Experimental Study to Analyze the Effect of Fan Speed on Energy

Efficiency in Open Cathode Pem Fuel Cells

Akhmad Fahruzi

1,* a

, Katherin Indriawati

1,† b

and Mat Syai’in

2,‡ c

1

Department of Engineering Physics, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

2

Ship Electrical Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

Keywords: Open Cathode, PEMFC, Air Supply, Stack Temperature.

Abstract: Open Cathode PEM Fuel Cells (OCPEMFCs) are widely used, performance OCPEMFCs is affected by

operating conditions such as temperature, humidity, air flow rate. In this paper, an experimental investigation

has been carried out on the effect of fan speed on stack performance and efficiency of energy that using

commercially from OCPEMFCs system 1kW. During the experiment, temperature, voltage and current of

stack will be monitored and recorded under various load level. It is referred that the optimal fan speed through

the duty cycle setting can reduce auxiliary power consumption. The results are compared with the commercial

system. The experimental results show that by loading a fuel cell gradually from 100 - 500W will produce the

optimum duty cycle values of the fans were obtained, namely 20, 30, and 40% respectively. From the duty

cycle value, the stack performance is still in a stable condition, it can be seen from the range of stack voltage

during the experiment that still allowed with nominal voltage range. Meanwhile, a comparison of the stack

power output between the fuel cell and the Company's and the Lab's system shows that the fuel cell and the

Lab's system have a smaller difference of about 8 W.

1 INTRODUCTION

Fuel cells are a type of new renewable energy that can

convert chemical energy into DC electricity through

the reaction of hydrogen and oxygen gases(Mousavi

& Mehrpooya, 2021)(Souleman et al., 2009). The fuel

cell will generate electricity continuously as long as

the supply of hydrogen gas to the anode channel and

oxygen to the cathode channel is full. Fuel cells are

becoming popular as an alternative energy source

because they have high power density, zero-

emissions, and low operating temperatures(Fernandez

et al., 2020). There are several types of fuel cells, such

as Solid Oxide Fuel Cells (SOFC), Direct Methanol

Fuel Cells (DMFC), and Polymer Electrolyte

Membrane or Proton Exchange Membrane (PEM)

Fuel Cells. Of these types of fuel cells, in general they

have several similarities, namely having an anode and

cathode channels as a fuel supply. While the PEMFC

type fuel cell has several advantages compared to

a

https://orcid.org/0000-0001-6650-2183

b

https://orcid.org/0000-0002-9333-088X

c

https://orcid.org/0000-0001-7459-4487

other types such as fast dynamic response and low

operating temperature(Pangaribowo et al., 2020)

(Meng et al., 2022).

PEMFCs with open cathode technology

(OCPEMFCs) have been widely used, especially in

electronic devices that are portable applications

because of their small shape and simple stack

design(Ling et al., 2016)(Zhao et al.,

2020)(Shahsavari et al., 2012). In OCPEMFCs,

electric fans are used to provide oxygen supply from

the surrounding air and control the stack

temperature(Huang et al., 2014). The advantage of

OCPEMPCs is their simple and lightweight fuel cell

configuration. This is because several sub systems

such as cooling, humidifier and inlet pressure control

have been eliminated(Kurnia et al., 2021). However,

the weakness of the open cathode type fuel cell is that

the performance of the fuel cell is affected by the

thermodynamic conditions of the surrounding

environment and for a higher current density, the

supply of reactants at the cathode may not be sufficient

336

Fahruzi, A., Indriawati, K. and Syai’in, M.

Experimental Study to Analyze the Effect of Fan Speed on Energy Efficiency in Open Cathode Pem Fuel Cells.

DOI: 10.5220/0012109000003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 336-341

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

to produce an optimal electrochemical reaction and

the heat generated by the reaction cannot be removed

effectively(Baik & Yang, 2020). However, in recent

years, the demand for OCPEMFCs as a source of

stationary energy and portable applications is growing

rapidly(Gopi et al., 2020).

The proton conductivity of the membrane is the

main factor affecting OCPEMFCs performance,

where the ionic conductivity depends on the amount

of water content in the membrane, while the amount

of water content is affected by flow rate, humidity and

temperature(Zhang et al., 2008). Pei et al.(Pei et al.,

2014) shows that high stack temperatures can cause

evaporation of water in the membrane, causing

dehydration of the membrane which results in

decreased stack performance.

Sasmito et al.(Sasmito et al., 2010) have studied

several factors that affect operating point and stack

temperature such as fan power, single fan or fans in

series, stack length, separate air-coolant channels.

Meyer et al.(Meyer et al., 2015) showed that parasitic

loads such as air blowers can affect stack performance

and temperature distribution. For the purposes of

energy efficiency, the effect of parasitic loads needs to

be investigated further. Analysis of how much the

minimum cooling air flow is needed to maintain the

temperature when there is a change in load from the

fuel cell, is a problem that needs to be answered.

From the problems above, this paper reports the

results of an experimental investigation on the effect

of fan speed on energy efficiency produced by

OCPEMFCs with various power loads where the fan

is used to maintain the stack temperature to be in

permissible conditions. The net power output, stack

temperature and energy efficiency produced

experimentally (which is named as the Lab's system)

will be compared with the company's system.

2 EXPERIMENTAL

2.1 Experimental Setup

The open cathode PEMFC used in this experiment is

A commercially available fuel cell system (G-HFCS-

1kW36V hydrogen fuel cell system produces 1000

W), which is named as the Company's system in this

paper, and it consists of an electrical fan, an inlet

valve, a purge valve and a control unit(Dr. Colleen

Spiegel, 2019). The electrical fan used consists of two

fans with a voltage specification of 12V and a current

of 4.1A for each fan. Figure 1. is a schematic diagram

of experimental setup.

Fuel CellHydrogen tank

Controller

Fan

Computer

Load

(net Power)

Pressure Transmitted

Buck boost

converter

Current

Sensor

Figure 1: A Schematic of experimental setup.

The hydrogen pressure entering the anode side

(stack inlet) is controlled by a pressure regulator at 5

psi and also a temperature sensor which is used to

measure the stack temperature. In addition, there are

voltage and shunt current sensors that are used to

monitor the fuel cell voltage and current. The fuel cell

power levels were applied using six light bulbs

connected to the dimmer shield as various power

loads. The microcontroller unit (MCU) is used to

control the fan speed. using pulse width modulation

signal and data acquisition sensors. All information is

processed by the microcontroller and sent to the

computer which is then processed and recorded using

Visual Basic.net software.

Table 1: Specification of fuel cell system (G-HFCS

1kW36V) (Dr. Colleen Spiegel, 2019).

Description Values

Nominal Power 1000W

Nominal Voltage 36V

Nominal Current 27.8A

DC voltage Range 32-55V

Hydrogen Pressure 0.004 – 0.006 MPa

Hydrogen Consumption 11.7 L/min (at

nominal power)

Ambient temperature -5 to +35

o

C

Ambient Humidity 10% RH to 95%RH

Storage Ambient Temperature -10 to 50

o

C

2.2 Experiment Procedure

In this study, the fuel cell system was operated at

various stack power outputs, ranging between 100

and 500 W. Fan speed was controlled by varying the

duty cycle from 10-60% with a delay every minute on

each stack power output, where the smaller the duty

cycle, the lower the fan speed, which means the lower

the power consumption. During operation, the value

of voltage, current, temperature of stack and duty

cycle will be recorded, while the pressure of hydrogen

gas flowing into the anode channel is set to be

constant at 5 psi.

Experimental Study to Analyze the Effect of Fan Speed on Energy Efficiency in Open Cathode Pem Fuel Cells

337

To find the optimal fan duty cycle value, namely

the fuel cell is given a certain load constantly, then

the duty cycle value is increased at each step with an

initial value of 10%, 20%, 30% to 60%. Furthermore,

observing the stack temperature, the optimal duty

cycle value is obtained if the stack temperature value

has started to decrease but also considering the stack

temperature value is still within the range of

permitted conditions, namely below 50

o

C.

In efficiency analysis of the fuel cell system, the

net power output (P

net

) between our Lab's system was

compared with that of the company's system, where

P

net

is the difference between the stack power output

(P

stack

) and the power consumption of the auxiliary

components (P

auxiliary

) (Bizon, 2014).

P

net

= P

stack

- P

auxiliary

(1)

For the operation fan speed, controller provides

the supply voltage with pulse width modulation

(PWM) under duty cycle setting. A duty cycle (D) is

expressed as

D = t

pulse

/ t

cycle

(2)

Where t

pulse

is the duration of the pulse width and t

cycle

is the signal period (Brown, 1990).

3 RESULT AND DISCUSSIONS

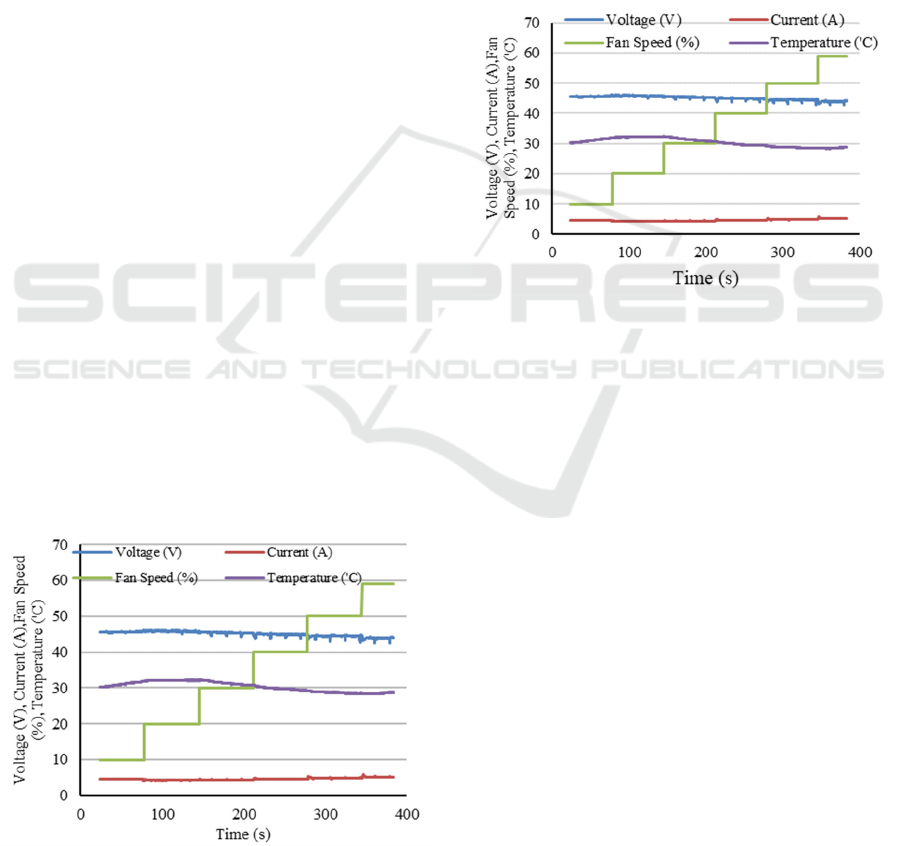

Fig. 2 shows the variations in the temperature,

voltage, and current of the OCPEMFC stack of the

Company's system under various load levels, which

auxiliary components of the Company’s system like

two electric fans that controlled by using built-in

controller so the user cannot control its velocity. It

can be seen that stack temperature and constant fan

speed to keep stack temperature below 50

o

C.

Figure 2: Distribution of temperature, voltage and current

of company’s System under variable speed fan.

The first experiment was the fuel cell was loaded

with 100 W where variations in the temperature,

current, and voltage of the OCPEMFC stack of the

Lab's system as shown in Figure 3. When the duty

cycle of the fan was 10%, the stack temperature

increased from 30 - 33

o

C in about 1 minute. When the

duty cycle changes to 20%, the stack temperature is

maintained constant at 33

o

C and the stack voltage

value is still maintained constant at 47 V. Next, when

the duty cycle is 30%, the stack temperature drops,

but the stack voltage also drops, this is due to there is

an additional load due to the faster fan speed. From

these results it can be stated that the optimal duty

cycle value for a 100W load is 20%.

Figure 3: Distribution of temperature, voltage and current

under variable speed fan with fuel cell loads 100W.

Figure 4 is the result of the fuel cell experiment

with a load of 200W. From the figure it can be seen

that when the duty cycle is less than 30%, the stack

temperature rises from 31-37

o

C for 140 seconds. This

phenomenon shows that the fan speed at a duty cycle

below 30%, the stack temperature will continue to

rise if it is operated for a long time and will cause a

decrease in fuel cell performance and result in

damage to the fuel cell membrane. When the duty

cycle is 30%, the stack temperature starts to drop and

at that time the stack voltage value is 45V. From this

experiment it can be concluded that the optimal value

of the duty cycle of the fan speed for a load of 200W

is 30%.

When the fuel cell is loaded with 300W as shown

in Figure 5, the stack temperature increases rapidly

from 33-43

o

C for 120 seconds with duty cycle values

of 10% and 20%. The stack temperature starts to drop

at 30% duty cycle with a constant stack voltage of

40V. From these results, that the optimal duty cycle

at 300W load is 30% and this is the same as at 200W

load.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

338

Figure 4: Distribution of temperature, voltage and current

under variable speed fan with fuel cell loads 200W.

Figure 5: Distribution of temperature, voltage and current

under variable speed fan with fuel cell loads 300W.

When the fuel cell is loaded with 400W, as shown

in Figure 6, the stack temperature continues to rise

when the duty cycle value is 10-30% with a value

close to 45

o

C, but when the duty cycle value is that

the stack voltage constant value is around 40V. When

the duty cycle is increased to 40%, the stack

temperature drops, followed by the stack voltage to

38V. So that the optimal duty cycle value is obtained

when the 400W load is 40%.

When the fuel cell is loaded with 500W as shown

in Figure 7, the fuel cell experiences a transient with

the stack voltage rising from 33V to a peak of 40V for

30 seconds. Besides that, the duty cycle of 10%, 20%,

30% is not able to reduce the stack temperature, as a

result, the stack temperature continues to increase

from 29 –44

o

C. When the duty cycle is 40%, the stack

temperature has decreased and the stack voltage has

reached a steady state point of 38V even though the

duty cycle value has been increased to 60%. From this

experiment it shows that the optimal duty cycle value

with a 500W load is 40% and this value is the same

when the fuel cell load is 400W.

Figure 6: Distribution of temperature, voltage and current

under variable speed fan with fuel cell loads 400W.

Figure 7. Distribution of temperature, voltage and current

under variable speed fan with fuel cell loads 500W.

Based on the experimental results above, it shows

that the stack temperature is very dependent on the

fuel cell load, the greater the fuel cell load, the greater

the stack temperature. In addition, the stack voltage at

steady state conditions also decreases when the load

increases (see Figure 8). Figure 8 also shows the stack

voltage to be a momentary drop caused by purging

activity. To increase fuel cell energy efficiency, apart

from maintaining the internal condition of the fuel

cell within the permitted area, it can also be done by

optimizing the power used to supply electronic

components such as electric fans which are used to

support the performance of the fuel cell or it is called

Auxiliary power consumption. As a result, the fan

needs to control its speed, where the size of the speed

is affected by the load from the fuel cell. Table 2

shows the conclusion of the results of the P

stack

comparison of the fuel cell between the Lab's System

and the Company's system during the experiment

with a load of 100-500 W.

Experimental Study to Analyze the Effect of Fan Speed on Energy Efficiency in Open Cathode Pem Fuel Cells

339

Figure 8: Comparison Stack Voltage under various

load of fuel cell.

Table 2: Comparison P

stack

fuel cell between Lab’s System

and Company’s system.

Fuel cell

loads

(Watt)

P

stack

of

Lab’s

system

(W)

P

stack

of

Company’s

system (W)

ΔP

stack

(W)

100 196.08 204.78 8

200 243.96 252.66 8.2

300 420 428.7 8.7

400 462.38 471.08 8.9

500 610.5 619.2 9

4 CONCLUSIONS

Based on the experimental results of setting the fan

speed manually at OCPEMFC 1000 watts with a load

of 100-500W, it can be concluded that:

1. The stack temperature is affected by the load of

the fuel cell. The greater the fuel cell load, the

stack temperature will increase faster.

2. Providing a fuel cell load of 100-500W or only

50% of the maximum capacity of the fuel cell, the

required duty cycle is no more than 40%.

3. The P

stack

power stack comparison between the

company's system and Lab's system is around 8W,

which means that the Lab's system's fuel cell can

minimize auxiliary power consumption by around

8W.

ACKNOWLEDGEMENTS

The author would like to thank the physics and

materials department for the support in the

development, research and innovation of fuel cell

technology. And also the author would like to thank

the fuel cell team such as supervisors and friends.

REFERENCES

Baik, K. D., & Yang, S. H. (2020). Development of cathode

cooling fins with a multi-hole structure for open-

cathode polymer electrolyte membrane fuel cells.

Applied Energy, 279.

https://doi.org/10.1016/j.apenergy.2020.115815

Bizon, N. (2014). Improving the PEMFC energy efficiency

by optimizing the fueling rates based on extremum

seeking algorithm. International Journal of Hydrogen

Energy, 39(20), 10641–10654.

https://doi.org/10.1016/j.ijhydene.2014.04.194

Brown, M. (1990). How a Switching Power Supply Works.

In Practical Switching Power Supply Design.

https://doi.org/10.1016/b978-0-08-051454-3.50005-9

Dr. Colleen Spiegel. (2019). Fuel Cell Store.

https://www.fuelcellstore.com/blog-section/how-to-

predict-fuel-cell-performance

Fernandez, A. M. I., Kandidayeni, M., Boulon, L., &

Chaoui, H. (2020). An Adaptive State Machine Based

Energy Management Strategy for a Multi-Stack Fuel

Cell Hybrid Electric Vehicle. IEEE Transactions on

Vehicular Technology, 69(1), 220–234.

https://doi.org/10.1109/TVT.2019.2950558

Gopi, K. H., Nambi, A., & Rajalakshmi, N. (2020). Design

and Development of Open Cathode PEM Fuel Cell –

Flow Analysis Optimization by CFD. Fuel Cells, 20(1),

33–39. https://doi.org/10.1002/fuce.201900124

Huang, Z. M., Su, A., Hsu, C. J., & Liu, Y. C. (2014). A

high-efficiency, compact design of open-cathode type

PEMFCs with a hydrogen generation system. Fuel,

122, 76–81. https://doi.org/10.1016/j.fuel.2013.12.058

Kurnia, J. C., Chaedir, B. A., Sasmito, A. P., & Shamim, T.

(2021). Progress on open cathode proton exchange

membrane fuel cell: Performance, designs, challenges

and future directions. Applied Energy, 283.

https://doi.org/10.1016/j.apenergy.2020.116359

Ling, C. Y., Cao, H., Chen, Y., Han, M., & Birgersson, E.

(2016). Compact open cathode feed system for

PEMFCs. Applied Energy, 164, 670–675.

https://doi.org/10.1016/j.apenergy.2015.12.012

Meng, K., Chen, B., Zhou, H., Shen, J., & Tu, Z. (2022).

Experimental investigation on voltage response

characteristics of hydrogen-oxygen proton exchange

membrane fuel cells under gas starvation. Energy

Conversion and Management, 268(July), 115973.

https://doi.org/10.1016/j.enconman.2022.115973

Meyer, Q., Himeur, A., Ashton, S., Curnick, O., Clague, R.,

Reisch, T., Adcock, P., Shearing, P. R., & Brett, D. J.

L. (2015). System-level electro-thermal optimisation of

air-cooled open-cathode polymer electrolyte fuel cells:

Air blower parasitic load and schemes for dynamic

operation. International Journal of Hydrogen Energy,

40(46), 16760–16766.

https://doi.org/10.1016/j.ijhydene.2015.07.040

ICATECH 2023 - International Conference on Advanced Engineering and Technology

340

Mousavi, S. A., & Mehrpooya, M. (2021). Fabrication of

copper centered metal organic framework and nitrogen,

sulfur dual doped graphene oxide composite as a novel

electrocatalyst for oxygen reduction reaction. Energy,

214. https://doi.org/10.1016/j.energy.2020.119053

Pangaribowo, T., Utomo, W. M., Bakar, A. A., &

Khaerudini, D. S. (2020). Review on Fuzzy Strategies

to Improve PEMFC Performance. 2020 2nd

International Conference on Broadband

Communications, Wireless Sensors and Powering,

BCWSP 2020, 53–58.

https://doi.org/10.1109/BCWSP50066.2020.9249458

Pei, H., Shen, J., Cai, Y., Tu, Z., Wan, Z., Liu, Z., & Liu,

W. (2014). Operation characteristics of air-cooled

proton exchange membrane fuel cell stacks under

ambient pressure. Applied Thermal Engineering, 63(1),

227–233.

https://doi.org/10.1016/j.applthermaleng.2013.11.012

Sasmito, A. P., Lum, K. W., Birgersson, E., & Mujumdar,

A. S. (2010). Computational study of forced air-

convection in open-cathode polymer electrolyte fuel

cell stacks. Journal of Power Sources, 195(17), 5550–

5563. https://doi.org/10.1016/j.jpowsour.2010.02.083

Shahsavari, S., Desouza, A., Bahrami, M., & Kjeang, E.

(2012). Thermal analysis of air-cooled PEM fuel cells.

International Journal of Hydrogen Energy, 37(23),

18261–18271.

https://doi.org/10.1016/j.ijhydene.2012.09.075

Souleman, N. M., Tremblay, O., & Dessaint, L. A. (2009).

A generic fuel cell model for the simulation of fuel cell

power systems. 2009 IEEE Power and Energy Society

General Meeting, PES ’09.

https://doi.org/10.1109/PES.2009.5275853

Zhang, J., Tang, Y., Song, C., Xia, Z., Li, H., Wang, H., &

Zhang, J. (2008). PEM fuel cell relative humidity (RH)

and its effect on performance at high temperatures.

Electrochimica Acta, 53(16), 5315–5321.

https://doi.org/10.1016/j.electacta.2008.02.074

Zhao, C., Xing, S., Chen, M., Liu, W., & Wang, H. (2020).

Optimal design of cathode flow channel for air-cooled

PEMFC with open cathode. International Journal of

Hydrogen Energy, 45(35), 17771–17781.

https://doi.org/10.1016/j.ijhydene.2020.04.165

Experimental Study to Analyze the Effect of Fan Speed on Energy Efficiency in Open Cathode Pem Fuel Cells

341