Modelling of Structural Strengthening Techniques for Existing

Building and Structures: Case Study Club House Graha Natura

Under Lift Loading Using Carbon Fibre-Reinforced Polymer (CFRP)

Eka Susanti

1,2 a

, Heri Istiono

1,2 b

, Indra Komara

1,* c

, Dewi Pertiwi

1d

, Jaka Propika

1,2 e

,

Yanisfa Septiarsilia

1,3 f

, Dita Kamarul Fitria

1,3 g

and Alexandria Inka Yayan

1

1

Civil Engineering Department, Institute Technology Adhi Tama Surabaya,

Jl. Arif Rahman Hakim 100, Klampis Ngasem, Sukolilo, Surabaya, East Java, Indonesia

2

Civil Engineering Department, Petra Christian Unviersity,

Jl. Siwalankerto No.121-131, Siwalankerto, Surabaya, 60236, East Java, Indonesia

3

Civil Engineering Department, Institut Teknologi Sepuluh Nopember,

Jl. Teknik Kimia, Keputih, Sukolilo, Surabaya, East Java, Indonesia

jakapropika@itats.ac.id, yanisfa.septi@itats.ac.id, ditaka.fitriyah@itats.ac.id, Alexandriainkayayan21@gmail.com

Keywords: Carbon Fibre-Reinforced Polymer (CFRP), RC Members, Strengthening, Modelling, Rehabilitation

Abstract: The carbon fibre-reinforced polymer, also known as CFRP, is a relatively new type of reinforcement that is

being used in concrete materials. It possesses a number of desirable mechanical and physical properties. In

addition to its other mechanical properties, CFRP possesses excellent compressive, flexural, and shear

strengths. Furthermore, the use of CFRP has enhanced ductility and makes it suitable for preventing cracks.

The research was carried out by contrasting the results of an independent computation of FRP-confined RC

section ductility with those of an analysis produced by SAP2000 under case study of Club house graha natura.

This comparison included the capacity of beam section added using CFRP. The existing building constructed

without consideration of lift loading which is affect the loading distribution. CFRP offer the additional

strength to support lift loading without changing the whole structure dimension significantly. The accuracy

of the software response that is being examined in this research was significantly improved by defining the

properties of the retrofitted material by using a variety of different approaches.

1 INTRODUCTION

Concrete structures that are susceptible to sustaining

a variety of forms of damage as a result of the

occurrence of natural disasters such as earthquakes,

fires, or hurricanes, in addition to other factors such

as errors in design, are referred to as "concrete

structures at risk." (Gagg, 2014; Jensen, Kovler and

Belie, 2016). A member of the concrete structure may

only have a small amount of reinforced steel or fibre,

meaning that it is unable to withstand any bearing

a

https://orcid.org/0009-0009-4773-729X

b

https://orcid.org/0009-0002-7220-3846

c

https://orcid.org/0000-0001-7260-0855

d

https://orcid.org/0009-0008-1010-1872

e

https://orcid.org/0009-0008-5622-9513

f

https://orcid.org/0009-0008-4486-1810

g

https://orcid.org/0009-0008-9954-0184

loads (Maalej and Leong, 2005; Khairi et al., 2021).

In a similar situation, shock loads from explosions,

changes to the construction's function, and increased

service loads on construction members that were not

accounted in the initial design all prevent the

constructions from performing their intended

functions. On the other hand, additional strengthening

support identify the service category (Arrangement et

al., 2013; Yildiz et al., 2019).

Under these circumstances, demolishing and

rebuilding concrete members is an inefficient

62

Susanti, E., Istiono, H., Komara, I., Pertiwi, D., Propika, J., Septiarsilia, Y., Fitria, D. and Yayan, A.

Modelling of Structural Strengthening Techniques for Existing Building and Structures: Case Study Club House Graha Natura Under Lift Loading Using Carbon Fibre-Reinforced Polymer

(CFRP).

DOI: 10.5220/0012107300003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 62-68

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

procedure when accounting for the cost, the effort,

and the amount of time involved (Novák, 2012;

Sonebi, Ammar and Diederich, 2016). As a result,

engineers have decided that the most effective course

of action is to reinforce and restore existing

construction members (ACI Committee 116, 2000;

Thanoon et al., 2005; Alexander, Dehn and Moyo,

2015). The first thought that came to mind was to

make the reinforced concrete (RC) components have

a larger cross-sectional dimension. However, this

approach increases concrete member durability and

changes space dimensions, especially in deep beams.

Due to these issues, new methods were developed,

such as raising threshold supports and concrete

member reinforcement ratios (Eide, Hisda and L,

2012). Nevertheless, these techniques resulted in an

increase in the structural loads in addition to other

issues. Researchers made ongoing efforts to find

other substitute methods and alternative materials to

overcome the loss caused by the problems that were

described earlier. They found that exterior packaging

made of polymeric fibres including carbon, aramid,

and glass fibre-reinforced polymer (FRP) concrete

strengthens and repairs concrete elements due to their

good mechanical and physical qualities (An,

Saadatmanesh and Ehsani, 1991; Maalej and Leong,

2005).

Figure 1: CFRP materials for strengthening and repair

purposes (Wu and Li, 2017).

CFRP can also be used to repair or strengthen

existing concrete. Previous CFRP research has

yielded promising results. Many research initiatives

have examined how CFRP affects normal concrete's

mechanical properties. However, CFRP modeling for

reinforcing and repairing concrete is limited and lacks

applications. Thus, to apply CFRP to NC, all essential

data must be collected. Based on the literature

evaluation, future research should highlight an

additional research gap and inadequate data (Asaei,

Lau and Bunnori, 2013; Hassan, Sherif and

Zamarawy, 2017).

Although steel-reinforced concrete members

provide superior strength, strengthening concrete

members is hampered by a number of factors, the

most significant of which are the weight of the

concrete members and the corrosion that occurs over

time, especially when exposed to significant

exposure. Additionally, restoring damage with steel

reinforcement in concrete is impossible (Wu and Li,

2017). Carbon, aramid, and glass fiber reinforced

polymers (FRP) are better for reinforcing and

rebuilding concrete sections due to their benefits (see

Figure 2).

Figure 2: Advantages and disadvantages of CFRP and

illustration of CFRP product (Mustafaraj and Yardim,

2018).

The CFRP is not only lightweight but also sturdy,

as it possesses a high tensile strength, stiffness,

resistance to chemicals and corrosion, and minimal

thermal expansion (Osman et al., 2016). Despite the

fact that CFRPs are more expensive than other

construction materials, they are frequently used in

situations that call for a high strength-to-weight

relation (Bukhari et al., 2010; Khairi et al., 2021). In

the construction industry, CFRPs are frequently used

to reinforce concrete, steel, and masonry structures.

This can be accomplished either by retrofitting

already-existing structures to increase their strength

or by using CFRPs as an alternative reinforcing

material to steel (Wu and Li, 2017). The primary

application of CFRP involves on retrofitting structure

to enhance load capacity and lower the damage. The

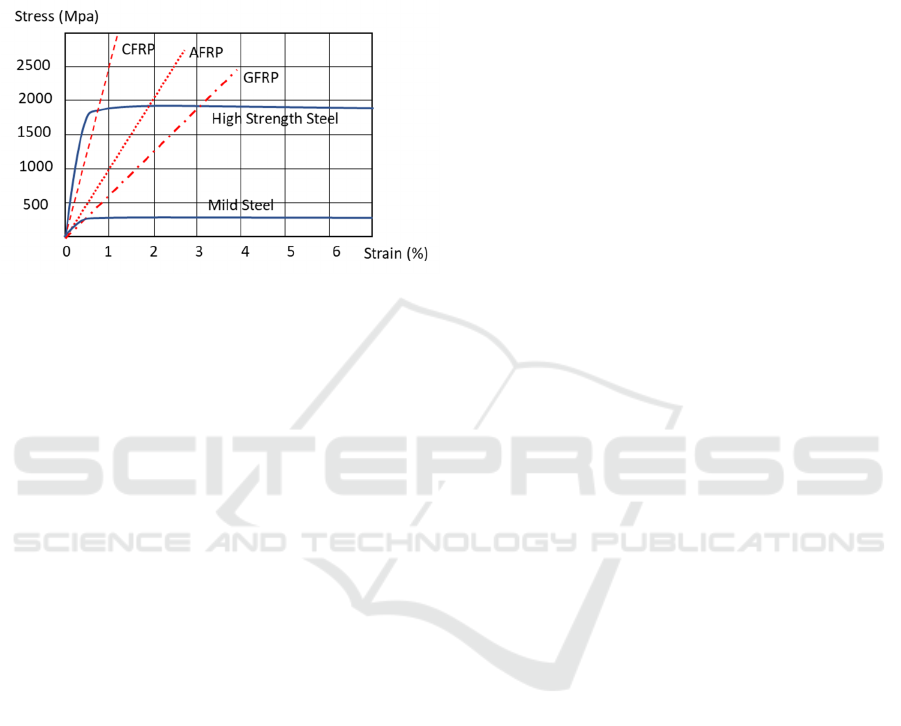

illustration properties of CFRF under various type vs.

steel presented in Figure 3. Not only that, to support

utilities, opening somehow necessary to be placed on

the structure (Komara et al., 2021; Pertiwi, Komara

and Fristian, 2021), FRP offer strengthening without

changing the conditions. FRP also popular to increase

durability performance especially when the it is

Modelling of Structural Strengthening Techniques for Existing Building and Structures: Case Study Club House Graha Natura Under Lift

Loading Using Carbon Fibre-Reinforced Polymer (CFRP)

63

attract the significant environmental compared to

high strength concrete (Komara et al., 2020; Casita,

Suswanto and Komara, 2022), concrete with

supplementary materials (Mooy et al., 2020) or

engineered cementitious concrete (Komara et al., no

date; Oktaviani et al., 2020).

Figure 3: CFRP strength properties vs steel (Hassan, Sherif

and Zamarawy, 2017).

2 STRENGTHENING RC

MEMBERS USING CFRP

FRP is increasingly used as reinforcement in RC

members due of its ultra-high strength and flexibility.

FRPs are durable, corrosive-resistant, and low-

maintenance (Thanoon et al., 2005). Recently, FRP

bars and sheets have proven to have endless promise

as a steel plate substitute for reinforcing or repairing

concrete structures (Maalej and Leong, 2005; Osman

et al., 2016).

In addition, FRP has established itself as a viable

option for the strengthening of RC members in

applications where the use of conventional

strengthening procedures might be difficult and

fraught with complications (Gu, Pan and He, 2019).

A method for increasing the strength of RC members

that involves externally epoxy-bonding steel plates is

comparable to the FRP approach. This method is very

prevalent and widely used. This method is

straightforward, useful, and economical all at the

same time. Nevertheless, this method is plagued by a

number of drawbacks and challenges, including the

following: the challenge of installing the heavyweight

steel plates at the construction site; the weakening of

the bond between the steel and the concrete as a result

of the corrosion of the steel; and the restricted

delivery lengths of steel plates (for the purpose of

reinforcing the long construction members) (Asaei,

Lau and Bunnori, 2013).

In circumstances such as these, FRP laminates,

sheets, and bars are evaluated as potential

replacements for steel plates in the context of the

strengthening of RC elements. Therefore, fiber

reinforced plastic (FRP) could be used in place of

steel for the purpose of reinforcing and repairing RC

members due to the fact that it is simple to install, has

a wide range of availability (in terms of length and

type), is simple to transport, requires minimal

maintenance, has a reduced influence from corrosion,

and possesses a number of other desirable

characteristics.

The effect of CFRP fortification on the general

behavior and failure modes of RC members has been

the subject of a great deal of research, and it has been

evaluated in a number of different ways.

Nevertheless, each of these studies recommended a

unique method of putting CFRP materials in place.

The carbon fiber reinforced plastic (CFRP)

components that are used in construction are typically

accessible in the form of sheets and bars (strips).

Additionally, these CFRP sheets and segments can be

installed in RC members according to the specific

requirements of the construction application. It is

possible to bind CFRP composite strips to the

external tension zones of beams and slabs, which will

result in an increase in the flexural strength of the RC

members. On the other hand, CFRP sheets can be

wrapped around RC columns to increase containment

and axial strength (Gao and Cai, 2015; Triantafillou,

2016). This is illustrated in the figure. Furthermore,

CFRP enhances ductility and shear strengthening in

columns and beams, in addition to increasing flexural,

shear, and torsion strengths (Inge, Nugroho and Njo,

2018; Muthukumaraswamy kamalakannan et al.,

2021).

3 CASE STUDY

3.1 Design Parameter of CFRP

The calculation of the bearing capacity of the flexural

members should meet the basic assumptions of the

Specifications for Design of Concrete Structures. In

addition to these basic assumptions, the calculation of

the bearing capacity when using carbon fiber to

strengthen the beam and slab members should also

meet the following requirements:

a. When the member achieves the ultimate state of

flexural load-bearing capacity, the tensile strain of

the carbon fiber is determined according to the

assumption that the section strain remains flat.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

64

This tensile strain, however, should not exceed the

allowable tensile strain of the carbon fiber;

b. When the influence of the secondary force is taken

into consideration, the initial strain of the concrete

at the edge of the tension zone before

reinforcement should be calculated based on the

load condition during reinforcement and the

supposition that the section strain continues to be

flat;

c. The tensile tension of carbon fiber ought to be

equal to the product of the carbon fiber's elastic

modulus and its tensile strain;

d. The bond between the carbon fiber and the

concrete does not fail to peel apart until after the

ultimate condition of flexural bearing capacity has

been reached.

Simple fitting of CFRP for the effective tension.

Assuming that the function of carbon fiber fabric is

comparable to that of a stirrup, the following equation

must be used in order to describe shear theory:

𝑉

=

𝑓

𝐴

ℎ

𝑠

(1)

𝜀

= 0.00001

𝑓

/

𝜌

𝐸

.

(2)

Where 𝑉

is the shear capacity, respectively,

𝑓

𝐴

ℎ

,

the effective tensile strength, the area of the carbon

and the height of the carbon fibre cloth. In addition,

𝑠

is spacing and 𝜀

is effective strain. From Eq. (1)

and (2), CFRP strain in proportion to the concrete

strength.

3.2 Structural Modelling – SAP 2000

In this evaluation, case study on building Club House

Graha Natura was used. To determine the current

situation which consider lift loading. In the beginning

the structure was not designed to have such load

parameters, then after some identification, lift then

decide to be constructed on the current structure.

CFRP is the alternative on the design implementation.

For the information, the building has a function as a

sport centre with 17.5 m height in total. It has 5-story,

each story having 3.5 m height. The building is

located in Surabaya using reinforced concrete (RC).

The inputted materials are Informed in Table 1 as

follows.

Table 1: Concrete and reinforcement quality.

Ite

m

Concrete stren

g

th (

f

’c)

- Column

- Beam

- Plate

25 MPa

25 MPa

25 MPa

Steel reinforcement (

fy

)

- Plain bar

- Deformed ba

r

240 MPa

490 MPa

The combination of loading is designed according

to the SNI 1727-2013 (Badan Standardisasi Nasional,

2013) , where the life load for all story assigned as 2.5

kN/m

2

. The response spectrum design parameter is

designed in accordance with the SNI 1726-2019

(Badan Standardisasi Nasional, 2019) with the

repetition period 50 years. The condition of the soils

characterized as soft soil (SE) with level of risk

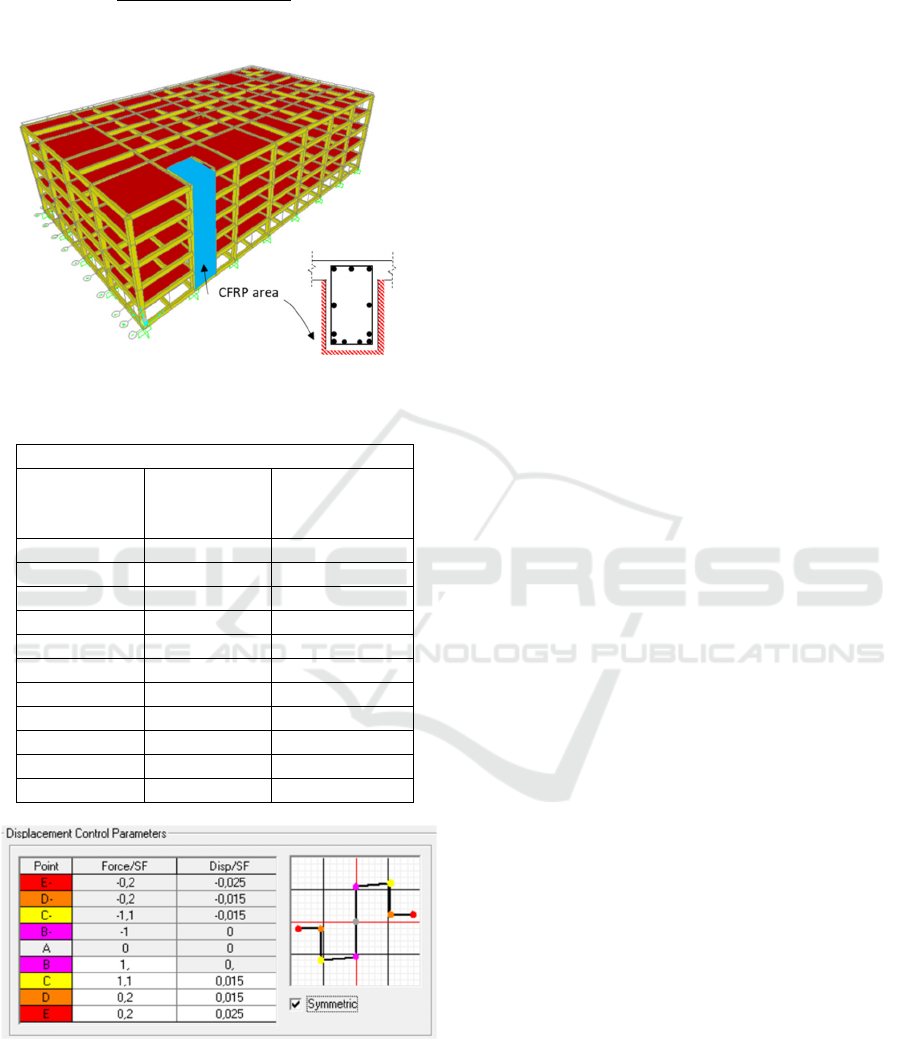

category is III. The model is illustrated in Figure 4.

Where moment curvature representing hinge

properties informed in Figure 5. This condition of

material property illustrates the real behaviour of RC

and CFRP.

The percentage of difference that exists between

the two different sets of outcomes can be calculated

using equation (3). The new stress strain of the

concrete material is calculated based on relevant

studies in order to arrive at the result of ultimate

moment and curvature for CFRP-confined concrete

(Elarbi, 2011; Asaei, Lau and Bunnori, 2013) and

then it is applied to the material definition of

SAP2000 analyser. This allows one to obtain the

result of ultimate moment and curvature for CFRP-

confined concrete. The findings of the difference

percentage have demonstrated that it is almost the

same, but there was a deviation from the permissible

range of difference. According to the manual

definition of SAP2000, the acceptable range of

difference for comparing the outcomes of

independent calculations and analyses using

SAP2000 is specified to be 5%. Although the

difference between an independent calculation and

the SAP2000 analysis outcome based on Yuan et al.

(Triantafillou, 2016) was 10.7% for ultimate moment,

the percentage difference for ultimate curvature was

only 1.7%. In spite of the fact that the difference was

very close to the acceptable range of variation when

using the method of calculation of moment and

curvature. It was discovered that the difference

between moment and curvature could be found with

a smaller amount of deviation when using the basic

calculation of ultimate moment and curvature.

Modelling of Structural Strengthening Techniques for Existing Building and Structures: Case Study Club House Graha Natura Under Lift

Loading Using Carbon Fibre-Reinforced Polymer (CFRP)

65

𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝑑𝑖𝑓𝑓𝑒𝑟𝑒𝑛𝑐𝑒

= 100

𝑆𝐴𝑃2000 𝑟𝑒𝑠𝑢𝑙𝑡

𝐼𝑛𝑑𝑒

𝑝

𝑒𝑛𝑑𝑒𝑛𝑡 𝑟𝑒𝑠𝑢𝑙𝑡

1

(3)

Figure 4: Structural model using SAP2000.

Table 2: Distribution of CFRP sheets.

Beam 1 - 5

Moment

ultimate

[kN]

Moment

nominal

[kN]

Strengthening

CFRP (sheet

number)

89 122 -

89 122 -

178 122 -

82 122 3

132 122 1

142 122 1

83 122 1

115 122 1

98 122 1

71 122 1

15 122 -

Figure 5: Hinges property under distribution of

displacement control parameter on the SAP2000 modelling.

The CFRP material that is using in this analysis

used SIKA Wrap 231C with specified tensile strength

4800 MPa and yield strain 1.8%. Modulus elasticity

informed with 2.34×10

5

MPa. Reduction factor

according to the ACI 440, CE = 0.95. With the result,

design ultimate strength of CFRP = 4560 MPa and ε

fe

= 0.004. From the evaluation, the placed CFRP on the

beam are needed 10 sheets in total which placed in

every stories. Detailed distribution of the

strengthening on beam element due to the lift loading

is illustrated in Table 2.

4 CONCLUSIONS

This research is focused on verifying the model of

FRP-confined columns in SAP2000, which states that

the calculation of the material properties of wrapped

RC columns. The modelling process and the process

of designating specialties are both discussed in

context, and the results of the analysis have been

compared to previous research in order to determine

the reliability of the analysis's findings. For FRP

confined RC columns, the SAP2000 permissible

range of difference is controlled both with and

without consideration to the ACI 440 rules for

rectangular and circular section. This is done in

accordance with the recommendation that was given.

Research was conducted to determine the

performance of FRP-confined columns. The

outcomes of this study revealed that the performance

of these columns is comparable to that of

conventional RC columns in terms of yield;

nevertheless, it is distinct from the performance of

these columns in terms of flexibility and post-yield.

In the meantime, it has been found out that an

adequate stress-strain model for FRP restricted

concrete material in the compression zone should also

be considered in order to generate an accurate

analysis and response of software in the pushover

analysis domain. This discovery came about as a

result of research that was conducted. Calculation

formula simplifies the numerical modelling

calculation process, and it can quickly evaluate the

actual project in certain circumstances.

REFERENCES

ACI Committee 116 (2000) ‘116R-90: Cement and

Concrete Terminology’, American Concrete Institute,

p. 58. Available at:

http://dl.mycivil.ir/dozanani/ACI/ACI 116R-00

Cement and Concrete Terminology_MyCivil.ir.pdf.

Alexander, M. G., Dehn, F. and Moyo, P. (2015) Concrete

Repair, Rehabilitation and Retrofitting IV, Concrete

Repair, Rehabilitation and Retrofitting IV. doi:

10.1201/b18972.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

66

An, W., Saadatmanesh, H. and Ehsani, M. R. (1991) ‘RC

beams strengthened with FRP plates. II: Analysis and

parametric study’, Journal of Structural Engineering

(United States), 117(11), pp. 3434–3455. doi:

10.1061/(ASCE)0733-9445(1991)117:11(3434).

Arrangement, A. et al. (2013) Calculation of Blast Loads

for Application to Structural Components. doi:

10.2788/61866.

Asaei, S. M. S., Lau, T. L. and Bunnori, N. M. (2013)

‘Modeling FRP-confined RC Columns using

SAP2000’, World Applied Sciences Journal, 27(12),

pp. 1717–1736. doi:

10.5829/idosi.wasj.2013.27.12.898.

Badan Standardisasi Nasional (2013) ‘Beban minimum

untuk perancangan bangunan gedung dan struktur lain.

SNI 1727:2013’, in Bandung: Badan Standardisasi

Indonesia, p. 196. Available at: www.bsn.go.id.

Badan Standardisasi Nasional (2019) ‘Sni 1726-2019’,

Tata Cara Perencanaan Ketahanan Gempa Untuk

Struktur Bangunan Gedung dan Non Gedung, (8), p.

254.

Bukhari, I. A. et al. (2010) ‘Shear strengthening of

reinforced concrete beams with CFRP’, (January). doi:

10.1680/macr.2008.62.1.65.

Casita, C. B., Suswanto, B. and Komara, I. (2022)

‘Analytical Study of Rectangular Concrete-Filled

Tubes ( RCFT ) Connections using Finite Element

Analysis under Cyclic Loading’, 19(17), pp. 1–15.

Eide, M. B., Hisda, J.-M. and L (2012) Ultra High

Performance Fibre Reinforced Concrete (UHPFRC) –

State of the art, SINTEF Building and Infrastructure.

Available at: www.coinweb.no%0Awww.coinweb.no.

Elarbi, A. M. (2011) ‘Durability performance of frp

strenghtened concrete beams and columns exposed to

hygrothermal environment’.

Gagg, C. R. (2014) ‘Cement and concrete as an engineering

material: An historic appraisal and case study analysis’,

Engineering Failure Analysis. Elsevier Ltd, 40, pp.

114–140. doi: 10.1016/j.engfailanal.2014.02.004.

Gao, H. and Cai, X. (2015) ‘5th International Conference

on Civil Engineering and Transportation (ICCET

2015)’, (Iccet), pp. 846–850.

Gu, D., Pan, J. and He, J. (2019) ‘Numerical Study on Shear

Behaviours of ECC Beams Reinforced with FRP Bars’,

pp. 1–6. doi: 10.21012/fc10.233096.

Hassan, N. Z., Sherif, A. G. and Zamarawy, A. H. (2017)

‘Finite element analysis of reinforced concrete beams

with opening strengthened using FRP’, Ain Shams

Engineering Journal. Faculty of Engineering, Ain

Shams University, 8(4), pp. 531–537. doi:

10.1016/j.asej.2015.10.011.

Inge, W., Nugroho, S. and Njo, H. (2018) ‘Strengthening

method of concrete structure’. doi: 10.1088/1755-

1315/.

Jensen, O. M., Kovler, K. and Belie, N. De (2016) Concrete

with Supplementary Cementitious Materials.

Khairi, W. et al. (2021) ‘CFRP for strengthening and

repairing reinforced concrete : a review’, Innovative

Infrastructure Solutions. Springer International

Publishing, 6(2), pp. 1–13. doi: 10.1007/s41062-020-

00417-5.

Komara, I. et al. (2020) ‘Experimental investigations on the

durability performance of normal concrete and

engineered cementitious composite’, IOP Conference

Series: Materials Science and Engineering, 930(1). doi:

10.1088/1757-899X/930/1/012056.

Komara, I. et al. (2021) ‘Behaviour of Reinforced Concrete

Beams with and Without Web Openings using Direct

Displacement Based Design’, Journal of Physics:

Conference Series, 2117(1), p. 012006. doi:

10.1088/1742-6596/2117/1/012006.

Komara, I. et al. (no date) ‘Experimental investigations on

the durability performance of normal concrete and

engineered cementitious composite’.

Maalej, M. and Leong, K. S. (2005) ‘Effect of beam size

and FRP thickness on interfacial shear stress

concentration and failure mode of FRP-strengthened

beams’, Composites Science and Technology, 65(7–8),

pp. 1148–1158. doi:

10.1016/j.compscitech.2004.11.010.

Mooy, M. et al. (2020) ‘Evaluation of Shear-Critical

Reinforced Concrete Beam Blended with Fly Ash’, IOP

Conference Series: Earth and Environmental Science,

506, p. 012041. doi: 10.1088/1755-1315/506/1/012041.

Mustafaraj, E. and Yardim, Y. (2018) ‘Review of

Strengthening Techniques and Mechanical Testing for

Unreinforced Masonry’, MATTER: International

Journal of Science and Technology, 3(2), pp. 33–50.

doi: 10.20319/mijst.2017.32.3350.

Muthukumaraswamy kamalakannan, S. et al. (2021)

‘Retrofitting of an existing structure design and

techniques’, IOP Conference Series: Materials Science

and Engineering, 1197(1), p. 012059. doi:

10.1088/1757-899x/1197/1/012059.

Novák, D. (2012) ‘Reliability assessment of concrete

bridges’, (July 2016). doi: 10.1201/b12352-88.

Oktaviani, W. N. et al. (2020) ‘Flexural Behaviour of a

Reinforced Concrete Beam Blended with Fly ash as

Supplementary Material’, IOP Conference Series:

Earth and Environmental Science, 506, p. 012042. doi:

10.1088/1755-1315/506/1/012042.

Osman, B. H. et al. (2016) ‘A state of the art review on

reinforced concrete beams with openings retrofitted

with FRP’, International Journal of Advanced

Structural Engineering. Springer Berlin Heidelberg,

8(3), pp. 253–267. doi: 10.1007/s40091-016-0128-7.

Pertiwi, D., Komara, I. and Fristian, R. (2021) ‘Design

concept of reinforced concrete beams with large web

openings’, IOP Conference Series: Materials Science

and Engineering, 1010, p. 012039. doi: 10.1088/1757-

899x/1010/1/012039.

Sonebi, M., Ammar, Y. and Diederich, P. (2016)

Sustainability of cement, concrete and cement

replacement materials in construction. Second Edi,

Sustainability of Construction Materials. Second Edi.

Elsevier Ltd. doi: 10.1016/b978-0-08-100370-1.00015-

9.

Thanoon, W. A. et al. (2005) ‘Repair and structural

performance of initially cracked reinforced concrete

Modelling of Structural Strengthening Techniques for Existing Building and Structures: Case Study Club House Graha Natura Under Lift

Loading Using Carbon Fibre-Reinforced Polymer (CFRP)

67

slabs’, Construction and Building Materials, 19(8), pp.

595–603. doi: 10.1016/j.conbuildmat.2005.01.011.

Triantafillou, T. (2016) Strengthening of existing concrete

structures: Concepts and structural behavior, Textile

fibre composites in civil engineering. Elsevier Ltd. doi:

10.1016/B978-1-78242-446-8.00014-8.

Wu, C. and Li, V. C. (2017) ‘CFRP-ECC hybrid for

strengthening of the concrete structures’, Composite

Structures. Elsevier Ltd, 178(July), pp. 372–382. doi:

10.1016/j.compstruct.2017.07.034.

Yildiz, S. et al. (2019) ‘International Journal of Impact

Engineering Characterization of adhesively bonded

aluminum plates subjected to shock- wave loading’,

127(November 2018), pp. 86–99. doi:

10.1016/j.ijimpeng.2019.01.007.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

68