Dynamic Simulation and Energy, Economic and Environmental

Analysis of a Greenhouse Supplied by Renewable Energy Sources

Francesco Calise

1a

, Francesco Liberato Cappiello

2b

, Luca Cimmino

c

and Maria Vicidomini

4d

DII, University of Naples Federico II, P.le Tecchio, 80, 80125 Naples, Italy

Keywords: Dynamic Simulation, Green Farm, PV Panels, Solar Thermal Collectors.

Abstract: This paper presents the design and dynamic modelling of a greenhouse coupled with renewable energy

technologies, such as PV panels, solar thermal collectors, biomass auxiliary heater. The system is also coupled

with a pyrogasifier, supplied by wood and agricultural wastes in the framework of a biocircular economic

approach. In order to match the real load of power and heat of the investigated user, a “green farm” located

in Naples (South of Italy) reducing the energy consumption and operating cost, all the main components of

the plant were suitably designed. The operation of the designed components was simulated by a dynamic

simulation model developed in TRNSYS environment and validated by means literature results. A

comprehensive energy, economic and environmental analysis of the greenhouse was presented. Main results

suggest that the proposed renewable system is able to reduce the total equivalent CO

2

emissions of 148,66 t/y.

Considering the high current increase of the energy prices due to energy crisis due to the war, the system

shows a very significant profitability with a simple payback of only 1.7 years.

1 INTRODUCTION

Renewable energy sources (RES) (Rahman, 2022)

can be integrated into several energy systems to

provide the energy required for the process and

significantly reduce the primary energy demand of

the systems itself. In particular, solar technologies -

such as solar thermal collectors (Chantasiriwan,

2022), photovoltaic (PV) panels (Xue, 2017) or

photovoltaic/thermal (PVT) collectors (Calise,

Cappiello et al. 2021) - can be easily integrated in

greenhouses (Azam, 2020). Such option seems very

attractive, to avoid or reduce the use of natural gas

boilers and power from the grid. For example, it is

possible to install a PV field to produce electricity

(Okakwu, 2022) as an alternative energy source of

water pumping for irrigation farming, or a solar

thermal collector field to supply the thermal energy

needed to the greenhouse heating system in order to

obtain the greenhouse operating temperature within

the designed temperature range (Xu, 2022). Several

authors investigated this issue. For example, a

a

https://orcid.org/0000-0002-5315-7592

b

https://orcid.org/0000-0001-6292-686X

c

https://orcid.org/ 0000-0001-6382-3619

d

https://orcid.org/0000-0003-2827-5092

nonlinear integrated controlled environment

agriculture model is developed to correlate the impact

of weather disturbances, temperature and humidity

control, fertilization, and irrigation, on the crop

growing conditions. Results of the simulation of a

renewable energy-powered semi-closed greenhouse

growing tomatoes located in Ithaca, New York were

presented. The integrated controlled environment

agriculture model can help in increasing renewable

energy usage efficiency from 4.7% to 127.5%. In the

work of (Singh, 2006) a mathematical model to

simulate a greenhouse was developed and validated

vs experimental data. The equations were written for

four components of the greenhouse, i.e. cover, inside

air, canopy surface and bare soil surface. The model

was applied to the Research Farm of the Punjab

Agricultural University, Ludhiana. The model solved

using Gauss–Seidel Iteration method, confirms a

good agreement with measured data related to the

winter operation for a tomato crop. A dynamic

greenhouse environment simulator was developed in

ref. (Fitz-Rodríguez, Kubota et al. 2010) to predict the

Calise, F., Cappiello, F., Cimmino, L. and Vicidomini, M.

Dynamic Simulation and Energy, Economic and Environmental Analysis of a Greenhouse Supplied by Renewable Energy Sources.

DOI: 10.5220/0012000300003491

In Proceedings of the 12th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2023), pages 137-143

ISBN: 978-989-758-651-4; ISSN: 2184-4968

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

137

dynamic behavior of greenhouse environments with

different configurations. The model was implemented

in a web-based interactive application that allowed

for the selection of the greenhouse design, operational

strategies, and weather conditions (four seasons of

four geographical locations). In order to predict the

hourly heating requirements of conventional

greenhouses a time-dependent, quasi-steady state

thermal model based on the lumped estimation of heat

transfer parameters of greenhouses was developed

(Ahamed, 2018). The model considers greenhouse

indoor environmental control parameters, physical

and thermal properties of crops and construction

materials, and hourly weather data including

temperature, relative humidity, wind speed, and cloud

cover. The model also includes the heat loss for plant

evapotranspiration, and the heat gain from

environmental control systems. Thermal analysis

indicates environmental control systems could reduce

13–56% of the total heating requirements over the

year. A comprehensive TRNSYS model for

predicting the transient heating requirement of a

Chinese-style solar greenhouse for Canadian Prairies,

was presented in ref. (Ahamed, 2020). The model in

TRNSYS environment was also validated by a new

heating simulation model. The same model developed

in ref. (Ahamed, 2020) was improved in ref. (Dong,

2021) and validated using the field data collected

from a solar greenhouse in Manitoba, Canada. The

annual simulation indicates that the daily average

heating in the coldest month (January) could be two

times higher (6.3 MJ/m2·day) compared with March

(3.4 MJ/m

2

·day). Comparing this solar greenhouse

with a traditional local one, the heating cost is about

55% lower.

1.1 Aim of the Work

This work aims at increasing the renewable energy

technologies usage in the agricultural sector. In

particular, in this work, the development of a

greenhouse dynamic simulation model in TRNSYS

environment and the related validation by the

literature values is presented. Then, the greenhouse

model is integrated into a comprehensive dynamic

simulation model, including several renewable

technologies based on the use of biomass and solar

source in order to evaluate the energy, economic and

environmental performance. With respect to the

literature review the work aims at showing how

hybrid renewable energy plants can be an optimal

solution in the framework of the green farm and

biocircular economy approach. In addition, the whole

system is dynamically simulated considering both the

dynamic demand of the greenhouse and user and the

dynamic power and heat production

2 METHOD

In this section the method adopted to develop this

work will be described. Here the greenhouse model

and its validation vs literature data will be reported.

Then, this model will be integrated into a

comprehensive simulation model including the

investigated renewable technologies according to the

investigated layout (Figure 1). The section also

includes some details of the modelling of the main

components, such as the solar thermal collector and

PV panel fields and the main economic and energy

indexes evaluated to perform the technoeconomic

analysis.

2.1 Layout

The layout investigated in this paper is represented in

Figure 1.

Figure 1: Layout.

It includes:

solar PV panels producing electricity to supply

the user and irrigation pumps.

solar thermal collectors to supply the thermal

energy demand of the greenhouse, corn drying

and the domestic hot water and heating energy

demand of the user.

a biomass auxiliary boiler in case of scarce

irradiation, during the night hours or switching

off of pyrogasifier, to match the global thermal

energy demand.

a water tank to store the produced thermal

energy by the solar field.

a pyrogasifier supplied by wood and

agricultural wastes to produce both thermal and

electric energy.

SMARTGREENS 2023 - 12th International Conference on Smart Cities and Green ICT Systems

138

The plant is connected to the grid in order to match

the electricity of the user if the production of the

included technologies is not enough.

2.2 Model

The simulation model of this system is developed

using the well-known dynamic simulation tool

TRNSYS. The tool includes a large library of

components, which are able to accurately simulate the

energy performance of the components included in

the investigated system. The types included in

TRNSYS environment are considered reliable and

validated (Klein SA, 2006). For sake of brevity, the

components used to model the whole plant are

summarized in Table 1.

Table 1: TRNSYS Types.

T

yp

e 1b Solar thermal collectors

T

yp

e 94 PhotoVoltaic

p

anels

Type 109 Weather conditions

Type 48 Inverter regulato

r

Type 4c Thermal storage tan

k

T

yp

e 114 Circulation

p

um

p

T

yp

e 6 Biomass auxiliar

y

boile

r

T

yp

e 641 Humidification s

y

stem

Type 77 Ground modelling

TRNSYS software is very reliable and accurate

for the evaluation of building energy demand (Calise,

2020) and it is considered by the scientific

community as a benchmark tool to validate the in-

house building simulation models (Buonomano and

Palombo, 2014, Calise, 2016, Buonomano, 2019).

However, its application can be suitable also for the

simulation of greenhouses as reported in ref.

(Ahamed, 2020). The next subsection includes the

description of greenhouse model and validation.

2.2.1 Greenhouse Model

Type 56 was selected to model the greenhouse. This

component calculates the dynamic energy demand,

by considering its 3D geometry (defined in the

Google SketchUp TRNSYS3d plug-in (Murray,

Finlayson et al. 2009)), the effects of the

environmental conditions (i.e. ambient temperature

and humidity, solar radiation, etc.) on the greenhouse

and the envelope thermophysical proprieties, as well

as the ventilation and infiltration rate. gain. The

greenhouse geometry analyzed in this work is

represented in Figure 2. The validation of the whole

Type 56 is presented in reference (Voit, 1994). It is

also worth noting that Type 56 considers a detailed

model for the calculation of radiation in the

greenhouse, considering a complex model for the

calculation of view factors and considering the

radiative properties of the surfaces as a function of the

wavelength.

Figure 2: Geometric model of the investigated greenhouse.

As a consequence, the model returns the surface

temperatures and the radiate flows emitted by the

surfaces and transmitted by the glazing surfaces.

The validation of the model of greenhouse was

carried out considering the greenhouse model

developed in TRNSYS according to the ref.

(Ahamed, 2020), where all the assumptions to

redevelop the model were reported.

Figure 3: Model Validation.

In Figure 3, the monthly average daily heating

requirement obtained both by ref. (Ahamed, 2020)

and our model were summarised.

2.2.2 Energy, Economic and Environmental

Model

A detailed thermo-economic model was also

developed in order to assess the energy and economic

profitability of the system under investigation. The

primary energy saving (PES) was evaluated

considering a reference system (RS) supplied by the

national grid for the electric energy demand and a

conventional gas boiler for the thermal energy

demand, featured by an efficiency of 46% and 90%

(η

el,GRID

, η

NGboiler

), respectively.

0

200

400

600

800

jan feb mar apr may jun jul aug sep oct nov dec

Monthly average daily heating requirements

[kWh/day]

TRNSYS MODEL

TRNSYS MODEL LIT

Dynamic Simulation and Energy, Economic and Environmental Analysis of a Greenhouse Supplied by Renewable Energy Sources

139

,,,

,

,,

e l f r o mGRI D e l f r o mGRI D e l t o GRI D

th NGboiler

RS PS

RS NGboiler elGrid elGrid

R

SPS

EEE

E

PE PE

PES

PE

ηη η

−

−

==+ −

(1)

The yearly operating cost saving ΔC of the proposed

system (PS) with respect to the RS considers the

purchasing of the electricity from the grid at unit cost

c

el,fromGrid

and of natural gas at unit cost c

NG

, for RS

and the purchasing/selling of the electricity from/to

the grid for PS. c

el,toGrid

is the selling unit cost in PS.

In PS, the biomass for the wood-chip auxiliary boiler

is purchased at unit cost c

bio.boiler

; the biomass for the

pyrogasifier supplied by wood and agricultural

wastes is purchased at unit cost c

bio,pyr.

The

maintenance Mn of all the components were

considered.

()( )

()

,, ,,,,

,, ,,

el fromGRID el fr omGri d NG NG bi o pyr bi o pyr bio boil er bi o boil er

R

SPS

e l f r omGR I D e l f r omGr i d e l t oGRI D e l t oGr i d

PS

Ec Vc MnMcMc

Ec Ec

C=+−+++

−−

Δ

(2)

The equivalent CO

2

emissions difference are

evaluated as follows:

()

,

,,2,

th NGboiler

el fromGRID el NG el fromGRID el toGRID el

P

S

NGboiler

RS

CO

E

EF F E EF

η

Δ

=+ −−

(3)

All the capital costs of the included technologies as

well as the main parameters for the thermoeconomic

analysis were reported in the case study section.

2.3 Case Study

The model of the greenhouse was applied to a suitable

case study located in Castelvolturno (Naples, South

of Italy). The main features of the greenhouse were

reported in Table 2. In Table 3, the design data of

proposed plant were also summarised. The plant is

designed to produce the electricity for the buildings

close to the greenhouse and the related irrigation

pumps, and to produce the thermal energy both for the

greenhouse heating and the domestic hot water and

space heating energy demand of the user. The

thermoeconomic and environmental assumptions for

Table 2: Greenhouse features.

Area 450 m

2

(

9 m x 50m

)

Max hei

g

ht 5

m

Slope of the roof 30 °

Air change infiltration 0.5 1/h

Ventilation 0.1 m/s

Artificial Li

g

htnin

g

30 W/m

2

Day/nigh humidification

rate for eva

p

otrans

p

iration

21.5/3.6 g/h

Heatin

g

tem

p

erature 20 °C

Materials

Plastic cover, steel

structure, chalk/cla

y

floo

r

the analysis of the PS with respect to RS were

summarised in Table 4. Figure 4 reports the thermal

energy demand of the greenhouse; Figure 5 reports

the power and heat load of the user.

Table 3: Design data of proposed plant.

Rated

p

ower PV field A 15 kW

Rated power PV field B 5 kW

Slope PV fiel

d

A0°

Slope solar thermal fiel

d

/

PV fiel

d

B 30°

Area solar thermal fiel

d

28 m

2

Rated

p

ower

p

y

ro

g

asifie

r

20 kW

Rate

d

thermal flow rate pyrogasifie

r

40 kW

Equivalent oper. hours pyrogasifie

r

7500 h

/

y

Efficiency curve coeff. solar collecto

r

a

0

0.785

a

1

1,03 W/m

2

K

a

2

0.0033 W/m

2

K

2

Table 4: Thermoeconomic and environmental parameters.

Data Value

P

y

ro

g

asifier cost 150

k

€

Biomass auxiliar

y

boiler cost 10

k

€

Ordinar

y

Maint. P

y

ro

g

asifier 3%/

y

Extraordinar

y

Maint. Pyrogasifie

r

5

k

€/2

y

Maint.

b

iomass auxiliary boile

r

2,50%

Unit cost of

p

urchased

b

iomass 0,12 €/k

g

Unit cost of self-

p

roduce

d

b

iomass 0,07 €/k

g

Lower heatin

g

value of woo

d

-chi

p

4 €/k

g

Unit cost of PV field 1800 €/kW

Maint. PV fiel

d

2%

Unit cost solar thermal fiel

d

400 €/

m

Maint. solar thermal fiel

d

2,5%

Lifetime

p

ro

p

osed s

y

ste

m

20

y

Discount rate 5%

CO

2

emission factor for electricity 0.48 kgCO

2

/kWh

CO

2

emission factor for primary

ener

gy

0.20 kgCO

2

/kWh

Figure 4: Thermal energy demand of the greenhouse.

It is clearly shown how the thermal energy

demand is very high during the winter months due to

0

50

100

150

200

250

Thermal flow rate (W/m

2

)

Time (h)

SMARTGREENS 2023 - 12th International Conference on Smart Cities and Green ICT Systems

140

the cold temperatures. Over 50% of all yearly heating

demand is concentrated in the coldest winter months.

The power load is mainly due to the irrigation

pumps (with a rated power of 55 kW). Note the high

peak value during the summer day, considering that

the irrigation time range is wider in the summer days.

In addition, the electric consumption due to

technologies and offices is negligible with respect to

the irrigation. The thermal flow rate during the winter

day reaches the peak value of 14 kW at 8 am, higher

than summer one, considering that the winter thermal

flow rate is due to the space heating and DHW

purposes and corn drying.

Figure 5: Heat (space heating and DHW) and power

demand of user (irrigation and offices demand).

3 RESULTS

In this section the results of the dynamic simulations

performed for one year of operation will be presented

according to different time basis: hourly, and yearly

basis. In particular, the results of the energy,

economic and environmental analysis will be also

reported when PS is compared with RS. In addition,

the economic analysis will be presented considering

the purchasing costs before and after the energy crisis.

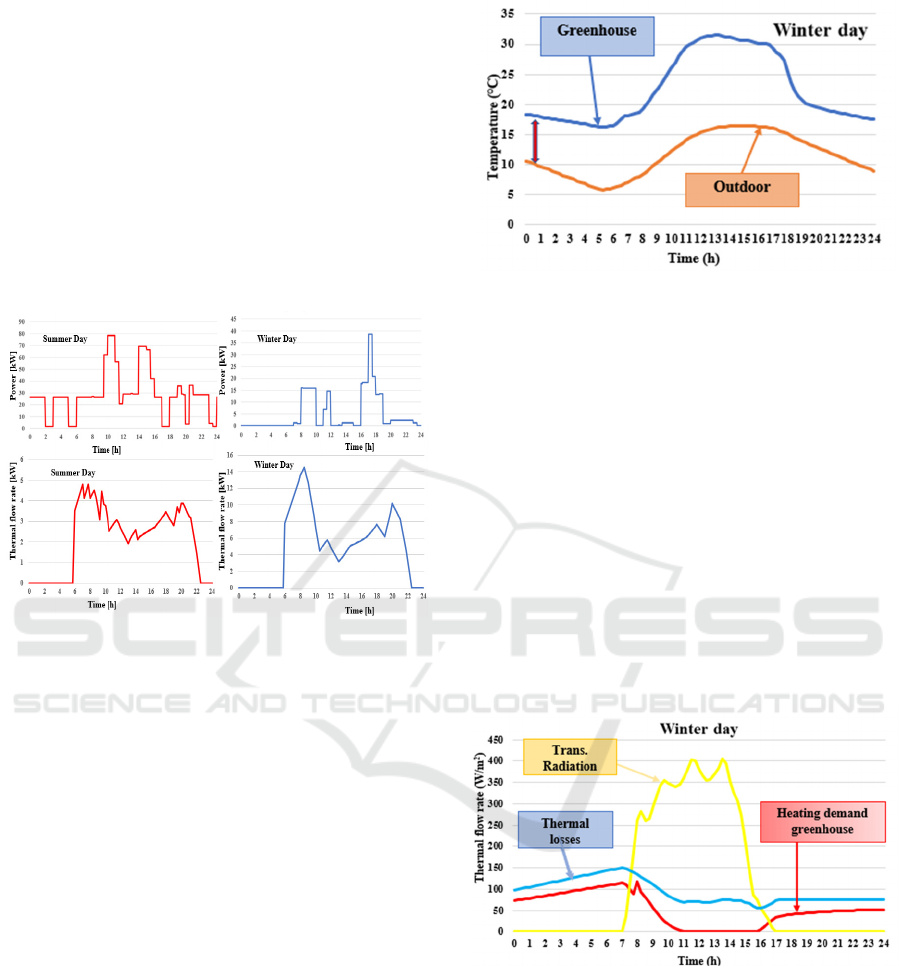

Figure 6 shows the trends of temperature of

greenhouse and outdoor air without the heating

system. Note that the heating of greenhouse quickly

occurs during the central hours of the day and that the

greenhouse temperature follows the same trend of the

ambient temperature.

The heating of the greenhouse occurs because the

rays of the sun enter through the glass of the

greenhouse featured by particularly high absorption

coefficients. However, the infrared radiation emitted

by the ground cannot be transmitted through some

materials, such as glass, guaranteeing a higher

temperature than the outdoor air temperature.

Figure 6: Temperature difference between greenhouse and

outdoor air.

A heated greenhouse allows an increase in the

yield of the crop, so that some crops can be cultivated

even in the winter months. Conversely, in case of

greenhouse with heating system, the trend of the

thermal flow rates represented in Figure 7 can be

observed.

The heating demand of greenhouse by the heating

system occurs only if the greenhouse temperature is

lower than 20°C, mainly when the radiation is absent

or for cold ambient temperature. During these hours,

the thermal losses by the construction materials are

high. Due to the transmitted solar radiation, the

thermal energy demand is null from 11 am to 16 pm

because the greenhouse temperature is higher than

20°C, although this is a winter day.

Figure 7: Transmitted solar radiation, thermal losses, and

heating demand of greenhouse.

Figure 8 reports the powers of the electric loop.

The power production of pyrogasifier is not

dependent on the weather conditions and it is constant

and very significant. Both the systems, pyrogasifier

and PV panels, are able to reduce the integrations of

electricity from the grid, although the higher power

demand of summer season due to the irrigation pumps

than the winter season one. Note that during the

central hours of the day, the pyrogasifier is switched

Dynamic Simulation and Energy, Economic and Environmental Analysis of a Greenhouse Supplied by Renewable Energy Sources

141

off to carry out the ordinary maintenance of the unit

and the electricity is only provided by the PV panels.

Note that the electricity is delivered to the grid mainly

during the night and late afternoon hours. This mainly

occurs because the irrigation pumps operate during

the central hours, doubling the power consumption.

Figure 8: Total power production of PV panels and

pyrogasifier, total power demand, power from/to grid

(space heating and DHW).

The yearly results of energy analysis were

summarised in Table 5 and 6. The electricity

integration from the grid is about 35% of the total

electric energy demand, whereas the thermal self-

consumption is 63% of the total thermal energy

demand. The electric self-consumption is 65% of the

total electric energy demand. The electric production

of the solar field covers only 17% of the total electric

energy production, result that confirm the small size

of PV field with respect to the pyrogasifier.

Table 5: Yearly energy results.

Energy Analysis

Energy [MWh/y] Value Energy [MWh/y] Value

User thermal

demand

44 Electric integration 108

Greenhouse

thermal demand

246

Thermal self-

consumption

182

Total heat demand 290 Thermal excess 136

Total electric

demand

122

Thermal production

solar field

22,7

Elec.production

(PV+pyrog)

179

Thermal production

pyrogasifier

296

Electric integration 42,3

Thermal product.

(solar field+pyrog)

318

Electric excess 99,7

Electric production

pyrogasifier

149

Electric self-

consumption

79,7

Electric production

PV field

30,6

The proposed system is able to obtain a reduction

of 149 t/y (Table 6). The primary energy saving of

121% is due to the high amount of the electric energy

delivered to the grid, equal to 55% of the total

electricity production. During the winter months, due

to the lower electric energy demand when the

irrigation pumps operate for only few hours per day,

the electric-self consumption with respect to the

demand reaches high value, also 90%. Therefore, the

excess of electricity reduces during the summer

months, although the higher PV production.

Table 6: Yearly energy and environmental results.

Primary energy RS 587,04 MWh/y

Primary energy PS -124,67 MWh/y

PES (Primary Energy Saving)

121

%

CO

2

emissions RS 122,93 t/y

CO

2

emissions PS -25,73

Avoided CO

2

emissions

121

%

Considering the increase of the purchasing costs

before and after the energy crisis, 0.70 vs 1.58 €/Sm

3

for natural gas, and 0.19 vs 0.66 €/kWh, the economic

indexes, reported in Table 7, clearly improve, with a

simple payback period, decreasing from 6.7 to 1.7

years.

Table 7: Economic results.

Adopted purchasing costs Post crisis Pre crisis

ΔC 122 k€/y 31 k€/y

SPB 1,7 y 6,7 y

DPB 1,8 y 8,4 y

NPV 1317 k€ 177 k€

PI 6,4 0,86

4 CONCLUSIONS

In this work the modelling and the energy, economic

and environmental analysis of a renewable plant

based on PV panels, solar thermal collectors and a

pyrogasifier was presented. The plant is designed to

satisfy the main energy demands of a farm, including

a greenhouse. The modelling was developed in

TRNSYS environent and the types of the software

were adopted, except for the greenhouse. For the

greenhouse a suitable model, validated by a literature

research work, was presented, allowing to evalute the

thermal energy demand for heating of greenhouse.

Subsequently, the validated model was

adapted for a

case study related to the Castelvolturno greenhouse

SMARTGREENS 2023 - 12th International Conference on Smart Cities and Green ICT Systems

142

(Naples, South of Italy) with a total heating demand

of 246 MWh/year. Considering the total thermal and

electrical energy demand of the farm, equal to 289

MWh/year and 122 MWh/year, coupling the mix of

renewable plants, the following results can be

summarized. The electric production covers more

than 65% of electric consumption (79 MWh/year).

The integration of thermal energy provided by the

biomass boiler is 108 MWh/year. The economic

analysis was performed considering the purchasing

energy costs before and after the energy crisis.

Significant differences were detected, with simple

payback values decreasing from 6.7 to 1.7 years.

Finally, the energy and environmental analysis

showed how much the implementation of green

systems connected to a circular economy can

positively affect the reduction of emissions (-148.66

tons of CO2/year) and the exploitation of fossil fuels

(-711 .7 MWh/year of primary energy).

REFERENCES

Ashraf, R. J., J. D. Nixon and J. Brusey (2022). "Using

multi-objective optimisation with ADM1 and measured

data to improve the performance of an existing

anaerobic digestion system." Chemosphere 301: 134523.

Ahamed, M. S., H. Guo and K. Tanino (2018). "A quasi

steady state model for predicting the heating

requirements of conventional greenhouses in cold

regions." Information Processing in Agriculture 5(1): 33-

46.

Ahamed, M. S., H. Guo and K. Tanino (2020). "Modeling

heating demands in a Chinese-style solar greenhouse

using the transient building energy simulation model

TRNSYS." Journal of Building Engineering 29:

101114.

Azam, M. M., M. A. Eltawil and B. M. A. Amer (2020).

"Thermal analysis of PV system and solar collector

integrated with greenhouse dryer for drying tomatoes."

Energy 212: 118764.

Buonomano, A., F. Calise, A. Palombo and M. Vicidomini

(2019). "Transient analysis, exergy and thermo-

economic modelling of façade integrated

photovoltaic/thermal solar collectors." Renewable

Energy 137: 109-126.

Buonomano, A. and A. Palombo (2014). "Building energy

performance analysis by an in-house developed

dynamic simulation code: An investigation for different

case studies." Applied Energy 113: 788-807.

Burke, M. J. and J. C. Stephens (2017). "Energy

democracy: Goals and policy instruments for

sociotechnical transitions." Energy Research & Social

Science 33: 35-48.

Calise, F., F. L. Cappiello, M. Dentice d’Accadia and M.

Vicidomini (2020). "Dynamic simulation, energy and

economic comparison between BIPV and BIPVT

collectors coupled with micro-wind turbines." Energy

191: 116439.

Calise, F., F. L. Cappiello, M. Dentice d’Accadia and M.

Vicidomini (2021)"Concentrating photovoltaic/thermal

collectors coupled with an anaerobic digestion process:

Dynamic simulation and energy and economic

analysis." Journal of Cleaner Production 311: 127363.

Calise, F., M. Dentice d'Accadia, L. Libertini, E. Quiriti and

M. Vicidomini (2016). "Dynamic simulation and

optimum operation strategy of a trigeneration system

serving a hospital." American Journal of Engineering

and Applied Sciences 9(4): 854-867.

Chantasiriwan, S. (2022). "Solar-aided power generation in

biomass power plant using direct steam generating

parabolic trough collectors." Energy Reports 8: 641-648.

Dong, S., M. S. Ahamed, C. Ma and H. Guo (2021) "A Time-

Dependent Model for Predicting Thermal Environment

of Mono-Slope Solar Greenhouses in Cold Regions."

Energies 14 DOI: 10.3390/en14185956.

Fitz-Rodríguez, E., C. Kubota, G. A. Giacomelli, M. E.

Tignor, S. B. Wilson and M. McMahon (2010).

"Dynamic modeling and simulation of greenhouse

environments under several scenarios: A web-based

application." Computers and Electronics in Agriculture

70(1): 105-116.

Klein SA, B. W., Mitchell JW, Duffie JA, Duffie NA,

Freeman TL, et al. (2006). "Solar Energy Laboratory,

TRNSYS. A transient system simulation program.

University of Wisconsin, Madison."

Murray, M. C., N. Finlayson, M. Kummert and J. Macbeth

(2009). Live Energy Trnsys -Trnsys Simulation within

Google Sketchup. Eleventh International IBPSA

Conference, Glasgow, Scotland July 27-30.

Okakwu, I. K., A. S. Alayande, D. O. Akinyele, O. E.

Olabode and J. O. Akinyemi (2022). "Effects of total

system head and solar radiation on the techno-

economics of PV groundwater pumping irrigation

system for sustainable agricultural production."

Scientific African 16: e01118.

Rahman, A., O. Farrok and M. M. Haque (2022).

"Environmental impact of renewable energy source

based electrical power plants: Solar, wind,

hydroelectric, biomass, geothermal, tidal, ocean, and

osmotic." Renewable and Sustainable Energy Reviews

161: 112279.

Singh, G., P. P. Singh, P. P. S. Lubana and K. G. Singh

(2006). "Formulation and validation of a mathematical

model of the microclimate of a greenhouse."

Renewable Energy 31(10): 1541-1560.

Voit, P., T. Lechner and M. T. Schuler (1994). Common EC

validation procedure for dynamic building simulation

programs - application with TRNSYS. Conference of

international simulation societies, Zürich.

Xu, Z., J. Lu and S. Xing (2022). "Thermal performance of

greenhouse heating with loop heat pipe solar collector

and ground source heat pump." Results in Engineering

15: 100626.

Xue, J. (2017). "Photovoltaic agriculture - New opportunity

for photovoltaic applications in China." Renewable and

Sustainable Energy Reviews 73: 1-9.

Dynamic Simulation and Energy, Economic and Environmental Analysis of a Greenhouse Supplied by Renewable Energy Sources

143