An Energy Management Unit for Predictive Solar Energy Harvesting IoT

Anuj Justus Rajappa

1 a

, Adnan Sabovic

1

, Burcu Celikkol

3

, Michiel Aernouts

1

, Philippe Reiter

1

,

Siegfried Mercelis

1

, Peter Hellinckx

2

and Jeroen Famaey

1

1

IDLab, University of Antwerp - imec, Sint-Pietersvliet 7, 2000 Antwerp, Belgium

2

IDLab, University of Antwerp, Groenenborgerlaan 171, 2020 Antwerp, Belgium

3

OnePlanet Research Center, Bronland 10, Wageningen, 6708 WH, Netherlands

Keywords:

EMU, Energy Management Unit, Energy Awareness, Energy Harvesting, Energy Aware Scheduler, Energy

Prediction, Modular.

Abstract:

As the need for stand-alone energy harvesting devices increases, the alleviation of the ecological and economic

impact of their production and maintenance is possible by increasing battery life while reducing needed bat-

tery capacity. However, the increasing energy requirements of far-edge Artificial Intelligence and long-range

wireless transmissions in the Internet of Things threaten to demand ever-larger battery capacities for such re-

mote devices. Dynamic adaptation of device operation based on harvestable energy – i.e., energy awareness –

is a proposed solution and can be implemented using an energy management unit. Standardizing this unit as a

separate, active electronic component with standardized drivers can simplify overall system development and

benefit existing devices. Hence, we propose a novel interface that allows decoupling this unit from the rest

of the system, independent of the power management unit in use. As a first step, we developed a prototype

that uses the proposed interface to make existing, solar energy-based, third-party devices energy-aware with

provisions to be cross-compatible with differing power management units. The prototype was evaluated using

an air quality sensing device and improved the overall device’s transmission rate.

1 INTRODUCTION

Energy Harvesting (EH) embedded devices and sys-

tems are widely encouraged due to their self-sufficient

nature and the flexibility they provide during the

installation and maintenance (Chetto and Queudet,

2016). These devices usually harvest energy from un-

intentional ambient power sources (e.g., light, wind,

heat, motion, etc.) (Shaikh and Zeadally, 2016), that

are not under any artificial control for the intents of

powering the device, and use the energy harvested for

their normal operation. Due to the nature of their

energy source, these devices have a low impact on

the ecosystem compared to a purely battery-powered

(Kang et al., 2013; Hamers, 2020) or grid-powered

device (Yue et al., 2021).

Current Energy Harvesting Internet of Thing(s)

(EH-IoT) devices often execute their tasks periodi-

cally with fixed time intervals (Kjellby et al., 2018;

Bhusal et al., 2020; Kjellby et al., 2019; Ramson

a

https://orcid.org/0000-0001-8167-9171

et al., 2021), without taking their available energy

budget into account. Consequently, this leads to

power failures during periods with a low energy yield.

On the other hand, excess energy is not optimally used

during periods with a high energy yield. Having a

large energy reservoir such as large capacity batter-

ies or super capacitors might solve this issue, but that

leads to higher costs, greater waste after end-of-life

and larger form-factors (Shaikh and Zeadally, 2016).

Ideally, devices should change their behavior based

on their currently available energy, which will re-

quire energy-aware task scheduling (EATS) schemes

for energy management (Babayo et al., 2017), where

the device’s behaviour is altered by scheduling tasks

based on the energy availability. For this purpose, re-

searchers have developed energy-aware task schedul-

ing algorithms for low power – and even battery-less

– Internet of Things (IoT) (Sabovic et al., 2022; Del-

gado and Famaey, 2021). However, there are two vari-

ations of the same question whose answer is impor-

tant to increase the EATS’s performance, “How much

energy will be available after a certain time period?”

Anuj, J., Sabovic, A., Celikkol, B., Aernouts, M., Reiter, P., Mercelis, S., Hellinckx, P. and Famaey, J.

An Energy Management Unit for Predictive Solar Energy Harvesting IoT.

DOI: 10.5220/0011839500003482

In Proceedings of the 8th International Conference on Internet of Things, Big Data and Security (IoTBDS 2023), pages 39-50

ISBN: 978-989-758-643-9; ISSN: 2184-4976

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

39

Nordic NRF52840 DK

APDS-9960

(Light sensor)

Active voltage divider

Solar charger

(PMU)

Li-ion battery

Arduino

MKR LTE-M

SIM

card

Serial flash

Watchdog

timer

Switch

SPI

Potentiostat

Potentiostat

RH/T sensorReal time clock

I2C

Gas sensor II

Gas sensor I

Antenna

Solar panel

Novel interface

(communication)

One Planet sensor box

(Third party device)

Data busPower Enclosure boundary

Prototype

(EMU)

Novel interface

(measure voltage)

Figure 1: Overall system block diagram.

(first question) and “When will a certain amount of

energy be available?” (second question). As both

questions are concerned with future available energy,

prediction algorithms, which allow the device to act

proactively, are used to answer them (Shafik et al.,

2018; Cammarano et al., 2016).

In this paper, unlike most of the current State of

the Art (SotA) techniques discussed in Section 2, we

focus on the second form of the question and answer

it with an Auto-regressive Integrated Moving Aver-

age (ARIMA) based energy prediction algorithm. A

simple EATS scheme uses the answer obtained (i.e.

the timing information) to maximize the efficient uti-

lization of harvested energy in a real EH-IoT device,

which is usually not the case in current SotA sys-

tems as the implementations based on the ARIMA

algorithm are often limited to simulation in this con-

text (Ji et al., 2009; Tanha et al., 2021). The pro-

posed predictive system is more adaptive and energy-

efficient compared to periodic polling-based reactive

techniques (Sabovic et al., 2022), which might require

a backup battery for continuous operation (Anagnos-

tou et al., 2018). Another novelty in our approach

is that, unlike most of the current SotA systems that

combine everything into one EH-IoT device, we sep-

arated the EATS scheme from the rest of the system

by building it into a prototype (cf. Section 4) i.e.

the energy management unit (EMU). This allows us

to add energy awareness (i.e., EATS) to non-energy-

aware third-party devices, through the proposed novel

interface, with ease. This idea was validated using

OnePlanet sensor box (Hofman et al., 2022) equipped

with Arduino as the third-party device and the corre-

sponding overall system block diagram with only the

significant connections is shown in Figure 1. The ex-

perimental setup used for validation is shown in Fig-

ure 5. In this paper, the role of EMU is associated

with optimal control of power consumed by the de-

vice with respect to time, while the role of the power

management unit (PMU) is associated with harvest-

ing maximum power from the energy harvester.

Other differences in our approach from most of

the current SotA are listed in Table 1. It includes han-

dling power cycles (Rodriguez Arreola et al., 2022),

due to energy shortages and additional overhead due

to energy predictions, which are usually unaccounted

by the current SotA energy prediction systems in

EH-IoT.

2 RELATED WORK

Current SotA techniques extensively use energy pre-

diction for answering the first question – i.e., “How

much energy will be available after a certain time pe-

riod ?” –, and use the energy information obtained

to improve their task scheduling schemes. Statistical

models, such as Exponentially Waited Moving Aver-

age (EWMA) (Kansal et al., 2007), Weather Condi-

tioned Moving Average (WCMA)(Recas Piorno et al.,

2009) and similar (Noh and Kang, 2011; Dehwah

et al., 2017), split a day into different time slots

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

40

Table 1: Difference between current SotA and our approach.

Current SotA approach Our approach

Requires accumulated energy data from time slots

older than at least a day (Kansal et al., 2007; Re-

cas Piorno et al., 2009; Cammarano et al., 2012;

Kosunalp, 2016; Stricker and Thiele, 2022; Yamin

and Bhat, 2021) for prediction. Hence, non-volatile

memory access to store day(s) old data and avoid

data loss is required, if the power cycle (Rodriguez

Arreola et al., 2022) is less than two days

Non-volatile memory access to store the time slot

data for prediction is not required as it can be col-

lected within a few minutes in the field. If the power

cycle is less than a few minutes, then the required

data can be augmented (cf. Section 3.2.2)

Overheads, such as the energy required to collect

data in the field for prediction are not usually con-

sidered as prediction overhead (Cammarano et al.,

2016; Stricker and Thiele, 2022; Yamin and Bhat,

2021)

Overheads associated with data collection in the

field for prediction purposes are mostly accounted

for and reported in Section 4 and Table 2

Accumulated solar energy (Yamin and Bhat, 2021;

Stricker and Thiele, 2022) or harvested power

(Cammarano et al., 2016; Kansal et al., 2007) is

the prediction variable. This variable’s present value

is measured in an EH-IoT device using either some

undisclosed circuitry (Yamin and Bhat, 2021) or so-

lar current with or without voltage (Kansal et al.,

2007; Dehwah et al., 2017), whose accuracy dis-

tortions due to PMU are not discussed. Training

a prediction model with this variable often requires

device-specific parameters, such as the characteris-

tics of its solar panels or training data collected from

a similar device, thus locking the trained model to

those device parameters (Stricker and Thiele, 2022;

Yamin and Bhat, 2021; Cammarano et al., 2016;

Kansal et al., 2007). Hence, changing a device pa-

rameter might often require retraining the prediction

model

Instantaneous solar irradiance is the prediction vari-

able. The present value of this variable is measured

using a dedicated light sensor, hence it is not af-

fected by the PMU (cf. last paragraph, Section 5).

Solar irradiance is the only variable used for training

the prediction model. The model’s predictions are

integrated with time and device parameters, such as

the efficiency of its solar panel, PMU, etc., for cal-

culating the actual harvestable energy (cf. Equation

1). As these device parameters can be changed even

during the run-time and are not involved in the pre-

diction model’s training process, it enables our pro-

totype to be plugged into different devices without

retraining the model

Long-term timekeeping (days) despite the power cy-

cles (Rodriguez Arreola et al., 2022) is required for

identifying time slots with respect to a day and for

managing old data (Cammarano et al., 2012; Kansal

et al., 2007; Stricker and Thiele, 2022; Yamin and

Bhat, 2021)

Long-term timekeeping is not required as there is

no need to identify any time slot with respect to a

day. Data older than a few minutes are usually not

required and are discarded

Prediction horizon is from short to long (minutes to

days) (Cammarano et al., 2016)

Prediction horizon is very short (seconds to min-

utes)

Aperiodic sleep is not possible as the device needs

to periodically collect the data for prediction (Cam-

marano et al., 2016; Kansal et al., 2007; Dehwah

et al., 2017; Yamin and Bhat, 2021)

Aperiodic sleep is possible as the missing periodic

data can be obtained using data augmentation (cf.

Section 3.2.2)

and records the energy accumulated in those time

slots during the present and previous days, which

is later used for predicting future energy accumula-

tion. PROfile Energy Prediction (Pro-Energy) (Cam-

marano et al., 2012) is based on data from previ-

ous days, but only typical days, which are charac-

terized as sunny, rainy, cloudy or mixed, are stored.

It analyzes the present-day weather condition and

matches it with the closest profile, whose time slot

data are then used for prediction. PROfile En-

ergy prediction model with Variable Length Times-

lots (Pro-Energy-VLT) (Cammarano et al., 2016) is

based on Pro-Energy but the granularity of time slots

for the profile are varied, based on the dynamics of

power source. Improved PROfile Energy Prediction

(IPro-Energy) (Muhammad et al., 2017) is based on

An Energy Management Unit for Predictive Solar Energy Harvesting IoT

41

Pro-Energy but the previous days recorded are based

on how old they are rather than typical day character-

ization. It uses an additional parameter called ‘smart-

ing factor’ that takes into account the rate of change of

energy between the time slots. Enhanced Pro-Energy

(Enhanced-Pro) (Deb and Roy, 2021) handles a previ-

ous day’s data similar to IPro-Energy but is also based

on Pro-Energy. It adds two new parameters: the tun-

ing factor, and the fine adjustment index to refine the

accuracy.

Machine learning algorithms are also used for pre-

dicting energy (Stricker and Thiele, 2022; Yamin and

Bhat, 2021). For instance, Q-learning-based solar

energy prediction (QL-SEP) (Kosunalp, 2016) is an

algorithm based on EWMA with an additional pa-

rameter called ‘daily ratio’, which is calculated us-

ing Q-learning. However, when dealing with short

term energy predictions in solar-based EH low-power

devices, statistical models are preferred to stochastic

and machine learning models (Wahba et al., 2020;

Bergonzini et al., 2009) due to their suitability in

terms of accuracy and overhead.

3 ENERGY AWARE TASK

SCHEDULER

This section describes our EATS, which consists of a

task scheduling algorithm aided by the energy predic-

tion algorithm. EATS is responsible for scheduling

tasks associated with actions such as sense and trans-

mit in the third-party device.

3.1 Task Scheduler

The prototype of EMU uses an energy-adaptive,

cyclic-scheduler to schedule independent atomic

tasks in the third-party device with the goal of max-

imizing the efficient utilization of harvested energy,

thereby decreasing residual energy utilization from

energy reservoirs. This is done in four steps. First,

the prototype checks the battery voltage and proceeds

to the next step if it is above the lower limit; else it

rechecks after a predefined period. Second, the proto-

type selects the task to execute next. Third, it calcu-

lates the waiting period (cf. Section 3.2.3) and waits

in sleep mode while collecting the energy required

to execute this task. However, this step is skipped

if the battery voltage is above the upper limit. Fi-

nally, it executes the task and the cycle repeats. Cal-

culating the waiting period based on the required and

harvestable energy is what makes the cyclic sched-

uler energy adaptive. It is done using energy predic-

tion. This scheduler can also be replaced with more

complex ones (Sabovic et al., 2022) (Delgado and

Famaey, 2021) based on task priorities and dependen-

cies, deadlines, etc.

3.2 Energy Prediction

A univariate time series forecasting technique is used

by the prototype of EMU for energy prediction, us-

ing the non-seasonal ARIMA model (Tanha et al.,

2021). The univariate being forecast is solar irradi-

ance, whose historical time series data is used to train

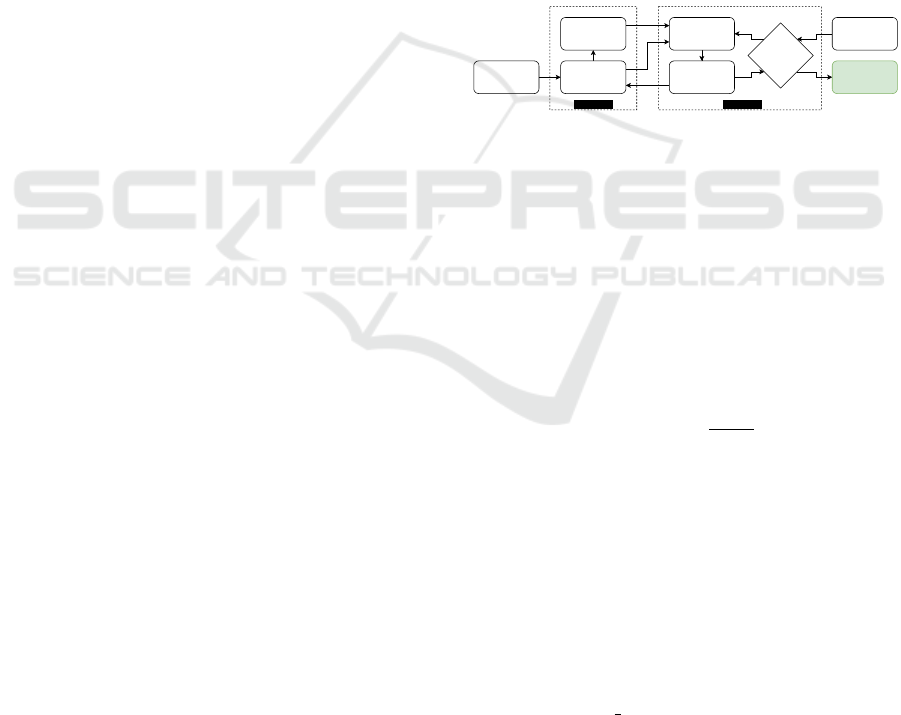

the model. Two functions, represented in Figure 2,

were used to implement the ARIMA model in the pro-

totype. Function 1 stores the observed data from the

prototype and calculates the residuals (difference be-

tween observed and predicted value). Function 2 uses

the observed data and residuals to predict the wait

time for accumulating a certain amount of energy.

Measured

harvester power

Energy required

(Er)

ARIMA model

Predict harvester

power in next

time point

Store / Update

the data and

time slot info.

Calculate

residuals

Net energy

>= Er ?

YES

NO

Function 1 Function 2

Number of time

slots to wait

Figure 2: Implemented ARIMA model abstract.

The consecutive data samples observed and pre-

dicted have equal time intervals (sample period) be-

tween them, which can be used to split the time do-

main into multiple, equally spaced time slots. A sam-

ple collected at the end of a time slot also belongs to

the beginning of the next time slot. The average of

the samples belonging to the beginning and end of a

particular time slot is assumed to be valid throughout

that time slot; i.e., if S

a

ir

and S

z

ir

are the solar irradiance

data measured at the beginning and end of a time slot,

then the solar energy harvested per m

2

in that time

slot is given by multiplying

S

a

ir

+S

z

ir

2

with the sample

period.

The observed data belonging to the beginning or

end of a time slot are called lag values and it is the

input to the Auto-regressive (AR) part of the ARIMA

algorithm. The difference between the observed data

and the corresponding prediction is called the resid-

uals or lagged forecast errors and it is the input to

the Moving Average (MA) part of the ARIMA al-

gorithm. The values P,D and Q are parameters that

define a ARIMA(P,D,Q) model, obtained after train-

ing the model using a custom framework in Python,

that uses the auto arima() function provided by ‘pm-

darima’ (Taylor G. Smith, 2022) Python library. P

represents the number of autoregressive terms, D rep-

resent the order of differencing required to convert a

time series data from non-stationary to stationary, and

Q is the number of residuals used by the prediction

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

42

model. After training the model, an intercept value

along with arrays of length P and Q containing co-

efficients corresponding to the AR and MA part of

the prediction model are obtained. The P,D,Q values,

coefficients and the intercept value are transferred to

the embedded platform of the prototype, described in

Section 4, and are used by the ARIMA model im-

plemented in it using the C language. The number

of lag values required by the model in the field for

prediction is given by max(P+D,Q). To complete the

training process within a reasonable time frame, the

P,D,Q values were constrained to 10, thus the maxi-

mum number of lag values possibly required by the

model would be 20. If each value consumes 4 bytes,

the worst case memory consumption by the lag values

will be 80 bytes.

3.2.1 Training and Testing

The dataset to train and test the model was col-

lected using a custom setup (Anuj Justus Rajappa,

2022a; Anuj Justus Rajappa, 2022b), shown in figure

3, which includes a solar panel (Seed Studio, 2022)

and APDS-9960 light sensor (BROADCOM, 2022)

whose surfaces are placed on the same plane and as

close to one another as possible, without obstruct-

ing the incoming light. The INA226 power sensor

(Texas Instruments, 2022) was used to collect the so-

lar panel’s open circuit voltage (V

ocv

) and closed cir-

cuit current (I

ccc

), while the light sensor was used

to collect the solar irradiance data. An additional

DHT22 temperature and humidity sensor (Aosong

Electronics Co.,Ltd, 2022) was used to record the

environmental data. The sensors were sampled ev-

ery 200ms and logged. The setup was placed in-

doors, next to a curtain-less glass window facing

south-west in Antwerp (Belgium) between August

of 2021 and February of 2022. The total data col-

lected over around 120 days consumes approximately

2GB in memory and is publicly accessible (Anuj Jus-

tus, 2022). ARIMA(5,1,0) was obtained after train-

ing with the dataset obtained between 12-11-2021 to

15-01-2022 and testing was done with the dataset ob-

tained between 24-01-2022 to 03-02-2022 due to their

continuity in time. The performance of the model

with the shortest prediction horizon (cf. Section 4)

is shown in Figure 4a. The root mean square error

(RMSE) for the prediction is around 7.99 × 10

−2

mW

cm

2

,

which is two orders of magnitude less than the aver-

age operating range during daytime.

3.2.2 Deployment and Data Augmentation

Once the prediction model is trained and its parame-

ters are transferred to the prototype of EMU, the past

Irradiance sensor

Power(VI) sensor

Solar panel

Figure 3: Custom setup for compiling historical dataset.

and present solar irradiance measurements from the

field are required to predict the future value(s) of that

variable, which is obtained using an APDS-9960 light

sensor (BROADCOM, 2022) attached to the proto-

type. The sensor is disabled when not in use by is-

suing an I2C command to improve the prototype’s

energy efficiency. The nature of the data required is

time series; i.e., it must have a constant sampling pe-

riod. Due to uncertainty in the energy availability, it is

not possible to guarantee that the system will wake-up

at regular intervals to collect the data for prediction.

Besides, the wake-ups would also be costly in terms

of energy consumption. So, whenever data is miss-

ing and is required for prediction, the required data is

augmented with naive prediction using the previously

observed data; i.e. using the previous observed data to

fill the missing data. This also applies when the pre-

diction horizon spans across more than one time slot.

Assume the current time slot as T and the consecutive

two time slots as T+1 and T+2. When predicting for

the end of T+1, actual observed data until T is used as

lag values. When predicting for the end of T+2, the

lag value from the end of T+1 is required. Since it is

in the future, the lag values are augmented by using

the lag value from the end of time slot T. This will

add to the prediction error such that it increases as the

prediction horizon lengthens, as shown in Figure 4b.

3.2.3 Calculating Wait Time

Let T be the current time slot. T + 1, T + 2, T + 3, . ..

represent the consecutive time slots in the future with

sample period SP. Let IR

a

T +n

and IR

z

T +n

be the solar

irradiance prediction for the beginning and end of the

time slot T+n, where n ∈ N. The harvested energy for

that time slot (Ehv

T +n

) is calculated using the Equa-

tion 1, where PV

area

is the surface area of the solar

panel with efficiency PV

e f f

and PMU

e f f

is the effi-

ciency of the PMU, which can be obtained from the

datasheet of the solar panel and PMU, respectively.

An Energy Management Unit for Predictive Solar Energy Harvesting IoT

43

2022-01-25 2022-01-26 2022-01-27 2022-01-28

Time (Datetime)

0.0

1.5

3.0

4.5

Irradiance

(

mW

cm

2

)

Observed irradiance

(

mW

cm

2

)

Predicted irradiance. RMSE = 0.0799

(

mW

cm

2

)

Ajx

Ajfalcon

(a) Observed vs. predicted irradiance.

(b) RMSE vs. time horizon of accumulated solar radiant

energy prediction.

(c) Measured vs. predicted panel power.

(d) Measured vs. sensor estimated panel power.

Figure 4: Analysis of the prediction and light sensor output.

Ehv

T +n

=

IR

a

T +n

+ IR

z

T +n

2

× SP × PV

area

×PV

e f f

× PMU

e f f

(1)

‘Function 2’ is responsible for calculating the wait

time (cf. Figure 2). Let the measured quantity of en-

ergy required for a task to execute (Er) be input to

the function. The lowest value of w which will satisfy

the Equation 2 is the function’s output, where w ∈ N.

The wait period is w×SP. The graph showing the plot

between the measured panel power using the custom

setup (cf. Section 3.2.1) and predicted panel power

(i.e. IR

x

× PV

area

× PV

e f f

, where IR

x

is the irradiance

predicted for the time point x) is shown in Figure 4c,

where the efficiency of the panel was evaluated based

on the obtained dataset and a typical fill factor value

of 80% (Khanna et al., 2013; University of Washing-

ton, 2022) was chosen to assume the effects of max-

imum power point tracking (MPPT) in PMUs. The

prediction’s RMSE is 1.35mW, which is an order of

magnitude less than the average operating range dur-

ing daytime.

Er < Ehv

T +1

+Ehv

T +2

+. . .+Ehv

T +(w−1)

+Ehv

T +w

(2)

4 PROTOTYPE DESCRIPTION

The prototype of EMU is shown in Figure 5 and it’s

block diagram is shown in Figure 1. It consists of

a Nordic nRF52840 development kit (Nordic Semi-

conductor, 2022) running in nRF only mode as the

compute unit for running the prediction algorithms.

Irradiance data is collected with the APDS-9960 light

sensor, which communicates with the compute unit

using I2C protocol. To monitor the energy reservoir,

such as batteries, its voltage needs to be measured.

However the range of voltage available at the battery

terminal is incompatible with the range of voltage that

can be input to the ADC unit of the prototype. Hence,

a custom active voltage divider circuit was developed

and was used to scale the battery voltage and bring

it within the ADC input range. Electrical parame-

ters of the prototype were measured with a Joule-

scope (Jetperch, 2022; Huybrechts et al., 2021) under

different conditions, such as short-term time keeping

with a high resolution timer (timer) versus a real-time

clock (RTC), as shown in Table 2. A active max.

scenario corresponds to the measurement made dur-

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

44

ing the active states, when the sensor and EATS are

in their maximum power consumption configuration.

The Worst-case execution time (WCET) measured for

the active states was around 240ms.

Interface

nRF52840_DK

OnePlanet

sensor box

Prototype

APDS-9960

Ajfalcon

Figure 5: OnePlanet sensor box (left) and Prototype (right).

The prototype was interfaced with an air qual-

ity sensor from OnePlanet (Hofman et al., 2022), as

shown in Figure 5. It consists of air quality monitor-

ing sensors, a solar panel, a rechargeable lithium bat-

tery (J & A, 2022), a power management board, a pro-

cessing and control unit from Arduino with onboard

transceiver from uBlox, which is a LTE Cat M1 / NB1

and EGPRS cellular module to transmit the measure-

ments at least once every 60 minutes. With our pro-

totype, it was required to transmit a measurement at

least once every 15 minutes i.e. to increase the per-

formance by four times. The flow of the prototype’s

firmware is shown in Figure 6. Function 2 (cf. Sec-

tion 3.2.3) shown in Figure 2 is invoked to accumulate

enough harvested energy only when the battery volt-

age is within its upper limit (4.1 V) and lower limit

(3.3 V), which approximately marks the 100% and

30% states of charge, respectively (J & A, 2022). The

last 30% of the battery is utilized as a reserve for han-

dling worst-case and unexpected scenarios. Even dur-

ing normal operation, it is not recommended to reach

100% depth of discharge, as it stresses the battery and

worsens the cycle life (Battery University, 2022) and

can cause the battery management system (BMS) to

shutdown the power output. If the battery voltage is

greater than the upper limit, it means enough energy

is already available and can execute the next task.

When battery voltage is below the lower limit, no

task is executed and voltage is rechecked after a pre-

defined period. WCET and Worst-case energy con-

sumption (WCEC) of the tasks executed on the One-

Planet sensor box were not readily available but they

are required to calculate the sample period and en-

ergy required in Function 2 (cf. Fig. 2). Hence, the

WCET and WCEC of the tasks were measured using

the Joulescope and the measurements are tabulated

in Table 3. During sleep, the OnePlanet box con-

sumes around 4.8mW at 3.29V. The execution time

was calculated based on the energy consumption pat-

tern. The worst case energy consumption is set as

0.13J for measurement and 14J for transmission (Tx),

Table 2: Electrical parameters of Prototype.

Scenario / Task Power Voltage

Sleep (timer0) 0.9mW 3.29

Active max. (timer0) 1.5mW 3.29

Sleep (rtc0) 35µW 3.29

Active max. (rtc0) 600µW 3.29

Initialize the timer,

ADC and I2C

peripherals

Reset the

I2C bus and

the sensor

Collect

minimum

data for

prediction

Read the

battery

voltage

Battery

voltage

greater than

upper limit

?

Battery

voltage

within limits ?

Predict the

wait time

(Function 2)

Wait for the

predefined

period when

battery voltage

is below lower

limit

Update the

data for

prediction

Update the

data for

prediction

Update the

data for

prediction

Wait for the

predicted

period

Update

the next

task

Wait for the task

completion, while

updating the data

for prediction

Interrupt

ext. app for

next task

execution

Yes

No

No

Yes

Figure 6: Flowchart of the prototype firmware.

which includes some overhead to account for its con-

sumption during sleep and operation of the prototype.

4.1 Time Management

The sample period used by the prediction model was

used to discretize the time domain and eliminate the

complexity involved in calculating the time in the

continuous time domain. Hence, all the execution

times and wait times used by the firmware of the pro-

totype of EMU are quantized with the quantum set as

the sample period (SP). This quantization of time do-

main can also reduce the number of wake-ups, cer-

tain routines and associated overheads by synchro-

nizing the events to the points in the discrete time

domain and therefore reducing the energy required.

To increase the efficient utilization of the harvested

energy, the device should be capable of executing

tasks consecutively without delay. Hence, an aver-

age execution time of 61.8s, obtained from Table 3

for both the Tx and measurement tasks in the One-

Planet sensor box, is considered for the sample pe-

riod; i.e., 61.8s is halved and rounded to 30s is used

as the sample period (1SP = 30s) by this prototype as

it provides fine-grained control over the time domain

during event scheduling. Lowering the sample period

further might provide even finer control but increases

the prediction overhead by increasing the iterations

required to solve for w in Equation 2, sensor on-time,

etc., thereby increasing the energy consumption as the

sample period decreases.

Based on Table 3, the execution time for a mea-

An Energy Management Unit for Predictive Solar Energy Harvesting IoT

45

surement task is fixed as 1SP and the Tx task is fixed

at 5SP and together they take 6SP; i.e., 3 minutes.

As there is a requirement to transmit at least every

15 minutes or 30SP, the maximum waiting period

affordable is 24SP, which is the maximum predic-

tion horizon used during evaluation by limiting the

maximum value for w as 24 in Equation 2 during

the evaluation. The maximum prediction horizon of

24SP(12 minutes) falls under very short to short pre-

diction horizon. Since the sample period is the time

slot period, the oldest data possibly required by the

model would be sample period times the maximum

number of lag values possibly required (cf. Section

3.2): i.e., 30s × 20 = 10 minutes.

4.2 Novel Interface

The interface of the prototype of EMU consists of

three parts, as shown in Figure 1. One is to power

our prototype, another to measure the voltage of the

reservoir, and the third one is responsible for com-

munication between the prototype and the third-party

device. Currently, the communication between our

prototype and the third-party device is done through

edge-triggered interrupts (one per task). Only a minor

firmware adaption was required in the third-party de-

vice to replace its old timer-based logic with interrupt-

based triggers, which enables the device to receive

alerts from our prototype when there is enough energy

to measure or Tx. The current prototype can be in-

terfaced to third-party devices with only solar panels

as energy harvesters. From the current SotA EH-IoT

systems, we couldn’t identify a similar interface for

decoupling EMU from the rest of the system. Hence

we consider this interface to be novel.

5 OBSERVATION AND

DISCUSSION

An APDS-9960 light sensor was configured to oper-

ate with the value of 192

10

in its ADC integration time

(ATIME) register during the experiment. This causes

the sensor to achieve maximum resolution of the ir-

radiance measurement equivalent to a 16-bit ADC

with the maximum count value of 65535

10

, which

takes almost 178ms of the execution time during the

active states of the prototype of EMU. By chang-

ing the ATIME register value to 255

10

, it only takes

2.78ms to conduct a measurement and the maximum

count value will be lowered to 1025

10

. Meanwhile

the active state’s WCET is reduced to around 14.3 ms

with approximate power consumption of 2mW. This

can significantly shorten the maximum energy con-

sumption during an active state from around 144µJ

to around 29µJ at the expense of the measurement’s

resolution.

The solar irradiance’s trend can be roughly de-

duced with the battery voltage data available from the

third-party backend server. As shown in Figure 7, it

hits the maximum value and remains constant around

the afternoon, when the solar irradiance is usually

high relative to the rest of the day. The number of

Tx and measurements along with the battery voltage

for a single day (12-05-2022) is shown in Figure 7

with respect to time. Red bars indicate the number

of Tx of the standalone third-party device, whereas

green bars show the number of Tx when our prototype

is plugged in. The standalone third-party device was

programmed by the third-party to make 1 Tx every

hour by default. The experiment was conducted on a

sundeck facing north-east for 63 hours, between 11

th

to 13

th

of May, 2022 at Antwerp (Belgium). Hence,

the standalone third-party device would have made 63

Tx. After plugging in our prototype to this device, we

were able to achieve 694 Tx, which is an eleven-fold

increase in Tx rate. Even if the default Tx rate was in-

creased to the minimum observed rate of 6 Tx every

hour, the performance improvement achieved would

be around 80% increase in Tx rate. This can be at-

tributed to EATS’s dynamic optimization of the Tx

rate compared to a constant Tx rate, as evident from

Figure 7, for devices that use unintentional ambient

power sources. Due to the cyclic nature of the sched-

uler, 1 Tx and measurement constantly consumes 8

active states, each consuming a maximum of around

144µJ (cf. Section 4 and Table 2). With the RTC for

time keeping, the energy consumed by the prototype

during the experiment would have been around 3.32J

per day (3.01J per day in sleep and around 0.31J per

day in active state).

Overall, the battery voltage did not show a de-

creasing trend during evaluation. This means the bat-

tery’s state of charge is regularly replenished despite

the increase in the operation rate, which can be at-

tributed to the third-party device’s dynamic adaption

to the harvestable energy due to the addition of the

prototype. It also means that the system is now capa-

ble of detecting excess available energy, which can be

effectively used by the third-party device for improv-

ing its quality of service (QoS) (Shafique et al., 2020)

and energy efficiency. However, a decreasing trend in

the battery voltage could have been noticed if the so-

lar panel had lower panel wattage rating or the battery

had lesser capacity, which opens the door for further

optimization.

The number of analog inputs required by the pro-

totype for measuring the voltage at energy reser-

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

46

Table 3: Electrical parameters of OnePlanet sensor box.

Scenario / Task Execution time Electric current Voltage Charge

Boot (connection timeout)

69 s 65 mA 4.95 V 4.5 C

80 s 36 mA 3.29 V 3 C

Boot (connected) 40 s 86 mA 4.17 V 3.4 C

1 measurement 1.75 s 14.2 mA 4.17 V 25 mC

(1 measurement) Tx failed

125 s - 3.29 V 2.42 C

71 s - 4.17 V 1.13 C

(0 measurement) Tx 31 s 88 mA 4.17 V 2.73 C

(1 measurement) Tx 80.25 s 41 mA 4.17 V 3.3 C

2022

-0

5-

1

2

00

:

0

6

:

5

5

2

02

2-

0

5

-12

0

0

:

2

5

:1

3

20

2

2-

0

5-

1

2

00

:

4

3:

3

0

2

0

2

2

-

0

5

-1

2

01

:1

0

:56

20

2

2

-05

-12

0

1

:

2

6:

10

2

02

2-

0

5-1

2

01

:

4

4:

2

7

202

2-

0

5

-

1

2

0

2:

0

2

:4

5

2

0

2

2

-0

5

-12

02

:

2

1:

0

3

2

0

2

2

-

0

5-

1

2

02

:3

9:

2

1

2

02

2-

0

5

-12

0

3

:

0

6:

48

2

02

2-

0

5

-

1

2

0

3

:

2

5:

05

202

2-

05-1

2

03

:4

3

:24

20

2

2

-05

-12

0

4

:

1

0:

51

2022

-0

5-

12

04

:

2

9:

0

8

2

0

22

-

0

5

-

12

0

4

:

4

7:

26

20

22

-

0

5

-

12

0

5

:

0

5

:4

4

2

0

2

2-

05

-1

2

05

:2

3:

3

3

20

2

2

-05

-12

0

5

:4

0

:

15

2

02

2

-05

-12

0

6

:

0

6:

38

20

22

-

0

5-

1

2

0

6

:

2

6:

1

5

2

0

2

2

-

0

5

-1

2

0

6:

3

9

:20

2

0

2

2

-0

5-

1

2

07

:

0

6:

3

0

2022

-0

5-1

2

07

:

1

6:

3

5

20

2

2-

0

5

-12

0

7

:

2

6

:3

9

20

2

2-

0

5-

1

2

08

:

0

6:

2

7

2

0

2

2

-

0

5-

12

08

:2

0:

0

4

2

02

2

-05

-12

0

8

:

2

9:

08

2022

-0

5

-

1

2

0

9

:

0

3:

2

4

202

2-

05-1

2

0

9

:1

1

:58

2

0

2

2

-0

5-

1

2

09

:

2

1:

0

2

2022

-0

5-

1

2

10

:

0

5

:

5

3

2

02

2-

0

5

-12

1

0

:

1

4

:5

8

20

2

2-

0

5-

1

2

10

:

2

4:

0

2

2

0

2

2

-

0

5

-1

2

11

:0

4

:52

20

2

2

-05

-12

1

1

:

1

2:

26

2

02

2-

0

5-1

2

11

:

2

0:

3

0

202

2-

0

5

-

1

2

1

2:

0

2

:5

0

2

0

2

2

-0

5

-12

12

:

1

0:

5

4

2

0

2

2

-

0

5-

1

2

12

:1

8:

5

7

2

02

2-

0

5

-12

1

3

:

0

5:

18

2

02

2-

0

5

-

1

2

1

3

:

1

2:

51

202

2-

05-1

2

13

:2

0

:25

20

2

2

-05

-12

1

4

:

0

2:

43

2022

-0

5-

12

14

:

1

0:

1

6

2

0

22

-

0

5

-

12

1

4

:

1

8:

20

20

22

-

0

5

-

12

1

5

:

0

4

:3

9

2

0

2

2-

05

-1

2

15

:1

2:

1

3

20

2

2

-05

-12

1

5

:1

9

:

46

2

02

2

-05

-12

1

6

:

0

2:

34

20

22

-

0

5-

1

2

1

6

:

1

0:

3

8

2

0

2

2

-

0

5

-1

2

1

6:

1

7

:11

2

0

2

2

-0

5-

1

2

17

:

0

5:

0

4

2022

-0

5-1

2

17

:

1

2:

3

7

20

2

2-

0

5

-12

1

7

:

2

0

:4

0

20

2

2-

0

5-

1

2

18

:

0

3:

0

0

2

0

2

2

-

0

5-

12

18

:1

0:

3

3

2

02

2

-05

-12

1

8

:

1

7:

36

2022

-0

5

-

1

2

1

9

:

0

5:

5

6

202

2

-

0

5-

1

2

1

9

:1

7

:31

2

0

2

2

-0

5-

1

2

19

:

2

5:

3

5

2022

-0

5-

1

2

20

:

0

4

:

2

2

2

02

2-

0

5

-12

2

0

:

1

2

:2

5

20

2

2-

0

5-

1

2

20

:

1

8:

5

9

2

0

2

2

-

0

5

-1

2

21

:0

6

:17

20

2

2

-05

-12

2

1

:

1

9:

21

2

02

2-

0

5-1

2

21

:

3

5:

3

3

202

2-

0

5

-

1

2

2

2:

1

0

:3

2

2

02

2

-

0

5

-

12

2

2

:

2

5

:4

6

2

0

2

2-

05

-12

22

:4

4:

0

4

2

0

22-

0

5

-12

2

3

:1

1

:

30

2

02

2

-05

-12

2

3

:

2

6:

45

20

2

2-

05-1

2

23

:

4

5:

0

2

2

0

2

2

-

0

5-

13

0

0:

0

6

:21

202

2

-0

5-

13

00

:

2

1:

3

6

2

0

22

-0

5

-

1

3

00

:

3

9:

5

3

20

2

2-

0

5

-13

0

1

:

0

7

:2

0

2

0

2

2-

05

-1

3

01

:

2

2:

3

4

2

0

2

2

-

0

5-

1

3

01

:4

0

:

5

2

2

02

2

-05

-13

0

2

:

0

8:

19

20

22

-0

5

-

1

3

0

2

:

2

6:

37

2

0

2

2-

0

5

-1

3

0

2:

4

4

:55

2

0

2

2

-0

5-

1

3

03

:

0

3:

1

3

2022

-0

5-

1

3

03

:

2

1:

3

1

20

2

2-

0

5

-13

0

3

:

3

9:

49

20

22

-

0

5

-

1

3

0

4

:

0

7

:1

6

2

0

2

2-

05

-1

3

04

:2

5:

3

5

2

0

2

2

-05

-13

0

4

:

43

:5

4

4.04

4.06

4.08

4.1

4.12

4.14

4.16

4.18

4.2

4.22

TIME (HOUR)

VOLTAGE (V)

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

7 7 7

6

7

8

7

12

11

13

14

16

15

14

13

15

14

17

15

12

13

7 7

8

6

7 7

6 6

Battery voltage Default Tx Energy aware Tx

00h

12h

00h

Figure 7: Number of Tx by default vs with the prototype.

voir can increase if the third-party device uses multi-

capacitor (Colin et al., 2018) or multi-battery based

power source and could have a dedicated PMU to han-

dle them. In such cases, the prototype is capable of

working with no analog input by leaving the voltage

checks to the third-party device, thus being able to

operate without accessing the electrical data of the en-

ergy reservoirs by always waiting to acquire enough

harvestable energy before executing a task. Currently,

the prototype’s interface requires one interrupt pin per

task. Hence, increasing the number of tasks will in-

crease the number of connections between the proto-

type and the third-party device. With this first imple-

mentation, there is no feedback when a task is exe-

cuted. It is assumed to be executed after the WCET.

Both these issues could be solved in the future using

a standard communication protocol.

Energy harvested from unintentional ambient

power sources can be difficult to monitor in an

EH-IoT device deployed in a real environment, as

conventional methods can be expensive in terms of

energy. Harvested energy can be calculated by di-

rectly measuring the harvester power and integrating

it with the sample period. Directly measuring power

requires measuring voltage and electrical current, but

the overheads can negate the overall benefit. For in-

stance, using a shunt resistor-based passive electri-

cal current measurement design consumes energy in

and of itself, depending on the design and the resis-

tor value. Another issue with direct power measure-

ment is the access to the PMU. When plugging into

third-party devices, this might not be easily possible.

Even if possible, some PMUs (e-peas, 2022b; e-peas,

2022a) uses V

ocv

of the solar panel to calculate the op-

erating maximum power point voltage (V

mpp

). Hence,

synchronization is required so that direct power mea-

surements aren’t made when the PMU is measuring

V

ocv

, which might require changing the PMU’s con-

figuration, the interface and our prototype’s firmware

depending on the exact PMU used by the third-party

device. Otherwise, the PMU’s V

ocv

measurement pro-

cess can distort the direct power measurement causing

its value to plummet to zero as the circuit is effectively

broken during a V

ocv

measurement.

In order to mitigate the disadvantages of the direct

power measurement and, as solar panels were the only

energy harvester being considered in this experiment,

we used the light sensor to measure the incoming light

energy in terms of irradiance (cf. Section 3.2.3). Us-

ing a separate sensor eliminates the need for tinker-

ing with the PMUs of third-party devices and results

in a more independent interface. It allows us to dis-

able this sensor when not in use or when the energy

is low. The accuracy trade-off between directly mea-

sured and sensor-estimated panel wattage was studied

using the custom dataset and was found to have an

RMSE of 1.22mW, which is an order of magnitude

less than the average operating range during daytime,

as shown in Figure 4d (cf. Section 3.2.3), with raw

solar irradiance data plotted in blue for reference.

6 CONCLUSION AND FUTURE

WORK

We proposed a novel interface that brings energy

awareness with ARIMA based short-term energy

forecasting to non-energy aware EH-IoT devices and

demonstrated its feasibility using OnePlanet sensor

box. Our real world experiments with this system

showed that the overall dynamically optimized Tx

rate outperforms constant Tx rate based solution (cf.

Section 5) and the efficient utilization of the harvested

An Energy Management Unit for Predictive Solar Energy Harvesting IoT

47

energy could be maximized, when compared to its

standalone state. Instead of only increasing the Tx

rate, the Tx power of the third-party device can also

be increased with the prototype of EMU, which, can

be more beneficial for exceedingly remote and indoor

deployments. The prototype’s ability to operate in-

dependently of the type of energy reservoir(s), and

its ability to operate without retraining the prediction

model even when the third-party device parameters

change enable easy adaptation. During the evalua-

tion period, the total energy overhead of our proto-

type (not just the prediction) built with commercial-

off-the-shelf (COTS) components was estimated to

be around 3.32J per day, with the majority of it con-

sumed during sleep. This can be reduced by using

more intentionally designed hardware (Zhang et al.,

2011) and software. Future experiments for research

purposes will benefit from increased evaluation peri-

ods, analyzing the impact of location and orientation

of the third-party device, and adding an externally

powered data acquisition (DAQ) system to monitor

the environmental and in-system parameters affecting

the system operation. It is also required to analyze

the drift in the outputs from system components such

solar panel, light sensor, PMU, etc., due to ageing or

other factors and take these into account. In addition,

the effect of spectral sensitivity on the error between

measured and sensor-estimated panel Wattage needs

to be analyzed.

ACKNOWLEDGEMENTS

Part of this research was funded by the Flemish FWO

SBO S001521N IoBaLeT (Sustainable Internet of

batteryless Things) project.

REFERENCES

Anagnostou, P., Gomez, A., Hager, P., Fatemi, H.,

de Gyvez, J. P., Thiele, L., and Benini, L. (2018). Tor-

por: A power-aware hw scheduler for energy harvest-

ing iot socs. In 2018 28th International Symposium on

Power and Timing Modeling, Optimization and Simu-

lation (PATMOS), pages 54–61.

Anuj Justus (2022). Custom dataset collected for energy

manager. https://doi.org/10.5281/zenodo.7044952.

Anuj Justus Rajappa (2022a). Build a long-term

daq system (part 1): The hardware design.

https://circuitcellar.com/research-design-hub/march-

circuit-cellar-sneak-preview-2022/. Last checked on

Aug 19, 2022.

Anuj Justus Rajappa (2022b). Build a long-term

daq system (part 2): The software design.

https://circuitcellar.com/research-design-hub/april-

circuit-cellar-sneak-preview-2022/. Last checked on

Aug 31, 2022.

Aosong Electronics Co.,Ltd (2022). Dht22 (dht22 also

named as am2302). https://www.sparkfun.com/

datasheets/Sensors/Temperature/DHT22.pdf. Last

checked on Aug 31, 2022.

Babayo, A. A., Anisi, M. H., and Ali, I. (2017). A review

on energy management schemes in energy harvesting

wireless sensor networks. Renewable and Sustainable

Energy Reviews, 76:1176–1184.

Battery University (2022). Bu-808: How to prolong

lithium-based batteries. https://batteryuniversity.

com/article/bu-808-how-to-prolong-lithium-based-

batteries. Last checked on Aug 19, 2022.

Bergonzini, C., Brunelli, D., and Benini, L. (2009). Al-

gorithms for harvested energy prediction in battery-

less wireless sensor networks. In 2009 3rd Interna-

tional Workshop on Advances in sensors and Inter-

faces, pages 144–149.

Bhusal, H., Khatiwada, P., Jha, A., Soumya, J., Koorapati,

S., and Cenkeramaddi, L. R. (2020). A self-powered

long-range wireless iot device based on lorawan. In

2020 IEEE International Symposium on Smart Elec-

tronic Systems (iSES) (Formerly iNiS), pages 242–

245.

BROADCOM (2022). Apds-9960. https://www.broadcom.

com/products/optical-sensors/integrated-ambient-

light-and-proximity-sensors/apds-9960. Last

checked on Aug 18, 2022.

Cammarano, A., Petrioli, C., and Spenza, D. (2012). Pro-

energy: A novel energy prediction model for solar and

wind energy-harvesting wireless sensor networks. In

2012 IEEE 9th International Conference on Mobile

Ad-Hoc and Sensor Systems (MASS 2012), pages 75–

83.

Cammarano, A., Petrioli, C., and Spenza, D. (2016). Online

energy harvesting prediction in environmentally pow-

ered wireless sensor networks. IEEE Sensors Journal,

16(17):6793–6804.

Chetto, M. and Queudet, A. (2016). 3 - harnessing ambi-

ent energy for embedded systems. In Chetto, M. and

Queudet, A., editors, Energy Autonomy of Real-Time

Systems, pages 57–83. Elsevier.

Colin, A., Ruppel, E., and Lucia, B. (2018). A re-

configurable energy storage architecture for energy-

harvesting devices. SIGPLAN Not., 53(2):767–781.

Deb, M. and Roy, S. (2021). Enhanced-pro: A new en-

hanced solar energy harvested prediction model for

wireless sensor networks. Wireless Personal Commu-

nications, 117(2):1103–1121.

Dehwah, A. H., Elmetennani, S., and Claudel, C. (2017).

Ud-wcma: An energy estimation and forecast scheme

for solar powered wireless sensor networks. Journal

of Network and Computer Applications, 90:17–25.

Delgado, C. and Famaey, J. (2021). Optimal energy-

aware task scheduling for batteryless iot devices.

IEEE Transactions on Emerging Topics in Computing,

pages 1–1.

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

48

e-peas (2022a). Aem10330 solar energy harvesting. https://

e-peas.com/wp-content/uploads/2021/08/Datasheet

AEM10330 solar energy harvesting IC REV1.1.pdf.

Last checked on Aug 18, 2022.

e-peas (2022b). Aem10941 solar energy harvesting.

https://e-peas.com/wp-content/uploads/2021/03/e-

peas-AEM10941-datasheet-energy-harvesting.pdf.

Last checked on Aug 18, 2022.

Hamers, R. J. (2020). Energy storage materials as emerg-

ing nano-contaminants. Chemical Research in Toxi-

cology, 33(5):1074–1081. PMID: 32275142.

Hofman, J., Nikolaou, M., Shantharam, S. P., Stroobants,

C., Weijs, S., and La Manna, V. P. (2022). Distant

calibration of low-cost pm and no2 sensors; evidence

from multiple sensor testbeds. Atmospheric Pollution

Research, 13(1):101246.

Huybrechts, T., Reiter, P., Mercelis, S., Famaey, J., Latr

´

e,

S., and Hellinckx, P. (2021). Automated testbench

for hybrid machine learning-based worst-case energy

consumption analysis on batteryless iot devices. En-

ergies, 14(13).

J & A (2022). J & a electronics li-ion cyclindrical data

sheet. https://www.olimex.com/Products/Power/

BATTERY-LIPO2200mAh/resources/JA18650-3.7V-

2200mAh-Cell-Specification-150112.pdf. Last

checked on Aug 19, 2022.

Jetperch (2022). Joulescope. https://www.joulescope.com/.

Last checked on Aug 31, 2022.

Ji, W., Chan, C., Loh, J., Choo, F., and Chen, L. (2009).

Solar radiation prediction using statistical approaches.

In 2009 7th International Conference on Informa-

tion, Communications and Signal Processing (ICICS),

pages 1–5.

Kang, D. H. P., Chen, M., and Ogunseitan, O. A. (2013).

Potential environmental and human health impacts

of rechargeable lithium batteries in electronic waste.

Environmental Science & Technology, 47(10):5495–

5503. PMID: 23638841.

Kansal, A., Hsu, J., Zahedi, S., and Srivastava, M. B.

(2007). Power management in energy harvesting sen-

sor networks. ACM Trans. Embed. Comput. Syst.,

6(4):32–es.

Khanna, A., Mueller, T., Stangl, R. A., Hoex, B., Basu,

P. K., and Aberle, A. G. (2013). A fill factor loss

analysis method for silicon wafer solar cells. IEEE

Journal of Photovoltaics, 3(4):1170–1177.

Kjellby, R. A., Cenkeramaddi, L. R., Frøytlog, A., Lozano,

B. B., Soumya, J., and Bhange, M. (2019). Long-

range & self-powered iot devices for agriculture &

aquaponics based on multi-hop topology. In 2019

IEEE 5th World Forum on Internet of Things (WF-

IoT), pages 545–549.

Kjellby, R. A., Cenkeramaddi, L. R., Johnsrud, T. E.,

Løtveit, S. E., Jevne, G., Beferull-Lozano, B., and

Soumya, J. (2018). Self-powered iot device based

on energy harvesting for remote applications. In

2018 IEEE International Conference on Advanced

Networks and Telecommunications Systems (ANTS),

pages 1–4.

Kosunalp, S. (2016). A new energy prediction algorithm

for energy-harvesting wireless sensor networks with

q-learning. IEEE Access, 4:5755–5763.

Muhammad, Qureshi, H. K., Saleem, U., Saleem, M., Pit-

sillides, A., and Lestas, M. (2017). Harvested en-

ergy prediction schemes for wireless sensor networks:

Performance evaluation and enhancements. Wireless

Communications and Mobile Computing, 2017.

Noh, D. K. and Kang, K. (2011). Balanced energy al-

location scheme for a solar-powered sensor system

and its effects on network-wide performance. Jour-

nal of Computer and System Sciences, 77(5):917–932.

PMECT 2009/ICCCN 2009.

Nordic Semiconductor (2022). nrf52840 dk.

https://www.nordicsemi.com/Products/Development-

hardware/nrf52840-dk. Last checked on Aug 18,

2022.

Ramson, S. R. J., Le

´

on-Salas, W. D., Brecheisen, Z., Fos-

ter, E. J., Johnston, C. T., Schulze, D. G., Filley, T.,

Rahimi, R., Soto, M. J. C. V., Bolivar, J. A. L., and

M

´

alaga, M. P. (2021). A self-powered, real-time, lo-

rawan iot-based soil health monitoring system. IEEE

Internet of Things Journal, 8(11):9278–9293.

Recas Piorno, J., Bergonzini, C., Atienza, D., and Simu-

nic Rosing, T. (2009). Prediction and management

in energy harvested wireless sensor nodes. In 2009

1st International Conference on Wireless Communi-

cation, Vehicular Technology, Information Theory and

Aerospace & Electronic Systems Technology, pages 6–

10.

Rodriguez Arreola, A., Verykios, T. D., Gurrola Navarro,

M. A., and Calvillo Cortes, C. F. (2022). Federated

time persistency in intermittently powered iot sys-

tems. Journal of Systems Architecture, 130:102667.

Sabovic, A., Sultania, A. K., Delgado, C., De Roeck, L.,

and Famaey, J. (2022). An energy-aware task sched-

uler for energy harvesting battery-less iot devices.

IEEE Internet of Things Journal.

Seed Studio (2022). Small solar panel 81x137mm

1.5w. https://www.seeedstudio.com/1-5W-Solar-

Panel-81X137.html. Last checked on Nov 18, 2022.

Shafik, R., Yakovlev, A., and Das, S. (2018). Real-

power computing. IEEE Transactions on Computers,

67(10):1445–1461.

Shafique, K., Khawaja, B. A., Sabir, F., Qazi, S., and Mus-

taqim, M. (2020). Internet of things (iot) for next-

generation smart systems: A review of current chal-

lenges, future trends and prospects for emerging 5g-

iot scenarios. IEEE Access, 8:23022–23040.

Shaikh, F. K. and Zeadally, S. (2016). Energy harvest-

ing in wireless sensor networks: A comprehensive re-

view. Renewable and Sustainable Energy Reviews,

55:1041–1054.

Stricker, N. and Thiele, L. (2022). Accurate onboard pre-

dictions for indoor energy harvesting using random

forests. In 2022 11th Mediterranean Conference on

Embedded Computing (MECO), pages 1–6.

Tanha, S. N., Mim, S. A., Roy, P., and Razzaque, M. A.

(2021). Prediction of energy harvesting in solar pow-

ered small cells networks. In 2021 3rd International

An Energy Management Unit for Predictive Solar Energy Harvesting IoT

49

Conference on Sustainable Technologies for Industry

4.0 (STI), pages 1–6.

Taylor G. Smith (2022). pmdarima. https://github.com/

alkaline-ml/pmdarima. Last checked on Aug 30,

2022.

Texas Instruments (2022). Ina226 high-side or low-side

measurement,bi-directional current and power moni-

tor with i2c compatible interface. https://www.ti.com/

lit/ds/symlink/ina226.pdf. Last checked on Aug 18,

2022.

University of Washington (2022). Physics of solar

cells. https://depts.washington.edu/cmditr/modules/

opv/physics of solar cells.html. Last checked on

Nov 20, 2022.

Wahba, M. A., Ashour, A. S., and Ghannam, R. (2020). Pre-

diction of harvestable energy for self-powered wear-

able healthcare devices: Filling a gap. IEEE Access,

8:170336–170354.

Yamin, N. and Bhat, G. (2021). Online solar energy predic-

tion for energy-harvesting internet of things devices.

In 2021 IEEE/ACM International Symposium on Low

Power Electronics and Design (ISLPED), pages 1–6.

Yue, H., Worrell, E., and Crijns-Graus, W. (2021). Impacts

of regional industrial electricity savings on the devel-

opment of future coal capacity per electricity grid and

related air pollution emissions – a case study for china.

Applied Energy, 282:116241.

Zhang, Y., Shakhsheer, Y., Barth, A. T., Powell Jr., H. C.,

Ridenour, S. A., Hanson, M. A., Lach, J., and Cal-

houn, B. H. (2011). Energy efficient design for body

sensor nodes. Journal of Low Power Electronics and

Applications, 1(1):109–130.

IoTBDS 2023 - 8th International Conference on Internet of Things, Big Data and Security

50