Risk Analysis of Biodiesel Production from Used Cooking Oils with

Risk-Based Thinking ISO 9001:2015 Approach

Muhammad Hasan Abdullah

1a

, Anak Agung Widyadhana Artanti

1b

,

Ong Andre Wahju Rijanto

1c

, Krisnadhi Hariyanto

1d

, Subaderi

1e

, Ampar Jaya Suwondo

1

,

Astria Hindratmo

1

, Fitriya Gemala Dewi

1

, Chendrasari Wahyu Oktavia

1

, Onny Purnamayudhia

1

and Nurwahyudi Widhiyatna

2

1

Industrial Engineering, Wijaya Putra University, Jalan Raya Benowo 1-3 Surabaya 60197, Indonesia

2

Information Engineering, Wijaya Putra University, Jalan Raya Benowo 1-3 Surabaya 60197, Indonesia

Keywords: Biodiesel, UCO, Risk Analysis.

Abstract: Risks and opportunities are elements that exist in every process. Risk can have a negative impact on the

process while opportunity is a potential that has a beneficial impact. Biodiesel production from UCO (Used

Coconut Oil) is produced through a long cycle. Partial identification of risks and opportunities has been carried

out. However, this identification is not fully integrated into a system. Our study comprehensively presents the

results of the identification of risks and opportunities at each stage of biodiesel. The SIPOC cycle is used to

identify risks and opportunities that arise at each stage. Risks and opportunities in the biodiesel business

process from UCO are identified through a risk-based thinking approach in ISO 9001:2015. External Issues

and Interest parties relevant to the business process are considered so that biodiesel from UCO becomes a

sustainable business process.

1 INTRODUCTION

The use of bioenergy as an energy source to replace

fossil fuels is a concern for the Indonesian

government. Biodiesel as a substitute for diesel has

long been developed and becomes an alternative that

continues to strengthen its bargaining position.

Including biodiesel from UCO which still has

problems in its production cycle. Indonesia's

biodiesel production in 2020 was recorded at 8.6

million kl. This is inseparable from the mandatory

policies of B20 in 2016 and B30 in 2020. Indonesia is

targeting 30% of biodiesel blends in subsidized diesel

fuel by 2022. It takes approximately 9.59 million kl

of biodiesel per year to meet the domestic demand.

Therefore, if the used cooking oil potency is managed

properly, it can meet 32% of the national biodiesel

demand (Ministry of Energy and Mineral Resources,

a

https://orcid.org/0009-0007-8060-1832

b

https://orcid.org/0009-0002-3082-6906

c

https://orcid.org/0000-0002-9580-7872

d

https://orcid.org/0009-0004-2692-9552

e

https://orcid.org/0000-0001-2345-6789

March 17, 2021) (Prasetiawan, 2022). From the

cooking process, 40-60% of cooking oil (6,46-9,72

million KL) becomes used cooking oil (UCO).

However, UCO actually generates economic,

social, and environmental benefits provided that their

disposal management are well coordinated (Perdana,

2021). The main feedstock for biodiesel production in

Indonesia is crude palm oil (CPO), which is also

increasingly used for domestic food production and

industrial applications. In fact, Indonesia can meet its

domestic demand for CPO until 2025 using the

equivalent of 63% of the oil palm planted area in

2014, while keeping the same average yield

(Khatiwada, Palmén, & Silveira, 2021). Projections

of future demand in 2025 for Indonesian crude palm

oil are 6.9 Mtonne from for domestic food production

and industrial application, then at least (40% x 6.9)

can be used as feedstock for biodiesel. Unfortunately,

the UCO collected in Indonesia has only reached 3

Abdullah, M., Artanti, A., Rijanto, O., Hariyanto, K., Subaderi, ., Suwondo, A., Hindratmo, A., Dewi, F., Oktavia, C., Purnamayudhia, O. and Widhiyatna, N.

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach.

DOI: 10.5220/0012117300003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 215-225

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

215

million KL or only 18% of the total national cooking

oil consumption. Of the 3 million KL that was

collected only 570 KL was converted for biodiesel

(ESDM, 2020). The challenge of UCO is abuse by

recycling UCO for resale. Utilizing UCO requires an

approach that takes stakeholders into account. Supply

chain management is a relevant approach to

implement because the flow of materials, information

flow and money flow can be managed in an integrated

manner along the supply chain (Ampuh & Doni,

2015). Utilization of UCO and its processing into

biodiesel requires an integrated management of

material flow, information flow and money flow. All

of these flows will involve parties such as cooking oil

consumers, UCO collectors, biodiesel processors,

governments and biodiesel consumers.

Besides Indonesia, several other Asian countries

also have potential UCO amounts, but only a few can

be collected. India (13%-19%), Malaysia (30%-

45%), Japan (21%-37%). However, several countries

were able to collect higher UCO, namely China

(60%-80%) and Korea (76%-92%) (Kristiana,

Baldino, Searle, & Stephanie, 2022). Another

problem faced in biodiesel production from UCO is

the price of UCO which exceeds the price of virgin

oil for biodiesel due to incentive policies and non-

transparent rules and regulations (Grinsven, Toorn,

Veen, & Kampman, 2020). The identification and

risk management of the biofuel process has been

carried out by several researchers. Biofuels can be

produced in various forms, solid liquid and gases. The

main hazards and the importance of managing risks

have been identified (Nair, 2011) and (Нatzisymeon,

Kamenopoulos, & Tsoutsos, 2019). Combustion,

emission and engine performance characteristics of

biodiesel and process waste have been identified

(Enweremadu & Rutto, Combustion, emission and

engine performance characteristics of used cooking

oil biodiesel-A review, 2010) and (Hayder &

Puniyarasen, 2016). he identification is still separate

and has not been comprehensively integrated into

business processes.

For this regard, to the design of biodiesel

production and distribution in the next few decades, a

risk and opportunity need to be assessed and

managed. In this article, researchers will present the

results of an analysis of risks and opportunities in the

biodiesel production process with a process approach

from upstream to downstream. Sources of secondary

data obtained from the observations of previous

researchers. Opportunities are used to make

improvements and maximize the process in

generating output. The Risk-Based Thinking (RBT)

approach involves the systematic definition and

management of processes, and interactions between

processes aimed at taking advantage of existing

opportunities and preventing unwanted risks.

2 METHODOLOGIES

This article uses a descriptive study method and

emphasizes a qualitative analysis approach as a

research methodology through reference to relevant

theories and information-based policies regarding

UCO and biodiesel. The data was collected by using

the literature study with triangulation technique.

Secondary data used were obtained or collected from

scientific literature, mass media, government

2.1 Theoritical Background

In ISO 9001:2015, Risk-based thinking enables an

organization to determine the factors that could cause

its processes and its quality management system to

deviate from the planned results, to put in place

preventive controls to minimize negative effects and

to make maximum use of opportunities as they arise.

Risk is the impact of uncertainty and any such

uncertainty can have a positive or negative impact.

Opportunities can arise as a result of a favorable

situation to achieve the desired result. Actions to

address opportunities may also include consideration

of the associated risks. There are two concepts about

risk and opportunity. First, if an activity or process

can achieve the desired result, then the activity has no

risk. Second, we can determine or identify risk if the

activity or process has a "potential" of adverse

impacts. We can determine the opportunity if the

activity or process has a potential beneficial impact.

In DIS 45001, Risk is defined as the combination

of the likelihood of an event occurring related to

severe injury; or work-related illness or exposure of a

person to a Hazard. So hazard is the nature of the

process that can harm the individual, and risk is the

probability that it will occur along with how severe

the consequences will be. RBT makes preventive

action a part of strategic and operational planning to

eliminate risks and maximize opportunities in the

business.

In Indonesia, sustainable biodiesel as renewable

energy can be reviewed into three aspects, including

environmental aspects, social aspects and economic

aspects (Yasinta, Karuniasa, & Mahawan, 2021)

(Dimawarnita, Kartika, A, & Hambali, 2021).

Government policy related to UCO is a significant

issue in its collection, processing and use

(Prasetiawan, 2022) (Zhou, Searle, & Kristiana,

ICATECH 2023 - International Conference on Advanced Engineering and Technology

216

2021) (Perdana, 2021) (Nurkhoiry, Azahari, Amelia,

& Roosganda, 2021) (Syahdan, Arkeman, & Wijaya,

2017) (Liu, Liu, Agyeiwaa, & Li, 2018). In other

asian countries China, the economic and

environmental assessments result that the integration

of stakeholders and markets increase efficiency and

sustainability. Unfair profit allocations will decrease

the amount of recycled materials (UCO) (Zheng, et

al., 2020 ). In EU, UCO is included in the category of

“edible oils and fat” where the policies for its

collection and processing have been regulated in the

“Household UCO” and “Biodiesel” policy

framework (Staff, 2015). In Turkey, Problem of

Biodiesel Standards, Lack of Awareness, Special

Consumption Tax, Biodiesel Distribution and

Logistics (Erdoğan & Keskin, 2015).

Supply chain has become the most topic of

research on UCOME (UCO Methyl Ester) or

biodiesel, the UCO recycle mode in China, US and

Japan is studied in this research. (Zhang, Ozturk,

Wang, & Zhao, 2014) (Zhang, Ozturk, Zhou, Qiu, &

Wu, 2015). Optimization and Sustainable supply

chain at UCOME is a topic of study by researchers

(Jiang & Zhang, 2016) (Gkouskos, Tournaki,

Giamalaki, & Tsoutsos, 2018) (Geng, Zhang, Sun, &

Geng, 2019) (Rezaei, Chaharsooghi, K, Kashan, &

Babazadeh, 2020). Raw material price subsidies and

finished products sales subsidies increase the profits

of recycler (Zhang, Li, Zhou, Hou, & Qiu, 2013). On

biofuel supply chain biodiesel price and social

objective have a significant impact, but the

environmental objective has low impact on the bio-

refinery in an emission allowances trading scheme.

(Zhang & Jiang, 2016). Hazard and emission risks are

also considered in the manufacture and application of

biodiesel from UCO. The manufacture of biodiesel

can be hazardous if suitable precautions are not taken,

as it involves the storage, handling and use of several

hazardous substances (Нatzisymeon, Kamenopoulos,

& Tsoutsos, 2019) (Nair, 2011). Identification and

evaluation of wastes from biodiesel process are

studied The qualification was based on Total

Suspended Solid (TSS) test, Chemical Oxygen

Demand (COD) test, pH test and Oil and Grease

(O&G) test (Hayder & Puniyarasen, 2016).

Combustion, emission and engine performance from

the use of UCOME are also other issues to consider

(Enweremadu & Rutto, Combustion, emission and

engine performance characteristics of used cooking

oil biodiesel-A review, 2010) (Sethin & Somnuk,

2022). The risks that arise in UCOME's business

processes have been assessed, including the AHP

approach (Jachryandestama, Nursetyowati, Fairus, &

Pamungkas, 2021) (Kurnia & Hadiguna, 2016). This

is then we use as the basis for conducting an

assessment in this research. The above issues affect

the sustainability of biodiesel as specially from UCO

and pose a risk to the business process.

2.2 Risk-Based Thinking and Develop

Structure Methodology

The method developed in this research is to adopt the

principle of risk-based thinking in ISO 9001:2015

with the SIPOC (supplier-input-process-output-

customer) approach to carry out risk and opportunity

analysis in the UCOME or biodiesel business process,

Figure 1. Risks and opportunities are embedded in the

PDCA (plan-do-check-act) cycle. To establish the

objectives of the system and its processes,

management must determine the risks and

opportunities at the “Planning (6)” stage (ISO

9001:2015, clause 6). These (risks and opportunities)

are then taken to the next cycle. The concept of risk-

based thinking is implemented in the biodiesel

business process from UCO. Through the SIPOC

approach, risk events in the UCOME business

process are identified at each stage. Furthermore, risk

assessment and mitigation are carried out. The

method developed in this research is to adopt the

principle of risk-based thinking in ISO 9001:2015

with the SIPOC (supplier-input-process-output-

customer) approach to carry out risk and opportunity

analysis in the UCOME or biodiesel business process,

Figure 1. Risks and opportunities are embedded in the

PDCA (plan-do-check-act) cycle. To establish the

objectives of the system and its processes,

management must determine the risks and

opportunities at the “Planning (6)” stage (ISO

9001:2015, clause 6). These (risks and opportunities)

are then taken to the next cycle. The concept of risk-

based thinking is implemented in the biodiesel

business process from UCO. Furthermore, risk

assessment and mitigation are carried out. The

following is the framework developed in our

research:

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach

217

Figure 1: The overview of adopted methodology.

3 RESULT AND DISCUSSION

In this section, we describe the relevant issues and

risk-opportunities derived from various sources such

as journals or proceedings, reports, and our previous

research. UCOME Risk-opportunity identified and its

process, presented in the form of tables and flow

diagrams.

3.1 External and Internal Issues

The organization (in this study is the producer of

UCOME) shall determine external and internal issues

that are relevant and that affect to the process (BSN,

2015). External issues can include legal,

technological, competitive, market, cultural, social

and economic environments. Internal issues are

related to organizational issues, so they are not

discussed in this study.

Table 1: Internal and external Issues

Issues Scope Positive issue

(+)

Negative issue

(-)

Internal

N

/A N/A N/A

External Environment Reduction on impact of global warming and to support all

efforts in reducing carbon-dioxide emissions on earth

(Nurkhoiry, Azahari, Amelia, & Roosganda, 2021)

Suffering from illegal logging, seasonal

forest fire and some illegal mining

operations (Nurkhoiry, Azahari, Amelia,

& Roosganda, 2021).

the environmental objective has a positive impact on the bio-

refinery in an emission allowances trading scheme (Zhang &

Jiang, 2016)

Accompanied by side reactionary

pollutant (Tsoutsos, Tournaki, Paraíba,

& Kaminaris, 2016)

Health and safety issue, risk or hazard

management (Нatzisymeon,

Kamenopoulos, & Tsoutsos, 2019) (Nair,

2011)

Issues Scope Positive issue

(+)

Negative issue

(-)

Economic Oil palm industry has become economic growth, biodiesel has

been catching up in the development (Nurkhoiry, Azahari,

Amelia, & Roosganda, 2021).

New jobs creation (Tsoutsos, Tournaki, Paraíba, & Kaminaris,

2016)

Circular Economy concept implementation (Perdana, 2021)

Social To fulfil the international standard and regulation and the

achievement of the SDGs (Nurkhoiry, Azahari, Amelia, &

Roosganda, 2021).

ICATECH 2023 - International Conference on Advanced Engineering and Technology

218

Issues Scope Positive issue

(+)

Negative issue

(-)

the social objective has a significant impact on simulating

b

iorefinery to collect more kitchen waste. (Zhang & Jiang, 2016)

Policy,

Regulation

Renewable energy policy, mandatory biodiesel policy program

(Nurkhoiry, Azahari, Amelia, & Roosganda, 2021).

determination of biodiesel price by the

government (Ampuh & Doni, 2015)

Fostering a low carbon economy is a key pillar of EU policies

(Gkouskos, Tournaki, Giamalaki, & Tsoutsos, 2018)

unfair profit allocations will decrease the

amount of recycled materials (Zheng, et

al., 2020 )

Subsidy mode by (Zhang, Li, Zhou, Hou, & Qiu, 2013)

Quality (biodiesel standard), Engine performance, Emission

characteristic (Enweremadu & Rutto, Combustion, emission

and engine performance characteristics of used cooking oil

b

iodiesel-A review, 2010) (Sethin & Somnuk, 2022)

Note: (+) (-) positive or negative impact for

suistainability UCOME production.

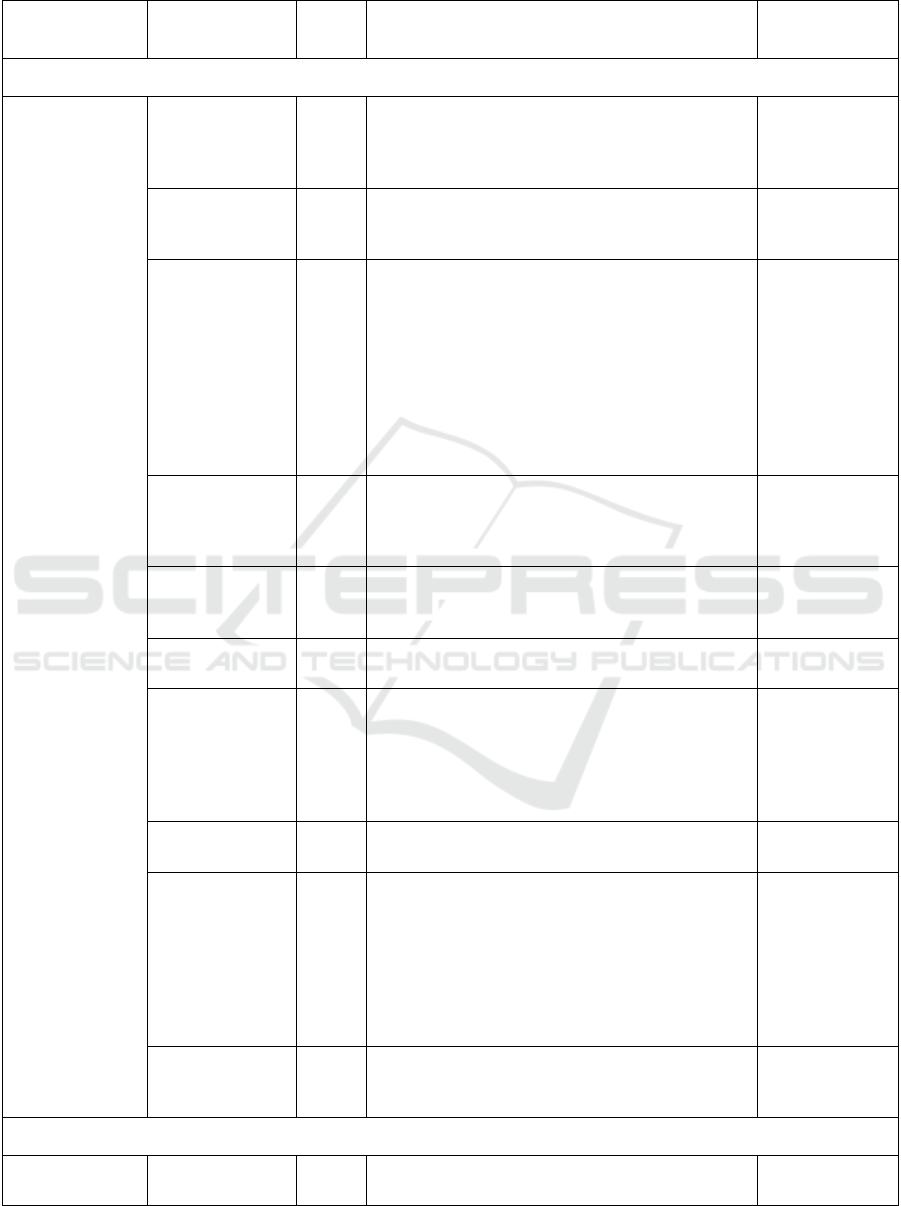

3.2 Interested Parties in UCOME

Utilization of used cooking oil requires an approach

that takes into account the needs and expectations of

stakeholders (Ampuh & Doni, 2015). The following

are the results of the identification of interested

parties with their functions and their needs and

expectations in Indonesia. Figure 2 gives a schematic

representation of any interested parties and shows the

interaction of its elements.

Each organization (interested parties) provides

products or services consistently that meet customer

requirements (needs and expectation) and applicable

statutory and regulatory. In figure 2, Its seen that the

government has significantly roles which regulation

or policy that they were released. It can affect the

process in each function.

Figure 2: Representation interest parties’

interrelationship.

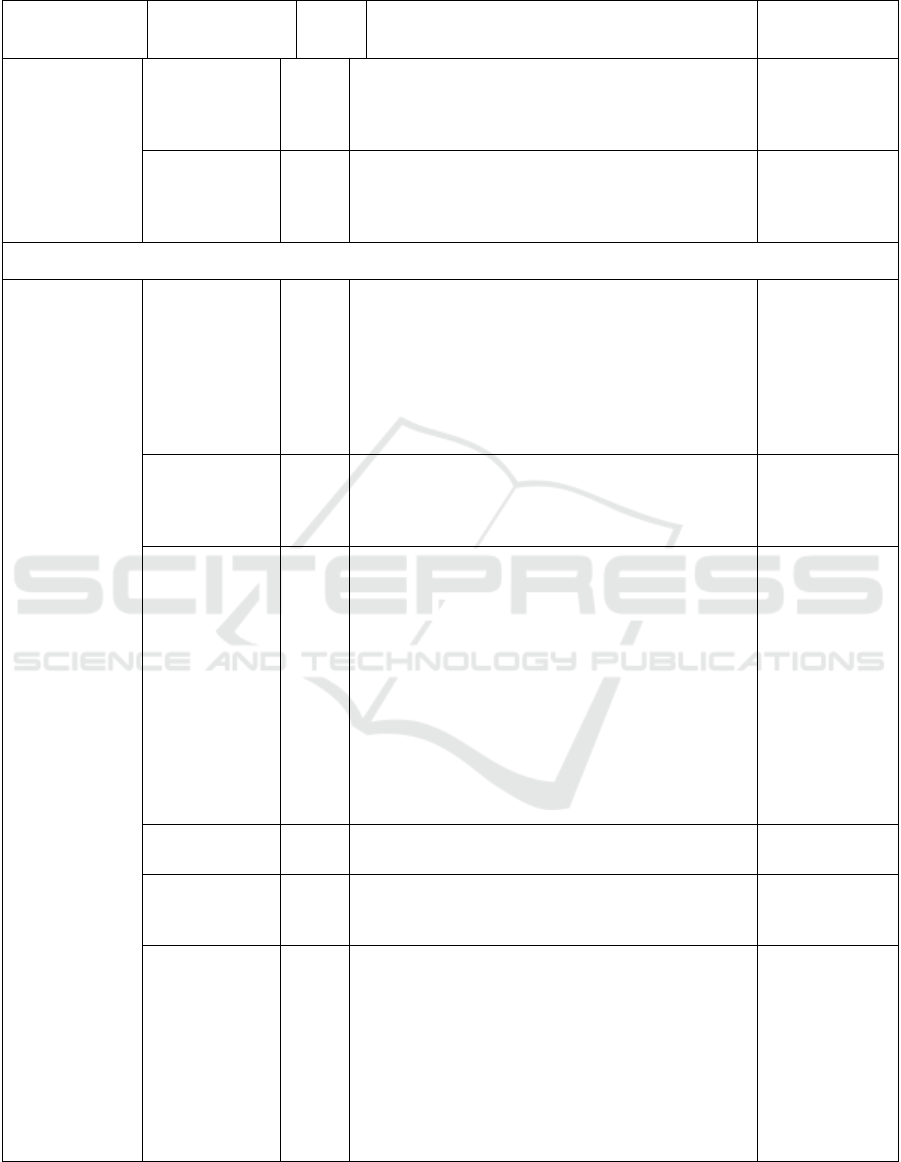

3.3 Risk Identification in UCOME

Production

Tables must appear inside the designated margins or

In this section, the researcher provides a complex

view of the risks that arise in the use of UCO for

biodiesel from upstream to downstream. Through

risk-based thinking and the SIPOC diagram approach,

risks can be identified in a sequential and

comprehensive manner. Table 2, shows the risk

identification of UCOME's business processes. The

risk number (R1, R2 etc.) indicates the identification

of the risks inherent in the business process.

Several studies have been conducted on the

specific risks in the UCOME production. Based on

previous studies, risks are classified into several

categories. The categories are, Supply risks, Product

recovery risks, Government risks, Demand risks,

Financial risks, Operational risks, Hazard risks and

Quality risks. Each element in the SIPOC chain has a

different category and amount of risk. Interested

parties and risk descriptions are described for each

element of Supplier (S), Input (I), Process (P), Output

(O) and Customer (C). Table 2 below is a summary

of the results of risk identification for each SIPOC

security element. Sources of data are provided to

facilitate tracing and as a review study for further

research. The results of the identification of these

risks also need to be analysed to the stage of Risk

Assessment and Mitigation.

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach

219

Table 2: Summary risk identification in SIPOC-UCOME

Interested parties Risk category Risk

number

Description Sources

SUPPLIER (S)

Household,

Restaurant, Hotel,

Food Industries,

UCO Collector,

Government,

Business Owner

Supply risk R1 UCO supply points, distribution centres (DCs) and

biodiesel plants

(Jiang & Zhang,

2016) (Geng,

Zhang, Sun, &

Geng, 2019)

Supply risk R2 Logistics costs (collecting, spoilage, transportation

of UCO)

(Ampuh & Doni,

2015) (Kurnia &

Hadi

g

una, 2016

)

Supply risk R3 Uncertainty feedstock supply (Geng, Fu, & Sun,

Stochastic

Programming of

Sustainable Waste

Cooking Oil for

Biodiesel Supply

Chain under

Uncertainty, 2021)

(Kurnia &

Hadi

g

una, 2016

)

Supply risk R4 Low participation levels from citizens (Tsoutsos,

Tournaki, Paraíba,

& Kaminaris,

2016)

Financial risks R5 Uncertainty price feedstock UCO (Caldeira, et al.,

2019 ) (Kurnia &

Hadi

g

una, 2016

)

Supply risk R6 Inconsistent or low partnership (Kurnia &

Hadi

g

una, 2016

)

Supply risk R7 Illegal collector and exporter (Jachryandestama,

Nursetyowati,

Fairus, &

Pamungkas, 2021)

(Prasetiawan,

2022

)

Government risk R8 Policy (regulations or legalities) (Ampuh & Doni,

2015

)

Government risk R9 Changing regulations and policies (Geng, Fu, & Sun,

Stochastic

Programming of

Sustainable Waste

Cooking Oil for

Biodiesel Supply

Chain under

Uncertaint

y

, 2021

)

Hazard risk R10 Hazard Car accident during oil transfer (Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019)

INPUT (I)

Quality risk R11 Quality variation of UCO feedstock (Kurnia &

Hadiguna, 2016)

ICATECH 2023 - International Conference on Advanced Engineering and Technology

220

Table 2: Summary risk identification in SIPOC-UCOME

Interested parties Risk category Risk

number

Description Sources

Employee,

Business Owner,

Government

Quality risk R12 High standards demand for UCO as raw material (Liu, Liu,

Agyeiwaa, & Li,

2018

)

Hazard risk R13 Hazard Fire in the collection area (Nair, 2011)

(Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019

)

Hazard risk R14 Hazard Explosion from methanol spillage (Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019

)

Hazard ris

k

R15 Storage of Flammable and Toxic Materials (Nair, 2011)

PROCESS (P)

Employee,

Business Owner,

Government

Operational risk R16 Improper selection or usage of:

technology/methodology, raw material, location and

facilit

y

(Nair, 2011)

(Kurnia &

Hadiguna, 2016)

Operational risk R17 Inadequate facility for the selected process Lan

d

area; Nearby facility and effects from and on them,

Proximit

y

to utilities like water, steam,

p

ower etc

(Nair, 2011)

Operational ris

k

R18 Unsafe design and layout (Nair, 2011)

O

p

erational ris

k

R19 Fault

y

construction and commissionin

g

(

Nair, 2011

)

Operational risk R20 No/inadequate provision for (Ventilation, Lighting,

Rest and cleaning, Weather protection)

(Nair, 2011)

Operational risk R22 Inadequate provision for pressure relief, safe

discharge of dangerous release and overpressure

p

rotection.

(Nair, 2011)

Operational risk R23 No provision for remote monitoring and control o

f

the

p

rocess

(Nair, 2011)

Operational risk R24 Provision for

p

roduction using temporary/make shift

arran

g

ements.

(Nair, 2011)

Hazard risk R25 Inadequate assessment of hazards in establishing

connection to existing facility for sharing power,

utilities, structure etc.

(Nair, 2011)

Operational risk R26 Complex procedure, Low recovery rate of UCO (Liu, Liu,

Agyeiwaa, & Li,

2018

)

Operational risk R27 Capacity of production, economic of scale (Kurnia &

Hadi

g

una, 2016

)

Hazard risk R28 Hazard from Methanol spillage during reactor feed (Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019)

Hazard risk R29 Hazard Skin contact with H2SO4, NaOH (Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019

)

Hazard risk R30 Hazard from Lightning (Нatzisymeon,

Kamenopoulos, &

Tsoutsos, 2019)

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach

221

Table 2: Summary risk identification in SIPOC-UCOME

Interested parties Risk category Risk

number

Description Sources

Hazard ris

k

R31 Runawa

y

/uncontrolled reaction

(

Nair, 2011

)

Hazard ris

k

R32 Explosion hazards and overpressure releases (Nair, 2011)

Hazard ris

k

R33 Toxic hazards, Steam flashes

(

Nair, 2011

)

Hazard risk R34 Hazards from Batch Processing, Material Handling,

Other Relate

d

(Nair, 2011)

OUTPUT (O)

Government,

Business Owner,

Civilian,

Hazard risk R35 Pollutants and side reaction (Tsoutsos,

Tournaki, Paraíba,

& Kaminaris,

2016

)

Hazard risk R36 Wastes from biodiesel production (glycerine, soap

etc

)

(Hayder &

P

uni

y

arasen, 2016

)

Government risk R37 Policy (regulations or legalities) (Ampuh & Doni,

2015

)

Government risk R38 Fostering a low carbon economy is a key pillar of EU

policies

(Gkouskos,

Tournaki,

Giamalaki, &

Tsoutsos, 2018

)

Government risk R39 Insignificant subsidies or not effective Subsidies

mechanism

(Zhang, Ozturk,

Wang, & Zhao,

2014) (Zhang,

Ozturk, Zhou, Qiu,

& Wu, 2015

)

Government risk R40 Unfair profit allocations will decrease the amount o

f

rec

y

cled materials

(

Zheng, et al., 2020

)

OUTPUT (O)

Government,

Business Owner,

Civilian,

Government risk R41 Changing regulations and policies (Geng, Fu, & Sun,

Stochastic

Programming of

Sustainable Waste

Cooking Oil for

Biodiesel Supply

Chain under

Uncertaint

y

, 2021

)

Financial risks R42 Fluctuate price Biodiesel (Kurnia &

Hadi

g

una, 2016

)

Financial risks R43 Price policy of biodiesel (Ampuh & Doni,

2015

)

Financial risks R44 Biodiesel production costs have been high in the

country

(Rezaei,

Chaharsooghi, K,

Kashan, &

Babazadeh, 2020

)

Financial risks R45 Lack of efficient economic incentive (Liu, Liu,

Agyeiwaa, & Li,

2018)

Government ris

k

R46 Not a s

p

ecial re

g

ulation for UCO mana

g

ement

(

Perdana, 2021

)

ICATECH 2023 - International Conference on Advanced Engineering and Technology

222

Table 2: Summary risk identification in SIPOC-UCOME

Interested parties Risk category Risk

number

Description Sources

Product recovery

risk

R47 Failure in screening defective products (Jachryandestama,

Nursetyowati,

Fairus, &

Pamungkas, 2021)

Product recovery

risk

R48 The design of inventory and safety stock capacity o

f

collectors and reprocessing centres

(Jachryandestama,

Nursetyowati,

Fairus, &

Pamungkas, 2021)

CUSTOMER (C)

Consumer,

Business

Distribution

Centres

Product recovery

risk

R49 Transportation mode, network design, delivery time

uncertainties

(Ampuh & Doni,

2015)

(Jachryandestama,

Nursetyowati,

Fairus, &

Pamungkas, 2021)

(Kurnia &

Hadiguna, 2016)

Product recovery

risk

R50 The impact of implementing a take-back obligation. (Jachryandestama,

Nursetyowati,

Fairus, &

Pamun

g

kas, 2021

)

Quality risks R51 Quality (fulfil biodiesel standard), Engine

performance, Emission characteristic

(Enweremadu &

Rutto,

Combustion,

emission and

engine

performance

characteristics of

used cooking oil

biodiesel-A

review, 2010)

(

Sethin & Somnuk,

2022) (Kurnia &

Hadiguna, 2016)

Quality risks R52 Customer complaint or rejected (Kurnia &

Hadiguna, 2016)

Demand risks R53 A small market for biodiesel (Liu, Liu,

Agyeiwaa, & Li,

2018

)

Demand risks R54 Uncertainty biodiesel demand (Geng, Fu, & Sun,

Stochastic

Programming of

Sustainable Waste

Cooking Oil for

Biodiesel Supply

Chain under

Uncertainty, 2021)

(Kurnia &

Hadi

g

una, 2016

)

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach

223

The risks table above is generated from several

studies in countries. They have different risk

categories and priority levels. It depends on the

method of approach used. As regards the hazards, The

study of M. Hatzisymeon et al. (Нatzisymeon,

Kamenopoulos, & Tsoutsos, 2019) stated that the

highest priority was the risk of explosion from

methanol spills, skin contact with acid, car accidents,

fire and lightning. As regards the risks in the GSC

approach, The study of Raden et al.

(Jachryandestama, Nursetyowati, Fairus, &

Pamungkas, 2021), stated that supply risk is the

highest risk, and is followed by product recovery,

demand, financial, and operational risks. The study of

Ruri et al. (Kurnia & Hadiguna, 2016), mentions the

priority of risks in the design of the UCOME supply

chain. Where feedstock is the main risk, followed by

demand risk, quality, production, transportation and

partnership. Finally, by knowing the risks in the

SIPOC chain, users are more aware and need to take

precautions to eliminate or reduce the negative impact

of these risks. It can also be used to formulate policies

for interested parties. UCOME business owners can

properly manage technology, standards and

management. They cannot operate their business

alone. Collaboration and partnership are necessary to

operate a sustainability business.

4 CONCLUSIONS

This research shows that the UCOME production has

complex risks at every stage. The risk identification

generated in this study results from a review of

several sources relevant to the UCO process into

biodiesel. As well as the results of experiments and

research conducted by the author. New risks may

have been identified, and interdependencies between

risks should be considered. UCOME business actors

need to respond to internal and external issues and the

needs and expectations of stakeholders.

The government has a significant role in creating

the sustainability of UCOME production. In the end,

the ISO 9001:2015 risk-based thinking approach is

able to identify the risks that exist in every UCOME

business process. Next, risk assessment and

mitigation actions will need to be carried out to

determine priority values and preventive actions.

REFERENCES

T. Prasetiawan, "Utilization of Used Cooking Oil In The

Midst of Chaotic Cooking Oil Management," Info

Singkat, vol. XIV, no. 9, pp. 19-24, 2022.

B. E. G. Perdana, "Circular Economy of Used Cooking Oil

in Indonesia: Current Practices and Development in

Special Region of Yogyakarta," Journal of World Trade

Studies, vol. VI, no. 6, pp. 28-39, 2021.

D. Khatiwada, C. Palmén and S. Silveira, "Evaluating The

Palm Oil Demand in Indonesia: Production Trends,

Yields, and Emerging Issues," Biofuels, vol. XII, no. 2,

pp. 136-147, 2021.

K. ESDM, "ebtk.esdm.go.id," Direktorat Jenderal EBTK, 7

December 2020. [Online]. Available:

https://googleweblight.com/sp?u=https://ebtke.esdm.g

o.id/post/2020/12/07/2725/minyak.jelantah.sebuah.pot

ensi.bisnis.energi.yang.menjanjikan&grqid=dMIUs2X

_&hl=id-ID. [Accessed 1 Oktober 2022].

H. R. Ampuh and P. Doni, Dinamika Jaringan Rantai Pasok

Biodiesel dari Minak Goreng Bekas (Analisis,

Pemodelan dan Kebijakan), PAdang: Andalas

University Press, 2015.

T. Kristiana, C. Baldino, Searle and Stephanie, "An

estimate of current collection and potential collection of

used cooking oil from major Asian exporting

countries," International Council on Clean

Transportation (ICCT), Washington, 2022.

A. Grinsven, E. Toorn, R. Veen and B. Kampman, "Used

Cooking Oil (UCO) as biofuel feedstock in the EU," CE

Delft, Delft, 2020.

S. Nair, "Identifying and Managing Process Risks Rrelated

to Biofuel Project and Plants," in SYMPOSIUM

SERIES NO. 156 Hazards XXII, Aberdeen, 2011.

M. Нatzisymeon, S. Kamenopoulos and T. Tsoutsos, "Risk

assessment of the life-cycle of the Used Cooking Oil-

to-biodiesel," Journal of Cleaner Production , no. 217,

pp. 836-843, 2019.

C. C. Enweremadu and H. L. Rutto, "Combustion, emission

and engine performance characteristics of used cooking

oil biodiesel-A review," Renewable and Sustainable

Energy Reviews, no. 14, p. 2863–2873, 2010.

G. Hayder and P. Puniyarasen, "Identification and

Evaluation of Wastes from Biodiesel Production

Process," Journal of Advanced Research in Applied

Sciences and Engineering Technology, vol. III, no. 1,

pp. 21-29, 2016.

T. Yasinta, Karuniasa and Mahawan, "Palm oil-based

biofuels and sustainability In Indonesia: assess social,

environmental and economic aspects," in IOP

Conference Series: Earth and Environmental Science

716, doi:10.1088/1755-1315/716/1/012113, 2021.

F. Dimawarnita, Kartika, I. A and E. Hambali,

"Sustainability of biodiesel B30, B40, and B50 in

Indonesia with addition of emulsifier," in IOP

Conference Series: Earth and Environmental Science

749 012026, doi:10.1088/1755-1315/749/1/012026,

2021.

Y. Zhou, S. Searle and T. Kristiana, "Opportunities for

Waste Fats and Oils as Feedstocks for Biodiesel and

ICATECH 2023 - International Conference on Advanced Engineering and Technology

224

Renewable Diesel in Indonesia," ICCT: International

Council on Clean Transportation, Washington, 2021.

R. Nurkhoiry, D. H. Azahari, R. Amelia and E. Roosganda,

"Environmental effect of biodiesel mandatory policy,"

in IOP Conference Series: Earth and Environmental

Science 892, doi:10.1088/1755-1315/892/1/012093,

2021.

A. D. Syahdan, Y. Arkeman and H. Wijaya, "Sustainable

supply chain design for waste cooking oil-based

biodiesel in bogor using dynamic system approach," in

IOP Conf. Series: Earth and Environmental Science 65

, doi :10.1088/1755-1315/65/1/012045, 2017.

Y. Liu, T. Liu, A. Agyeiwaa and Y. Li, "A SWOT analysis

of biodiesel production from waste cooking oils," in

IOP Conf. Series: Earth and Environmental Science

170, doi :10.1088/1755-1315/170/2/022136, 2018.

T. Zheng, B. Wang, M. A. Rajaeifar, O. Heidrich, J. Zheng,

Y. Liang and H. Zhang, "How government policies can

make waste cooking oil-to-biodiesel supply chains

more efficient and sustainable," Journal of Cleaner

Production, no. 263 (2020) 121494, pp. 1-20, 2020 .

E. Staff, "Transformation of Used Cooking Oil into

biodiesel - From waste to resource," EUBIA - The

European Biomass Industry Association, EU, 2015.

Y. Erdoğan and M. Keskin, "Evaluation of Biodiesel

Production Problems In Turkey By Swot Analysis," in

Proceedings of the World Congress on New

Technologies (NewTech 2015), Barcelona, 2015.

H. Zhang, U. A. Ozturk, Q. Wang and Z. Zhao, "Biodiesel

produced by waste cooking oil: Review of recycling

modes in China, the US and Japan," Renewable and

Sustainable Energy Reviews, vol. 38, no.

http://dx.doi.org/10.1016/j.rser.2014.07.042, p. 677–

685, 2014.

H. Zhang, U. A. Ozturk, D. Zhou, Y. Qiu and Q. Wu, "How

to increase the recovery rate for waste cooking oil-to-

biofuel conversion: A comparison of recycling modes

in China and Japan," Ecological Indicators , vol. 51, no.

http://dx.doi.org/10.1016/j.ecolind.2014.07.045, p.

146–150, 2015.

Y. Jiang and Y. Zhang, "Supply chain optimization of

biodiesel produced from waste cooking oil," in The 9th

International Conference on City Logistics.

Transportation Research Procedia 12 ( 2016 ) 938 –

949, Tenerife, 2016.

Z. K. Gkouskos, S. K. Tournaki, M. P. Giamalaki and T. D.

Tsoutsos, "From Used Cooking Oil to biodiesel. Full

Supply Chain demonstration," in Conference paper.

https://www.researchgate.net/publication/332320910,

Chania, 2018.

N. Geng, Y. Zhang, Y. Sun and S. Geng, "Optimization of

Biodiesel Supply Chain Produced from Waste Cooking

Oil: A Case Study in China," in IOP Conf. Series: Earth

and Environmental Science 264 , doi:10.1088/1755-

1315/264/1/012006, 2019.

M. Rezaei, Chaharsooghi, S. K, A. H. Kashan and R.

Babazadeh, "Optimal design and planning of biodiesel

supply chain network: a scenario based robust

optimization approach," International Journal of

Energy and Environmental Engineering, vol. 11, no.

https://doi.org/10.1007/s40095-019-00316-1, p. 111–

128, 2020.

H. Zhang, L. Li, P. Zhou, J. Hou and Y. Qiu, "Subsidy

modes, waste cooking oil and biofuel : Policy

effectiveness and sustainable supply chains in China,"

Energy Policy, no.

http://dx.doi.org/10.1016/j.enpol.2013.10.009, pp. 1-5,

2013.

Y. Zhang and Y. Jiang, "Robust optimization on sustainable

biodiesel supply chain produced from waste cooking oil

under price uncertainty," Waste Management, no.

http://dx.doi.org/10.1016/j.wasman.2016.11.004, pp.

1-11, 2016.

C. C. Enweremadu and H. L. Rutto, "Combustion, emission

and engine performance characteristics of used cooking

oil biodiesel-A review," Renewable and Sustainable

Energy Reviews, vol. 14, no.

doi:10.1016/j.rser.2010.07.036, p. 2863–2873, 2010.

A. Sethin and K. Somnuk, "Effect of Biodiesel B7 and B10

on Common Rail Diesel Engine Emission

Characteristics at Different Engine Speeds," in IOP

Conf. Series: Earth and Environmental Science 1050 ,

doi:10.1088/1755-1315/1050/1/012014, 2022.

R. Jachryandestama, P. Nursetyowati, S. Fairus and B.

Pamungkas, "Risk Analysis in Jakarta’s Waste Cooking

Oil to Biodiesel Green Supply Chain Using Group AHP

Approach," SINERGI, vol. 25, no. 2, pp. 227-236,

2021.

R. Kurnia and R. A. Hadiguna, "Penentuan Prioritas Risiko

pada Rancangan Rantai Pasok Biodiesel dari Minyak

Goreng Bekas di Kota Padang," Jurnal Rekayasa

Sistem Industri , vol. 5, no. 1, pp. 15-25, 2016.

BSN, SNI ISO 9001:2015 Quality Management System-

Requirements, Jakarta: Badan Standarisasi Nasional,

2015.

T. D. Tsoutsos, S. Tournaki, O. Paraíba and S. D.

Kaminaris, "The Used Cooking Oil-to-biodiesel chain

in Europe assessment of best practices and

environmental performance," Renewable and

Sustainable Energy Reviews , vol. 54, no.

http://dx.doi.org/10.1016/j.rser.2015.09.039, p. 74–83,

2016.

N. Geng, Q. Fu and Y. Sun, "Stochastic Programming of

Sustainable Waste Cooking Oil for Biodiesel Supply

Chain under Uncertainty," Journal of Advanced

Transportation, no.

https://doi.org/10.1155/2021/5335625, pp. 1-18, 2021.

C. Caldeira, O. Swei, F. Freire, L. C. Dias, E. A. Olivettie

and R. Kirchainf, "Planning strategies to address

operational and price uncertainty in biodiesel

production," Applied Energy , vol. 238, no.

https://doi.org/10.1016/j.apenergy.2019.01.195, p.

1573–1581, 2019 .

Risk Analysis of Biodiesel Production from Used Cooking Oils with Risk-Based Thinking ISO 9001:2015 Approach

225