Damage Simulation Using Digital Image Correlation Technique

Under Review Development for Structural Monitoring

Cintantya Budi Casita

1,2,* a

, Data Iranata

1b

, Budi Suswanto

1c

and Masahide Matsumura

3d

1

Department of Civil Engineering, Faculty of Civil Engineering, Planning and Geo Engineering, Institut Teknologi Sepuluh

Nopember, Surabaya, Indonesia

2

Department of Civil Engineering, Faculty of Engineering, Universitas Pembangunan Nasional Veteran Jawa Timur,

Surabaya, Indonesia

3

Department of Civil Engineering, Faculty of Engineering, Kumamoto University, Kumamoto, Japan

Keywords: Digital Image Correlation, Structure Performance, Damage Characteristics, Monitoring, Stress-Strain,

Cracking, Technical Assessment.

Abstract: For a realistic assessment and forecast of the technical condition of a reinforced concrete, steel, or composite

structure during all phases of loading, it is necessary to have precise information regarding the stress–strain

state of the structure. Digital image correlation (DIC) is the optimal way for acquiring this information. DIC

is a method for identifying contactless structures that involves acquiring an image from an experimental

program as a physical object, converting it to digital form, and investigating its behavior in depth. In this

paper, a comprehensive examination of theoretical and experimental findings from numerous works is

presented. The open-source platform Ncorr built by the MATLAB software, a special capability to recognize

this DIC analysis as a support assessment is examined further. To comprehend the parameters, a systematic

technique and its correlation were also introduced in terms of image acquisition and post-processing. The

findings enable us to use DIC for more accurate stress-strain parameter measurement and structural behavior

evaluation.

1 INTRODUCTION

The damage of structural element is now concentrated

to be evaluated precisely, since it is related to the

performance of the infrastructure. Element structure

that interacts with the significant environment or

defect by high earthquake need to be repaired before

the life span of the structure reached (Alexander et al.,

2015; Fu & Larmie, 2005; Halstead, 1986; Interior &

Further, 2021; Yang & Li, 2012). Another case, such

a long-term operation, moving load, blasting load, or

any specific criteria to support the function of

structure, necessities specific stress-strain. This

particular condition also considered by the material

property. Reinforced concrete, steel and composite

structure will have a different behaviour in particular

to have a response to the effect of the damage (Yang

a

https://orcid.org/0000-0002-6628-9631

b

https://orcid.org/0000-0002-2988-3316

c

https://orcid.org/0000-0003-0274-9800

d

https://orcid.org/0000-0002-5794-2088

& Li, 2012). Various experimental program and

simulation modelling of damaged for any type of

structural elements has been studied to accommodate

the illustration of reliable assessment. This study is to

investigate the actual technical conditions that will

give the recommendation as well as to predict the

performance with its influence by the variety of

external factors (Abhyuday, 2017; Lindvall, 2003a;

Maalej et al., 2010).

In order to obtain the fully behaviour for the

purposes of the assessment, a high amount of

specimens under examination of experimental

program need to be conducted, which often

impractically difficult (Mccarter, 2010; Taffese et al.,

2019). Under numerical modelling, some

assumptions need to be included which sometimes

not similar to the actual case. Still the further

Casita, C., Iranata, D., Suswanto, B. and Matsumura, M.

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring.

DOI: 10.5220/0012113200003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 17-28

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

17

investigation needs to be verified. Digital Image

correlation (DIC) come as the alternative to identify

its structure stress-strain state at all stages of loading

with high accuracy, which will not be possible

conducted by conventional technique. As the

information, DIC is a class contactless methods

obtaining an image from the actual experimental –

physical object then converted into digital form. The

result can be plotted then specified the necessary

information about stress-strain state (Kumar et al.,

2019; Tambusay et al., 2020).

In addition, DIC is also called as an optical

metrology technique for measuring surface

deformation. It is a full-field image analysis

technique used to evaluate the mechanical properties

of a specimen by directly measuring displacement.

The displacement of the specimen is computed by

connecting a collection of images taken before,

during, and after loading. The surface geometry is

determined by observing a speckled pattern (typically

black and white) and monitoring how the pattern

deforms when multiple images from the sensor pair

are captured in time (Jarrett, 2021; Jones et al., 2018).

This data analysis using a photographic

illustration consists of comparison of the surface of

the reference image. This reference image compared

to the progress loading which in the next condition

also compare to the progress loading ahead (Sciuti et

al., 2021). DIC technique also correspond to the

different of deformation process which is followed by

the stress – strain accordingly (Blikharskyy et al.,

2022; Chai et al., 2020). Open source Ncorr Program

which built on MATLAB is used as the parameter of

investigation which provide some promising tool to

measure the stress-strain and displacement. It is also

a free software that include the postprocessing

analysis (Meng et al., 2017; Suryanto et al., 2017;

Tambusay et al., 2018a; Z. Zhang et al., 2018).

2 GENERAL REVIEW AND DIC

IMPLICATIONS

Since its introduction in the 1980s (Angst et al., 2009;

Farshadfar, 2017; Lindvall, 2003b), DIC has

functionally considerable used for a broad range of

applications across various disciplines, including

engineering. It is nowadays popular as a non-contact

full-field technique to measure stress – strain,

geometry and displacement of materials and structure

(Ghorbani et al., 2015; Helfrick et al., 2011). The

development of DIC technique to recent development

presents in Figure 1. DIC has widely used to section

program under laboratory testing where the size and

the dimension of the specimen is clearly specified. In

some current studies, DIC gain attention in large-

scale structural testing due to its benefits for

accommodating the testing conditions over point

measurement, with a proper distance (Banjare & Rao,

2018; Ghorbani et al., 2015; Hansen et al., 2019b;

Helfrick et al., 2011; Bing Pan et al., 2009; Practices

Figure 1: The history review of the development of DIC technique (Sciuti et al., 2021).

ICATECH 2023 - International Conference on Advanced Engineering and Technology

18

& Quanti, 2018; Sciuti et al., 2021). In large amount

literatures, DIC also classified as digital speckle

correlation method (Blikharskyy et al., 2022;

Carolina & Carolina, 2013; Tambusay et al., 2020).

Some identified as computer aided speckle

interferometry (Alexander et al., 2008), texture

correlation (Alexander et al., 2008; Azarsa & Gupta,

2017; Pontevedra et al., 2019), and electronic speckle

photography (Helfrick et al., 2011; Bing Pan et al.,

2009). Despite of variety of names, DIC in principle

based on the digital image processing and numerical

computation. In this particular review, 2D DIC

method will be more subjected to the measurement

since it is easy to be applicated. Somehow, if the test

specimen has a curve shape, this technique is no

longer applicable (Yin et al., 2019).

It should be concerned that speckle pattern serve

as the important rule in DIC method. Burch and

Tokarski discovered that a succession of speckles

appear when an item is irradiated by a coherent light

source, such as a laser. This finding suggests that the

speckle pattern is an important rule in DIC method.

(Burch & Tokarski, 1968), and These artificial white-

light speckle patterns aid in the identification of

surface deformation, which is necessary for the

research. Later on, Leendertz applied this technique

to the measurement of metrological standards. The

laser speckle method is typically utilized when

tension measurements are being carried out. The laser

speckle technique, which is an interference approach,

has certain limitations, including the following: It is

expensive and requires a testing environment that is

extremely steady (free from vibration) (Leendertz,

1970). Other research try to create a new approach

that use white light rather than a laser. This method is

known as the white light digital speckle technique. In

fact, the majority of recent studies on DIC feature

white-light speckle patterns, which were created

using a white light source or natural light

illumination.

After many years of research and investigation,

the DIC method has matured into a refined technique

(Asundi & North, 1998b; Chiang & Asundi, 1979).

DIC has numerous uses, such as measuring

displacement (Asundi & North, 1998a), velocity,

forecasting failure (Guo et al., 2020), and performing

fatigue study. Strain measurement is one of the most

useful applications of this technology because of its

outstanding accuracy over a wide variety of materials

(Ge et al., 2018; Rana et al., 2018; K. Yu et al., 2018;

W. Zhang et al., 2018). In this assessment, Pan et al.,

investigated a various digital image correlation

technique (Dong & Pan, 2017; B Pan et al., 2009;

Bing Pan, 2009; Bing Pan et al., n.d., 2012, 2016),

which have made significant advances in the areas of

measurement accuracy, efficiency, and resilience due

to their dogged efforts. 2D DIC illustrate to provide

some benefits as illustrated in Figure 2.

More significantly, 2D DIC provides some

constant images with high resolution that can be used

to provide any information related to the specimen

identification criteria. This information can include

actual cracking and changes in the specimen's

geometry, for example. This method also can be

applied to many areas. It is possible to state that two-

dimensional differential interference contrast (2D

DIC) is one of the most well-known and alluring

techniques that is widely used for a variety of

applications. In spite of this, the 2D DIC

methodology has a few drawbacks, which are

illustrated in Figure 3.

Figure 2: 2D DIC attractive advantages for structural

monitoring systems (Bing Pan et al., 2009).

Figure 3: 2D DIC disadvantages for structural

monitoring system (Bing Pan et al., 2009).

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring

19

Despite the fact that there is a great deal of

published material available on 2D DIC, there is a

shortage of a review study that concentrates on the

technical specifics and accuracy analysis of the

optical approach that is both straightforward and very

popular (Kumar et al., 2019). It would therefore

appear to be required to conduct a more in-depth

analysis of this strategy. The aim of this review is to

systematically give the technical assessment and give

the guidance to use advance 2D DIC, especially when

it is using opensource software such as Ncorr within

a part of MATLAB. The typical condition to take the

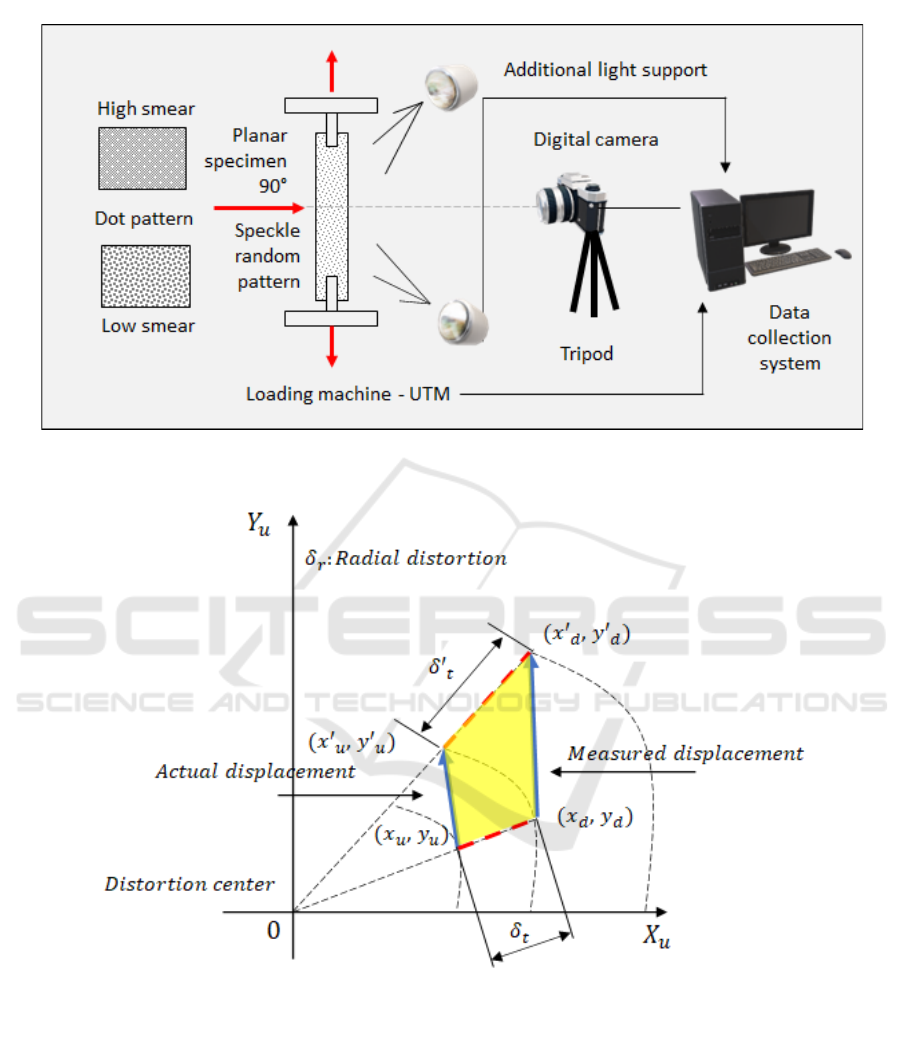

2D DIC technique refer to Figure 4 – optical image

acquistion (Bing Pan et al., 2009). This DIC also

consider as a low cost identification images since any

camera can be used for this analysis. For a clear

information, influence of distortion of changing

speckle pattern is illustrated in Figure 5. This is to

Figure 4: Typical photographic acquisition system for 2D DIC technique (Kumar et al., 2019).

Figure 5: Dot to dot – influence of distortion on the classifying 2D DIC measurement: coordinate before and

after loading (Bing Pan et al., 2009).

ICATECH 2023 - International Conference on Advanced Engineering and Technology

20

measure the displacement based on the progress

image (compare first image to the last image after

testing).

Implementing the 2D DIC approach typically

entails the following three steps, which must be

completed in that order: (1) setting up the specimen

and experiment; (2) taking pictures of the planar

specimen surface both before and after loading; and

(3) utilizing a computer software to process the

pictures in order to extract the needed displacement

and strain data. The topics of specimen preparation

and picture capturing are introduced initially in this

section (B Pan et al., 2009; Taylor et al., 2010). The

fundamental ideas and concepts of 2D DIC are then

explained. For support characteristics, some studies

also included, to have a proper understanding of the

the materials properties i.e., steel (Casita et al., 2022;

Casita, Sarassantika, et al., 2020; Casita, Wibisana,

et al., 2020), concrete (Komara, Wahyuni, et al.,

2019; Pertiwi et al., 2021; Susanti et al., 2021) and

composite materials (Komara, Tambusay, et al.,

2019)

2.1 Specimen Preparation

The schematic illustration of DIC system presented in

Figure 4. This kind of set up generally implies for 2D

DIC method (Kumar et al., 2019). The test specimen

requires to have random speckle pattern. To provide

the pattern artifical technique normally be made by

spraying black paints with the initial white painting as

the based of the surface. This based painting is

necessary when the surface colour representing a not

clear area.

To accommodate the better visualitation, a flat

contour normally be provided for each specimen.

Patterning also one important parameter, the most

frequent way of patterning in DIC is to apply a solid

white background followed by a random black speckle

pattern (Alaswad et al., 2018; Kim et al., 2018). Even

when alternative patterns are utilized, the pattern

applied to the surface of a specimen is typically known

as a speckle pattern. To ensure that each subset is

distinct, it is necessary to apply a speckle pattern with

recognizable, distinct, random features throughout its

region (Dong & Pan, 2017; Xu et al., 2017). Thus,

parameters like speckle size (Reu, 2015), pattern

contrast (Sciuti et al., 2021), edge sharpness of the

speckle (Thai, 2020), and speckle density (Jarrett,

2021) must also be considered.

For the DIC algorithm to recognize a pattern as

non-repeating and isometric, there must be enough

contrast between the pattern's light and dark portions

for each unique feature to be recognized (Reu, 2015).

The contrast of the pattern is affected by elements like

as the strength of the light source, the aperture of the

lens, the exposure duration of the camera, and the type

of paint used for the speckle (Jones et al., 2018). If an

image region is oversaturated or underexposed, the

DIC algorithm may wrongly correlate or drop

portions. Therefore, portions of a speckle pattern with

low contrast will enhance the noise of a DIC

measurement (Sciuti et al., 2021).

The speckle density relates to the quantity, size,

and distance between individual features in a speckled

pattern. The speckle density effects the size of a subset

and, consequently, the spatial smoothing and noise of

DIC displacement data. Effectively, the smaller the

speckle size that can be identified by the algorithm, the

smaller the subset size that may be applied. The good

practices guide produced by the International DIC

Society (iDICs) specifies the best feature density as

50% dark to light features, with 3-5 pixels as the

recommended size for one feature (Jones et al., 2018),

where a feature is defined as a distinct speckle dot or

form within the speckle pattern.

There are various ways to create a successful

speckle pattern. Commonly, the surface of the

specimen is sprayed with a solid backdrop of white

spray paint, followed by misting the surface by

spraying black paint into the air and allowing the

droplets to land on the surface (R B Berke et al., 2016;

Ryan B. Berke & Lambros, 2014; Ryan B Berke &

Lambros, 2014). A similar method includes

airbrushing black paint over the surface to produce a

black-and-white pattern (Hansen et al., 2019a).

Another method employs toothbrush bristles to flick

black paint across the specimen's surface (B. Yu et al.,

2017).

The challenge to prepare the images in this

measurement relate to the camera and lens

requirement and also the effective distance to position

the camera. This parameter relates to the spatial

resolution of each images (Practices & Quanti, 2018;

Thai, 2020), which considers to visualize the stress –

strain characteristics. To prevent having distortion and

blurry images. some recommendation to aquire 2D

DIC method ilusrated in Table 1.

Table 1: Recommendation of DIC techinque (Blikharskyy

et al., 2022).

DIC pattern Concep

t

High

contrast

Dark black dots on a bright white

background on bright white dots

on a dark black back

g

round

50%

covera

g

e

Equal amounts of white and

b

lack on the surface

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring

21

DIC pattern Concep

t

Consistent

speckle sizes

At least five pixels in size

Isotropic No bias in any particular

orientation

Rando

m

N

or repetitive

2.2 Data Acquisition

From the process of experimental program, digital

images is recorded during the phase of loading.

During the process, stress – strain will be developed

in the region of interest. The accuracy of the result

may be obtained by the resolution of the images

which is considered to have a proper zoom in

analysed area (Blikharskyy et al., 2022). A previous

research recommend to have subset size in pixels

64×64 under resolution of image 250 pixels/mm.

Additional light may be added according to the actual

conditions. Ghani et. Al., implied the research using

4.288×2.848 pixels with a setup of Nikon D90 (Ghani

et al., 2016). Another characterized as a low budget

DIC camera, using low to medium acquisition speed

with 5 M pixels at the sampling speed at 0.2 Hz , or

the research with 3.2 M pixels with the speed up to

121 fps (Blikharskyy et al., 2022).

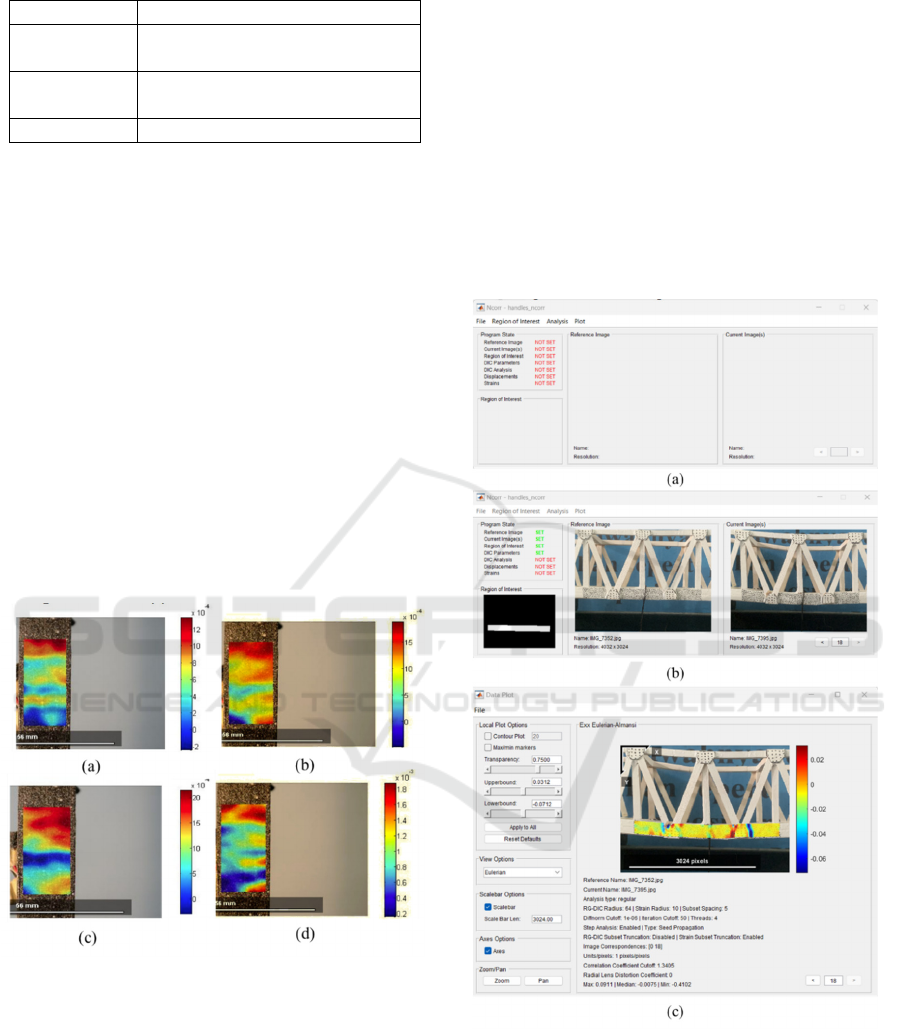

Figure 6: Data acquisition 2D DIC – matching to uniaxial

test method (Ghani et al., 2016).

As the setup of DIC completed, the integrated test

also prepared in parallel, to plot stress – strain curve

using uniaxial testing machine matching with the load

cell and LVDT. Some illustrations given as follow to

record the acquisition of images in accordance to

Gani, et. al. (Ghani et al., 2016). This study

illustrating the process of 2D DIC using Ncorr

opensource program based on MATLAB. The data

acquisition taken from tensile testing of coupon steel

specimen, where the speckle pattern provided by

black paint as the based and sprayed by white paint

using air spray. The loading cited to take the

illustrated images for each step respectively, 0.5 kN,

1, kN, 1.5 kN and 2.0 kN.

2.3 Ncorr Program

Ncorr is an open source 2D digital image correlation

MATLAB software. It employs numerous unique 2D

DIC methods, is entirely contained within the

MATLAB environment, and includes plotting tools

for the generation of figures.

Figure 7: (a) Ncorr main interface, (b) Second interface

after loading reference image, (c) Strain profile.

The computationally expensive algorithms are

optimized with C++/MEX, while the GUI is primarily

written in m-code. The objective is to give the users

an easy to use, efficient, and versatile DIC

application. In detail the use of Ncorr is to aims

several objectives; (1) develop a strong, open-source

ICATECH 2023 - International Conference on Advanced Engineering and Technology

22

code for 2D digital picture correlation, (2) provide

resources for the use/understanding of the software

and the underlying DIC algorithms, and (3) display

applications and examples of the program, (4) receive

constructive input from users to help improve the

application and resources on this website (Suryanto et

al., 2017; Tambusay et al., 2018b).

The main menu of Ncorr program is illustrated in

Figure 7(a), which included to identify the reference

image - the image before loading. To obtain the

specify section area to undertake stress – strain, the

object needs to be classified to small subset. Each

subset need to be have a special pattern, so the

program can distinguish the similarity. This small

subset evaluated by subset radius parameter, r, and

subset spacing parameter, s. In this program, the

deformation is assumed to imply homogeneously

(Francesca et al., 2018; Ghani et al., 2016; Meng et

al., 2017). Apart from the feature provided by Ncorr,

the program also supports to handle multi-thread

computation. For more information on the

development of the program, can be found

http://www.ncorr.com/.

The local displacement vector is formed, and the

deformation inside each subset is computed, based on

the location of the center-point of the subset, which is

present in both the reference picture and the target

image. In order to acquire the whole displacement

map, which is necessary for deriving strains, this

method must be performed for each and every subset

block that covers the entire surface of the object

(Dong & Pan, 2017).

Figure 7(b) displays the main interface of Ncorr

program after input reference image. One things after

open the program on MATLAB, the images with the

same file name need to be uploaded and this will then

displayed on the main screen. Then, those images that

is taken during the loading process uploaded after. In

the next step, the region of interset needs to be

clarified as inform on the Figure 7(c). Figure 7

presents the an example illustration of the strain maps

after processing the 2D DIC analysis.

3 CASE STUDY – STEEL

STRUCTURE

The research focused by Yoneyama, et al., on the 2D

DIC under experimental program of a simple beam

structure. The test set up is for flexural beam within

the concept of three points bending. The deflection is

the objective of this study in terms of classifying DIC

method under structural element with variety of

speckle pattern. A wide flange beam element

500cm×20cm×0.8cm is used with the steel grade of

SS400. The modulus elasticity is 210 GPa with the

moment inertia 16×10

6

mm

2

. The quality of the

images set up to 3504×2336 pixels using a normal

lens and a shift lens. The speckle random pattern

placed using spraying gun with a white color

(Yoneyama et al., 2005).

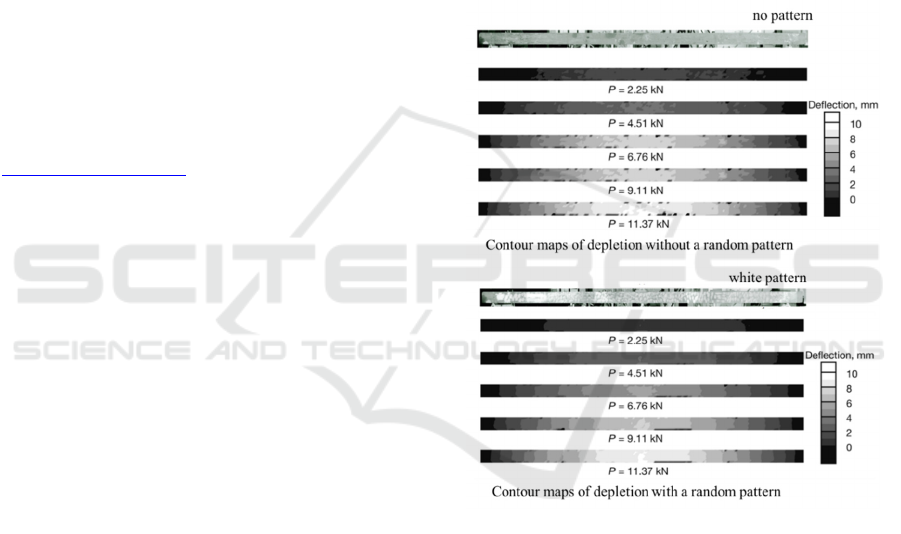

From those images in Figure 8, it is obvious that

high accuracy measurement provided with the

specimen with random pattern. The deflection of the

specimen without pattern represent no accurate

deformed shape on the digital illustration (Yoneyama

et al., 2005).

Figure 8: Illustrated 2D DIC obtained by two different

condition – with and without random speckle pattern vs.

normal lens and shift lens (Yoneyama et al., 2005).

Further investigation conducted by Arola, et. al.,

under ultra-high strength structural steels (Pontevedra

et al., 2019). The test conducted on UTM machine.

The objective of the research is to measure the

bending force which relate to the punch stroke

corresponding to bending angle. Then

100mm×150mm×6mm rectangular are investigated.

The speed rate for the experimental program used as

0.7 mm/s. The illustrated set up and specimen are

presented in Figure 9, where the digital camera

positioned under the specimen. With this study, a

better understanding of the behaviour of ultra-high

strength steel under bending conditions can be

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring

23

evaluated. More detailed information can be found

and assessted as parameter analysis on the optimal

strain calculation.

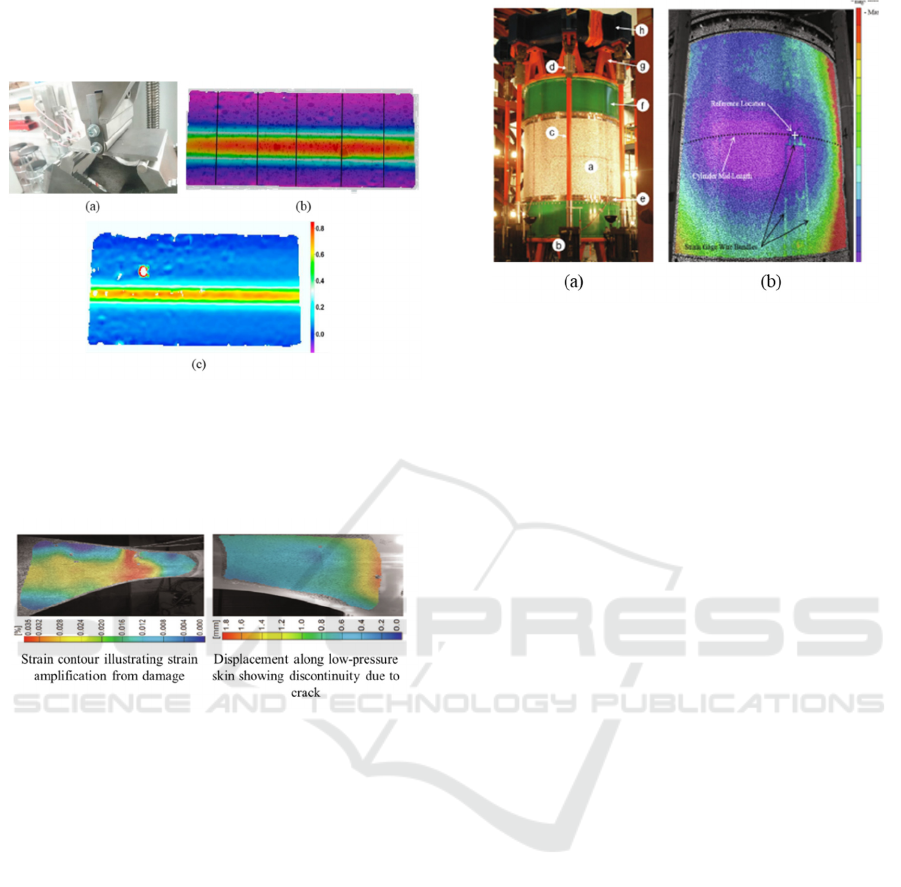

Figure 9: (a) Uniaxial bending test of steel plate specimen;

the position of the camera to take the images is below the

specimen, (b) 2D DIC taken from the bottom of the plate –

seen from the deform axis, (c) homogenous strain surface

(Pontevedra et al., 2019).

Figure 10: Damage detection results using DIC technique

(Janeliukstis & Chen, 2021).

Another implementated large scale structural

testing application introduced by another

researchers, Leblanc et. al., identified the damage of

water turbine blade using full-field DIC

measurements (see the Figure 10). This analysis

detecs the damage location coming from the stress

concentration arising from the load. Sufficient

illustrations found in good agreement with finite

element simulation results (Janeliukstis & Chen,

2021). Interesting structural system also represent in

8-feet diameter cylinder shell which investigated the

effects of buckling parameter (Janeliukstis & Chen,

2021) as illustrated in Figure 11.

It is confirmed that the change phase of each step

of loading can be provided by DIC measurements.

This valuable illustration can assess high accuracy to

determine recommendation and selection criteria

considering the size, position and dimensions. The

data capture from DIC also allowed for the

determination

of crack length measurements during

F

igure 11: (a) Specimen configuration – a shell cylinder use

for drainage hollow, (b) measured of stress-strain plane (B

Pan et al., 2009).

the experiment. This crucial performance and

material characterisation can aid in the creation of

finite element analysis models for the prediction of

composite failure and lead to design enhancements

(Dong & Pan, 2017; Janeliukstis & Chen, 2021).

4 CONCLUSIONS

Reclusively, the DIC technique has been widely used

for variety of specimen; start from small specimens to

large full-scale structures, but less so for testing steel

structure especially in the connection. This review

focuses on the basic parameter and example of recent

study of the DIC measurements. Ncorr program

represent one of the alternatives which is applied

globally. Some findings are taken as the consideration

as follows: (1) preparation phase consider as the

important part to identify the results of observation

i.e., images quality, pattern condition, effective

distance and surface of the specimen followed by the

lightning conditions, (2) to accommodate the

accuracy, controlled evaluation of the experimental

program also needed. Emphasises are specially

placed on the displacement. (3) concern as the easy

application of analysis, 2D DIC come as a great

alternative but limited for in-plane deformation. For

the complex component such as multi-shaped

product, curved shaped surface and etc, the advanced

evaluation needs to use 3D DIC. It is more practical

and effective, but high use of technology needed. It is

believed that 3D DIC will more gain applications in

the near future.

Further work will focus on a number of

prospective avenues for extending the existing

research, Future research will focus on a number of

ICATECH 2023 - International Conference on Advanced Engineering and Technology

24

prospective avenues for extending our existing

research, such as high-performance hybrid CPU and

GPU parallel computation to further improve the

computation efficiency in order to accomplish real-

time measurement by balancing the computation jobs

within them. In addition, the measurement accuracy

near the crack is frequently low, so it is still necessary

to develop high-accuracy DIC measurement in the

case of a fracture by detecting the crack based on the

significant changes in displacements and assigning

different weightages to the pixels in the deformed

subsets based on the position of the crack.

ACKNOWLEDGEMENTS

The author gratefully acknowledged the financial

support of the Indonesia Endowment Fund for

Education (LPDP) Ministry of Finance Republic

Indonesia and the support of Kumamoto University

under the partnership scheme.

REFERENCES

Abhyuday, T. (2017). Fundamentals of direct displacement

based design procedure - A brief introduction. Disaster

Advances, 10(6), 40–43.

Alaswad, G., McCarter, W. J., & Suryanto, B. (2018).

Moisture movement within concrete exposed to

simulated hot arid/semi-arid conditions. Proceedings of

the Institution of Civil Engineers - Construction

Materials, 1–15.

https://doi.org/10.1680/jcoma.18.00012

Alexander, M. G., Dehn, F., & Moyo, P. (2008). Concrete

Repair, Rehabilitation and Retrofitting II. In Concrete

Repair, Rehabilitation and Retrofitting II.

https://doi.org/10.1201/9781439828403

Alexander, M. G., Dehn, F., & Moyo, P. (2015). Concrete

Repair, Rehabilitation and Retrofitting IV. In Concrete

Repair, Rehabilitation and Retrofitting IV.

https://doi.org/10.1201/b18972

Angst, U., Elsener, B., Larsen, C. K., & Vennesland, Ø.

(2009). Cement and Concrete Research Critical

chloride content in reinforced concrete — A review.

Cement and Concrete Research, 39(12), 1122–1138.

https://doi.org/10.1016/j.cemconres.2009.08.006

Asundi, A., & North, H. (1998a). White-light Speckle

Method - Current Trends. Optics and Lasers in

Engineering, 29(2–6), 159–169.

https://doi.org/10.1016/S0143-8166(97)00083-3

Asundi, A., & North, H. (1998b). White-light Speckle

Method — Current Trends. 29, 159–169.

Azarsa, P., & Gupta, R. (2017). Electrical Resistivity of

Concrete for Durability Evaluation: A Review.

Advances in Materials Science and Engineering, 2017.

https://doi.org/10.1155/2017/8453095

Banjare, S. V. R., & Rao, H. M. B. C. (2018). Mechanical

Testing of Micro-specimens of Al6061-T6 Using DIC

for Strain Measurement.

Berke, R B, Sebastian, C. M., Chona, R., Patterson, E. A.,

& Lambros, J. (2016). High Temperature Vibratory

Response of Hastelloy-X : Stereo-DIC Measurements

and Image Decomposition Analysis. 231–243.

https://doi.org/10.1007/s11340-015-0092-3

Berke, Ryan B., & Lambros, J. (2014). Ultraviolet Digital

Image Correlation (UV-DIC) for High Temperature

Applications. Review of Scientific Instruments, 85(4),

1–10. https://doi.org/10.1063/1.4871991

Berke, Ryan B, & Lambros, J. (2014). Ultraviolet digital

image correlation ( UV-DIC ) for high temperature

applications. 045121, 1–10.

Blikharskyy, Y., Kopiika, N., Khmil, R., & Selejdak, J.

(2022). applied sciences Review of Development and

Application of Digital Image Correlation Method for

Study of Stress – Strain State of RC Structures.

Burch, J. M., & Tokarski, J. M. J. (1968). Production of

Multiple Beam Fringes from Photographic Scatterers.

Optica Acta: International Journal of Optics

, 15(2),

101–111. https://doi.org/10.1080/713818071

Carolina, S., & Carolina, S. (2013). Digital imaging

techniques in experimental stress analysis Digital

imaging techniques in experimental stress analysis.

Optical Engineering, 21(3), 427–431.

Casita, C. B., Sarassantika, I. P. E., & Sulaksitaningrum, R.

(2020). Behaviour of Rectangular Concrete Filled

Tubes and Circular Concrete Filled Tubes under Axial

Load. Journal of Applied Sciences, Management and

Engineering Technology, 1(1), 14–20.

Casita, C. B., Suswanto, B., & Komara, I. (2022).

Analytical Study of Rectangular Concrete-Filled Tubes

( RCFT ) Connections using Finite Element Analysis

under Cyclic Loading. 19(17), 1–15.

Casita, C. B., Wibisana, H., & Kamandang, Z. R. (2020).

Algorithm Analysis of Polynomial Mathematical

Models of Noise Pollution due to Traffic Volume in the

Region of West Surabaya. Journal of Physics:

Conference Series, 1569(4).

https://doi.org/10.1088/1742-6596/1569/4/042043

Chai, J., Liu, Y., Ouyang, Y., Zhang, D., & Du, W. (2020).

Application of Digital Image Correlation Technique for

the Damage Characteristic of Rock-like Specimens

under Uniaxial Compression. 2020.

Chiang, F. P., & Asundi, A. (1979). White Light Speckle

Method of Experimental Strain Analysis. Applied

Optics, 18(4), 409.

https://doi.org/10.1364/ao.18.000409

Dong, Y. L., & Pan, B. (2017). A Review of Speckle Pattern

Fabrication and Assessment for Digital Image

Correlation. https://doi.org/10.1007/s11340-017-0283-

1

Farshadfar, O. (2017). Performance Evaluation of

Corrosion Protection Systems for Reinforced Concrete.

PhD Thesis, University of Kansas, United States of

America, 122.

Francesca, S., Carlo, C. G., Luca, D. N., Rocco, F., &

Marco, R. (2018). Comparison of low-complexity

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring

25

algorithms for real-time QRS detection using standard

ECG database. International Journal on Advanced

Science, Engineering and Information Technology,

8(2), 307–314.

https://doi.org/10.18517/ijaseit.8.2.4956

Fu, C. C., & Larmie, E. A. (2005). State Highway

Administration Rehabilitation and Maintenance of

Road Pavements Using High Early Strength Concrete.

August.

Ge, W. J., Ashour, A. F., Ji, X., Cai, C., & Cao, D. F.

(2018). Flexural behavior of ECC-concrete composite

beams reinforced with steel bars. Construction and

Building Materials, 159, 175–188.

https://doi.org/10.1016/j.conbuildmat.2017.10.101

Ghani, A., Ali, M. B., Malingam, S. D., & J, M. (2016).

Digital Image Correlation ( DIC ) Technique in

Measuring Strain Using Opensource Platform. Journal

of Advanced Research in Applied Mechanics, 26(1),

10–21.

Ghorbani, R., Matta, F., & Sutton, M. (2015). Full-Field

Deformation Measurement and Crack Mapping on

Confined Masonry Walls Using Digital Image

Correlation Full-Field Deformation Measurement and

Crack Mapping on Confined Masonry Walls Using

Digital Image Correlation. January.

https://doi.org/10.1007/s11340-014-9906-y

Guo, X., Yang, J., & Xiong, G. (2020). Influence of

supplementary cementitious materials on rheological

properties of 3D printed fly ash based geopolymer.

Cement and Concrete Composites, 114(July), 103820.

https://doi.org/10.1016/j.cemconcomp.2020.103820

Halstead, W. J. (1986). Use of Fly Ash in Concrete.

National Cooperative Highway Research Program,

Synthesis of Highway Practice, 96(Reapproved), 1–34.

Hansen, R. S., Bird, T. J., Voie, R., Burn, K. Z., & Berke,

R. B. (2019a). A High Magnification UV Lens for High

Temperature Optical Strain Measurements. Review of

Scientific Instruments, 90(4).

https://doi.org/10.1063/1.5081899

Hansen, R. S., Bird, T. J., Voie, R., Burn, K. Z., & Berke,

R. B. (2019b). A high magnification UV lens for high

temperature optical strain measurements A high

magnification UV lens for high temperature optical

strain measurements. 045117(April).

https://doi.org/10.1063/1.5081899

Helfrick, M. N., Niezrecki, C., Avitabile, P., & Schmidt, T.

(2011). 3D digital image correlation methods for full-

field vibration measurement. Mechanical Systems and

Signal Processing, 25(3), 917–927.

https://doi.org/10.1016/j.ymssp.2010.08.013

Interior, I., & Further, R. R. (2021). Standard corrosion

protection systems for buildings. 1–12.

Janeliukstis, R., & Chen, X. (2021). Review of digital

image correlation application to large-scale composite

structure testing. Composite Structures, 271

(April),

114143.

https://doi.org/10.1016/j.compstruct.2021.114143

Jarrett, S. R. (2021). The Effect of Bit Depth on High

Temperature Digital Image Correlation Measurements.

In Utah State University.

Jones, E. M. C., Iadicola, M. A., Bigger, R., Blaysat, B.,

Boo, C., Grewer, M., Hu, J., Jones, A., Klein, M.,

Raghavan, K., Reu, P., Schmidt, T., Siebert, T.,

Simenson, M., Turner, D., Vieira, A., & Weikert, T.

(2018). A Good Practices Guide for Digital Image

Correlation. International Digital Image Correlation

Society, 94.

Kim, J., McCarter, W. J., & Suryanto, B. (2018).

Performance assessment of reinforced concrete after

long-term exposure to a marine environment.

Construction and Building Materials, 192, 569–583.

https://doi.org/10.1016/j.conbuildmat.2018.10.151

Komara, I., Tambusay, A., Sutrisno, W., & Suprobo, P.

(2019). Engineered Cementitious Composite as an

innovative durable material: A review. ARPN Journal

of Engineering and Applied Sciences, 14(4).

Komara, I., Wahyuni, E., Suprobo, P., & Taşkin, K. (2019).

Micro-Structural Characterization of the bond strength

capacity of adhesive material in the alternative of cold-

formed steel frame system. IOP Conference Series:

Materials Science and Engineering, 462(1).

https://doi.org/10.1088/1757-899X/462/1/012004

Kumar, S. L., Aravind, H. B., & Hossiney, N. (2019).

Results in Engineering Digital image correlation ( DIC

) for measuring strain in brick masonry specimen using

Ncorr open source 2D MATLAB program. Results in

Engineering, 4(August), 100061.

https://doi.org/10.1016/j.rineng.2019.100061

Leendertz, J. A. (1970). Interferometric Displacement on

Scattering Surfaces utilizing Speckle Effect. Journal of

Physics Engineering: Scientific Instruments, 3, 214–

218.

Lindvall, A. (2003a). Environmental actions on concrete

exposed in marine and road environments and its

response.

Lindvall, A. (2003b). Environmental actions on concrete

exposed in marine and road environments and its

response.

Maalej, M., Chhoa, C. Y., & Quek, S. T. (2010). Effect of

cracking, corrosion and repair on the frequency

response of RC beams. Construction and Building

Materials, 24(5), 719–731.

https://doi.org/10.1016/j.conbuildmat.2009.10.036

Mccarter, W. J. (2010). ARROW @ TU Dublin

Developments in Monitoring Techniques for Durability

Assessment of Cover-zone Concrete.

Meng, D., Huang, T., Zhang, Y. X., & Lee, C. K. (2017).

Mechanical behaviour of a polyvinyl alcohol fibre

reinforced engineered cementitious composite (PVA-

ECC) using local ingredients. Construction and

Building Materials, 141, 259–270.

https://doi.org/10.1016/j.conbuildmat.2017.02.158

Pan, B, Xie, H., Yang, L., & Wang, Z. (2009). Accurate

Measurement of Satellite Antenna Surface Using 3D

Digital Image Correlation Technique. 194–200.

Pan, Bing. (2009). Reliability-guided digital image

correlation for image deformation measurement. 48(8),

1535–1542.

Pan, Bing, Qian, K., Xie, H., & Asundi, A. (n.d.). Two-

dimensional digital image correlation for in-plane

ICATECH 2023 - International Conference on Advanced Engineering and Technology

26

displacement and strain measurement : a review.

https://doi.org/10.1088/0957-0233/20/6/062001

Pan, Bing, Qian, K., Xie, H., & Asundi, A. (2009). Two-

dimensional digital image correlation for in-plane

displacement and strain measurement : a review.

Measurement: Journal of the International

Measurement Confederation, 062001(20), 1–17.

https://doi.org/10.1088/0957-0233/20/6/062001

Pan, Bing, Tian, L., & Song, X. (2016). NDT & E

International Real-time , non-contact and targetless

measurement of vertical de fl ection of bridges using

off-axis digital image correlation. NDT and E

International, 79, 73–80.

https://doi.org/10.1016/j.ndteint.2015.12.006

Pan, Bing, Wu, D., & Yu, L. (2012). Optimization of a

three-dimensional digital image correlation system for

deformation measurements in extreme environments.

51(19), 4409–4419.

Pertiwi, D., Komara, I., & Fristian, R. (2021). Design

concept of reinforced concrete beams with large web

openings. IOP Conference Series: Materials Science

and Engineering, 1010, 012039.

https://doi.org/10.1088/1757-899x/1010/1/012039

Pontevedra, V., Arola, A., Kaijalainen, A., Kesti, V.,

Pokka, A., & Larkiola, J. (2019). Digital image

correlation and optical strain measuring in bendability

Digital image correlation and optical strain measuring

in bendability assessment of strength structural steels

Engineering of strength structural steels Costing

models for capacity opti. Procedia Manufacturing, 29,

398–405.

https://doi.org/10.1016/j.promfg.2019.02.154

Practices, G., & Quanti, U. (2018). A Good Practices Guide

for Digital Image Correlation.

Rana, M. M., Lee, C. K., Al-Deen, S., & Zhang, Y. X.

(2018). Flexural behaviour of steel composite beams

encased by engineered cementitious composites.

Journal of Constructional Steel Research, 143, 279–

290. https://doi.org/10.1016/j.jcsr.2018.01.004

Reu, P. (2015). All about Speckles : Contrast. 51(4), 1–2.

Sciuti, V. F., Canto, R. B., Neggers, J., & Hild, F. (2021).

On the benefits of correcting brightness and contrast in

global digital image correlation : Monitoring cracks

during curing and drying of a refractory castable. Optics

and Lasers in Engineering, 136(June 2020), 106316.

https://doi.org/10.1016/j.optlaseng.2020.106316

Search, H., Journals, C., Contact, A., Iopscience, M., &

Address, I. P. (n.d.). Interferometric displacement

measurement on scattering surfaces utilizing speckle

effect. 214.

Suryanto, B., Tambusay, A., & Suprobo, P. (2017).

Crack

Mapping on Shear-critical Reinforced Concrete Beams

using an Open Source Digital Image Correlation

Software Crack Mapping on Shear-critical Reinforced

Concrete Beams using an Open Source Digital Image

Correlation Software. September.

https://doi.org/10.9744/ced.19.2.93-98

Susanti, E., Istiono, H., Komara, I., Pertiwi, D., &

Septiarsilia, Y. (2021). Effect of fly ash to water-

cement ratio on the characterization of the concrete

strength. IOP Conference Series: Materials Science

and Engineering, 1010, 012035.

https://doi.org/10.1088/1757-899x/1010/1/012035

Taffese, W. Z., Nigussie, E., & Isoaho, J. (2019). Internet

of things based durability monitoring and assessment of

reinforced concrete structures. Procedia Computer

Science, 155(2018), 672–679.

https://doi.org/10.1016/j.procs.2019.08.096

Tambusay, A., Suryanto, B., & Suprobo, P. (2018a).

Visualization of shear cracks in a reinforced concrete

beam using the digital image correlation. International

Journal on Advanced Science, Engineering and

Information Technology, 8(2), 573–578.

https://doi.org/10.18517/ijaseit.8.2.4847

Tambusay, A., Suryanto, B., & Suprobo, P. (2018b).

Visualization of Shear Cracks in a Reinforced Concrete

Beam using the Digital Visualization of Shear Cracks

in a Reinforced Concrete Beam using the Digital Image

Correlation. May.

https://doi.org/10.18517/ijaseit.8.2.4847

Tambusay, A., Suryanto, B., & Suprobo, P. (2020). Digital

Image Correlation for Cement-based Materials and

Structural Concrete Testing. Civil Engineering

Dimension, 22(1), 6–12.

https://doi.org/10.9744/ced.22.1.6-12

Taylor, P., Burch, J. M., & Tokarski, J. M. J. (2010). Optica

Acta : International Journal of Optics Production of

Multiple Beam Fringes from Photographic Scatterers

Production of multiple beam fringes from

photographic. November 2014, 37–41.

https://doi.org/10.1080/713818071

Thai, T. Q. (2020). DigitalCommons @ USU Improvement

of Ultraviolet Digital Image Correlation ( UV-DIC ) at

Extreme Temperatures.

Xu, L., Pan, J., & Chen, J. (2017). Mechanical Behavior of

ECC and ECC/RC Composite Columns under Reversed

Cyclic Loading. Journal of Materials in Civil

Engineering, 29(9), 04017097.

https://doi.org/10.1061/(asce)mt.1943-5533.0001950

Yang, E., & Li, V. C. (2012). Cement and Concrete

Research Tailoring engineered cementitious

composites for impact resistance. 42, 1066–1071.

https://doi.org/10.1016/j.cemconres.2012.04.006

Yin, Y., Qiao, Y., & Hu, S. (2019). Four-point bending tests

for the fracture properties of concrete. Engineering

Fracture Mechanics

, 211(November 2018), 371–381.

https://doi.org/10.1016/j.engfracmech.2019.03.004

Yoneyama, S., Kitagwa, A., Kitamura, K., Kikuta, H., &

Corporation, H. Z. (2005). Deflection distribution

measurement of steel structure using digital image

correlation. 5880, 1–8.

https://doi.org/10.1117/12.614364

Yu, B., Ning, C. lie, & Li, B. (2017). Probabilistic

durability assessment of concrete structures in marine

environments: Reliability and sensitivity analysis.

China Ocean Engineering, 31(1), 63–73.

https://doi.org/10.1007/s13344-017-0008-3

Yu, K., Li, L., Yu, J., Wang, Y., Ye, J., & Xu, Q. F. (2018).

Direct tensile properties of engineered cementitious

composites: A review. Construction and Building

Damage Simulation Using Digital Image Correlation Technique Under Review Development for Structural Monitoring

27

Materials, 165, 346–362.

https://doi.org/10.1016/j.conbuildmat.2017.12.124

Zhang, W., Yin, C., Ma, F., & Huang, Z. (2018).

Mechanical properties and carbonation durability of

engineered cementitious composites reinforced by

polypropylene and hydrophilic polyvinyl alcohol

fibers. Materials, 11(7).

https://doi.org/10.3390/ma11071147

Zhang, Z., Jiang, W., Zhu, K., & Gong, A. (2018).

Deformation Fields Measurement of Crack Tip under

High-Frequency Resonant Loading Using. 2018.

ICATECH 2023 - International Conference on Advanced Engineering and Technology

28