated type

of training data on each phase, reporting the preci-

sion and recall in detecting the different target classes

(IoU threshold 0.5). The models were trained during

10000 iterations via Google Colab (12-15 hours per

model, depending on the dataset size and GPU avail-

able). The input image size is 476×476 (RGB im-

ages). The training parameters were selected accord-

ing to (Fernando and Sotheeswaran, 2021): learn-

ing rate=0.001, max batches=10000 (number of it-

erations), steps=8000, 9000 (iterations at which the

learning rate is adjusted), filters=30 (kernels in con-

volutional layers). Tests, including FPS computa-

tion, were done on a laptop with an 11th Gen Intel(R)

Core(TM) i7-1185G7 @ 3.00GHz 1.80 GHz CPU, In-

tel(R) Iris(R) Xe Graphics GPU, 16GB of RAM, and

Windows 10 Enterprise.

First Test Phase. Phases one and two (below) have

acted as guidelines to refine the experiments. The

training data is from the databases described in Sec-

tion 3.1. Results are given in Table 2, including the

number of training occurrences of each object. The

test data consisted of images from three different peo-

ple (two males, one female) that we acquired with a

smartphone, with a camera-person distance of 3, 5,

and 7 meters. Some examples are given in Figure 3

(left). Each person wears all PPE from different an-

gles, lighting, and distances, with a total amount of

119 images (3 meters), 127 (5 meters), 111 (7 me-

ters). In general, the images have backgrounds with

inferences of different nature (including other peo-

ple) and poor lighting due to shadows or light sources

in the background. With this test data, we aimed at

simulating uncontrolled imaging conditions, as those

shown in Figure 2, albeit indoor. From the results,

we observe a high precision in most classes and dis-

tances, but the recall is low for three objects (safety

gloves, glasses, and hearing protection) regardless of

the distance. High precision but low recall means

that the majority of positive classifications are posi-

tives, but the model detects only some of the posi-

tive samples (in our case, it means missing many PPE

occurrences). These three objects do not just appear

smaller than hardhats of safety vests in the crop of

a person, but they are also under-represented in the

training set (at least glasses and hearing protection).

Safety vests occupy a significant portion of the body,

and they have a significant shape and color. Hard-

hats may not occupy a big portion, but they have the

same dimension ratio and are usually visible from any

pose, facilitating their detection at any distance. On

ICPRAM 2023 - 12th International Conference on Pattern Recognition Applications and Methods

398

Table 3: Results of the second test phase. The number of occurrences in brackets indicates the increase with respect to the

first test phase.

Precision/Recall Training data

Object 3m 5m 7m Occurrences Percentage

Hardhat 100% / 100% 99% / 93% 94% / 95% 3636 (+269) 29%

Safety vest 100% / 100% 98% / 100% 100% / 100% 2912 (+114) 24%

Safety gloves 100% / 59% 100% / 53% 100% / 17% 2891 (+265+264) 23%

Safety glasses 100% / 18% 100% / 8% 0% / 0% 1418 (+260+261) 12%

Hearing protection 100% / 55% 100% / 9% 0% / 0% 1482 (+311+311) 12%

Table 4: Results of the third test phase.

3m 5m Training data

Object Prec/Rec AP Prec/Rec AP Occurrences Percentage

Hardhat 100% / 100% 100% 100% / 100% 100% 3636 29%

Safety vest 100% / 100% 100% 100% / 100% 100% 2912 24%

Safety gloves 100% / 96% 96% 100% / 96% 89% 2891 23%

Safety glasses 100% / 62% 27% 100% / 60% 21% 1418 12%

Hearing protection 100% / 76% 99% 100% / 16% 76% 1482 12%

mAP: 85% mAP: 77%

the other hand, the bounding box and appearance of

safety gloves, glasses, and hearing protection may be

different from different viewpoints of the camera, or

suffer from occlusions by body parts. As a result,

their detection is significantly more difficult.

Second Test Phase. To analyze the effect of the

class imbalance on the performance, this section will

consider additional training data via augmentation to

include more occurrences of the different objects and

increase the proportion of under-represented classes.

Some images have been modified in brightness, con-

trast, and sharpness as follows (affecting mostly the

three under-performing classes of the first phase):

• 269 hardhat images had +20% brightness, +10%

contrast, and sharpened

• 114 safety vest: +10% brightness, -20% contrast,

and blurred

• 265 safety gloves: +40% brightness, +30% con-

trast, and sharpened

• 264 safety gloves: -20% brightness, -30% con-

trast, and blurred

• 260 safety glasses: +25% brightness, -25% con-

trast, and blurred

• 261 safety glasses: -15% brightness, +40% con-

trast, and sharpened

• 311 hearing protection: +30% brightness, -40%

contrast, and blurred

• 311 hearing protection: -30% brightness, +10%

contrast, and sharpened

The same test data from phase one is also used

here. Results of the second test phase, including the

training occurrences after adding the mentioned aug-

mentation, are given in Table 3. The frames per sec-

ond were measured at 0.7 with the test laptop at this

stage of the process.

The two classes that were doing well previously

(hardhat and safety vest) remain the same here. Only

hardhat does a little worse at 7 meters. Safety gloves

have slightly improved recall at 3 and 5 meters, al-

though still 41% and 47% of the positives are unde-

tected. At 7 meters, it keeps without detecting 83% of

the occurrences. The improvement of safety glasses

is negligible, missing the majority of occurrences as

in the previous phase, and at 7 meters, it does not de-

tect any. The small size and transparency of safety

glasses may be the reason why they are difficult to

detect, which may be affected by variations in reflec-

tions under different lighting. Regarding hearing pro-

tection, it shows some improvement at 3 meters (re-

call goes from 44 to 55%), but at 5 and 7 meters, the

system is unusable. The shape, size, and visibility of

hearing protection can vary from different angles, as

mentioned in the previous test phase, making detec-

tion more difficult.

Third Test Phase. Overall, the data augmentation

of the previous test phase contributed to slightly im-

proving two difficult objects (safety gloves and hear-

ing protection) at close distances (3 meters). The re-

call values were 59% and 55%, respectively, mean-

ing that at least, more than half of the occurrences are

detected. Safety glasses remain difficult, and in any

case, longer distances (5 and especially 7 meters) are

Visual Detection of Personal Protective Equipment and Safety Gear on Industry Workers

399

Table 5: Results of the fourth test phase. The number of occurrences in brackets indicates the increase with respect to the

second and third test phases.

3m 5m Training data

Object P/R AP P/R AP Occurrences Percentage

Hardhat 100% / 100% 100% 100% / 100% 100% 3636 25%

Safety vest 100% / 100% 100% 100% / 100% 100% 2912 20%

Safety gloves 100% / 100% 98% 100% / 99% 91% 2891 20%

Safety glasses 100% / 96% 97% 100% / 58% 59% 2523 (+1105) 17%

Hearing protection 100% / 100% 99% 100% / 54% 94% 2587 (+1105) 18%

mAP: 99% mAP: 89%

‘reserved’ for the less difficult hardhat and safety vest

classes only.

To isolate the difficulties imposed by operation in

uncontrolled environments, we captured new test data

in a more controlled environment. Consequently, we

gathered additional testing data from two new per-

sons in a controlled environment with a less disturb-

ing background (Figure 3, right), in particular 100 im-

ages from 3 meters, and 100 images from 5 meters. A

test at 7 meters is not relevant for the intended sce-

nario. The camera is positioned at head-level height,

with the person in frontal or nearly frontal view. Both

the subject and the camera are static to reduce blurri-

ness. We also used a more uniform white background

(a wall) to eliminate inferences. Our aim with this re-

search is to enable a system like the one depicted in

Figure 1, where PPE detection and facial recognition

can be used with collaborative subjects in an entry

access point to a restricted area. This setup is simi-

lar e.g. to entry kiosks with face biometrics control,

where the person is asked to stand briefly while being

pictured, and non-frontal view angle is unusual. Two

add-ons here are that i) the person can stay at a certain

distance of 3 or 5 meters for increased convenience,

and ii) we add, via our developments in this paper, a

PPE compliance check. The training set employed is

the same as in the second phase.

Detecting the person and cropping the bounding

box before doing PPE detection is also expected to

impact accuracy and speed results positively. Thus,

from this phase, we added a human detection and

cropping step, which was not included in the previ-

ous phases. This was achieved via the CVZone li-

brary in Python3, which uses OpenCV at the core.

Cropping people before detecting any objects reduces

the information that must be sent or processed, al-

lowing for higher frame rates or usage of less pow-

erful solutions, such as edge computing. This also

improves execution time and detection accuracy of

further modules (Nath et al., 2020), e.g., by eliminat-

ing the risk of potential background objects similar to

PPE, or detecting objects not worn by persons. The

algorithm for human detection is based on Histogram

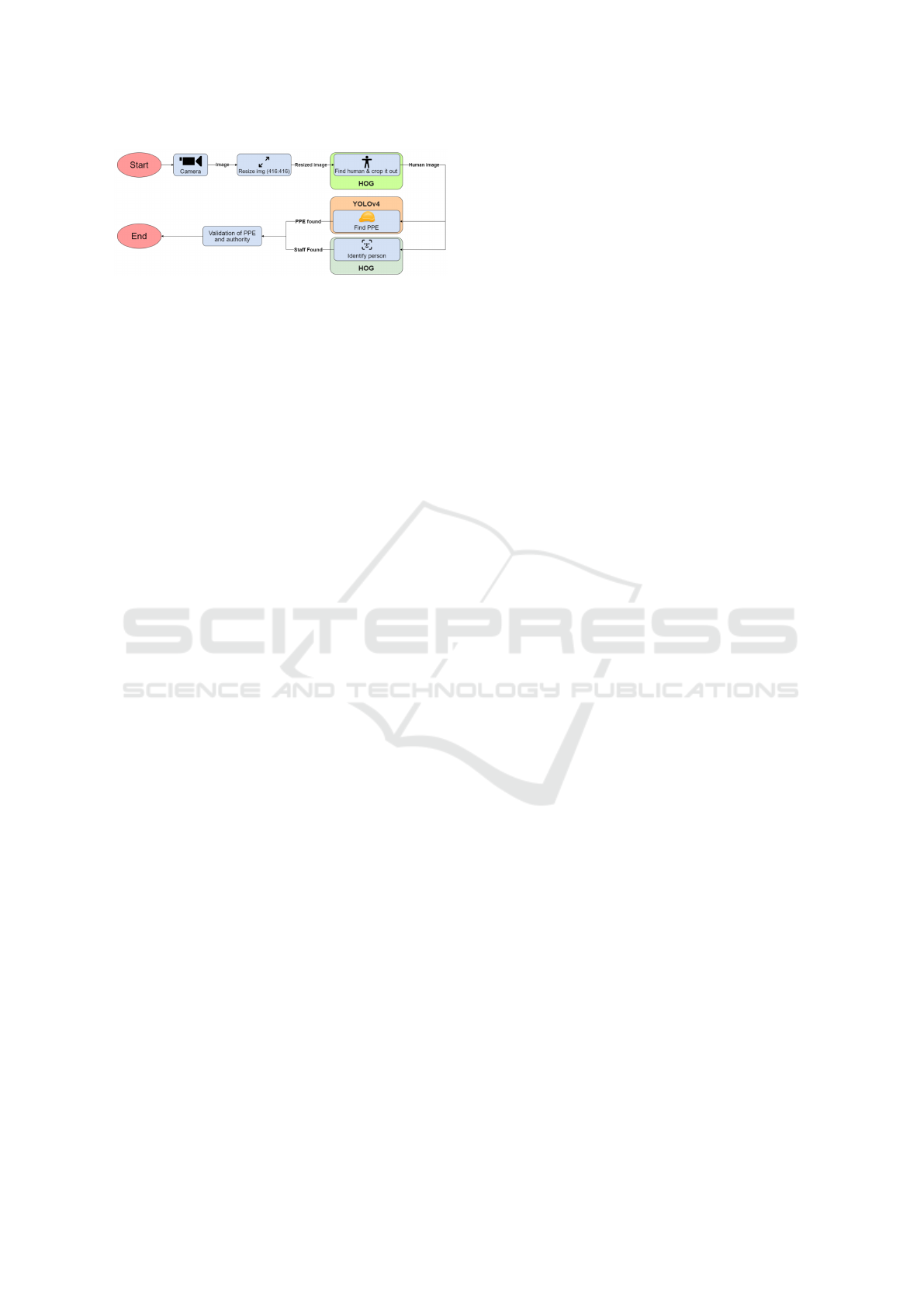

of Oriented Gradients (HOG). PPE detection is then

achieved with YOLOv4. It can also be combined

with face recognition to produce virtual key cards for

workers and allow access only if the right person en-

ters with the appropriate gear (Figure 4).

The new test environment of this phase achieved

the results shown in Table 4. The system ran with a

frame per second rate of 1.2, higher than the 0.7 of

the previous phase. We attribute this improvement to

adding the human detection and cropping step, which

reduces the input information to the YOLO detector.

As observed previously, hardhat and safety vest de-

tection is possible with very high accuracy, achiev-

ing perfect detection in the controlled environment

of this phase. The safety gloves improved the recall

from 59% at 3m and 53% at 5m to 96% at both dis-

tances, meaning that this item would be missed on

a few occasions only in the new scenario. The safety

glasses also improved the recall from 18/8% (at 3/5m)

to 62/60%, respectively. The recall for hearing pro-

tection increased from 55/9% (at 3/5m) to 76/16%,

respectively, meaning that detection at a long distance

(5 meters) remains difficult.

In this phase, we also added Average Precision

(AP) results, which correspond to the area under the

precision-recall curve, providing a single metric that

does not consider the selection of a particular thresh-

old in the IoU. The Mean Average Precision (mAP) is

also given, as the average of APs from all classes. The

AP values are high for all classes, except for safety

glasses which stay at 27/21% for 3/5m. In comparison

to the other objects, safety glasses can be transparent

and tiny, making more challenging to find them even

if we control the acquisition process. Hearing protec-

tion also has a small AP at 5 meters compared to the

other objects. As pointed out in the previous phases,

this object is smaller than others, which will be fur-

ther magnified at longer distances. In addition, it can

be partially occluded by the face, even with minor un-

noticeable departures from frontal viewpoint. Hear-

ing protection is also an underrepresented class in

the training set (despite efforts to augment it), which

could also be part of the issue.

ICPRAM 2023 - 12th International Conference on Pattern Recognition Applications and Methods

400

Figure 4: Illustration of the intended pipeline of our system.

Fourth Test Phase. In this phase, we aim to im-

prove further the representation of classes with fewer

images (safety glasses and hearing protection) via ad-

ditional training data. To do so, new images from two

of the contributors of phase one were captured, this

time only wearing safety glasses and hearing protec-

tion. In particular, 110 images of one person and 111

images of another person were captured. The first 110

images have also been augmented four times as fol-

lows:

• +30% brightness, +30% contrast, and sharpened

• -40% brightness, +20% contrast, and sharpened

• +20% brightness, -10% contrast, and sharpened

• +30% brightness, +60% contrast, and blurred

and the other 111 images as:

• -10% brightness, -20% contrast, and blurred

• -40% brightness, and sharpened

• +50% brightness, +50% contrast, and sharpened

• +40% brightness, and blurred

This results in 1105 new occurrences of safety

glasses and hearing protection. The new images were

taken in a similar test environment as phase three

(frontal view, camera at head level, static) to consider

our intended conditions of a collaborative setup like

Figure 1. The same test data from phase three and

person cropping is also used here. The two persons

contributing to the training set of this phase are dif-

ferent than the two persons in the test set, ensuring

independence. The results obtained with these new

training conditions are shown in Table 5. As can be

seen, any eventual uneven distribution of object oc-

currences in the training set is now corrected. The

frames per second with the test laptop were measured

at 1.2.

The results show that, with the addition of new

training images with safety glasses and hearing pro-

tection, detection of all classes is feasible at 3 me-

ters (recall of 96% or higher). Hearing protection

also increases recall at 5 meters from 16% to 54%,

although the system struggles to find safety glasses

and hearing protection at this distance, which we still

attribute to the factors mentioned earlier: smaller size,

transparency (glasses) or occlusion by the head (hear-

ing protection). The new training environment con-

tributed to better AP and mAP values as well, with

an mAP of 99% (3 meters) and 89% (5 meters), sur-

passing by a great margin the results of the previous

phase.

4 CONCLUSIONS

This work studies the use of cameras to detect Per-

sonal Protective Equipment (PPE) usage in indus-

trial environments where compliance is necessary be-

fore entering certain areas. For this purpose, we

have collected appropriate data, and evaluated sev-

eral detection models based on the popular YOLOv4

(Bochkovskiy et al., 2020) architecture. We con-

tribute with a study where the number of target classes

(hardhat, safety vest, safety gloves, safety glasses, and

hearing protection) is higher than in previous works,

which usually focus only on detecting one or two

(typically hardhats or vests). To aid in the detection

accuracy and speed, we also incorporate human de-

tection and cropping, so the PPE detector only has to

concentrate on regions with a higher likelihood of a

person wearing the target equipment.

We have carried out four test phases of our sys-

tem, improving the results iteratively after identifying

potential drawbacks in the previous one. Test data

with people wearing the complete PPE set and not

appearing in the training set was used to measure the

detection accuracy of our system. Based on the re-

sults of our last iteration, a well-functioning system

is obtained, with a mean average precision of 99%

at a 3 meters distance, and 89% at 5 meters work-

ing on controlled setups like an airlock room (Fig-

ure 1). The system works best at close distances and

in a controlled environment (phases 3 and 4), and it is

also benefited from data augmentation through modi-

fications in image brightness, contrast, and sharpness.

The latter contributes to enriching our training data

and balancing under-represented classes.

At longer distances, uncontrolled environments,

or without human detection and cropping, the sys-

tem operates worse. The difficult imaging conditions

and the size of some objects are highlighted as po-

tential reasons. Objects such as hardhats and safety

vests are well detected regardless of environment and

distance, while hearing protection, safety gloves, and

especially glasses are more difficult since they can

appear smaller or partially occluded by body or face

parts. Regarding detection speed, we achieve frame-

per-second (FPS) rates of 1.2 in a laptop. This could

Visual Detection of Personal Protective Equipment and Safety Gear on Industry Workers

401

be sufficient if the accuracy with just one frame is

good since the system can operate as the person ap-

proaches. Currently, our method carries out detec-

tion on a frame-by-frame basis, but more robustness

could be obtained by consolidating the result of sev-

eral frames, especially to detect the most difficult

classes. To help in this mission, we could also in-

corporate tracking methods to analyze image regions

where previously there was a detection with high ac-

cumulated confidence. However, this would come at

the cost of needing more frames, so more powerful

hardware would be needed.

Another improvement, in addition to frame fusion

or tracking, is to look for PPE objects in areas where

they are expected to appear. For example, hardhats,

glasses and hearing protection will likely be in the top

part of the body (the head), whereas safety vests must

occupy a significant portion in the middle. Skeleton

detection (Cao et al., 2019) may also assist in finding

where safety gloves may be, as well as refine the other

elements.

When deploying a detection system like the one

in this paper, one must consider the various ethical

questions related to camera-based detection, due to

humans appearing in the footage. Whenever a camera

is capturing or streaming such type of data to a re-

mote location, privacy, security and GDPR concerns

emerge. These concerns would be significantly coun-

teracted via edge computing, with data processed as

close as possible to where it is being captured, dimin-

ishing transmission of sensitive data to a different lo-

cation through data networks. Also, necessary frames

must be deleted as soon as computations are done.

The present system only uses one frame, but even

combining several frames with sufficient frame rate

would mean that the necessary data to be processed

only affects a few milliseconds of footage. Handling

the data in this way means that no sensitive data would

ever be stored, or transmitted elsewhere.

ACKNOWLEDGEMENTS

This work has been carried out by Jonathan Karls-

son and Fredrik Strand in the context of their Bach-

elor Thesis at Halmstad University (Computer Sci-

ence and Engineering), with the support of HMS Net-

works AB in Halmstad. Authors Bigun, Alonso-

Fernandez and Hernandez-Diaz thank the Swedish

Research Council (VR) and the Swedish Innovation

Agency (VINNOVA) for funding their research.

REFERENCES

Ahmed Al Daghan, A. T. et al. (2021). A deep learning

model for detecting ppe to minimize risk at construc-

tion sites. In IEEE CONECCT.

Baltru

ˇ

saitis, T. et al. (2016). Openface: An open source

facial behavior analysis toolkit. In IEEE WACV.

BLS (2021). National census of fatal occupational injuries

in 2020. Tech. report, Bureau of Labour Statistics.

Bochkovskiy, A. et al. (2020). Yolov4: Optimal speed and

accuracy of object detection. CoRR, abs/2004.10934.

Cao, Z. et al. (2019). Openpose: Realtime multi-person

2d pose estimation using part affinity fields. IEEE

TPAMI.

Delhi, V. S. K. et al. (2020). Detection of personal pro-

tective equipment (ppe) compliance on construction

site using computer vision based deep learning tech-

niques. Frontiers in Built Environment, 6.

Fang, Q. et al. (2018). Detecting non-hardhat-use by a deep

learning method from far-field surveillance videos.

Automation in Construction, 85:1–9.

Fernando, W. H. D. and Sotheeswaran, S. (2021). Auto-

matic road traffic signs detection and recognition us-

ing yolov4. In SCSE, volume 4, pages 38–43.

HMS (2022). https://www.hms-networks.com.

ILO (2005). Facts on safety at work. Technical report, In-

ternational Labour Organization, ILO.

Jana, A. P. et al. (2018). Yolo based detection and classifi-

cation of objects in video records. In IEEE RTEICT.

Lin, T.-Y. et al. (2020). Focal loss for dense object detec-

tion. IEEE TPAMI, 42(2):318–327.

Liu, W. et al. (2016). Ssd: Single shot multibox det. ECCV.

Nath, N. D. et al. (2020). Deep learning for site safety:

Real-time detection of personal protective equipment.

Automation in Construction, 112:103085.

Nilsson, F., Jakobsen, J., and Alonso-Fernandez, F. (2020).

Detection and classification of industrial signal lights

for factory floors. In ISCV, pages 1–6.

Protik, A. A. et al. (2021). Real-time personal protective

equipment (ppe) detection using yolov4 and tensor-

flow. In 2021 IEEE TENSYMP.

Redmon, J. and Farhadi, A. (2018). Yolov3: An incremental

improvement.

Ren, S. et al. (2015). Faster r-cnn: Towards real-time object

detection with region proposal networks. In NIPS.

Tan, L. et al. (2021). Comparison of retinanet, ssd, and

yolo v3 for real-time pill identification. BMC Medical

Informatics and Decision Making, 21(1).

W

´

ojcik, B. et al. (2021). Hard hat wearing detec-

tion based on head keypoint localization. CoRR,

abs/2106.10944.

Zhafran, F. et al. (2019). Computer vision system based for

ppe detection by using cnn. In IES.

ICPRAM 2023 - 12th International Conference on Pattern Recognition Applications and Methods

402