Productivity Analysis of Heavy Equipment in the Nglurup Pond

Project, Tulungagung Regency East Java Examined from Time and

Cost Analysis

Siti Choiriyah, Felicia Nuciferani, Theresia Maria Chandra Agusdini, Dewi Kusumaningrum

and Yoga Ilham

Civil Engineering, Planning and Civil Engineering Faculty, Institut Teknologi Adhi Tama Surabaya, Indonesia

Keywords: Cost, Efficiency, Heavy Equipment, Time.

Abstract: The construction of the Reservoir Nglurup in Tulungagung District has a length of 50 meters, this is used to

store water when it rains and can be stored for use during the summer. The process of excavating the body of

the reservoir uses heavy equipment to support dewatering work at the work site, excavating soil and removing

soil. The large number of heavy equipment operating at the location limits the ability of heavy equipment to

move, so it is necessary to plan the position of the heavy equipment in order to facilitate the work. The research

method was carried out by observing in the field. The excavation work for the reservoir body took 19 working

days with a total heavy equipment operational cost of IDR 270,000,000. While the planning calculation for

14 days with the total operational cost of heavy equipment amounted to IDR 382,889,800. The results of

calculating operator efficiency in terms of Availability Index, Physical Availability, Use of Ability, Effective

Utilization show how the operator's work is planned better than operators in the field.

1 INTRODUCTION

The pond development project is a building that is

built between hills where the area is limited for

maneuvering because the contours have extreme

different elevation. Meanwhile, excavation process in

the pond body needs to be prepared since the

excavation process would affect the water surface of

the construction area. Starting from the dewatering

and flow out the water to nearby body water such as

river (Robert J. Kodoatie & Roestam Sjarief, 2008).

As quoted from Rostiyanti in 2002, (Susy Fatena

Rostiyanti, 2008) heavy equipment is important for

construction project work, where the purpose of the

heavy equipment was utilized in construction work in

huge scale can be achieved as scheduled with result

as it planned. Excavation work on the body of the

Nglurup pond uses heavy equipment including

excavators, dump trucks, and water pumps. The

effectivity of heavy equipment is influenced by

several factors, the most significant of which are the

capacity, the duration of the process, and efficiency

factor (Hidayat, Iskandar, & Kudiantoro, F. F.

Wijayaningtyas, 2019). The skill level of the operator

in using the equipment will greatly affect the

effectiveness of the tool. skillful operator adaptive

their operation to the excavating environment based

on their empirical knowledge, and realizing the

efficient excavating. (Sakaida, Chugo, Yamamoto, &

Asama, 2008) The pond construction project needs to

pay attention to the stages of excavation work and the

effectivity of heavy equipment.

The pond was built due to drought conditions and

reduced water availability irrigation, construction of

reservoirs using the hydrological analysis method by

looking at the flood discharge using the Weduwen

method (Utami et al., 2015), analysis of the mainstay

discharge using the basic year method, analysis of

water demand and water balance (Herison,

Romdania, Purwadi, & Effendi, 2018). From the

results of the analysis of water demand, it is known

that the pond was planned with 100,752.736 m3, the

pond height is 18m, the elevation of the base of the

reservoir is 274.48 m, the effective width is 22.127 m.

(Hanggara & Irvani, 2019)

The work was planned to be completed in 14 days

whereas in reality, the work in the field was

completed in 19 days. Due to this delay, this study

was conducted to offer some solutions by changing

the specifications and amount of heavy equipment

348

Choiriyah, S., Nuciferani, F., Agusdini, T., Kusumaningrum, D. and Ilham, Y.

Productivity Analysis of Heavy Equipment in the Nglurup Pond Project, Tulungagung Regency East Java Examined from Time and Cost Analysis.

DOI: 10.5220/0012109600003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 348-353

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

from result of data analysis. However, the technic of

the pond’s construction will not be re-evaluated in

this study.

2 THEORETICAL REVIEWS

2.1 Heavy Equipment Productivity

As Rostiyanti (Susy Fatena Rostiyanti, 2008) state

that productivity is a comparison of the completion

achieved with all the resources used. The hourly

productivity equation and the factor of an equipment

efficiency are entered, the equation used is:

Productivity = Capacity x (60: Cycle Time) x

Efficiency (1)

2.2 Job Duration

How to calculate the duration of work is obtained

from the calculation of the volume of work divided

by productivity per day:

Duration = Work Volume/ Productivity per days (2)

2.3 Water Pump Productivity

The equation for calculating water pump productivity

refers to:

Q = Max Pump Capacity x Equipment Efficiency x

60 (3)

2.4 Excavator Productivity

The amount of productivity is influenced by capacity,

efficiency and cycle period. So that work can be done

without any problems and heavy equipment can be

used properly, the productivity requirements for the

excavator that will be used must be estimated first.

The equation for calculating excavator cycle time

(CT)

CT = Digging Time + Swing Fill Time + Empty

Swing Time + Dumping Time (5)

The equation for calculating the productivity of an

excavator (Q)

Q = (Work Volume per cycle (m3) x 60 x

Efficiency): CT (6)

The equation calculates the cost per day

Operating Cost = (Rental price + Fuel Price +

Operator Cost) x Working hours (7)

Determination for a small size of the bucket value

can be influenced by soil conditions according to

Table 1 as follows: (Sağlam & Bettemir, 2018).

Table 1: Bucket filling factor.

Material Bucke

t

Filling

Facto

r

General Floo

r

0.85-1.10

Sand and Gravel 0.90-1.05

Firm Clay 0.75-0.95

Soft Cla

y

0.65-0.90

Rock, well blaste

d

0.65-0.85

Rock, poorly blasted 0.40-0.65

2.5 Dump Truck Productivity

The equation for calculating dump truck cycle time

(CT)

CT = Load Time + Hauling Time (Loaded) +

Dumping Time + Hauling Time (Unloaded) + Idle

Time (8)

The equation for calculate the productivity of a

dump truck (Q)

Q = (Work Volume per cycle (m3) x 60 x Efficiency):

CT (9)

The equation calculates the cost per day, same as

Eq.7.

2.6 Operator Work Efficiency

Operator efficiency depends on the operator's mastery

or expertise in working on equipment while

completing a job. The more ideal the ability of an

operator, the higher the effectiveness factor. One of

the rules that can be used to calculate the operator

efficiency factor is as shown in Table 2 as follows:

(Zulkarnain, 2020).

Table 2: Operator efficiency value.

Tire Type

Efficiency Criteria

Day Time

N

ight Time

Crawler

50 minutes

(83%)

45 minutes

(75%)

Rubber

45 minutes

(75%)

40 minutes

(67%)

Productivity Analysis of Heavy Equipment in the Nglurup Pond Project, Tulungagung Regency East Java Examined from Time and Cost

Analysis

349

Availability Index (AI) is used to understand the

condition of the heavy equipment used. The equation

used is like:

𝐴𝐼

%

=

× 100%(10)

Physical Availability (PA) is a record of the

physical condition of the heavy equipment used. The

equation used is like:

PA = (W+ Standby Duration (S)): (W+R+S)) x 100%

(11)

Use of Ability (UA) is a way to find out how much

duration is used by heavy equipment to work when

used. The equation used is like:

UA = (W: (W+S)) x 100% (12)

Effective Utilization (EU) is a way of knowing

what percentage of available work time can be used

to operate productively. The equation used is like:

UE = (W: (W+R+S)) x 100% (13)

2.7 Heavy Equipment Used

The equation for calculating water pump productivity

refers to: Heavy equipment, which is often known in

work, is a device used to assist human work in

completing a job that is expected to use the assistance

of heavy equipment, especially for very large scope

development projects. Using heavy equipment aims

to ease human work and can provide the best results

in development work in a fairly short period of time

(Rochmanhadi, 1992). In the process of excavating

the reservoir body requires an effective tool to

support the work. Useful tools for the field are:

2.7.1 Water Pump

Water pump is a tool used to remove water or drain

water in the excavation area so that the workplace can

be effective when work is carried out. The diesel-

powered water pump was used in this project for its

portability and independently of electric supply.

(Water Master, 2017).

2.7.2 Excavator

According to Rostiyanti (Susy Fatena Rostiyanti,

2008) an excavator is a hydraulic digger that has a

bucket mounted in front of it. Excavators have two

types of wheels, namely tires and crawler wheels. The

excavator can be used in the same way that the bucket

is moved down and then up to the excavator body

where there is an arm, a boom, and a bucket which

driven by hydraulic power using a machine on the

track shoe.

2.7.3 Dump Truck

A dump truck is primarily used to transport materials

to and from a construction site. It is the safest way to

quickly transport loose materials from a site, and is

especially important in the early phases of a project

where the ground is being prepared for work to

commence. (ARDENT NEWSLETTER, 2019).

3 RESEARCH METHOD

3.1 Secondary Data Collections

Secondary data were used as mentioned are technical

specifications, to determine the length, height and

width of the reservoir body. Shop drawings were used

to calculate the volume for excavation. And the

Budgeting and Cost Estimating was used to estimate

the cost of excavation of the pond. The flowchart of

this research can be seen at figure 1.

The form should be completed and signed by one

author on behalf of all the other authors.

In order to construct the pond, the river stream

would be dammed and turned to other side until the

construction of pond had completed (Li, Xu, Xu, Liu,

& Wang, 2018). The following illustration, figure 2a,

depict the river meandering with A as the dam on

upstream and downstream, B as the diversion

channel, and C is the location of the water pump for

dewatering.

Figure 2b was depict the excavation process of the

pond gradually done from the left side of the origin

stream. Therefore, the loose soil would be transferred

by dump truck outside the area.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

350

Figure 1: Research flowchart.

Figure 2: a) Dewatering Process, b) Excavation Process.

4 RESULT AND DISCUSSION

When carrying out the work on the Nglurup pond

project, the suggested technique should be easier to

assess time and cost, excavation work on the Nglurup

pond body has a volume of 9,157 m3, on the

excavation planning schedule, it is planned to work

for 14 days, while the implementation that occurs in

the field is up to 19 days, so researchers re-evaluate

and provide better solutions to achieve planned

schedule.

Figure 3: Reservoir cut image.

Based on the figure 2a, before excavation was

carried out, it was necessary to make diversion

channels and dams so that water from upstream can

flow downstream through temporary diversion

channels without disturbing the excavation area, then

the next stage can be dewatered because there is no

water flow until the work area is free from remaining

water, while the excavation work area for the pond

body is divided into 2 sides, namely the left side P1

to P4 and the right side P4 to P7. And the volume of

soil that needs to be excavated in total is 9158 m3,

then the excavated soil is put into the dump truck and

moved to a predetermined location

4.1 Calculation of Heavy Equipment

Productivity

The specifications of the heavy equipment used in the

site can be seen in Table 3.

Start

Secondary Data Collection:

1. Technical Specifications

2. Shop Drawing

3. Budgeting & Cost Estimating

Data Analysis:

1. Methodology

2. Work Volume

3. Productivity

4. Time

5. Operational Cost

6. Operator Efficiency Value

Finish

Theoretical Review

Research Gap

Conclusion and suggestion

Productivity Analysis of Heavy Equipment in the Nglurup Pond Project, Tulungagung Regency East Java Examined from Time and Cost

Analysis

351

Table 3: Specifications of Heavy Equipment in the Field.

Equipment Type Efficiency Bucket factor

Workin

g

hour/Days

Cost (IDR) /Hours

Water

pump

- 0,78 Cap 6 HP 7

Ren

t

: 13.400

Fuel: 20.000

Excavator

Komatsu PC-

200-8 MO

0,75 1,2 m

3

7

Ren

t

: 276.500

Operator: 102.200

Fuel: 143.000

Dump

truck

Hino 130 HD 0,8 5 m

3

7

Ren

t

: 185.000

Operator: 63.200

Fuel: 30.000

4.2 Comparison of on Site and Planned

Productivity

The results of calculating the productivity, time and

cost of each heavy equipment in the field can be seen

in Table 4, namely:

Table 4: Productivity of Heavy Equipment on site.

No. Equipment T

y

pe Tools Amount

(Unit)

Production/

Hours

Production/

Hours

C

y

cle Time

(Mins)

Amount/

Days

1. On site water pump 1 211 m

3

1477 m

3

1

2. Planned water pump 1 211 m

3

1477 m

3

1

1. On site Excavato

r

2 34 m

3

233 m

3

0,6 19

2. Planned Excavato

r

2 51 m

3

357 m

3

0,6 14

1. On site dump truc

k

6 11,2 m

3

78,4 m

3

30 19

2. Planned dump truc

k

8 11,2 m

3

78,4 m

3

30 14

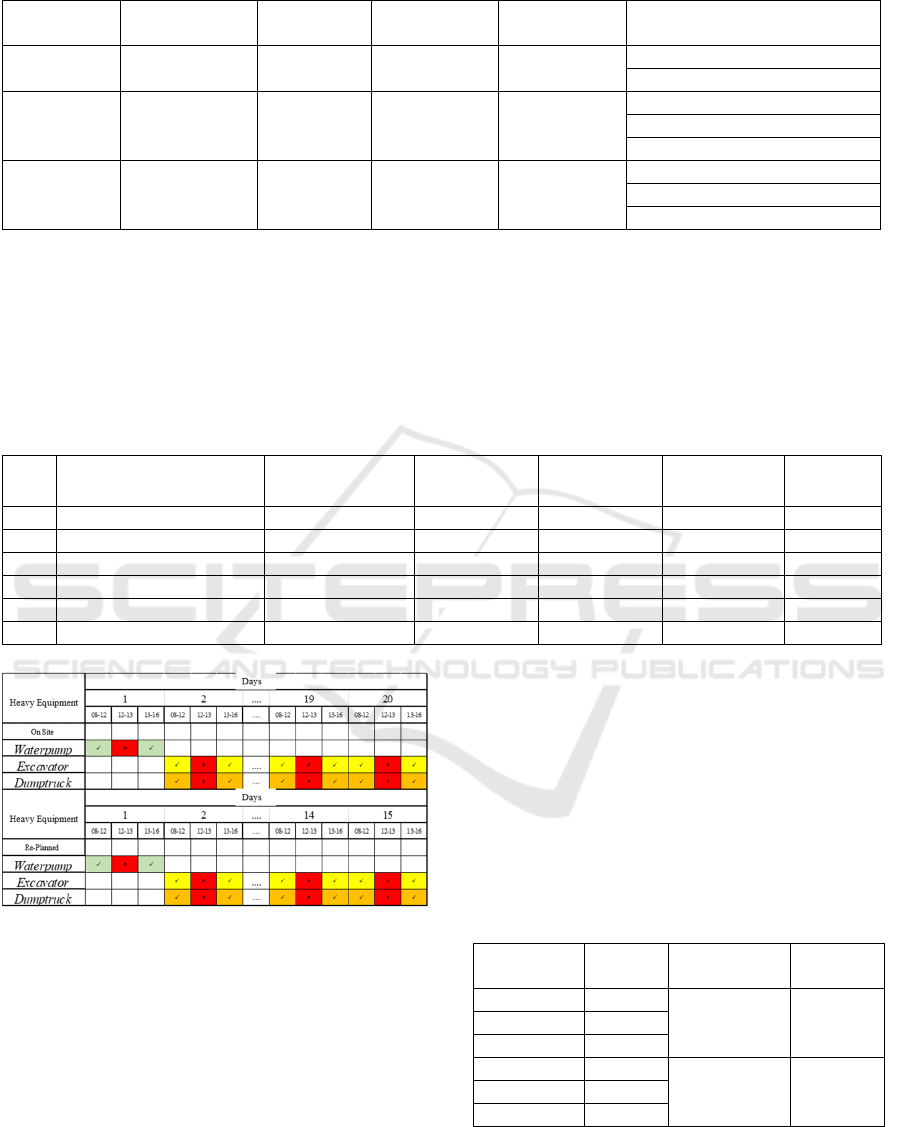

Figure 4: Graph simulation comparison of heavy equipment

work time.

According to Figure 4, Green; yellow; and orange

mark represents working hours, while red mark

represents lunch break hours. The data related to the

simulation graph that excavation is planned for 14

days but in the field of work it takes up to 19 days, so

the researchers tried to remark to the initial duration

of 14 days.

4.3 Comparison of Costs for

Excavation of Reservoir Body

After calculating the rental costs for each tool on the

table 3, the next step is to compare the productivity

on-site with planned as depict on table 5 and could be

conclude in table 5. It showed the total cost was

increased since the productivity by well-skilled

operator would also cost more.

Table 5: Cost comparison chart.

Equipment

Duration

(Days)

Cost Total Remark

Water pump 1

IDR

270.000.000

On site

work

Excavator 19

Dump truck 19

Water pump 1

IDR

382.889.800

Re-plan

work

Excavator 14

Dump truck 14

ICATECH 2023 - International Conference on Advanced Engineering and Technology

352

5 CONCLUSIONS

Based on the results of the analysis of productivity,

time, operating costs of heavy equipment and

comparison of operator work efficiency in the

Nglurup reservoir body excavation, the following

conclusions can be drawn:

1. The cost required for the work to go according

to the 14-day plan is IDR 382,889,800

2. Because there are differences in the

specifications of excavators and the number of

dump trucks, productivity was also different.

Productivity was planned to be better than in

the field because it has bigger specifications

and more numbers.

3. The results of calculations carried out by

researchers due to delays in work in the field

where the work should have gone 14 days to

19 days, the solution needs to be a change in

the specifications of the excavator and an

increase in the number of dump trucks so that

the results obtained are in accordance with the

desired target.

REFERENCES

ARDENT NEWSLETTER. (2019). How to Use a Dumper

Truck in Construction Projects.

Hanggara, I., & Irvani, H. (2019). Analisa Kelayakan

Teknis dan Ekonomi Embung Putukrejo Kabupaten

Malang. Reka Buana : Jurnal Ilmiah Teknik Sipil Dan

Teknik Kimia, 4(1), 30.

doi:10.33366/rekabuana.v4i1.1062

Herison, A., Romdania, Y., Purwadi, O. T., & Effendi, R.

(2018). Kajian Penggunaan Metode Empiris dalam

Menentukan Debit Banjir Rancangan pada Perencanaan

Drainase (Review). Jurnal Aplikasi Teknik Sipil, 16(2),

77. doi:10.12962/j2579-891x.v16i2.3819

Hidayat, S., Iskandar, T., & Kudiantoro, F. F.

Wijayaningtyas, M. (2019). Heavy equipment

efficiency, productivity and compatibility of coal mine

overburden work in east kalimantan. International

Journal of Mechanical Engineering and Technology

(IJMET), 10(6), 194–202.

Li, Z., Xu, X., Xu, C., Liu, M., & Wang, K. (2018). Dam

construction impacts on multiscale characterization of

sediment discharge in two typical karst watersheds of

southwest China. Journal of Hydrology, 558, 42–54.

doi:https://doi.org/10.1016/j.jhydrol.2018.01.034

Robert J. Kodoatie, P. D., & Roestam Sjarief, P. D. (2008).

Pengelolaan Sumber Daya Air Terpadu. Jakarta: Andi

offset.

Rochmanhadi. (1992). Alat-alat Berat Dan Penggunaannya.

Jakarta: Departemen Pekerjaan Umum.

Sağlam, B., & Bettemir, Ö. H. (2018). Estimation of

duration of earthwork with backhoe excavator by

Monte Carlo Simulation. Journal of Construction

Engineering, Management & Innovation, 1, 85–94.

doi:10.31462/jcemi.2018.01085094

Sakaida, Y., Chugo, D., Yamamoto, H., & Asama, H.

(2008). The analysis of excavator operation by skillful

operator - extraction of common skills -. In 2008 SICE

Annual Conference (pp. 538–542).

doi:10.1109/SICE.2008.4654714

Susy Fatena Rostiyanti. (2008). Alat Berat Untuk Proyek

Konstruksi (Second Edi). Jakarta: Rineka Cipta.

Utami, H. A., Nalendra, G. S., P, P. N., Sipil, J. T., Teknik,

F., Diponegoro, U., & Air, K. (2015). Perencanaan

Embung Somosari di Jepara. Jurnal Karya Teknik Sipil,

4(4), 529–537.

Water Master. (2017). How to Choose a Water Pump.

Zulkarnain, F. (2020). Pemindahan Tanah Mekanis dan

Peralatan Konstruksi. (M. Arifin, Ed.). Medan: Umsu

Press.

Productivity Analysis of Heavy Equipment in the Nglurup Pond Project, Tulungagung Regency East Java Examined from Time and Cost

Analysis

353