Practical Implementation of Diode SPICE Model with Reverse Recovery

Denys Igorovych Zaikin

a

Advent Technologies A/S, Lyngvej 8, Aalborg DK-9000, Denmark

Keywords:

Diode Reverse Recovery, SPICE, Circuit Simulation.

Abstract:

Peter O. Lauritzen and Cliff L. Ma proposed an approach for creating a physical model of reverse recovery

for soft recovery diodes in 1991. The current paper demonstrates how to create the proper SPICE sub-circuit

using only the specifications from the diode datasheet from the manufacturer. Software for characterization

tools has been developed, tested, and is now openly accessible for use.

1 INTRODUCTION

Of the many SPICE-based simulators on the market,

most still use the old standard diode SPICE model

that does not cover reverse recovery correctly. Both

LTspice (Analog Devices, Inc., 2008) and Pspice

(Cadence Design Systems, Inc., 2015) are powerful

pieces of software that are widely used for power elec-

tronics simulation. These SPICE simulators use a ba-

sic diode model. Adding a feature to simulate diode

reverse recovery will improve loss estimation and cir-

cuit behaviour simulation. This is especially attrac-

tive for LTspice, which is a powerful, free simulator

that can be used in complex design simulation. This

paper applies original theoretical work (Lauritzen and

Ma, 1991) to the practical implementation of a SPICE

macro model of diodes with reverse recovery. The

model described in (Lauritzen and Ma, 1991) is based

on real physical processes in a diode and, because of

this, is robust.

A Windows OS application was created to gener-

ate a diode macro model using only parameters from

the diode manufacturer’s datasheet or measurement

data.

2 DIODE MODEL DESCRIPTION

Original work (Lauritzen and Ma, 1991) provides the

following three equations for diodes with reverse re-

covery:

i(t) =

(q

E

− q

M

)

T

M

, (1)

a

https://orcid.org/0000-0003-4080-5631

0 =

dq

M

dt

+

q

M

τ

−

(q

E

− q

M

)

T

M

, (2)

q

E

= I

s

τ(e

(

v

nV

T

)

− 1). (3)

From equations (1)-(3), the forward DC-bias char-

acteristic can be obtained:

i =

I

s

(1 + T

M

/τ)

(e

(

v

nV

T

)

− 1). (4)

Here, i is the diode current, v is diode junction

voltage, V

T

= kT /q is the thermal voltage, I

s

is satura-

tion current (similar to the SPICE basic diode model

parameter) and n is the emission coefficient (similar

to the SPICE basic diode model parameter). The vari-

ables from (Lauritzen and Ma, 1991) are as follows:

T

M

represents diffusion time, τ recombination life-

time, q

M

total stored charge and q

E

charge variable.

This model is completed with ohmic resistance R

s

and

junction capacitance C

j

, as shown in Figure 1.

RS

D

CJ

Vf

v

i

Figure 1: Diode model components.

The practical implementation of equations (1)-(4)

in the SPICE model, along with ohmic resistance and

junction capacitance, are shown in Figure 2.

92

Zaikin, D.

Practical Implementation of Diode SPICE Model with Reverse Recovery.

DOI: 10.5220/0012096500003546

In Proceedings of the 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2023), pages 92-96

ISBN: 978-989-758-668-2; ISSN: 2184-2841

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

R1

{RS}

VALUE={-1/tau*V(qm)+V(qe,qm)/TM}

G1

C1

1

VALUE={Is*tau*(exp(V(C1,2)/(N*Vt))-1)}

E1

VALUE={V(qe,qm)/TM}

G2

R3

100G

D1

Cap

1

2

qe

qmC1

.param Temp_diode=1.250000e+002 k=1.381000e-023 q=1.602000e-019 Vt=3.430949e-002

.param Rs=2.196899e-002 Is=7.942178e-004 N=2.357317e+000 Tau=9.273759e-008 Tm=1.527752e-007

.param VJ=2.000000e+000 CJ0=9.311509e-010 M=6.974055e-001 FC=0.500000

.model Cap d (Is=1e-14 N=200 rs=10u Xti=0 Eg=0 CjO={Cj0} M={M} VJ={VJ} FC={FC})

Figure 2: Implementation of new diode model in SPICE.

3 EXTRACTION OF MODEL

PARAMETERS

Equations (1)-(3) fully describe diode reverse recov-

ery and DC bias characteristics of the diode. To use

these equations, it is necessary to define τ, T

M

, n and

I

s

parameters.

Parameters τ and T

M

are defined with the approach

used in (Lauritzen and Ma, 1991). An additional in-

termediate parameter – reverse recovery time constant

τ

rr

– is used and can be measured directly from the

reverse recovery waveform or defined from the diode

datasheet’s parameter T

rr

, the reverse recovery time.

Figure 3 shows the JEDEC Standard (JEDEC Stan-

dard No. 282B.01, 2000) definition of T

rr

.

Trr

1

e

I

RM

τ

rr

di

dt

t=0

t

T0

T1

I

F

i(t)

I

RM

0.25 I

RM

Figure 3: JEDEC reverse recovery time T

rr

definition and

waveform.

From Figure 3, τ

rr

can be found as follows:

τ

rr

= 0.75

I

RM

di

dt

− T

rr

!

1

ln(0.25)

. (5)

Now, when τ

rr

is known, parameters τ and T

M

can

be found using numerical equation solving of the fol-

lowing equations from reference (Lauritzen and Ma,

1991):

1/τ

rr

= 1/τ + 1/T

M

, (6)

I

RM

=

di

dt

(τ − τ

rr

)(1 − e

−

T 1

τ

). (7)

To find parameters I

s

, n and ohmic resistance R

s

in equation (4), the standard diode forward DC-bias

SPICE model equations are used (Figure 1):

V

f

= R

s

· i + v, (8)

i = I

′

s

· (e

v

nV

T

− 1). (9)

Based on Equation (9) and Figure 4, it can be seen

that I

s

’ is the leakage reverse current at the maximum

reverse voltage according to the datasheet’s reverse

DC-bias characteristic of the diode.

V

-I

s

'

V

f1

V

f2

I

d1

I

d2

1

2

Figure 4: DC-bias characteristic points.

Using Equations (4) and (9), I

s

can be found:

I

s

= I

′

s

· (1 + T

M

/τ). (10)

To find R

s

and n, two points should be defined

on the DC-bias diode characteristic (Figure 4). From

equations (8) and (9), there is system of equations

with two unknown variables, R

s

and n:

(

V

f 1

= n ·V

T

· ln(I

d1

/I

′

s

+ 1) + R

s

· I

d1

V

f 2

= n ·V

T

· ln(I

d2

/I

′

s

+ 1) + R

s

· I

d2

.

(11)

After system (11) is solved, R

s

and n are found:

n =

V

f 1

· I

d2

−V

f 2

· I

d1

ln

I

d1

I

′

s

+1

·I

d2

I

d2

I

′

s

+1

·I

d1

·

1

V

T

, (12)

R

s

=

V

f 2

−V

T

· n · ln(I

d2

/I

′

s

+ 1)

I

d2

. (13)

Practical Implementation of Diode SPICE Model with Reverse Recovery

93

To simulate non-linear junction capacitance, equa-

tions from the standard diode SPICE model are used

(Kielkowski, Ron M, 1995):

C

J

= C

J0

·

1 −

v

V

J

−M

, v < F

C

·V

J

, (14)

C

J

=

C

J0

(1 − F

C

)

M+1

×

1 − F

C

· (M + 1) +

M · v

V

J

, v ≥ F

C

·V

J

. (15)

In this model for junction capacitance, fixed parame-

ters are assumed: V

J

= 2.0 and F

C

= 0.5. It is also nec-

essary to find parameters M and C

J0

using two points

on the datasheet’s reverse bias capacitance curve in

Figure 5.

V

C

J

2

1

V

r1

V

r2

C

j2

C

j1

Figure 5: Junction capacitance points.

Using these two points, a system of equations can

be obtained based on Equation (14):

C

j1

= C

J0

·

1 +

V

r1

V

J

−M

C

j2

= C

J0

·

1 +

V

r2

V

J

−M

.

(16)

After (16) is solved, M and C

J0

can be found:

M =

ln

C

j1

C

j2

ln

1+V

r2

/V

J

1+V

r1

/V

J

, (17)

C

J0

= C

j1

·

1 +

V

r1

V

J

M

. (18)

To implement junction capacitance in the new

diode model, the standard SPICE diode model is

placed in parallel with the diode body (Figure 2).

The new diode SPICE model implements the be-

havior of the diode at a fixed temperature. Lead

inductances should be added externally for parasitic

simulation.

4 SIMULATION RESULTS

The newly generated model was tested in two simula-

tors – LTspice and Pspice. The LTspice IV simulation

results for the MUR460 diode are shown in Figure 6.

Figure 6: Comparison of current and standard waveform

LTspice IV simulation results for the MUR460 diode. The

MUR460 standard diode model was taken from the LT-

spice IV library.

Pspice 16.6 simulation results for the

HFA25TB60 diode are shown in Figure 7.

Figure 7: Comparison of current and standard waveform

Pspice 16.6 simulation results for the HFA25TB60 diode.

The HFA25TB60 standard diode model was taken from the

Pspice 16.6 library.

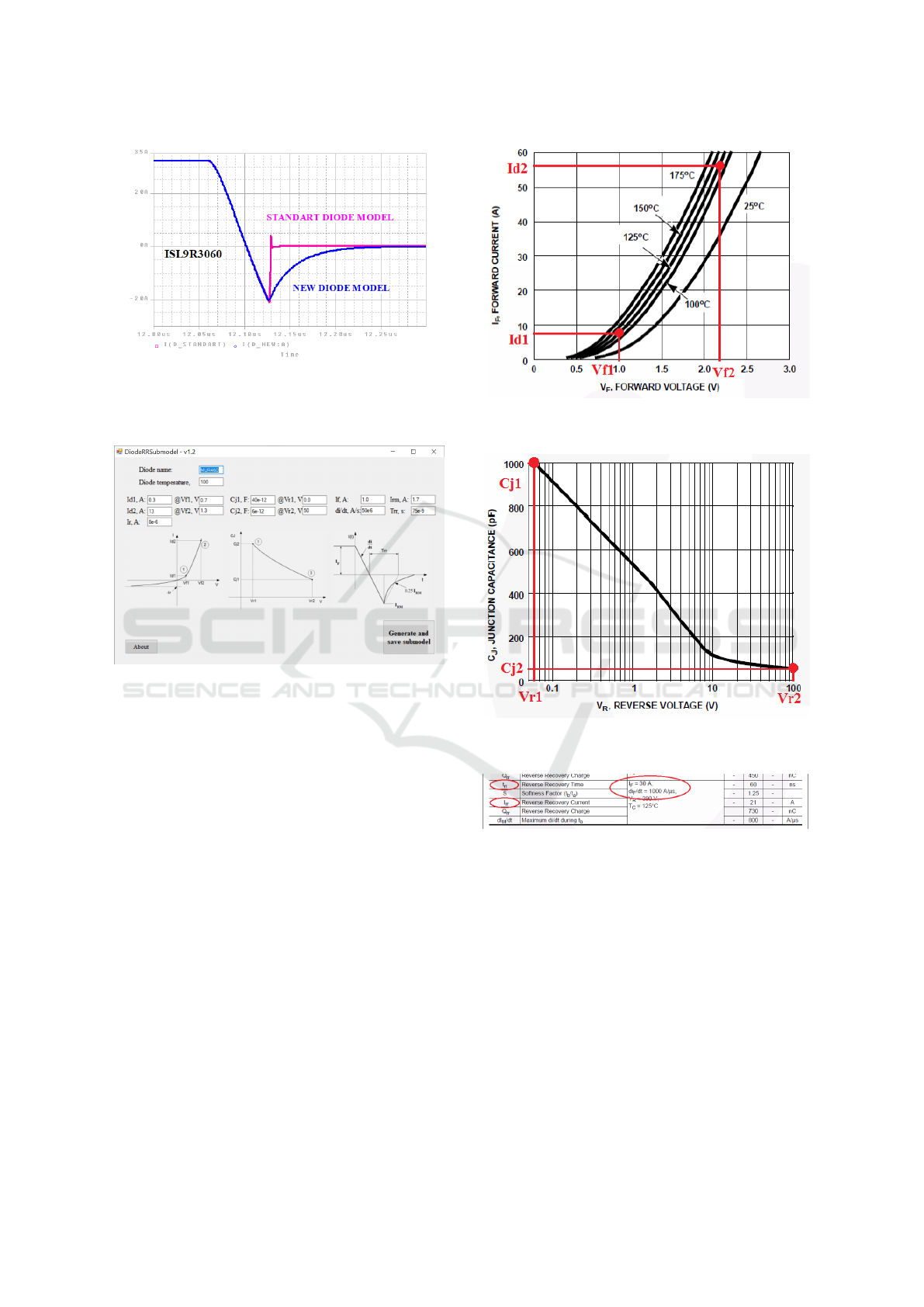

The Pspice 16.6 simulation results for ISL9R3060

diode are shown in Figure 8.

5 SOFTWARE DESCRIPTION

To generate the diode SPICE model using the man-

ufacturer’s datasheet characterization, the software

(SW) tool “DiodeRRSubmodel” was made (Figure 9).

It is a Windows OS application and can be freely

downloaded from the link (ZAIKIN D.I., 2021).

Next, input data from the datasheet are used as fol-

SIMULTECH 2023 - 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

94

Figure 8: Comparison of current and standard waveform

Pspice 16.6 simulation results for the ISL9R3060 diode.

The ISL9R3060 standard diode model was taken from the

manufacturer webpage.

Figure 9: Windows OS application SW for diode model ex-

traction.

lows:

• user enters diode name;

• user defines work temperature of diode;

• user enters two points on the DC-bias forward

characteristic for the specified temperature (Fig-

ure 4, Figure 10). Points far enough away from

each other should be chosen;

• user enters reverse leakage current for diode at

specified temperature;

• user enters two points on the junction capacitance

(Figure 5, Figure 11). Points far enough away

from each other should be chosen;

• user enters the reverse recovery specification from

the diode datasheet at the specified temperature:

I

f

, di/dt, I

RM

, and T

rr

(Figure 3, Figure 12).

The extracted model file is placed in the same folder

as the .exe file of the SW. An example of a generated

netlist is shown in Figure 13.

Figure 10: Two points selected on the DC-bias characteris-

tic.

Figure 11: Two points selected on the junction capacitance

characteristic.

Figure 12: Reverse recovery datasheet’s specifications.

* Diode isl9r3060g2 A K

.subckt isl9r3060g2 1 2

.param Temp_diode=125 k=1.381E-23 q=1.602E-19 Vt=0.03430948

.param Rs=0.02156586 Is=0.0004614982 N=2.460456 Tau=5.909138E-08

+Tm=3.181049E-08

.param VJ=2 CJ0=9.311509E-10 M=0.6974055 FC=0.5

R1 C1 1 {RS}

G1 0 qm VALUE={-1/tau*V(qm)+V(qe,qm)/TM}

C1 qm 0 1

E1 qe 0 VALUE={Is*tau*(exp(V(C1,2)/(N*Vt))-1)}

G2 C1 2 VALUE={V(qe,qm)/TM}

R3 qm 0 100G

D1 C1 2 Cap

.model Cap d (Is=1e-14 N=200 rs=10u Xti=0 Eg=0 CjO={Cj0} M={M} VJ={VJ}

+FC={FC})

.ends isl9r3060g2

Figure 13: Generated netlist of new diode sub-model.

Practical Implementation of Diode SPICE Model with Reverse Recovery

95

6 CONCLUSION

In the work that is being presented, the diode SPICE

model is implemented together with an accurate sim-

ulation of reverse recovery. The study that is given

is based on the physical representation that was first

created in the source (Lauritzen and Ma, 1991). The

current work offers automated diode model develop-

ment based on datasheet specifications from the man-

ufacturer. Open source software is publicly accessi-

ble for diode characterisation and model generation

(ZAIKIN D.I., 2021).

REFERENCES

Analog Devices, Inc. (2008). LTspice - SPICE simulator

software. https://www.analog.com/en/design-center/

design-tools-and-calculators/ltspice-simulator.html.

Accessed 19-05-2023.

Cadence Design Systems, Inc. (2015). PSPICE - Circuit

Simulation. www.pspice.com. Accessed 19-05-2023.

JEDEC Standard No. 282B.01 (2000). Silicon Rectifier

Diodes.

Kielkowski, Ron M (1995). SPICE: Practical Device Mod-

eling. McGraw Hill.

Lauritzen, P. and Ma, C. (1991). A simple diode model

with reverse recovery. IEEE Transactions on Power

Electronics, 6(2):188–191.

ZAIKIN D.I. (2021). Software tool for the article: Prac-

tical implementation of diode SPICE model with re-

verse recovery. https://doi.org/10.6084/m9.figshare.

14912769. Accessed 19-05-2023.

SIMULTECH 2023 - 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

96