Design and Build Two Wheel Balancing Robot Simulation with

Fuzzy PID

Santoso, Izzah Aula Wardah, Puji Slamet, Aris Heri Andriawan and Abdul Rahman Algopiki

Electrical Engineering Study Program, Faculty of Engineering, University of 17 August 1945, Surabaya, Indonesia

Keywords: Robot, Fuzzy, PID, Human.

Abstract: This research produces a two-wheeled equilibrium robot with Fuzzy PID as its motion control. Generate

designs and simulations of robotic systems namely gyroscope, PID, Fuzzy simulation, and motor control. In

the PID simulation the stability values are obtained at Kp = 100, Ki = 200, Kd = 10, and from the gyroscope

simulation results obtained a minimum value of 0.074616, a maximum value of 0.110321, an average value

of 0.092469, a standard deviation of 0.025247, sum of data (sum) 0.184937, mean 0.092469. The results of

this study are expected to be developed using a stepper motor, improving the complement or Kalman filter

algorithm to produce a gyroscope sensor signal that is clean from noise interference, as well as adding an

input membership function to get a better motion response.

1 INTRODUCTION

The development of robotics technology has made the

quality of human life even higher. Currently the

development of robotics technology has been able to

increase the quality and quantity of production in

various industries(Tugaev & Kulibaba, 1986; Weik,

2000). Robotics technology has also reached the side

of entertainment and education for humans. One way

to increase the level of intelligence of a robot is to add

sensors, control methods and even provide artificial

intelligence to the robot. Robots that have intelligence

One of them is a self-balancing robot (Frankovský et

al., 2017; Gonzalez et al., 2017; Mai et al., 2019;

Santoso & Mursyid, 2017). balance robot (balancing

robot) is a robot that has two wheels on the right and

left which will not be balanced without a controller.

This balance robot is the development of an inverted

pendulum model that is placed on a wheeled train

(Odry & Fuller, 2018; Xin et al., 2011). Balancing a

two-wheeled robot requires a good hardware circuit

and a reliable control method to maintain the robot's

position perpendicular to the earth's surface. The

concept of a balance robot has been used as a means

of transportation called a segway(Yun et al., 2019).

To

be able to see the performance response of a system

with various combinations of input signals and control

actions is a difficult thing. to perform these steps

required high accuracy and the depiction is often less

accurate. because the transfer function in a system is

in the s region or in the laplace function, to analyze a

system response it is necessary to perform the inverse

laplace function or change from the s region to the t

region. Of course, this is very inefficient and time

consuming. Therefore, software is used, to make it

easier to understand, analyze, and get the desired

system response.

2 LITERATURE REVIEW

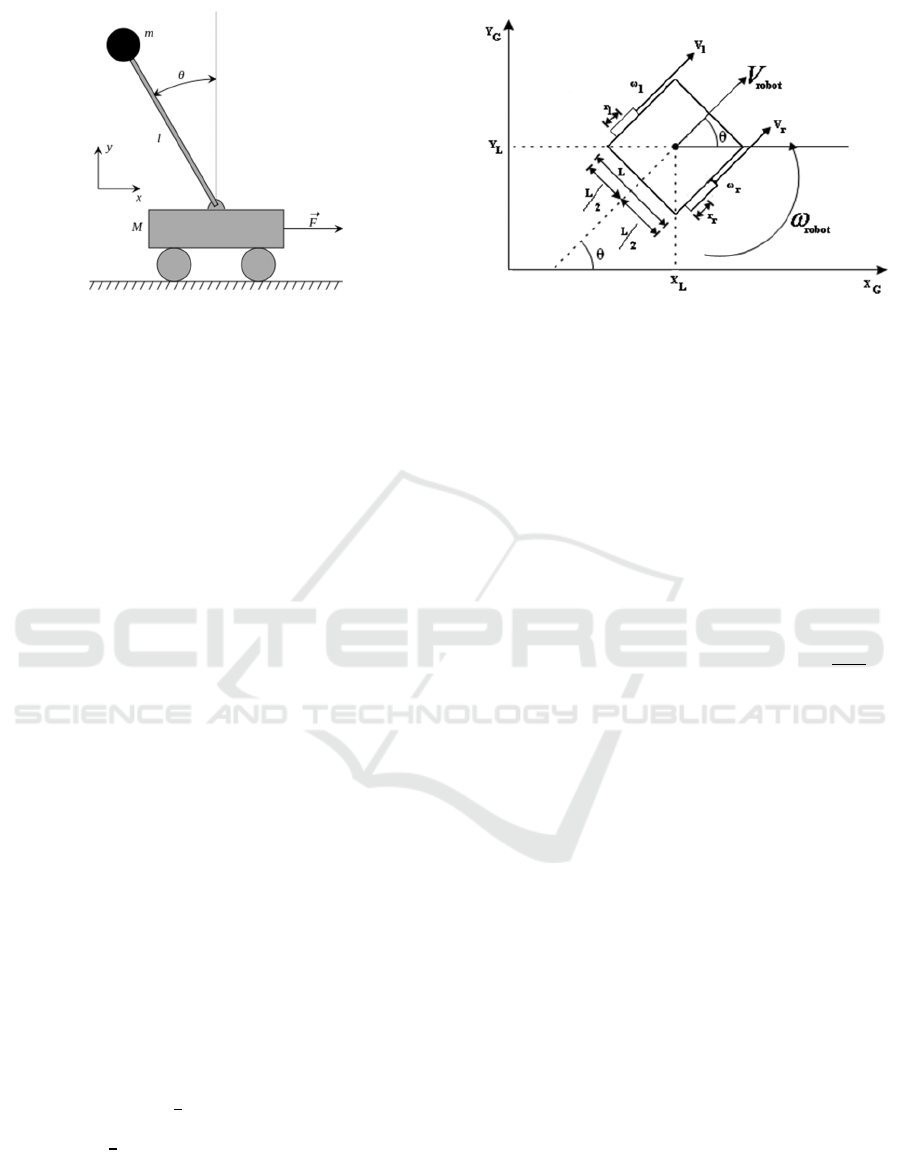

2.1 Inverted Pendulum

The equilibrium robot applies an inverted pendulum

model, with the ability to maintain an upright position

with respect to an object(Huang et al., 2011; Odry &

Fuller, 2018). The process of equilibrium is usually

called stability control (Yıldırım & Arslan, 2018).

Two wheels are placed on the ground surface and

allow the robot body to maintain an upright position

and move forward, backward, rotating in an effort to

maintain the center of mass above the axles (Huang

et al., 2011).

124

Santoso, ., Aula Wardah, I., Slamet, P., Heri Andriawan, A. and Rahman Algopiki, A.

Design and Build Two Wheel Balancing Robot Simulation with Fuzzy PID.

DOI: 10.5220/0012108300003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 124-128

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Schematic of an inverted pendulum.

As a result of the earth's gravitational force, an

inverted pendulum which is initially perpendicular

then begins to form a tilt angle of theta (θ) and over

time it will fall. Therefore, in maintaining and

maintaining the pendulum's position at a point, a force

action is needed that can restrain the pendulum's

movement. The method used to produce this force is

by making the train go forward in the direction in

which the pendulum will fall (Fahmizal et al., 2017).

2.2 Two-Wheeled Robot Kinematics

In the case of a two-wheeled robot, as presented in

Figure 2, each wheel is controlled by an independent

motor. XG and YG represent the global framework,

while XL and YL represent the local framework. The

speed of the robot is determined by the linear and

angular velocity, which is a function of the linear and

angular speed of each wheel and the distance L

between the two wheels, is the linear and angular

speed of the right wheel, is the linear and angular

speed of the left wheel, θ is robot orientation and (ω)

are the radius of the left and right wheels

V

(

t

)

ω

(

t

)

ω

(

t

)

V

(

t

)

ω

(

t

)

V

(

t

)

ω

(

t

)

r

r

(1)

The linear speed of each wheel is determined by

the relationship between the angular velocity and the

radius of the wheel(Chhotray et al., n.d.).

V

(

t

)

ω

(

t

)

r

,V

(

t

)

ω

(

t

)

r

(2)

The speed of the robot consists of the center mass

linear velocity and the angular velocity generated by

the difference between the two wheels.

V

(

t

)

V

(

t

)

ω

(

t

)

,V

(

t

)

V

(

t

)

ω

(

t

)

(3)

Figure 2: Two-wheeled robot kinematics.

2.3 PID

The PID controller is a combination of three types of

controllers, namely proportional controllers, integral

controllers, and derivative controllers. The purpose of

combining the three types of controllers is to improve

system performance where each controller will

complement and cover each other's weaknesses and

strengths. proportional, integral, and derivative terms

are added up to calculate the output of the PID

controller. By defining a controller output, the final

form of the PID algorithm is:

u

(

t

)

P

(

t

)

K

e

(

t

)

K

e

(

τ

)

dτ K

()

(4)

𝐾

: Proportional gain, tuning parameters

𝐾

: Integral Gain, tuning parameters

𝐾

: Derivative Gain, tuning parameters

𝑒: Error = 𝑌

𝑌

𝑌

: Setpoint

𝑌

: Process variable

𝑡: Time

𝜏: Integration variable; the value is taken from

time zero to 𝑡

L

(

s

)

K

K

/s K

s (5)

with

𝑆: The frequency of complex numbers

2.4 Fuzzy Logic

Fuzzy logic is a way of mapping the input space into

the output space, with continuous values(Zadeh,

2009, 2015). Fuzzy expressed in degrees of

membership and degrees of truth. Therefore

something can be said to be partly right and partly

wrong at the same time. In fuzzy logic are

Design and Build Two Wheel Balancing Robot Simulation with Fuzzy PID

125

fuzzification, rule evaluation (inference) based on

rule base, and defuzzification(Medynskaya, 2015;

Sadegh-Zadeh, 1999).

3 DESIGNS

The proposed system design is shown in Figure 3.

PID Fuzzy control is the main control used in this

system. The main input parameter used in PID control

is the error value or the difference between the system

output value (process variable) and the expected

value (set point).(Bimarta et al., 2015). The addition

of Fuzzy control is expected to help improve the

performance of the equilibrium robot. With the

addition of fuzzy logic for the magnitude of the

coefficient value of the PID and combined with the

setpoint of the sensor data value, errors and error

differences will be obtained, to be used as fuzzy logic

input values, the control results will be fed to the

controller to then produce PWM, the value of the

PWM will control DC motor movement(Mai et al.,

2019; Yu et al., 2017).

Figure 3 Balancing robot block diagram

3.1 A Two-Wheeled Balanced Robot

The design of the balancing robot is built using two

wheels, the Arduino controller is placed between the

two wheels, the support circuit is arranged to produce

a balanced pressure between the two wheels, the

sensor circuit is placed on top of the robot, in order to

produce maximum power change, accepted by

Arduino as input data (position) is processed in fuzzy

logic and PID, to then be fed to the DC motor drive

circuit by controlling the PWM to be kept constant

according to the desired value setting, the coefficients

will be displayed on the LCD display, changes in

position x, y, z(Anitha et al., 2019; Cameron, 2019;

Odry & Fuller, 2018; Pan & Zhu, 2018).

4 RESULTS AND ANALYSIS

Using two motors, an L298 motor control, arduino

uno, virtual serial (compin), and virtual terminal, the

software is built on the Arduino IDE, simulation is

carried out by setting pin IN1=0, IN2=1, IN3=0,

IN4=1 , ENA=1, ENB=1, the motor speed is set by

setting the value of ENA, ENB from the lowest value

0 to the highest value 255(Frankovský et al., 2017;

Hsu & Lee, 2011).

4.1 PID Simulation

PID control will produce a response that is influenced

by the parameters Kp, Ki and Kd(Mai et al., 2019;

Odry & Fuller, 2018). The test is carried out by

changing the parameters and paying attention to the

results of the robot's movement, the value and shape

of the signal are obtained as follows:

(a)

(b)

Figure 4 (a) Kp=100, Ki=200, Kd=1, (b) Kp=100, Ki=200,

Kd=10

Figure 4 (b) shows the step response graph has a long

value to be stable, this is because the integral gain

value is small (Ki = Small), so it takes a long time for

the unification action and reduces the fixed condition

error, with the addition of the Ki value the process can

be accelerated, Figure 4(a). With the addition of the

Ki value, the steady-state error can be reduced faster

ICATECH 2023 - International Conference on Advanced Engineering and Technology

126

than before, but also increasing the spikes, with the

addition of the Kd value will reduce the spikes, shown

in Figure 4(b).

4.2 Fuzzy Logic Simulation

Fuzzy control will produce a final value according to

a predetermined value, in this study the angle value is

obtained from the IMU MPU6050 sensor.

(a)

(b)

(c)

Figure 5 (a) Angle change input membership function, (b)

PWM output membership function, (c) Correlation of angle

change to PWM value

From Figure 5 (d) it can be seen that the pwm

value increases as the angle changes, the pwm value

is 0-120, at an angle movement between 0-5

degrees, the pwm is stable at 130, at an angle

movement of 4.7-13 degrees, the pwm increases at

angle change between 14-20 degrees.

4.3 Gyroscope Simulation

The simulation was made using the proteus program,

by simulating three signals from the gyro sensor with

three variable resistors, and connected to A0, A1, and

A2 from the Arduino. The received value data is

randomized, and forwarded to Matlab for storage and

signal plots.

5 CONCLUSIONS

The results of testing the balancing robot using angle

value data according to the variable input previously

mentioned, it can be seen that the robot graph is able

to balance with a balance range between (-3 to 3

degrees) on a flat plane even with fairly constant

noise or error. From the simulation results, the

minimum value is 0.074616, the maximum value is

0.110321, the average value is 0.092469, the standard

deviation is 0.025247, the sum of data (sum) is

0.184937, the mean is 0.092469.

REFERENCES

Anitha, T., Gopu, G., Nagarajapandian, M., & Devan, PAM

(2019). Hybrid Fuzzy PID Controller for Pressure

Process Control Applications. 2019 IEEE Student

Conference on Research and Development (SCORED),

129–133.

https://doi.org/10.1109/SCORED.2019.8896276

Bimarta, R., Putra, AE, & Dharmawan, A. (2015).

Balancing Robot Using Derivative Integral

Proportional Control Method. IJEIS (Indonesian

Journal of Electronics and Instrumentation Systems),

5(1), 89. https://doi.org/10.22146/ijeis.7157

Cameron, N. (2019). Robot Car. In N. Cameron, Arduino

Applied (pp. 467–497). Apress.

https://doi.org/10.1007/978-1-4842-3960-5_24

Chhotray, A., Pradhan, MK, Pandey, KK, & Parhi, DR (nd).

Kinematic Analysis of a Two-Wheeled Self-Balancing

Mobile Robot. 8.

Fahmizal, F., Setyawan, G., Arrofiq, M., & Mayub, A.

(2017). Fuzzy Logic in Two-Wheeled Inverted

Pendulum Robot. Journal of Information Technology

and Computer Science, 4(4), 244.

https://doi.org/10.25126/jtiik.201744484

Frankovský, P., Dominik, L., Gmiterko, A., Virgala, I.,

Kurylo, P., & Perminova, O. (2017). Modeling of Two-

Wheeled Self-Balancing Robot Driven by DC

Gearmotors. International Journal of Applied

Mechanics and Engineering, 22(3), 739–747.

https://doi.org/10.1515/igame-2017-0046

Gonzalez, C., Alvarado, I., & Peña, DML (2017). Low cost

two-wheel self-balancing robot for control education.

IFAC-PapersOnLine, 50(1), 9174–9179.

https://doi.org/10.1016/j.ifacol.2017.08.1729

Hsu, C.-F., & Lee, B.-K. (2011). FPGA-based adaptive PID

control of a DC motor driver via a sliding-mode

approach. Expert Systems with Applications, 38(9),

Little

Oblique

Medium

Oblique

Oblique

Much

Lit tle

Oblique

Slow Slow Slow

Medium

Oblique

Slow Medium Fast

Oblique

Much

Fast Fast Fast

Fuzzy Logic Ru les

OBLIQUE A NGLE DA TA OF

CURRENTLY

OBLIQUE

ANGLE DATA

OF

PREVIOUSLY

Design and Build Two Wheel Balancing Robot Simulation with Fuzzy PID

127

11866–11872.

https://doi.org/10.1016/j.eswa.2011.02.185

Huang, C.-H., Wang, W.-J., & Chiu, C.-H. (2011). Design

and Implementation of Fuzzy Control on a Two-Wheel

Inverted Pendulum. IEEE Transactions on Industrial

Electronics, 58(7), 2988–3001.

https://doi.org/10.1109/TIE.2010.2069076

Kecskés, I., & Odry, P. (2014). Optimization of PI and

Fuzzy-PI Controllers on Simulation Model of

Szabad(ka)-II Walking Robot. International Journal of

Advanced Robotic Systems, 11(11), 186.

https://doi.org/10.5772/59102

Mai, TA, Dang, TS, Anisimov, DN, & Fedorova, E. (2019).

Fuzzy-PID Controller for Two Wheels Balancing

Robot Based on STM32 Microcontroller. 2019

International Conference on Engineering Technologies

and Computer Science (EnT), 20–24.

https://doi.org/10.1109/EnT.2019.00009

Matsui, N., & Shigyo, M. (1992). Brushless DC motor

control without position and speed sensors. IEEE

Transactions on Industry Applications, 28(1), 120–127.

https://doi.org/10.1109/28.120220

Medynskaya, MK (2015). Fuzzy set theory. The concept of

fuzzy sets. 2015 XVIII International Conference on

Soft Computing and Measurements (SCM), 30–31.

https://doi.org/10.1109/SCM.2015.7190402

Noga, S. (2006). Kinematics and dynamics of some

selected two-wheeled mobile robots. Archives of Civil

and Mechanical Engineering, 6(3), 55–70.

https://doi.org/10.1016/S1644-9665(12)60241-6

Odry, A., & Fuller, R. (2018). Comparison of Optimized

PID and Fuzzy Control Strategies on a Mobile

Pendulum Robot. 2018 IEEE 12th International

Symposium on Applied Computational Intelligence and

Informatics (SACI), 000207–000212.

https://doi.org/10.1109/SACI.2018.8440947

Pan, T., & Zhu, Y. (2018). Using Sensors with the Arduino.

In T. Pan & Y. Zhu, Designing Embedded Systems with

Arduino (pp. 45–100). Springer Singapore.

https://doi.org/10.1007/978-981-10-4418-2_3

Perdukova, D., Fedor, P., & Fedak, V. (2019). A Fuzzy

Approach to Optimal DC Motor Controller Design.

2019 International Conference on Electrical Drives &

Power Electronics (EDPE), 48–53.

https://doi.org/10.1109/EDPE.2019.8883896

Sadegh-Zadeh, K. (1999). Advances in fuzzy theory.

Artificial Intelligence in Medicine, 15(3), 309–323.

https://doi.org/10.1016/S0933-3657(98)00060-8

Santoso, S., & Mursyid, S. (2017). PROPORTIONAL

INTEGRAL (PI) CONTROL ON LINE FOLLOWER

ROBOT. Journal of Science and Informatics, 1(1), 10–

10.

Tugaev, VD, & Kulibaba, V. Ya. (1986). Introduction of an

industrial robot in a machine shop. Metallurgist, 30(10),

380–381. https://doi.org/10.1007/BF00741414

Weik, MH (2000). Manipulating industrial robots. In MH

Weik, Computer Science and Communications

Dictionary (pp. 972–972). Springer US.

https://doi.org/10.1007/1-4020-0613-6_11017

Xin, Y., Xu, B., Xin, H., Xu, J., & Hu, L. (2011). The

Computer Simulation and Real-Time Control for the

Inverted Pendulum System Based on PID. In M. Ma

(Ed.), Communication Systems and Information

Technology (Vol. 100, pp. 729–736). Springer Berlin

Heidelberg. https://doi.org/10.1007/978-3-642-21762-

3_95

Yıldırım, Ş., & Arslan, E. (2018). ODE (Open Dynamics

Engine) based stability control algorithm for six legged

robots. Measurements, 124, 367–377.

https://doi.org/10.1016/j.measurement.2018.03.057

Yu, G.-R., Leu, Y.-K., & Huang, H.-T. (2017). PSO-based

fuzzy control of a self-balancing two-wheeled robot.

2017 Joint 17th World Congress of International Fuzzy

Systems Association and 9th International Conference

on Soft Computing and Intelligent Systems (IFSA-

SCIS), 1–5. https://doi.org/10.1109/IFSA-

SCIS.2017.8023296

Yun, H., Bang, J., Kim, J., & Lee, J. (2019). High speed

segway control with series elastic actuator for driving

stability improvement. Journal of Mechanical Science

and Technology, 33(11), 5449–5459.

https://doi.org/10.1007/s12206-019-1039-x

Zadeh, LA (2009). Toward extended fuzzy logic—A first

step. Fuzzy Sets and Systems, 160(21), 3175–3181.

https://doi.org/10.1016/j.fss.2009.04.009

Zadeh, LA (2015). Fuzzy logic—A personal perspective.

Fuzzy Sets and Systems, 281, 4–20.

https://doi.org/10.1016/j.fss.2015.05.009

ICATECH 2023 - International Conference on Advanced Engineering and Technology

128