Conv-LSTM for Real Time Monitoring of the Mineral Grades in the

Flotation Froth

Ahmed Bendaouia

1,2 a

, El Hassan Abdelwahed

1 b

, Sara Qassimi

4 c

, Abdelmalek Boussetta

3

,

Intissar Benzakour

3

, Oumkeltoum Amar

2

, Franc¸ois Bourzeix

2

, Achraf Soulala

1

and Oussama Hasidi

1,2

1

Computer Systems Engineering Laboratory (LISI), Computer Science Department, Faculty of Sciences Semlalia, Cadi

Ayyad University, Marrakech, Morocco

2

SEIA Departement, Moroccan Foundation for Advanced Science Innovation and Research (MAScIR), Rabat, Morocco

3

R&D and Engineering Center, Reminex, Managem Group, Marrakech, Morocco

4

Computer and Systems Engineering Laboratory (L2IS), Computer Science Department,

Faculty of Science and Technology, Cadi Ayyad University, Marrakech, Morocco

Keywords:

Deep Learning, Industry 4.0, Flotation Froth, Mining Industry, Monitoring.

Abstract:

Accurate monitoring of the mineral grades in the flotation froth is crucial for efficient minerals separation in

the mining industry. In this study, we propose the use of ConvLSTM, a type of neural network that combines

Convolutional Neural Networks (CNNs) and Long Short-Term Memory (LSTM) networks, to create a model

that can extract spatial and temporal patterns from flotation froth video data. Our model enables the analysis of

both spatial and temporal patterns, making it useful for understanding the dynamic behavior of the froth surface

in the flotation processes. Using ConvLSTM, we developed a more accurate and reliable model for monitoring

and controlling the flotation froth quality. Our results demonstrate the effectiveness of our approach, with mean

absolute error (MAE) of 2.59 in a lead, copper and zinc differential flotation site. Our findings suggest that

artificial intelligence can be an effective tool for improving the flotation monitoring and control, with potential

applications in other areas of the mining industry.

1 INTRODUCTION

In recent years, research has demonstrated a signifi-

cant decline in mineral resources. This decline can be

attributed to both the depletion of existing mineral re-

serves and the unpredictable reductions in raw materi-

als. In response to these challenges, the mining indus-

try has been compelled to innovate in various aspects

of its operations, including mining, exploration, pro-

cessing, logistics, and marketing. This industry-wide

push towards innovation has been further supported

by the emergence of the fourth industrial revolution,

also known as Industry 4.0. This revolution is char-

acterized by the integration of digital technologies

and physical systems, resulting in the development

of smart factories that are highly productive and ef-

ficient. Industry 4.0 is reliant on a range of disruptive

a

https://orcid.org/0000-0003-0017-9285

b

https://orcid.org/0000-0002-2786-6707

c

https://orcid.org/0000-0002-9441-986X

technologies, including the Internet of Things (IoT),

cloud computing, big data, and Cyber-Physical Sys-

tems (CPS) (Qassimi and Abdelwahed, 2022). Within

this context of digital transformation, our study aims

to investigate how disruptive technologies and inno-

vations can be utilized to optimize mineral processing

productivity and efficiency in the mining industry.

Given the challenges facing the mining indus-

try regarding the declining mineral resources and the

need for innovation, one technique that has gained

significant attention is the flotation separation. The

flotation has emerged as a promising technique in the

last century. It is a mineral processing method that

leverages the differences in surface properties of min-

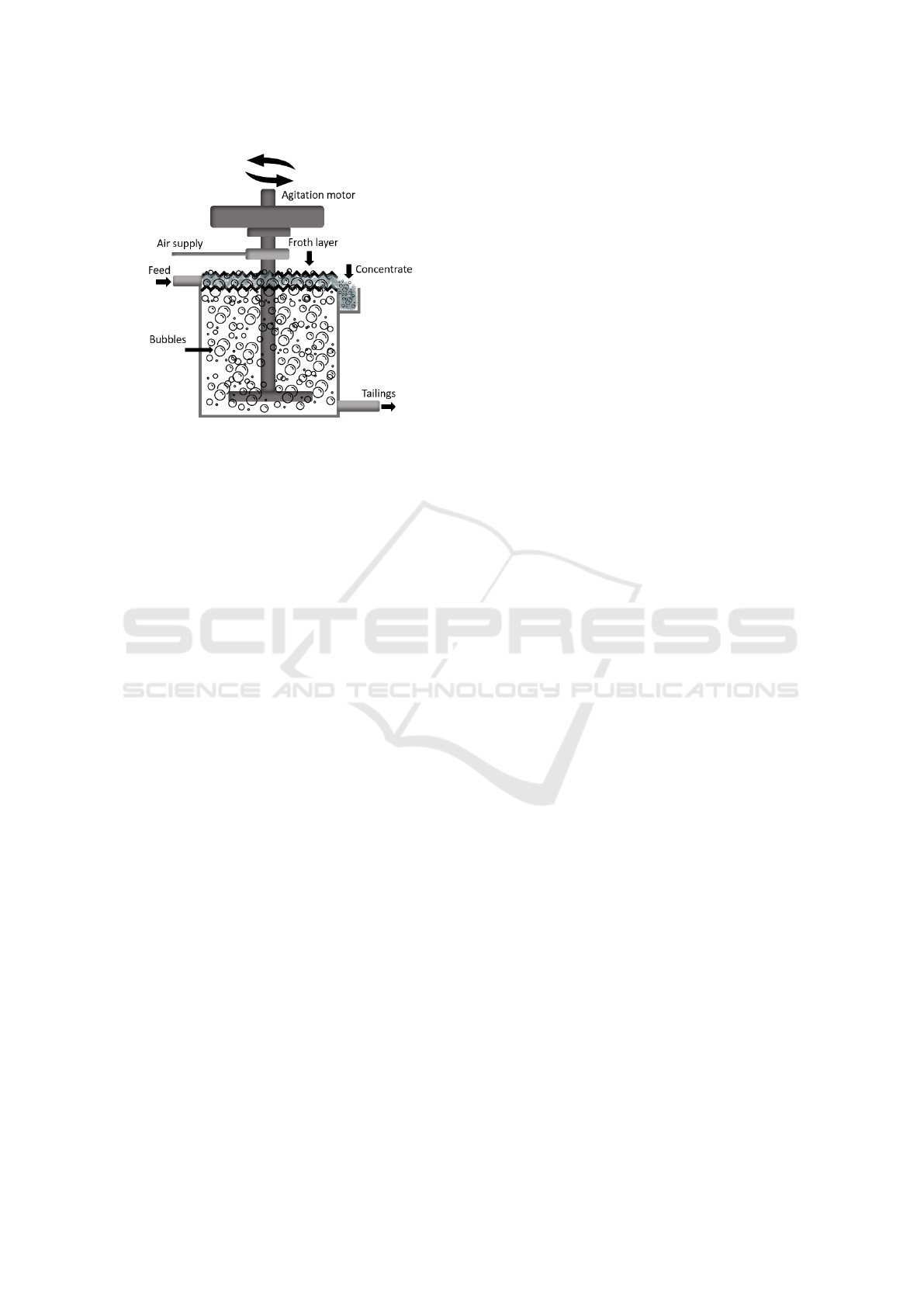

erals to separate them (see figure 1). This approach

is widely employed in the mining industry to extract

valuable minerals from ores. Recent developments in

technology and research have led to the creation of

new flotation separation methods, including the use of

innovative reagents and equipment. Against the back-

drop of the digital transformation of the mining indus-

Bendaouia, A., Abdelwahed, E., Qassimi, S., Boussetta, A., Benzakour, I., Amar, O., Bourzeix, F., Soulala, A. and Hasidi, O.

Conv-LSTM for Real Time Monitoring of the Mineral Grades in the Flotation Froth.

DOI: 10.5220/0012090100003541

In Proceedings of the 12th International Conference on Data Science, Technology and Applications (DATA 2023), pages 89-96

ISBN: 978-989-758-664-4; ISSN: 2184-285X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

89

Figure 1: Froth flotation separation technique.

try and the need for enhanced efficiency and produc-

tivity, this research aims to propose a new flotation

monitoring technique based on artificial intelligence

that can be utilized to optimize the flotation monitor-

ing.

This paper focuses on the monitoring of the flota-

tion froth and proposes a cost-effective and low-

maintenance solution that enables real-time measure-

ment of mineral grades. To achieve this goal, we

employ artificial intelligence and deep learning tech-

niques in the mineral processing flotation-based. This

paper is organized into five sections. The first section

provides an introduction and outlines the general con-

text of the research, while the second section presents

the state of the art in flotation froth monitoring and

the use of deep learning techniques. The third sec-

tion details the methodology employed, including the

data types and preprocessing steps, model architec-

ture, and experimental process. The fourth section

reports the application and results of the proposed so-

lution, including mineral grade identification, perfor-

mance evaluation, and discussion. Finally, the fifth

section offers a conclusion and perspective on the re-

search findings.

2 STATE OF THE ART

2.1 Flotation Froth Monitoring

To achieve the optimization and control of the flota-

tion process, accurate monitoring of the flotation con-

centrate grades is crucial. While several existing

monitoring techniques are available, they can be ex-

pensive to implement and may have high mainte-

nance requirements in addition to their latency. Cur-

rently, the most used monitoring techniques are XRF-

fluorescence-based or laboratory analysis basically

the Atomic Absorption (AA). The laboratory analysis

method is considered the most accurate but has limita-

tions due to manual sampling and preparation, leading

to latency issues. The online mineral control method

using X-ray fluorescence (XRF) detection, specifi-

cally the XRF-based Courier 6G, is used at the Com-

pagnie Mini

`

ere de Guemassa (CMG) flotation factory

where this study was conducted. This method can

measure up to six individual process streams, mak-

ing it suitable for monitoring complex polymineral-

lic flotation circuits that contain lead, copper, iron

and zinc. However, XRF analysers require contin-

uous and high-cost maintenance and suffer from in-

sufficient detection of lightweight materials (Uusitalo

et al., 2020).

2.2 Deep Learning for Flotation

Monitoring

In recent years, both literature and practical experi-

ence acknowledge that the visual characteristics of

the froth surface are significant and strongly corre-

lated with the quality of the flotation froth (Liu et al.,

2020) (Farrokhpay, 2011) (Kaartinen et al., 2006)

(Aldrich et al., 2022). This alternative solution for the

flotation monitoring based on Machine Vision is not

only cost-effective but also requires minimal main-

tenance. Furthermore, the visual inspection of the

flotation froth offers the added benefit of enabling

real-time measurement of mineral grades, providing

a significant improvement over current monitoring

techniques such ad XRF-fluorescence and laboratory

analysis. The biggest portion of these applications

are froth classification based on Convolutional Neu-

ral Networks (CNN). Basically because of the capac-

ity of CNN to learn rich hierarchical sets of features

from images. Furthermore, CNN enables the com-

putational power of the deep learning to extract the

features from froth images for classification (Zhang

and Gao, 2021) (Zarie et al., 2020) (Cao et al., 2022)

(Wen et al., 2021). CNNs have proved their capa-

bility of determining the mineral grades more ac-

curately than the classical Machine Learning along

with the supervised features extraction of the flota-

tion froth (Bendaouia et al., 2022). In addition to the

CNNs, Long Short-term-memory based (LSTM) net-

works was used for mineral grades monitoring using

flotation froth video sequences (Zhang et al., 2021).

LSTM architecture is also used for damage detection

in pipelines (Huang et al., 2022), anomaly detection

for technical systems (Lindemann et al., 2021) and

predicting the electric power consumption (Cascone

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

90

et al., 2023). Researchers and engineers are benefit-

ing from the LSTM capability of extracting temporal

patterns in time series data.

The froth flotation video sequence can be con-

sidered as temporal information that can improve the

monitoring accuracy. Therefore, in our study, we pro-

pose the use of ConvLSTM to create a model that

can extract spatial and temporal patterns from flota-

tion froth. ConvLSTM is a type of neural network

that combines the properties of Convolutional Neu-

ral Networks (CNNs) and Long Short-Term Memory

(LSTM) networks. This allows the model to analyze

both spatial and temporal patterns in data, making it

useful for understanding the dynamic behavior of the

froth surface in flotation processes. By using ConvL-

STM, we created a more accurate and reliable model

for monitoring and controlling the flotation froth qual-

ity.

3 METHODOLOGY

The flotation process is a physio-chemical process

that is influenced by numerous parameters. The min-

erallurgist operators acquire the expertise of visually

monitoring the flotation froth based on the froth char-

acteristics. An important factor is the color and tex-

ture of the froth surface, which contains valuable in-

formation about the mineral composition (Farrokh-

pay, 2011). By identifying the mineral types based on

the color and texture of the froth surface, the flotation

performance can be assessed, and operation instruc-

tions can be adjusted accordingly.

In this study, we propose a digital approach that seeks

to replicate the expertise of human operators in visu-

ally monitoring the flotation froth. Specifically, we

propose the use of Conv-LSTM, which combines the

strengths of Convolutional Neural Networks (CNNs)

in image classification with Recurrent Neural Net-

works (RNNs) for processing sequential data, such

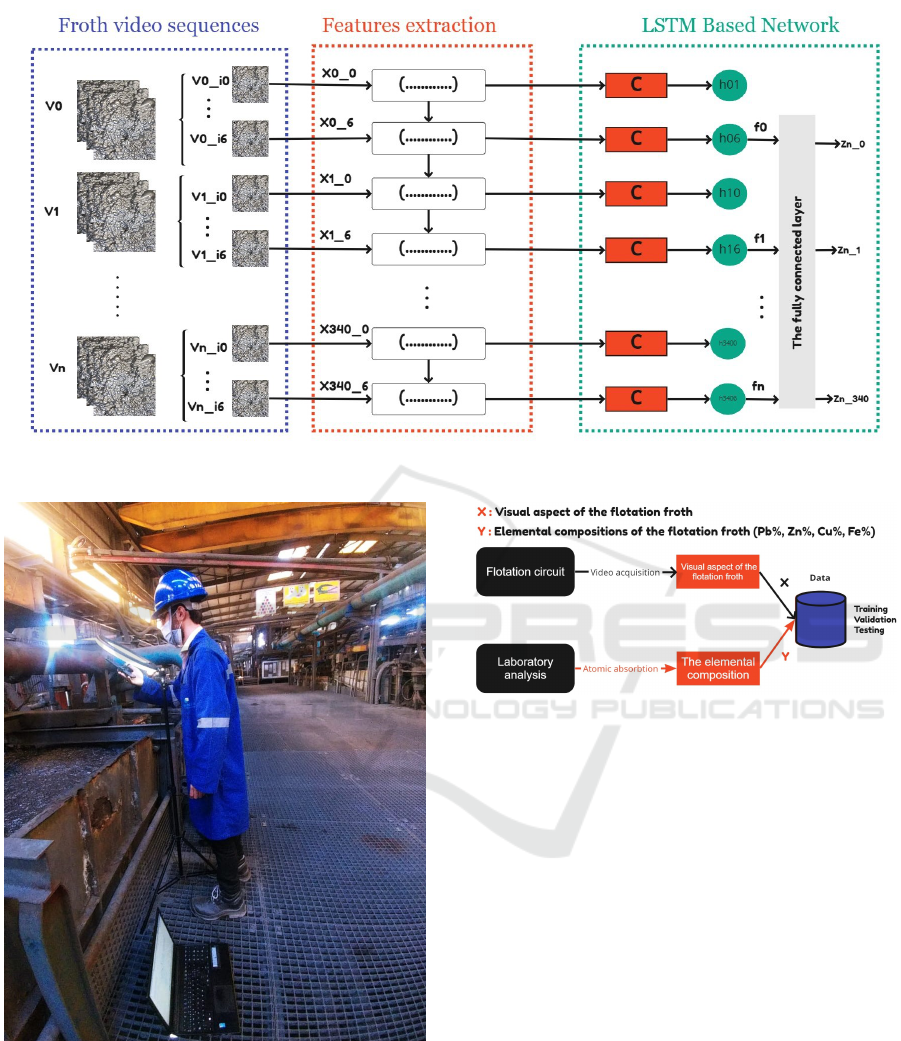

as video frames figure 2. By using Conv-LSTM, we

can extract sequential characteristics from the video

frames of the flotation froth, enabling a more accu-

rate assessment of the mineral composition and thus

better optimization of the flotation process.

3.1 Experimental Process

The experimental process employed in our study

to predict the percentages of minerals in flotation

cells using a Convolutional Long Short-Term Mem-

ory (ConvLSTM) network consisted of the following

steps:

• Data Collection: A large dataset of labeled video

frames of the flotation froth of the Zn circuit was

collected, where each video frame was labeled

with the corresponding percentages of the four

minerals (Zn, Cu, Fe, and Pb) in the flotation

froth.

• Data Preprocessing: The collected video frames

were preprocessed by resizing them to a consis-

tent size and format and splitting them into se-

quences of frames that could be used as input to

the ConvLSTM network.

• Model Architecture: The model architecture was

defined using the Sequential class. The hyper-

parameters were selected after many training and

evaluation operations.

• Model Training: The model was trained using the

labeled video sequences as input and the corre-

sponding percentages of the minerals as output.

The model was trained for several epochs using

the Adam optimizer and the mean squared error

(MSE) as the loss function.

• Model Evaluation: The trained model was eval-

uated using a separate test dataset of video se-

quences and corresponding mineral percentages.

The model’s performance was measured using

metrics such as accuracy and mean squared error.

• Model Deployment: The trained model was de-

ployed for use in the flotation froth cells, where it

was used to predict the percentages of the miner-

als in real-time. The predictions were utilized for

monitoring the flotation process and improve the

efficiency of the separation of the minerals.

3.2 Data Collection

We collected a real world dataset from the differential

flotation site of CMG Managem group in Morocco

figure 3. This dataset includes visual aspect parame-

ters and the elemental composition of Pb, Cu, Zn and

Fe. During the data collection phase, we collected a

sample from the flotation froth and analyzed it in the

laboratory using atomic absorption. Additionally, we

recorded a video of the flotation froth using an RGB

camera under stable luminosity to capture the visual

aspect parameters as described in the figure 4.

3.3 Data Augmentation

To further explain the approach used in the study, the

following paragraph describes the dataset and model

used for training and testing. The study utilized 340

videos from the flotation site of CMG Managem-

Group in Morocco, which were processed into seven-

frame sequences with each frame having a shape of

Conv-LSTM for Real Time Monitoring of the Mineral Grades in the Flotation Froth

91

Figure 2: Framework of the LSTM-based mineral grade monitoring system using the froth flotation video data.

Figure 3: The data acquisition system of the flotation froth

videos.

224x224x3. The sequences were then used as input

for a recurrent neural network (RNN) designed to pre-

dict the percentages of copper (Cu), iron (Fe), lead

(Pb), and zinc (Zn) in the videos. The dataset was split

into 313 training videos and 27 testing videos, with

each target value containing the concentrations of Cu,

Figure 4: The data sources and types.

Fe, Pb, and Zn. The seven-frame sequences and target

mineral grades were combined to enable the model to

accurately predict mineral concentrations by captur-

ing the patterns and dependencies in the data. Ad-

ditionally, the data was augmented by adding noise

between 0 and 0.25 to artificially increase the dataset

size and improve the model’s performance. The con-

trolled addition of noise was an effective way to in-

troduce variability and diversity into the labels while

preserving their overall structure and meaning.

3.4 ConvLSTM-Based Network

We are using ConvLSTM to build a model that can

extract simultaneously both spatial and temporal pat-

terns from the flotation froth. ConvLSTM is a type of

recurrent neural network that combines the strengths

of CNNs and LSTMs, allowing it to process both spa-

tial and sequential data effectively. In a ConvLSTM,

convolutional operations are applied to the input, for-

get, and output gates of an LSTM cell, enabling the

network to learn spatial and temporal patterns simul-

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

92

taneously. This makes ConvLSTM a powerful tool for

tasks such as video prediction and time-series fore-

casting. The equations for a ConvLSTM cell are

shown below:

i

t

= σ(W

xi

∗ x

t

+W

hi

∗ h

t−1

+W

ci

⊙ c

t−1

+ b

i

)

f

t

= σ(W

x f

∗ x

t

+W

h f

∗ h

t−1

+W

c f

⊙ c

t−1

+ b

f

)

c

t

= f

t

⊙ c

t−1

+ i

t

⊙ tanh(W

xc

∗ x

t

+W

hc

∗ h

t−1

+ b

c

)

o

t

= σ(W

xo

∗ x

t

+W

ho

∗ h

t−1

+W

co

⊙ c

t

+ b

o

)

h

t

= o

t

⊙ tanh(c

t

)

• x

t

is the input at time step t

• h

t−1

is the hidden state at time step t − 1

• c

t−1

is the cell state at time step t − 1

• i

t

, f

t

, o

t

are the input, forget, and output gates,

respectively, at time step t

• σ is the sigmoid activation function

• ∗ denotes convolution operation

• ⊙ denotes element-wise multiplication

• W and b are the weight matrices and bias vectors,

respectively, for the input, hidden state, and cell

state

4 Conv-LSTM FOR MINERAL

GRADES DETERMINATION

4.1 Model Architecture

The ConvLSTM network architecture was used in our

study to predict the percentages of four different min-

erals in flotation cells from video data figure 5. The

architecture was effective in processing both the spa-

tial and temporal information present in the video

frames and sequences, which was crucial for our task.

In addition to the ConvLSTM layer, the model also in-

cluded a BatchNormalization layer, a MaxPooling3D

layer, a Dropout layer, a Flatten layer, and a Dense

layer. The Adam optimizer with a low learning rate

of 0.0001 was chosen for its effectiveness in adapt-

ing the learning rate for each parameter and avoiding

overshooting the optimal solution.

4.2 Performance Evaluation

To evaluate the performance of our model in predict-

ing the percentages of the mineral grades from the

froth video, we utilized a separate test dataset that

was not used during the training process. Evaluation

was conducted using several metrics, including accu-

racy, mean squared error (MSE), mean absolute error

(MAE), and mean absolute percentage error (MAPE).

Evaluation is particularly crucial for this study aim-

ing to predict mineral percentages from froth videos

for several reasons. Evaluation allows us to deter-

mine how close the model’s predictions are to the true

values and how much error is present in the predic-

tions. This information can be leveraged to choose the

best model for deployment or identify the key factors

that influence the model’s performance. As the model

is deployed and new data is collected, it is essential

to assess its performance to ensure that it continues

to make accurate predictions. The figure 6 shows a

comparison between the measured and the predicted

mineral grades using our proposed model. The ta-

ble 1 evaluate the model according to the MSE, MAE,

MAPE evaluation metrics. The Standard deviation

(STD) was also calculated for the different elements

in the data test.

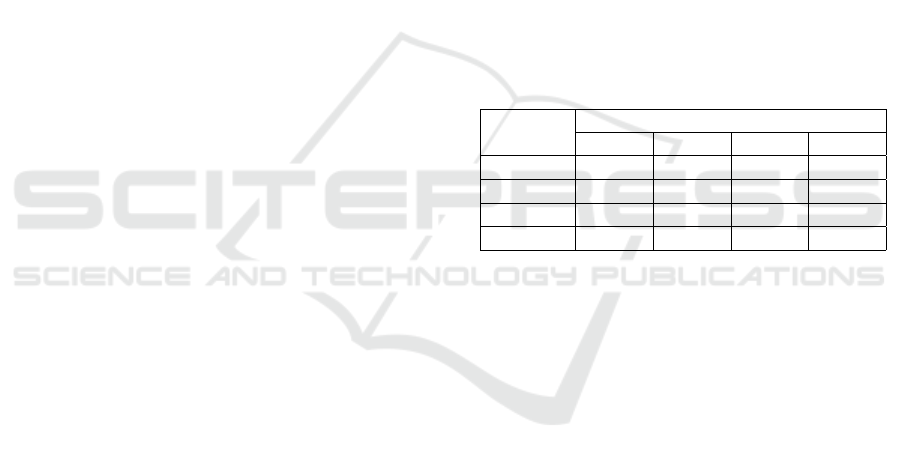

Table 1: The evaluation metrics of the ConvLSTM model

on datatest.

Elements Evaluation metrics

MSE MAE MAPE STD

Zn 11.43 2.59 6.22 16.10

Cu 0.66 0.68 77.70 0.31

Fe 5.81 1.98 15.037 10.54

Pb 0.168 0.313 65.51 0.78

4.3 Discussion of the Results

The table 1 displays the MSE, MAE, and MAPE val-

ues for each elemental composition. Each metric

value corresponds to a specific target mineral. For the

Zn mineral, the MAE value is 2.59, and the MAPE

value is 6.22 while the standard deviation is 16.10,

which is an accurate result according to the variation

of the Zn mineral grade in the Zn flotation circuit. The

low values for these metrics indicate that the model

is making more precise predictions according to high

standard deviation of the Zn mineral grades. Addi-

tionally, the table emphasizes that the model’s perfor-

mance varies depending on the mineral, which is due

to the variety of the concentrate grades distributions.

Compared to other minerals, the Copper has lower

MSE, MAE, and MAPE values, indicating that the

model is making more accurate predictions for this

particular mineral.

The model’s performance varies among the differ-

ent minerals. Overall, the predictions are more accu-

rate for the low grade elements copper (Cu) and lead

(Pb).

Conv-LSTM for Real Time Monitoring of the Mineral Grades in the Flotation Froth

93

Figure 5: The used architecture for the Zn, Fe, Cu and Pb mineral grades prediction.

Figure 6: The measured values of copper, zinc, lead, and iron with the predicted values provided by the ConvLSTM-based

network on deployment data.

5 CONCLUSIONS

Our study demonstrated the added value an indus-

trial application of artificial intelligence in mining in-

dustry. We used a Convolutional Long Short-Term

Memory (ConvLSTM) network to accurately predict

the percentages of minerals in real time in flotation

froth. By utilizing video data as input, the model was

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

94

able to effectively process both spatial and temporal

information, resulting in precise predictions of min-

eral percentages. Our proposed approach has a direct

added value on the monitoring of flotation processes.

The model demonstrated a good level of accuracy and

precision, indicating its ability to be generalized on

the whole differential flotation. The use of the Con-

vLSTM network in flotation froth monitoring, show-

cases its potential for similar industrial applications

that require processing of spatial and temporal infor-

mation.

The real time monitoring the flotation froth is a cru-

cial aspect of optimizing and controlling the flotation

process. Our proposed approach offers significant ad-

vantages over existing monitoring techniques, as it is

not only less expensive and low-maintenance but also

provides real-time information on mineral grades.

This makes it a valuable addition to the flotation mon-

itoring process. Once implemented on the zinc cir-

cuit, our proposed soft sensor will be tested for its

ability to accurately monitor the mineral grades of the

CMG differential flotation circuit’s three base miner-

als: lead, copper, and zinc. By combining froth fea-

tures, physio-chemical sensors, and intelligent control

techniques, this innovative approach has the potential

to become a reliable and effective flotation monitor-

ing system. Our proposed approach of using Con-

vLSTM neural networks for real-time monitoring of

mineral grades in flotation froth has significant po-

tential for future industrial applications beyond lead,

copper, and zinc differential flotation sites. Specif-

ically, we will be testing the generalization of our

approach to other mineral compositions using froth

video data, an aspect that will be addressed in future

work. We acknowledge the limited experimental data

used in this study and are committed to conducting

further research to validate the effectiveness of our

proposed solution in a wider range of industrial set-

tings.

ACKNOWLEDGEMENTS

The Smart Connected Mine project, which this re-

search is a part of, was supported by the Moroccan

Ministry of Higher Education, Scientific Research

and Innovation, the Digital Development Agency

(DDA), and the National Center for Scientific and

Technical Research of Morocco (CNRST) through

the Al-Khawarizmi program. The project was a

collaboration between MASCIR (Moroccan Founda-

tion for Advanced Science, Innovation and Research),

REMINEX R&D (an engineering and project man-

agement subsidiary of the MANAGEM Group), UCA

(Cadi Ayyad University), ENSMR (National School

of Mines of Rabat), and ENSIAS (National School

of Computer Science and Systems Analysis at Mo-

hammed V University). We would like to express our

gratitude to the MANAGEM Group and its subsidiary

CMG for providing us with the opportunity to conduct

research, collect and validate data on-site, and for be-

ing an industrial partner in this project.

REFERENCES

Aldrich, C., Avelar, E., and Liu, X. (2022). Recent advances

in flotation froth image analysis. Minerals Engineer-

ing, 188:107823.

Bendaouia, A., Abdelwahed, E. H., Qassimi, S., Boussetta,

A., Benhayoun, A., Benzakour, I., Amar, O., Zen-

nayi, Y., Bourzeix, F., Ba

¨

ına, K., Ba

¨

ına, S., Khalil, A.,

Cherkaoui, M., and Hasidi, O. (2022). Digital Trans-

formation of the Flotation Monitoring Towards an On-

line Analyzer. In Hamlich, M., Bellatreche, L., Sia-

dat, A., and Ventura, S., editors, Smart Applications

and Data Analysis, Communications in Computer and

Information Science, pages 325–338, Cham. Springer

International Publishing.

Cao, W., Wang, R., Fan, M., Fu, X., Wang, H., and

Wang, Y. (2022). A new froth image classification

method based on the MRMR-SSGMM hybrid model

for recognition of reagent dosage condition in the coal

flotation process. Appl. Intell.

Cascone, L., Sadiq, S., Ullah, S., Mirjalili, S., Siddiqui, H.

U. R., and Umer, M. (2023). Predicting Household

Electric Power Consumption Using Multi-step Time

Series with Convolutional LSTM. Big Data Research,

31:100360.

Farrokhpay, S. (2011). The significance of froth stability

in mineral flotation — A review. Advances in Colloid

and Interface Science, 166:1–7.

Huang, L., Hong, X., Yang, Z., Liu, Y., and Zhang, B.

(2022). CNN-LSTM network-based damage detec-

tion approach for copper pipeline using laser ultra-

sonic scanning. Ultrasonics, 121:106685.

Kaartinen, J., H

¨

at

¨

onen, J., Hy

¨

otyniemi, H., and Miettunen,

J. (2006). Machine-vision-based control of zinc flota-

tion—A case study. Control Engineering Practice, 14.

Lindemann, B., Maschler, B., Sahlab, N., and Weyrich, M.

(2021). A survey on anomaly detection for technical

systems using LSTM networks. Computers in Indus-

try, 131:103498.

Liu, J., Gao, Q., Tang, Z., Xie, Y., Gui, W., Ma, T., and

Niyoyita, J. P. (2020). Online Monitoring of Flotation

Froth Bubble-Size Distributions via Multiscale De-

blurring and Multistage Jumping Feature-Fused Full

Convolutional Networks. IEEE Transactions on In-

strumentation and Measurement, 69:9618–9633.

Qassimi, S. and Abdelwahed, E. H. (2022). Disruptive

Innovation in Mining Industry 4.0. In Distributed

Sensing and Intelligent Systems, Studies in Distributed

Conv-LSTM for Real Time Monitoring of the Mineral Grades in the Flotation Froth

95

Intelligence, pages 313–325. Springer International

Publishing.

Uusitalo, S., Soudunsaari, T., Sumen, J., Haavisto, O.,

Kaartinen, J., Huuskonen, J., Tuikka, A., Rahkamaa-

Tolonen, K., and Paaso, J. (2020). Online analysis

of minerals from sulfide ore using near-infrared Ra-

man spectroscopy. Journal of Raman Spectroscopy,

51(6):978–988.

Wen, Z., Zhou, C., Pan, J., Nie, T., Zhou, C., and Lu, Z.

(2021). Deep learning-based ash content prediction of

coal flotation concentrate using convolutional neural

network. Minerals Engineering, 174:107251.

Zarie, M., Jahedsaravani, A., and Massinaei, M. (2020).

Flotation froth image classification using convolu-

tional neural networks. Minerals Engineering.

Zhang, D. and Gao, X. (2021). Soft sensor of flotation froth

grade classification based on hybrid deep neural net-

work. International Journal of Production Research.

Zhang, H., Tang, Z., Xie, Y., Gao, X., Chen, Q., and Gui, W.

(2021). Long short-term memory-based grade moni-

toring in froth flotation using a froth video sequence.

Minerals Engineering, 160:106677.

DATA 2023 - 12th International Conference on Data Science, Technology and Applications

96