COVID-19 Impact on the Laboratory Practices of the Automation

Subjects at the University of La Laguna

Silvia Alayón

a

and Marta Sigut

b

Department of Computing Engineering and Systems, University of La Laguna, La Laguna, Spain

Keywords: Automation, COVID-19, Virtual Laboratory.

Abstract: Our practice programs have changed drastically after the appearance of COVID-19. The practical sessions

designed for all Automation subjects until 2019 were face-to-face. But the arrival of the pandemic and health

restrictions resulted in the closure of our university facilities, which forced us to redo the laboratory

experiences. It is in this context that simulation and gamification helped us to move forward, since the solution

we followed was the virtualization of the laboratory. Although the degree of satisfaction of the students with

the new practical sessions is quite good, the purpose of this paper is not to present a detailed analysis of all

the simulation and gamification tools we studied, but to explain what our situation was like before COVID-

19, how we faced the change, what we learned in the process, what the new practice programs we are currently

following are like, what tools have helped us, and what goals we still have to achieve. We hope that our

experience can be useful to other teachers.

1 INTRODUCTION

It is well known that practical sessions in engineering

are essential for the acquisition of the discipline's

competences. For this reason, all educational plans in

university schools include them in their subjects.

Automation is no exception; in fact, it is probably one

of the fields where laboratory practice is the most

enriching for students.

The authors of this work are teachers at the

School of Engineering and Technology of the

University of La Laguna. Part of their teaching is in

the area of Automation. Depending on the course,

they teach Automation subjects with different levels

of complexity. This requires the design of practice

programs differentiated in methodology and learning

objectives. Planning automation laboratories is not a

trivial task, since usually the schools do not have

enough space or budget to incorporate real industrial

plants to their practice programs. This is where

simulation comes into play, providing important

advantages from an educational point of view. There

are many studies that demonstrate the benefits of

simulation in the field of Education. In particular, the

last decade has seen a remarkable increase in the use

a

https://orcid.org/0000-0001-8498-3275

b

https://orcid.org/0000-0001-7377-4582

of simulators in the teaching of automation: PLCSIM

(Calderon et al., 2018), Codesys (Kaneps et al.,

2016), CIROS (Freund et al. 2000), OpenPLC (Alves

et al., 2014), Factory I/O (Vargas et al., 2022), etc.

These simulators allow users to model an industrial

plant, predict the behavior of a process,

simultaneously analyze different cases by modifying

variables in real time, optimize operating conditions

in existing or new plants, and monitor a plant

throughout its useful life. Although many of these

simulation tools are not free, the cost of the licenses

is much lower than that of any real industrial plant,

making it a very interesting alternative, and

sometimes the only possible one, when resources are

limited.

On the other hand, the use of gamification as a

tool to increase students’ interest and motivation in

subjects has spread to cover all educational levels,

from early childhood to higher education. There are

numerous works that highlight the multiple

advantages of gamification in classroom and distance

education, such as (Seaborn et al., 2015; Hamari et

al., 2016; Sousa et al., 2022, Manzano et al., 2020,

Ycekaya et al., 2021). The idea of learning by playing

is very attractive in all fields, but in the field of

566

Alayón, S. and Sigut, M.

COVID-19 Impact on the Laboratory Practices of the Automation Subjects at the University of La Laguna.

DOI: 10.5220/0011994100003470

In Proceedings of the 15th International Conference on Computer Supported Education (CSEDU 2023) - Volume 2, pages 566-573

ISBN: 978-989-758-641-5; ISSN: 2184-5026

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

automation it is also relatively easy to carry out with

the help of the simulators mentioned above.

Our practice programs have changed drastically

after the appearance of COVID-19. The practical

sessions designed for all Automation subjects until

2019 were face-to-face. But the arrival of the

pandemic and health restrictions resulted in the

closure of our university facilities, which forced us to

redo the laboratory experiences. It is in this context

that simulation and gamification helped us to move

forward. The purpose of this paper is not to present a

detailed analysis of all the simulation and

gamification tools we studied, but to explain what our

situation was like before COVID-19, how we faced

the change, what we learned in the process, what the

new practice programs we are currently following are

like, what tools have helped us, and what goals we

still have to achieve. We hope that our experience can

be useful to other teachers.

2 PRACTICE PROGRAM PRIOR

TO COVID-19

Practical sessions in Automation subjects, until the

advent of COVID-19, took place in the laboratory on

a face-to-face basis. The following is a brief

description of these pre-COVID-19 practice

programs.

2.1 Introductory Automation Courses

The automation practices for the introductory

automation courses consisted of simulating very basic

processes on the Programmable Logic Controllers

(PLC) present in the laboratory. These PLCs are

Siemens S7-1200. Each PLC had an external board

with switches connected to its input interface, to

manually activate and deactivate the system inputs,

and thus simulate the activation and deactivation of

hypothetical sensors connected to the PLC. The

students proposed a KOP code of the proposed

problem, loaded it into the PLC, and checked its

proper functioning by activating and deactivating

these switches, simulating the occurrence of events in

the system.

The practice program consisted of several

sessions where the students tackled the programming

of simple problems:

• Session 1: introduction to Tia Portal and to

PLC S7-1200.

• Session 2: automation of a garage door.

• Session 3: control of the capacity of a public

parking.

• Session 4: automation of a traffic light.

• Session 5: control of a chemical process, a

mixer or a precise weighing system.

2.2 Advanced Automation Courses

Advanced automation students tackle the

programming of the Festo educational plant available

in our laboratory (Festo, 2023). This plant has five

stations controlled with Siemens S7-1200 and S7-

1500 PLCs. The students, divided in groups, perform

the programming of one station and the

communication with the remaining stations. Figure 1

shows the five Festo stations:

• Station 1: Storage and distribution of parts.

• Station 2: Parts size measurement and

classification.

• Station 3: Parallel processing of parts.

• Station 4: Pneumatic arm for parts

manipulation.

• Station 5: Parts sorting and storage.

Figure 1: FESTO educational plant.

3 STATUS OF AUTOMATION

PRACTICES WITH COVID-19

The arrival of the pandemic and health restrictions led

to the closure of our university facilities. The teaching

activity was resumed in a non-presential way, through

videoconferences and audiovisual material, which

each professor carried out as best he could at home

with the personal means at his disposal. Evidently, we

were not prepared to face such an abrupt change, and

this negatively affected the quality of teaching in the

first months of the pandemic.

The practical activities of the subjects were the

most affected by the lack of face-to-face attendance.

COVID-19 Impact on the Laboratory Practices of the Automation Subjects at the University of La Laguna

567

In our case, the most immediate solution was to

convert the Automation practices of all the subjects

into simulated practices. For this purpose, the

Siemens simulator included in the Tia Portal (Tia

Portal, 2023), the S7-PLCSIM program, was used.

This emergency solution presented several major

drawbacks:

1. We were forced to explain the operation of the

Tia Portal and the simulator through videos.

2. From a pedagogical point of view, especially for

the students who had to simulate the

programming of the Festo plant, it was difficult

to imagine what the system they had to control

looked like without being able to see it

physically. They were provided with

explanatory videos of the operation of each

station, but even so, the task of debugging the

code without working with the real plant was not

easy.

3. The Tia Portal and its PLCSIM simulator are

proprietary programs. Although temporary

licenses were purchased for all students, some

had problems installing and running the

software on their personal PCs, because it is a

very computationally demanding program.

These circumstances pushed us to look for new

technological solutions that would allow us to teach

practical sessions remotely in a more efficient way,

and that could also be used in face-to-face sessions,

when they were resumed. We clearly saw that there

was a need to virtualize the Automation laboratory in

order to make teaching more flexible and make the

practical sessions more accessible to students, and to

do so quickly, since at that time there was great

uncertainty about how the health situation would

evolve. The use of virtual laboratories for the

practical teaching of Automation is not a new idea

(Potkonjak et al., 2016), but in our case, we had not

had the need to implement it until this moment.

Therefore, we started to study and analyze the

applicability of different simulation and gamification

tools for the virtualization of our laboratory.

4 FINAL SOLUTION ADOPTED:

VIRTUALIZATION OF THE

AUTOMATION LABORATORY

WITH FACTORY I/O

Our efforts were focused on designing a virtual tool

for practical laboratory teaching, with the objective of

developing new practical teaching in various

contexts:

▪ In the context of confinement or reduced

presence, as we have experienced during the

years 2019-2022: this virtual laboratory would

allow students to perform practical sessions

from home, on realistic 3D virtual industrial

plants, and with the automation tools that they

would use in person in the laboratory. This

practical teaching could be more flexible and

adapted to the student's schedule and

availability.

▪ In the context of normality: the virtualization of

the laboratory could be used to create new

stations, so that more people could attend the

practical sessions simultaneously, and to make

practical sessions of longer duration and higher

quality. These new stations would be virtual,

since adding more physical stations to the

Automation Laboratory would be very

expensive, and would also cause difficulties due

to the physical limitations of the available space.

Being able to work with simulated virtual

stations would allow the use of a computer

classroom as an automation laboratory, where

the student can learn to program automation in

the same way as on the actual physical

laboratory floor. In the same way, students

could practice on the 3D model in their personal

study time, in order to be able to take advantage

of the classroom sessions on the real physical

plant in a more optimal way.

For this purpose, we studied several software

packages. On the one hand, PLC simulators: Codesys

(Codesys, 2023), PLCSIM (PLCSIM, 2023) and

OpenPLC (OpenPLC, 2023), and on the other hand,

3D modeling and simulation software for industrial

plants: Realvirtual.io (Realvirtual.io, 2023), Factory

I/O (Factory I/O, 2023), Emulate3D (Emulate3D,

2023), and Ciros (Ciros, 2023).

These programs present different advantages

and disadvantages. With respect to the PLC

simulators, we decided to continue using the Siemens

Tia Portal integrated simulator, PLCSIM, because we

wanted the students to continue learning the use and

management of Tia Portal, software that is widely

used in the working world. It is a commercial

software, but we had already purchased temporary

licenses for the students, so the investment was made.

With respect to modeling packages, the decision was

more complicated. Finally, the two software packages

that we liked the most were Factory I/O and

Realvirutal.io, because of their benefit-cost ratio, and

because they allow us to introduce gamification

strategies in the experiences designed with them.

CSEDU 2023 - 15th International Conference on Computer Supported Education

568

Both programs are specifically oriented to 3D

modeling and simulation of industrial plants,

allowing the control of these simulated plants with a

real PLC and/or a PLC simulator. This aspect was

convenient for us, because it allowed us to reuse the

models in the two contexts mentioned above (in

confinement and adapted presence, the PLC

simulator could be used, and in normality, the real

PLC could be used directly). The big difference

between the two packages is that Factory I/O has been

designed to model some of the most common

scenarios that can be found in an industrial facility,

and the elements and scenes it presents are not

editable, while Realvirutal.io is an open framework

for visualization and simulation, based on the Unity

game engine, which allows the user to create fully

customized elements and plants. Finally, we opted to

purchase Factory I/O floating licenses because it is a

simpler program, the plants are pre-designed, and it is

not necessary to know Unity programming to use it.

The next step was the selection, design and

implementation of the industrial plants to be modeled,

analyzing which were the most appropriate for each

subject. The following section will show some of the

new practices designed with this tool. While

designing these new experiences, we analyzed the

feasibility of installing them on a virtual desktop, so

that students could access them remotely from home.

In the end, it was not necessary to implement this

point, because at that moment we went from the

confinement state to the adapted face-to-face state

(presence in small groups). So we quickly had to

install the models of the new practices in the physical

laboratory, and connect them to the real PLCs

available to us. But it is important to note that the

plants are perfectly controllable with the PLC

simulator, we had it initially working in this way.

Finally, we evaluated the new practice

methodology implemented in the laboratory, a

combination of simulated 3D plants controlled by real

PLCs. For this purpose, we conducted a usability

study, and analyzed the improvement in student

learning, taking into account students’ feedback. This

point will be discussed in detail later.

5 POST-COVID-19 PRACTICE

PROGRAM

The practice programs have changed a lot since the

introduction of Factory I/O models. In the following

subsections we will show some examples of

practices, depending on the level of the subject.

5.1 Introductory Automation Courses

The automation practices designed for students

starting in the discipline propose the automation of

simple plants. The complexity of the practices

gradually increases from one practice to the next, and

different learning objectives are pursued in each of

them. Basically, with these practices, it is intended

that the student is able to handle the Tia Portal, make

a program, load it into the PLC, run it and debug it.

The designed practices are the following ones:

• Session 1: Introduction to Tia Portal,

Factory IO and PLC S7-1200.

• Session 2: Automation of a conveyor belt.

• Session 3: Control of a lift.

• Session 4: Control of traffic lights.

• Session 5: Automation of a sorting system

for large and small boxes.

Some of these practices are shown in Figures 2-4.

Figure 2: Automation of a conveyor belt.

Figure 3: Automation of a sorting system for large and

small boxes.

5.2 Advanced Automation Courses

For advanced automation students, the complexity of

the models to be automated increases considerably.

We assume that the students already know the PLC

environment, know how to program it and handle the

software tools properly. They are not only required to

program the basic operation of the model, but it is also

important that they design and implement a GEMMA

guide for each plant, and that they test the different

COVID-19 Impact on the Laboratory Practices of the Automation Subjects at the University of La Laguna

569

Figure 4: Control of a lift.

states included in the guide on the model. The

designed practices are the following ones:

• Automation of a box weighing and color

sorting system.

• Automation of a parts assembly system and

subsequent classification according to the

color of the parts.

• Automation of a box sorting system based

on the height of the box.

• Automation of a system for the removal of

boxes on pallets and sorting by weight.

• Automation of a parallel parts processing

and storage system.

• Automation of a parallel parts processing

and color sorting system.

Some of these practices are shown in Figures 5-7.

It is important to clarify that nowadays, with the

return of the students to the laboratory, these practices

are combined with those performed in the real

physical Festo plant. We tried to model the Festo

plant workstations with Factory I/O, but it was really

difficult to achieve. The Factory I/O program offers

non-editable elements (from individual parts to

complete stations), which can be combined as the user

wishes to build the plants. But in the Festo plant there

are stations that are composed of parts not contained

in the program libraries. Only stations 2 and 5 could

be modeled properly. Figure 8 shows the actual

station 5 and its Factory I/O model.

Figure 5: Automation of a box weighing and colour sorting

system.

Figure 6: Automation of a parts assembly system and

subsequent classification according to the color of the parts.

Figure 7: Automation of a box sorting system based on the

height of the box.

As an example of an unsuccessfully modeled

plant, we can look at station 3, which consists of a

circular rotary table that allows parallel processing of

four parts at a time. As nothing similar exists in

Factory I/O, we tried to realize a model that would at

least allow parallelization of the process (Figure 9).

Our goal was to achieve a model that, at the

programming level, would be as close as possible to

the programming of the real station. However, it can

be seen that the visual aspect of the real station and

its corresponding model is quite different, and we

considered that it was not going to be of great help to

the student.

CSEDU 2023 - 15th International Conference on Computer Supported Education

570

Figure 8: Station 5 of the FESTO plant (up) and its Factory

I/O model (down).

Therefore, we have discarded the use of Factory

I/O to model the stations of the Festo plant. But we

think it is very important to achieve it, so we are

currently starting to analyze the Realvirutal.io

program, in order to accurately model each station,

since this software allows the user to define their own

elements and create a customized industrial plant, as

if it were the design of a video game, under the Unity

environment.

6 EVALUATION OF NEW

PRACTICE PROGRAMS

DESIGNED WITH FACTORY I/O

After almost two courses using this new educational

strategy, based on simulation and gamification, we

have observed notable improvements in the

acquisition of knowledge and practical skills by

students. Specifically, we have found that our effort

Figure 9: Station 3 of the FESTO plant (up) and its Factory

I/O model (down).

has been worthwhile, since with the new practical

experiences:

▪ Learning is transformed and dynamized: the

practical experience is carried out in a different

way, through a fun interactive experience.

▪ A gamification component is included in the

teaching process, which generates a more

motivating learning experience.

▪ The simulated experiences are almost real, with

no risk of accidents and environmentally

responsible, which are important aspects in the

industrial environment.

▪ Simulated industrial plants can be immersive

scenarios of great realism, which brings the

student closer to a realistic and professional

context.

▪ Monitoring and evaluation of learning can be a

simpler and more transparent process.

▪ The range of industrial plants to be automated is

expanded: generating 3D models of new plants is

COVID-19 Impact on the Laboratory Practices of the Automation Subjects at the University of La Laguna

571

always less costly than acquiring these industrial

plants physically (which is often unfeasible, and

not only for economic reasons).

▪ Active student learning is encouraged with

interactive simulations and their motivation is

favored.

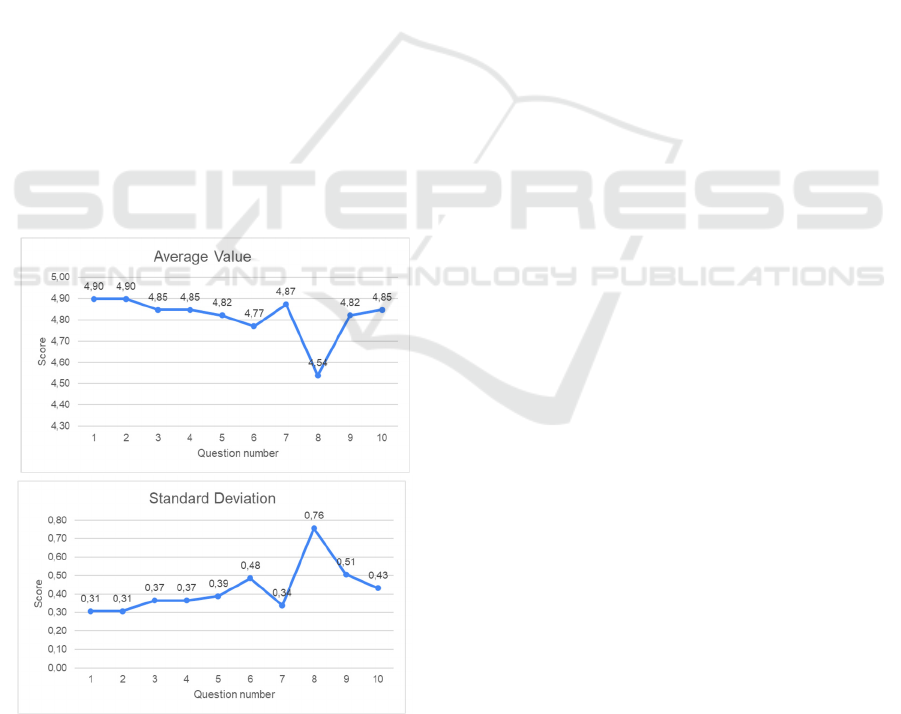

We received feedback from the students, through

the completion of a satisfaction questionnaire. This

questionnaire consisted of the following ten

questions:

1.

The Factory I/O software made it easier for me to

interact with a real PLC.

2.

The Factory I/O software has allowed me to

apply the KOP programming knowledge

acquired in the theory classes.

3.

The information provided in the 3D model is

effective and helps me to complete the

programming of the industrial plant.

4.

The Factory I/O 3D models are simple,

educational and easy to use.

5.

Factory I/O system interface is user-friendly and

intuitive,

6.

The Factory IO models help to understand how

the KOP elements (timers, counters, etc) work.

7.

I am able to easily check the validity of my KOP

programs on the Factory I/O 3D model.

8.

The tool allows me to detect and correct my

programming errors quickly.

Figure 10: Mean value and standard deviation of the score

given by the 39 students who answered the 10 questions

posed.

9.

The progressive difficulty of the 3D models

during the internships seemed to me to be correct

and facilitated my learning process.

10.

I am satisfied with the use of Factory I/O during

the practices.

The questionnaire has been answered by 39

students and the results are shown on a five-point

Likert scale. Figure 10 shows the mean value and the

standard deviation of the score given by the students

for each question. It can be seen that the degree of

satisfaction of the students with the new practical

sessions is quite good.

7 CONCLUSIONS

The health crisis that occurred with the appearance of

COVID-19 affected all areas of our society,

including, of course, Education. Traditionally face-

to-face teaching suffered especially from the effects

of this "hiatus" in our normality. We teachers were

forced to change our teaching habits and

methodologies to adapt to the new situation. In our

experience, the hardest thing was to realize that we

could not continue to develop the practical part of our

subjects as we had been doing up to that moment. We

had to update and make the practical experiences

more flexible and accessible remotely, and we had to

do it quickly. Therefore, we started working on the

virtualization of the laboratory.

The virtual practices must meet the same

objectives as the traditional practices taught in the

physical laboratory, and be able to transmit the

didactic concepts of Automation, such as: knowledge

of industrial processes and the elements that integrate

them, the design and optimization of the assemblies

that make up the process, the programming and

control of automatons and, finally, the use of specific

software for industrial activities. We believe that the

solution we finally arrived at, based on the use of

simulation and gamification tools, allowed us to

virtualize the laboratory in an adequate way, not only

for extreme situations of confinement, but also for

normal contexts. Furthermore, the degree of

satisfaction of the students with the new practical

sessions is quite good.

As mentioned in the introduction, the purpose of

this article is not to present a detailed analysis of all

the simulation and gamification tools we studied, but

to explain what our situation was like before COVID

19, how we faced the change, what we learned in the

process, what the new practice programs we are

currently following are like, what tools have helped

us, and what goals we still have to achieve.

CSEDU 2023 - 15th International Conference on Computer Supported Education

572

On this last point, our future work is the

virtualization of the Festo plant with the

Realvirutal.io software. Although we are no longer in

a situation of confinement or adapted face-to-face

context, we have seen the benefits of introducing this

type of practice also in a context of normality, and we

believe that having representative models of the

stations could greatly enrich the experimentation with

this educational plant.

REFERENCES

Alves, T.R., Buratto, M., Rodrigues, T.V. (2014).

OpenPLC: An Open Source Alternative to Automation.

In CHTC, 4th annual IEEE Global Humanitarian

Technology Conference, PP. 585-589.

Calderon, A.J., González, I. (2018). Software-in-the-loop

approach for automation and supervisory systems

education. In INTED, 12th International Technology,

Education and Development Conference, pp. 4241-

4245.

Ciros (2023): https://ip.festo-didactic.com/InfoPortal/CI

ROS/EN/Download.html

Codesys (2023): https://www.codesys.com/

Emulate3D (2023): https://www.emulate3d.com/

Factory I/O (2023): https://factoryio.com

Festo, educational plant (2023): https://www.festo-

didactic.com/int-en/

Freund, E., Rossmann, J., Schluse, M. (2000). Virtual

reality for intelligent and interactive operating, training,

and visualization systems. In Proc. SPIE vol. 4196,

Sensor Fusion and Decentralized Control in Robotic

Systems III.

Hamari, J., Shernoff, D.J., Rowe, E., Coller, B., Asbell-

Clarke, J., Edwards, T. (2016). Challenging games help

students learn: An empirical study on engagement, flow

and immersion in game-based learning. In Computers

in Human Behavior, vol. 54, pp. 170-179,

https://doi.org/10.1016/j.chb.2015.07.045.

Kaneps, J., Gerina-Ancane, A. (2016). Learning problems

and solutions for mechatronic and basic of automation

production in mechanical engineering and industrial

design studies. In MECHANIKA, 21st International

Scientific Conference, pp.116-123.

Manzano Le, A., Shez Shez, M., Trigueros Ramos, R.,

lvarez Hernez, J., Aguilar−Parra, J.M. (2020).

Gamification and Breakout Edu in Vocational Training.

The "Grey Place" program in Social Integration.

EDMETIC, 9(1), 1−20. https://doi.org/10.21071/

edmetic.v9i1.12067.

OpenPLC (2023): https://openplcproject.com/

PLCSIM (2023): https://support.industry.siemens.com/

cs/document/109772889/trial-download-simatic-s7-

plcsim-advanced-v3-0?dti=0&lc=en-US

Potkonjak V., Gardner M., Callaghan V., Mattila P., Guetl

C., Petrović V.M., Jovanović K. (2016) Virtual

laboratories for education in science, technology, and

engineering: A review. In Computers & Education, V.

95, pp. 309-327, https://doi.org/10.1016/j.

compedu.2016.02.002.

Realvirtual.io (2023): https://realvirtual.io/en/

Seaborn, K., Fels, D.I. (2015). Gamification in theory and

action: A survey. In International Journal of Human-

Computer Studies, vol. 74, pp. 14-31,

https://doi.org/10.1016/j.ijhcs.2014.09.006.

Sousa-Vieira, M.E., López-Ardao, J.C., Fernández-Veiga,

M., Rodríguez-Rubio, R.F. (2022). Study of the impact

of social learning and gamification methodologies on

learning results in higher education. In Computer

Applications in Engineering Education, 31 (1), pp. 131-

153.

Tia Portal, Siemens (2023): https://new.siemens.com/

global/en/products/automation/industry-software/auto

mation-software/tia-portal.html

Vargas, H., Heradio, R., Donoso, M. et al. (2022). Teaching

automation with Factory I/O under a competency-based

curriculum. In Multimed Tools Appl,

https://doi.org/10.1007/s11042-022-14047-9.

Ycekaya, M. A., Sagin, A. E., Ugras, S. (2021). Physical

Education and Sports Lesson in Distance Education:

Content Analysis of Videos on Youtube. IJERI:

International Journal of Educational Research and

Innovation, (15), 533−551. https://doi.org/10.46661/

ijeri.5766.

COVID-19 Impact on the Laboratory Practices of the Automation Subjects at the University of La Laguna

573