Impact of Climate Change on Corroded Reinforced Concrete

Structure in Indonesia Using Web Information Systems and

Technology-Probability Approach

Indra Komara

1,* a

, Priyo Suprobo

2b

and Kivanc Taskin

3c

1

Civil Engineering Department, Institute Technology Adhi Tama Surabaya, Jl. Arif Rahman Hakim 100, Klampis Ngasem,

Sukolilo, Surabaya, East Java, Indonesia

2

Civil Engineering Department, Institut Teknologi Sepuluh Nopember, Jl. Teknik Kimia, Keputih, Sukolilo, Surabaya, East

Java, Indonesia

3

Civil Engineering Department, Eskişehir Teknik Üniversitesi 2 Eylül Kampüsü, 26555 Tepebaşı/Eskişehir, Turkey

Keywords: Climate Change, Probability Approach, Corrosion, Concrete Deterioration, Web Information Technology and

Systems, and Durability Issues.

Abstract: The deterioration of concrete over time, which is influenced by environmental circumstances, is a crucial

factor in determining its durability. This environment may be altered by climate change, accelerating the

deterioration process and affecting the safety, durability, and serviceability of concrete infrastructure,

especially in Indonesia. The concrete deterioration evaluated by the environmental parameter using integrated

web information system provided by the meteorological, climatological, and geophysical agency (BMKG)

website data set using monte Carlo analysis. This approach is used in general to adapt models and investigate

the changing of environment. Climate change connected with the frequency of reinforcing corrosion initiation

and corrosion-induced damage in concrete structures from 2000 to 2023. Since CO

2

concentration and

temperature are the primary causes of increased concrete deterioration, the damage risks will increase.

Change's effect on deterioration cannot be ignored, but it can be countered through innovative design

approaches. Existing concrete structures whose design did not take into account the effects of a changing

climate may deteriorate more quickly than anticipated.

1 INTRODUCTION

In the coming years, infrastructure demand will

increase exponentially. Both developed and

developing countries are investing heavily in their

infrastructure systems to improve quality of life and

economic growth. To accommodate growing

populations and economic growth, developing

countries are investing more in infrastructure

planning and construction. To meet infrastructure

demands, rising Asian countries will need to invest

776 billion dollars every year between 2010 and

2025. (Bhattacharyay, 2012). With 12 billion metric

tonnes used worldwide, concrete is the most widely

used construction material (Ranade, 2014; Yildirim,

a

https://orcid.org/0000-0001-7260-0855

b

https://orcid.org/0000-0003-2521-2280

c

https://orcid.org/0000-0001-8024-4600

Şahmaran and Anil, 2017). It is suited for use in both

developed and developing countries due to the fact

that it is composed of inexpensive and abundant raw

materials. In addition, concrete is a versatile building

material since it can be moulded in a variety of ways

and its mechanical properties may be utilised in a vast

array of structural situations (Taylor and Sæther,

2011).

As a direct result of the widespread usage of

concrete in construction, the material properties and

performance of concrete have a substantial impact on

the global infrastructure's overall health. Concrete is

sadly one of the most fragile materials, despite being

the most commonly used building material. Due to its

brittleness, concrete is susceptible to cracking, which

reduces the durability and sustainability of concrete

Komara, I., Suprobo, P. and Taskin, K.

Impact of Climate Change on Corroded Reinforced Concrete Structure in Indonesia Using Web Information Systems and Technology-Probability Approach.

DOI: 10.5220/0012104500003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 237-246

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

237

structures. Both newly restored and previously

existing concrete structures exhibit deterioration,

corrosion, and faults. The cost retrofitting under

corrosion is estimated to be between 3 and 4 percent

of their gross domestic product (Stewart, Wang and

Nguyen, 2011; Damme, 2018).

In addition, the most significant performance

requirements for the design, building, and

maintenance of concrete structures are safety,

serviceability, and durability (Ding et al., 2018;

Hájková et al., 2018); In spite of this, all three of these

characteristics will worsen as time passes. The rate at

which concrete structures deteriorate is determined

not only by the environment in which they are placed,

but also by the methods and materials used in their

construction. There is a chance that climate change

will drastically impact this environment, especially

over the long term (Kim, McCarter and Suryanto,

2018; Strategy, Carbon and Resilience, 2021). As a

result, concrete deteriorates differently, affecting its

safety, usage, and lifetime. Climate change can

accelerate corrosion by a few percent, resulting in

hundreds of billions of dollars in yearly maintenance

and repair expenses. Corrosion directly and indirectly

costs a lot (Mattei, 2017).

Several research inform climate change as a long-

term environmental effect on building. Humans'

greenhouse gas emissions are blamed for the planet's

climate. The worldwide bank and meteorological,

climatological, and geophysical agency's annual

reports showed a large increase in atmospheric carbon

dioxide (CO

2

) from 280 ppm in 1850 to 490 ppm in

2023, with an accelerating trend (Wang et al., 2010).

The most conservative estimate of the increase in

global temperatures since industrialization due to

greenhouse gas concentrations in the atmosphere is

2.1 degrees Celsius at 450 parts per million (ppm) of

CO2-equivalent, 2.9 degrees at 550 ppm, 3.6 ppm at

650 ppm, 4.3 ppm at 750 ppm, and 5.5 ppm at 1000

ppm (Intergovernmental panel on climate Change,

2000). Over the past century, thermal expansion and

water transfer between oceans and other reservoirs

like glaciers have caused the global mean temperature

and sea level to rise (Asian Development Bank,

2016).

The anticipated increase in both the intensity and

frequency of severe storms may have a substantial

impact on the loading activities that must be

considered when designing concrete structures. This

must be taken into account (Wang, 2009; Stewart,

Wang and Nguyen, 2011). Consequently,

infrastructure will become more vulnerable as a result

of future increases in loads, deterioration, and

capacity loss. This subject will not be discussed

within the scope of this study, which focuses on the

effects of climate change on the deterioration of

concrete (Bastidas-arteaga et al., no date).

As demonstrated in Figure 1, climate change—

variations in CO

2

, temperature, and relative

humidity—can directly or indirectly cause concrete

structures to deteriorate. Environmental pollutants

cause most climate change-related concrete

degradation. Carbon dioxide and chloride cause

reinforcing steel corrosion. Due to increased

diffusivity, steel corrodes, and hazardous compounds

enter faster at higher temperatures. For every 2

degrees Celsius temperature increase, corrosion may

increase by 15%. Elevated CO2 levels, moderate

temperatures, and high humidity promote concrete

deterioration, affecting Indonesia's and all concrete

infrastructure worldwide. This study focuses on

concrete infrastructure, although temperature and

humidity can affect steel structures (Asian

Development Bank, 2016).

Figure 1: The effects of climate change on reinforced

concrete constructions (Asian Development Bank, 2016).

Buildings and infrastructure have a 30-200-year

lifespan; thus, their design, upkeep, and replacement

must reflect the future environment. Despite the

unpredictability of the climate, an event-based Monte

Carlo simulation can be used to assist in the analysis

of potential implications in this decision-making

process (Stewart, 2010; Stewart, Wang and Nguyen,

2011). This system could inform us of the amount of

design and maintenance modifications required to

ensure safety, serviceability, and durability under any

of the known climate change scenarios (Stewart,

2010). 5–10% more CO2 is found in urban air than in

ICATECH 2023 - International Conference on Advanced Engineering and Technology

238

rural air. Carbonation depths of Reinforced Concrete

(RC) structures with 100-year service lives were

evaluated assuming a climate change scenario

involving up to 450 parts per million of carbon

dioxide (Wales and Carolina, 1998).

This study employs a probabilistic and reliability-

based method to predict corrosion start and severe

cracking for Indonesian concrete infrastructure

exposed to carbonation and chloride-induced

corrosion due to increased CO2 levels and

temperatures using web information approach. The

approach is dissected into its component elements in

great detail in this study. This study examines how

various climate change scenarios may affect

Indonesian concrete constructions' longevity and

damage risk. In turn, these realisations would have

equivalent implications for a number of other nations.

2 SIMULATION AND

PROBABILISTIC MODELLING

USING WEB INFORMATION

SYSTEM

Figure 2 shows that a probabilistic simulation was

used to model carbonation and chloride penetration-

driven concrete degradation. The concept using

analytical approach followed by web-based

illustration technology. Probabilistic modelling of

material property, dimension, model error, ambient

conditions, and uncertainties is used. CO

2

concentration, annual mean temperature, and relative

humidity. Climate influence under reinforced

concrete—corrosion assessment Calculating climate

risk for typical Portland cement–concrete structures

above ground using Life 365 v2.2.

The modelling and simulation approach the

research conducted by Stewart et al. (Stewart, 2010)

and Wang et al.'s study (Wang, 2009). Multiple

models are simulated to comply the comparison

criteria. Time dependant also created as parameter,

followed by environmental parameter. The results

show penetration depth distributions, means, and the

risk of corrosion and damage.

2.1 Corrosion Modelling

Steel reinforcement corrosion can be caused by

carbonation of the concrete cover and chloride

concentrations in excess of a critical threshold. This

cycles parameter is the more common cause of

corrosion. In every circumstance, the expanding

corrosion products cause tensile pressures to be

exerted on the concrete, which ultimately results in

spalling, cover cracking, and a loss of structural

strength. This type of corrosion-related damage is not

only costly but also disruptive to society.

Figure 2: Simulation of reinforced concrete deterioration

under climate change (Al-ostaz et al., 2010).

To account for time-dependent variations in CO

2

concentration, temperature, and relative humidity,

numerous deterioration models need to be adjusted.

2.1.1 Carbonation Penetration Models

The DuraCrete model is considered to be adapted on

which the carbonation depth is assisted (DuraCrete,

1998). It includes time-dependent CO

2

(t) and

temperature f

T

modifications. Those criteria are

distinguished by the carbonation depth model, based

on the model proposed by DuraCrete, with time-

dependent CO

2

(t) and temperature f

T

corrections (t),

which characterized by several equations as follow:

𝑥

(𝑡

)≈

2

𝑓

(𝑡

)𝐷

(𝑡

−2000)

𝑎

𝑘

(1)

Impact of Climate Change on Corroded Reinforced Concrete Structure in Indonesia Using Web Information Systems and

Technology-Probability Approach

239

𝐶

(𝑡

)𝑑𝑡

1

𝑡

−2000

where:

𝐷

(

𝑡

)

=𝐷

𝑡

(2)

𝑎=0.75𝐶

𝐶

𝑂

∝

𝑀

𝑀

(3)

𝑓

(

𝑡

)

≈𝑒

(

)

(4)

𝑇

(𝑡

)≈

∑

𝑇

(

𝑡

)

𝑡

−2000

(5)

CCO

2

(t) is the illustrated time-dependent considering

mass of atmospheric concentration a molecule of

carbon dioxide in 10

-3

kg/m

2

where t is time in years

and t' is the year commencing in the first investigated

in this case a year of 2000. DCO

2

(t) is a carbon

dioxide diffusion coefficient inside concrete, D

1

is the

carbon dioxide diffusion coefficient after one year,

and n

d

is the age factor for the carbon diaxoide

diffusion coefficient. CaO represents the ratio of

calcium oxide concentration in cement; H represents

the degree of hydration; MCaO represents the weight

of molar mass of calcium oxide; and MCO

2

represents the molar mass of carbon dioxide. f

T

(t') is

the temperature (nm) associated with the frequency of

wetting and drying cycles (assuming nm = 0 for factor

of the diffusion coefficient compared to one at 20°C,

E is the diffusion activation energy in kJ/mol, and R

is the constant gas. Carbonation occurs at RH 40–75%

or 50–70% (Bouzoubaâ et al., 2010; Stewart, Wang

and Nguyen, 2011). Another research state that where

the RH below 30% there is little or no carbonation

(Kaewunruen et al., 2018), However, carbonation

processes cannot occur below 50% RH (Atiş, 2003).

2.1.2 Chloride Penetration Models

Diffusion equations form the chloride penetration

model can be seen in Equation (3) followed the

popular model (DuraCrete, 1998). C(x,t) describes

the chloride concentration across depth x at time t or

a calendar year t', t = t+2000.

𝐶

(

𝑥,𝑡

)

=𝐶

1−𝑒𝑟𝑓

𝑥

2

𝑘

𝑘

𝑘

𝑓

(

𝑡

−2000

)

𝑥

𝐷

1

𝑡

−2000

(

𝑡

−2000

)

(6)

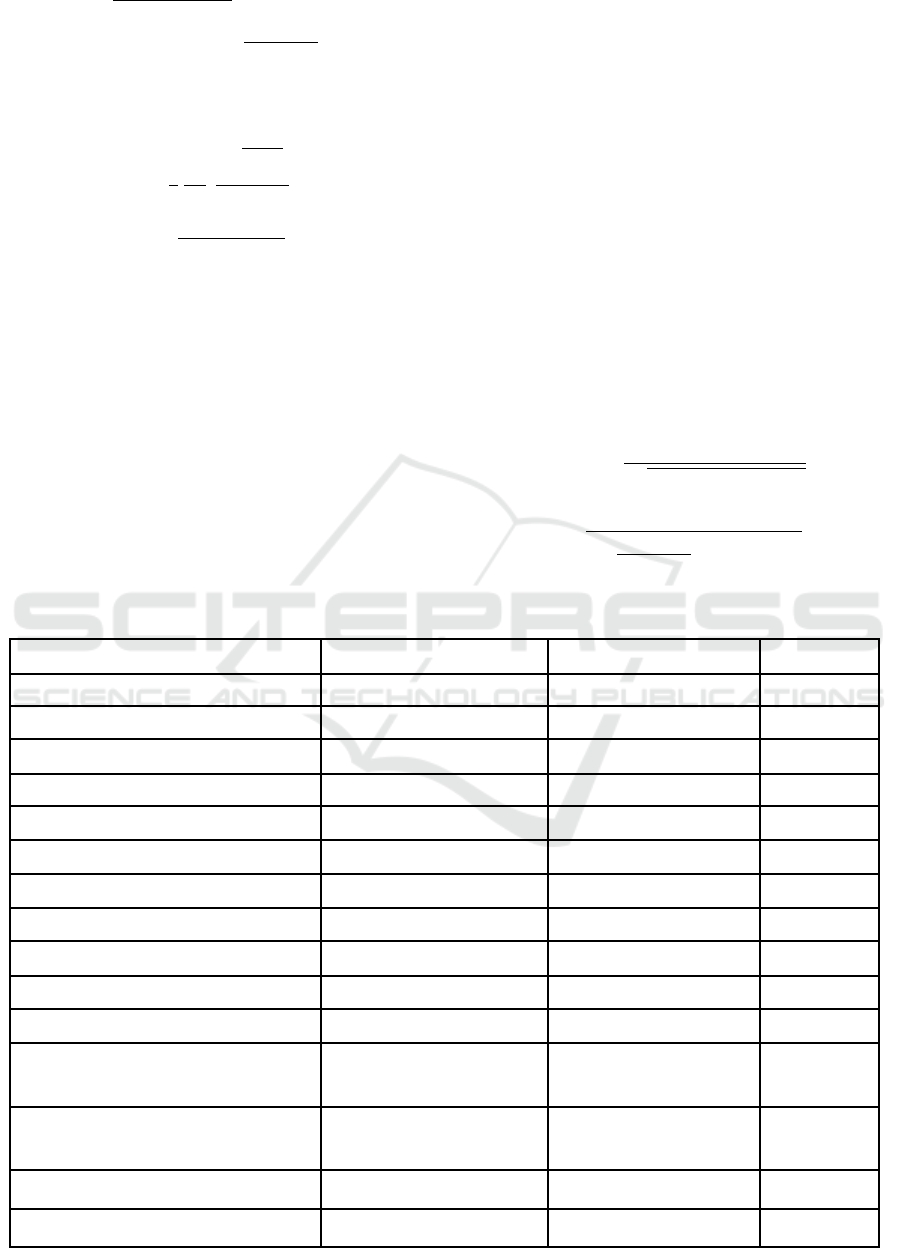

Table 1: Corrosion parameter, material properties and dimension adapted from Stewart (Stewart, 2010).

Parameter Mean COV Distribution

f

c

(28) 1.03f’

c

0.18 Normal

CO

2

diffusion coeff. (D

1

)

0.47 – 2.22 × 10

-4

cm

2

s

-1

σ = 0.15 Normal

Age factor – Carbonation (n

d

) 0.19 – 0.240 0.12 Normal

Age factor – Chloride (n) 0.37 – 0.65 σ = 0.07 Normal

Environmental factor (k

e

) 0.265 – 0.924 σ = 0.05 – 0.16 Normal

Diffusion coefficient (D

c

)

7 – 15 ×10

-12

cm

2

s

-1

0.285 Normal

Model Error for crack propagation 1.04 0.09 Normal

k

urban

1.15 0.10

Normal

1

Cover C

nom

+ 6 mm σ =11.5 mm

Normal

2

Surface chloride concentration

1.15 – 7.35 kg/m

3

0.5 – 0.7 Normal

Critical chloride concentration

3.35 kg/m

3

0.375

Normal

3

Corrosion rate (i

corr-20

) – Carbonation

0.17 – 0.43 μA/cm

2

σ = 0.086 – 0.259

μA/cm

2

Lognormal

Corrosion rate (i

corr-20

) – Chloride

2.586 – 6.035 μA/cm

2

σ = 1.724 – 3.448

μA/cm

2

Lognormal

f

t

0.53(f

c

)

0.5

0.13 Normal

E

c

4600(f

c

)

0.5

0.12 Normal

ICATECH 2023 - International Conference on Advanced Engineering and Technology

240

Table 2: Concrete design class category in accordance with SNI 2847 – 2019.

Figure 3: Climate change scenarios for period 100 years (Al-ostaz et al., 2010).

The concentration of surface chloride is denoted

by C

0

, the coefficient of diffusion is denoted by D

c

,

the age factor is denoted by n, and the environmental

component of concrete is denoted by k

e

. k

c

and k

t

refer

to the curing factor and the test technique,

respectively. This study does not take into account the

influence that relative humidity has on chloride

absorption. Because of the reduction in relative

humidity caused by climate change, equation (6) does

not include chloride penetration.

In fact, the characterization of first evaluation is

employed

by using Equation (6), which can be

Exp.

class

Maximum

w/cm

1

Minimum

f’

c,

Mpa

Cementitious materials

2

-types

Calcium

chloride

admixture

ASTM C150 ASTM C595

ASTM

C1157

S0 T/A 17 No type of restriction

S1 0.50 28

II

3,4

Type IP, IS or IT

with (MS)

designation

MS

Not restriction

S2 0.45 31

V

4

Type IP, IS or IT

with (HS)

designation

HS

Not restriction

S3 0.45 31

V plus pozzolan

or slag cement

5

Type IP, IS or IT

with (HS)

designation plus

pozzolan or slag

cemen

t

5

HS plus

pozzolan or

slag

cement

5

Not permitted

W0 N/A 17 None

W1 0.50 28 None

Maximum water-soluble chloride

ion (Cl–) content in concrete,

percent by weight of cement

6

Additional provisions

No prestressed

concrete

Prestressed

concrete

C0 N/A 17 1.00 0.06 None

C1 N/A 17 0.30 0.06

C2 0.40 35 0.15 0.06

Concrete cover

7

Impact of Climate Change on Corroded Reinforced Concrete Structure in Indonesia Using Web Information Systems and

Technology-Probability Approach

241

Figure 4: Result summary using web-based information category in Indonesia (Meteorological, climatological, and

geophysical agency, 2023).

accessed to identify the current condition and the

expected model criteria. Where, the corroded

condition parameter in accordance with the actual

corrosion value of Equation (7).

𝑖

(𝑡)=𝑖

1+𝐾

(

𝑇

(

𝑡

)

−20

)

(7)

where i

corr

20 is the corrosion rate at 20°C and K =

0.025, at least for temperature below 20°C but may

be conservative for T(

t

)>20°C. DuraCrete researched

both values. Equation (7) states that a 2°C

temperature increase increases corrosion by 15%

(Bamforth, 1997; DuraCrete, 2000; Alexander and

Beushausen, 2019).

2.2 Probability of Corrosion Initiation

and Corrosion Damage

When carbonation depth reaches the reinforcing bar's

surface or chloride concentration above the critical

chloride concentration, corrosion ensues. Corrosion

requires these two conditions (Stewart, 2010). The

following equations show the cumulative likelihood

of corrosion starting at time t or calendar year t':

𝑝

(

𝑡′

)

=

Pr

ℎ−𝑥

(

𝑡′

)

<0

Pr

𝐶

(

ℎ,𝑡′

)

−𝐶𝑟<0

(8)

In accordance to Equation above, h symbolises the

concrete cover, x

c

(t) illustrate as the carbonation

depth, C(h,t) alternate as the chloride concentration,

and C

r

the critical chloride concentration. Thus, t = t'

- 2000.

The RC corrosion normally causes by damaged of

the cover or the concrete can easily absorb the water

from outside which interact with the reinforcement

bars. When a crack is wider than one millimetre,

corrosion damage may develop. Then, when the

cracks are in extreme condition, it will lead to

delaminated stage, where all the concrete cover

spalling. This cracks parameter was determined

through simulation using fracture initiation and

propagation models. These models computed the

duration of severe cracking and spalling considering

some past research created by some researches

(Komara et al., 2019, 2020, 2021; Mooy et al., 2020;

Susanti et al., 2021) and are primarily impacted by

cover, concrete strength, and corrosion rate. The

likelihood of corrosion damage is then calculated as

follows:

𝑝

(

𝑡

)

=𝑃𝑟𝑡≥𝑇

(9)

3 STUDY OF PROBABILITY

ANALYSIS OF CORRODED RC

Deterioration of concrete, particularly in RC

structures, is caused by environmental exposures that

can be categorised using a variety of criteria. Past

researchers (Alexander, Dehn and Moyo, 2008)

classifies exposure in regard to the type of

deterioration. In comparison AS3600 (Australian

Standard, 2009) is used to assesses exposure based

on the concrete structure's distance from the coast or

ICATECH 2023 - International Conference on Advanced Engineering and Technology

242

sea, climate (arid, temperate, and tropical), and

industrial zones. Since Indonesian and Australian

environments are similar. In fact, Indonesia exposure

classified by SNI 2847-2019 (Badan Standardisasi

Nasional, 2019) where in detail it is divided into three

categories, S0, S1, S2, S3 (sulphate group), W0 – W1

(in contact with water) and C0 – C2 (corrosion

protection of reinforcement), more information can

be seen in Table 2 this standard also related with ACI

318-14 (American concrete Institute, 2014).

Figure 4 approximates the environmental

exposure of concrete structures in Indonesia, which

depends on temperature, relative humidity, and K-

index. Figure 4 illustrates all Indonesian

archipelagos. which encompasses Borneo, Java, the

Lesser Sunda Islands, Sulawesi, Sumatra, and West

Papua. Each place has its own condition. This

webpage links global demographic statistics confirm

the actual situation cited by annual database

https://www.worlddata.info/asia/indonesia/index.php

(WorldData, 2023) and BMKG (Meteorological,

climatological, and geophysical agency, 2023)

provide records from the previous seventy-three years

which can be accessed through the website processing

by https://www.bmkg.go.id/iklim/?p=tren-suhu. This

data is inputted to conduct the probability analysis.

As a type of additional analysis, inputted distance

exposure also included as design parameter (see

Table 3). This parameter is derived from an

equivalent geographical location to the one being

compared. The combination criterion as a category

for exposure in relation to the minimum cement

concentration and w/c ratio is presented in Table 4.

These two categories are also considered for inclusion

in the evaluation criteria.

Table 3: Exposure class classification varied by nominal

concrete strength.

Exposure

classification

Nominal concrete cover divided by

characteristics strength

unit [MPa] 20 25 32 40 ≥ 50

≥ 50 km 20-50 20-30 20-25 20 20

1 – 50 km 60 40-65 30-45 25-50

≤ 1 km 70 50-65

Table 4: exposure classification to w/c ratio.

Exposure

classification

Minimum cement

content (kg/m3)

Maximum water

/ cement ratio

≥ 50 km 320 0.56

1 – 50 km 320 - 370 0.50 – 0.46

≤ 1 km 420 0.4

The record earlier data created by BMKG, which

is based on a multi-model dataset by the program for

climate model diagnostics (see Figure 4), are also

evaluated for climate change projections.

(Meteorological, climatological, and geophysical

agency, 2023).

As illustrated in Figure 4-5, temperature (T) and

relative humidity (RH) in 2023 based on BMKG,

respectively, T

min

8, T

max

12 and RH

min

5.3%, RH

max

100%. The T and RH in the range of 8% and 70%

increase from 1999. It should be indicated that the

environmental change my be provided by BKMG

models, but they appear mostly to provide similar

trends for all environmental conditions, including

wheatear i.e., rain and wind. Within such range,

change in carbonation and chloride penetration

induced corrosion may not be small enough to be

ignored.

4 DISUCSSION

Simulations suggest that as a result of climate change,

concrete buildings may become both more fragile and

more resistant to damage. The threat posed by climate

change cannot be disregarded in Indonesia or

anywhere else given the fact that increases in CO

2

and

temperatures will have an effect on most, if not all, of

the world's places.

The evaluation of the impact places more of an

emphasis on the relative change in corrosion start and

damage risks as a result of higher CO

2

levels and

temperature compared to values in the year 2000 than

it does on absolute risk forecasts. This is because

higher temperatures and higher CO

2

levels both

increase the likelihood of corrosion starting. This is

due to the fact that both the temperature and the levels

of CO

2

are forecasted to keep climbing over the next

few years. On the other hand, these models are based

on the assumption that the surrounding environment

would not change. Determining the extent to which

environmental factors that are dependent in both time

and space may play a role in the deterioration of

concrete is currently one of the most pressing

questions facing the scientific community. If it turns

out that other models of deterioration are more

applicable, including them into the stochastic and

reliability framework that has been given in this

research won't be a difficult task at all. Even though

different models of deterioration will each generate

their own one-of-a-kind estimates of absolute risk, the

choice of deterioration model ought to have less of an

impact on comparative risks. This is the case despite

the fact that there are multiple models of deterioration.

Impact of Climate Change on Corroded Reinforced Concrete Structure in Indonesia Using Web Information Systems and

Technology-Probability Approach

243

Figure 5: Environment exposure in Indonesia due to (a) Temperature, (b) Relative humidity and (c) K-index (Meteorological,

climatological, and geophysical agency, 2023).

ICATECH 2023 - International Conference on Advanced Engineering and Technology

244

Responses to this change in risk will be new

procedures and materials can reduce corrosion risk in

unbuilt structures. Existing concrete structures can be

made more durable to reduce climate change. Cover

design, cement and mix selection, surface coating

barriers, extraction, and cathodic protection are

examples. A new design might reduce environmental

exposure by enhancing cover and strength grade and

lowering material diffusion coefficient without

harming concrete durability and serviceability. Our

research will highlight the design improvements

needed to maintain concrete structure durability.

Climate change is projected to accelerate the

decay of many existing concrete structures that did

not account for environmental changes. A little

increase in damage hazards could cost hundreds of

billions or trillions of dollars in maintenance and

repair. A cautious approach would propose enhanced

monitoring and maintenance of concrete structures

because this risk varies widely based on location,

environmental exposure, and material design, making

it impossible to predict for each structure. This

research shows that site-specific costs and benefits

will be critical for successful adoption.

5 CONCLUSIONS

In order to evaluate the probabilities of corrosion

initiation and corrosion damage for existing concrete

infrastructure in Indonesia that is subject to climate

change in the current year, which shows future

change, a time-dependent probability study has been

carried out. Compared to the previous figure,

forecasts of atmospheric CO

2

concentration, local

temperature, and humidity changes across the

Indonesian continent for the next 100 years will

increase. The probabilistic study factored in the

unpredictability of CO

2

concentration, degradation

processes, material characteristics, dimensions, and

predictive models. Carbonation-induced damage

risks have been found to rise similarly to the

environment during the past year. The risk of

corrosion due to chloride increases by less than 10

percent, as indicated by the larger figure. The results

were especially sensitive to fluctuations in

atmospheric CO

2

levels. Since CO

2

concentration and

temperature are the key drivers of accelerated

concrete deterioration, the elevated infrastructure

damage risks in Indonesia are anticipated to be

observed in many other concrete infrastructures

across the world. Existing concrete structures whose

design does not account for the effects of climate

change may deteriorate more quickly than expected.

ACKNOWLEDGEMENTS

In accordance with the research strategy of

collaboration No.1031/PKS/ITS/2022 with Eskisehir

Technical University, the author would like to

express their gratitude to the ITS – department of civil

engineering as well as the ITS – laboratory of

concrete, advanced materials, and computational

mechanics for their assistance in conducting this

study.

REFERENCES

Al-ostaz, A. et al. (2010) ‘Deterioration of Bond Integrity

between Repair Material and Concrete due to Thermal

and Mechanical Incompatibilities’, (4), pp. 136–145.

Alexander, M. and Beushausen, H. (2019) ‘Durability,

service life prediction, and modelling for reinforced

concrete structures – review and critique’, Cement and

Concrete Research. Elsevier, 122(April), pp. 17–29.

doi: 10.1016/j.cemconres.2019.04.018.

Alexander, M. G., Dehn, F. and Moyo, P. (2008) Concrete

Repair, Rehabilitation and Retrofitting II, Concrete

Repair, Rehabilitation and Retrofitting II. doi:

10.1201/9781439828403.

American concrete Institute (2014) Building Code

Requirements for Structural Concrete, American

Concrete Institute.

Asian Development Bank (2016) Indonesia Country Water

Assessment.

Atiş, C. D. (2003) ‘High-volume fly ash concrete with high

strength and low drying shrinkage’, Journal of

Materials in Civil Engineering, 15(2), pp. 153–156.

doi: 10.1061/(ASCE)0899-1561(2003)15:2(153).

Australian Standard (2009) ‘AS 3600-2009 Concrete

structures’, in, pp. 50–59.

Badan Standardisasi Nasional (2019) ‘Persyaratan Beton

Struktural Untuk Bangunan Gedung Dan Penjelasan

Sebagai Revisi Dari Standar Nasional Indonesia. SNI

03-2847:2019’, Badan Standarisasi Nasional, (8), pp.

1–695.

Bamforth, P. (1997) ‘Probabilistic Performance Based

Durability Design of Concrete Structures’.

Bastidas-arteaga, E. et al. (no date) ‘Influence of global

warming on durability of corroding RC structures : a

probabilistic approach’, 33(0), pp. 1–30.

Bhattacharyay, B. (2012) Estimating Demand for

Infrastructure in Energy, Transport,

Telecommunications, Water, and Sanitation in Asia and

the Pacific: 2010-2020, SSRN Electronic Journal. doi:

10.2139/ssrn.1678417.

Bouzoubaâ, N. et al. (2010) ‘Carbonation of fly ash

concrete: Laboratory and field data’, Canadian Journal

of Civil Engineering, 37(12), pp. 1535–1549. doi:

10.1139/L10-081.

Damme, H. Van (2018) ‘Cement and Concrete Research

Concrete material science : Past , present , and future

Impact of Climate Change on Corroded Reinforced Concrete Structure in Indonesia Using Web Information Systems and

Technology-Probability Approach

245

innovations ☆’, Cement and Concrete Research.

Elsevier, (May), pp. 0–1. doi:

10.1016/j.cemconres.2018.05.002.

Ding, Y. et al. (2018) ‘Structural behaviors of ultra-high

performance engineered cementitious composites

(UHP-ECC) beams subjected to bending-experimental

study’, Construction and Building Materials. Elsevier

Ltd, 177, pp. 102–115. doi:

10.1016/j.conbuildmat.2018.05.122.

DuraCrete (1998) ‘DURACRETE – PROBABILISTIC

PERFORMANCE BASED DURABILITY DESIGN

OF CONCRETE STRUCTURES’, pp. 1–10.

DuraCrete (2000) ‘BE95 1347 DuraCrete - Probabilistic

performance based durability of corrosion strucutres’,

in, pp. 50–68.

Hájková, K. et al. (2018) ‘Prediction of reinforcement

corrosion due to chloride ingress and its e ff ects on

serviceability’, 174(February), pp. 768–777. doi:

10.1016/j.engstruct.2018.08.006.

Intergovernmental panel on climate Change (2000) IPCC

SPECIAL REPORT EMISSIONS SCENARIOS.

Kaewunruen, S. et al. (2018) ‘Vulnerability of structural

concrete to extreme climate variances’, Climate, 6(2),

pp. 1–13. doi: 10.3390/cli6020040.

Kim, J., McCarter, W. J. and Suryanto, B. (2018)

‘Performance assessment of reinforced concrete after

long-term exposure to a marine environment’,

Construction and Building Materials. Elsevier Ltd,

192, pp. 569–583. doi:

10.1016/j.conbuildmat.2018.10.151.

Komara, I. et al. (2019) ‘Engineered Cementitious

Composite as an innovative durable material: A

review’, ARPN Journal of Engineering and Applied

Sciences, 14(4), pp. 822–833.

Komara, I. et al. (2020) ‘Experimental investigations on the

durability performance of normal concrete and

engineered cementitious composite’, IOP Conference

Series: Materials Science and Engineering, 930(1). doi:

10.1088/1757-899X/930/1/012056.

Komara, I. et al. (2021) ‘Behaviour of Reinforced Concrete

Beams with and Without Web Openings using Direct

Displacement Based Design’, Journal of Physics:

Conference Series, 2117(1), p. 012006. doi:

10.1088/1742-6596/2117/1/012006.

Mattei, N. J. (2017) ‘A comprehensive assesment of

Americas’s Infrastructure’, in Infrastructure Report

Card ASCE. 2017th edn. Washington: ASCE, pp. 1–

112. Available at:

https://www.infrastructurereportcard.org/.

Mooy, M. et al. (2020) ‘Evaluation of Shear-Critical

Reinforced Concrete Beam Blended with Fly Ash’, IOP

Conference Series: Earth and Environmental Science,

506, p. 012041. doi: 10.1088/1755-1315/506/1/012041.

Ranade, R. (2014) ‘Advanced Cementitious Composite

Development for Resilient and Sustainable

Infrastructure’, p. 419.

Stewart, M. G. (2010) ‘Life-Cycle Cost Assessment of

Climate Change Adaptation Measures to Minimise

Carbonation-Induced Corrosion Risks’, 2, pp. 35–46.

Stewart, M. G., Wang, X. and Nguyen, M. N. (2011)

‘Climate change impact and risks of concrete

infrastructure deterioration’, Engineering Structures.

Elsevier Ltd, 33(4), pp. 1326–1337. doi:

10.1016/j.engstruct.2011.01.010.

Strategy, L., Carbon, L. and Resilience, C. (2021)

‘Indonesia Long-Term Strategy for Low Carbon and

Climate Resilience 2050 (Indonesia LTS-LCCR

2050)’.

Susanti, E. et al. (2021) ‘Effect of fly ash to water-cement

ratio on the characterization of the concrete strength’,

IOP Conference Series: Materials Science and

Engineering, 1010, p. 012035. doi: 10.1088/1757-

899x/1010/1/012035.

Taylor, P. and Sæther, I. (2011) ‘Structure and

Infrastructure Engineering : Maintenance ,

Management , Life-Cycle Design and Performance

Bond deterioration of corroded steel bars in concrete’,

(November 2014), pp. 37–41. doi:

10.1080/15732470802674836.

Wales, N. S. and Carolina, S. (1998) ‘Time-dependent

reliability of deteriorating reinforced concrete bridge

decks’, 4730(97).

Wang, X. (2009) ‘Hazard of extreme wind gusts to

buildings in Australia and its sensitivity to climate

change’, (July), pp. 2576–2582.

Wang, X. et al. (2010) ‘Analysis of Climate Change

Impacts on the Deterioration of Concrete Infrastructure

Part 3: Case Studies of Concrete Deterioration and

Adaptation’, CSIRO Climate Adaptation Flagship, p.

128.

Yildirim, G., Şahmaran, M. and Anil, Ö. (2017) Engineered

cementitious composites-based concrete, Eco-efficient

Repair and Rehabilitation of Concrete Infrastructures.

doi: 10.1016/B978-0-08-102181-1.00015-0.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

246