Integration of Lean Six Sigma and Green Productivity for

Manufacturing SMEs

O. A. W. Riyanto

1

, M. B. Setiawan

1

, K. Hariyanto

1

, A. J. Suwondo

1

, A. Hindratmo

1

, C. W. Oktavia

1

,

O. Purnamayudhia

1

, Subaderi

1

, F. G. Dewi

1

, M. H. Abdullah

1

, B. Endarto

2

and N. Widhiyanta

3

1

Industrial Engineering, Faculty of Engineering, Universitas Wijaya Putra, Surabaya, Indonesia

2

Faculty of Law, Universitas Wijaya Putra, Surabaya, Indonesia

3

Informatic Engineering, Faculty of Engineering, Universitas Wijaya Putra, Surabaya, Indonesia

Keywords: Lean Six Sigma, Manufacturing, SMEs, Green Productivity

Abstract: A small manufacturing company is a small entity that functions like a business. In the current era of industrial

revolution, SMEs need to remain competitive in order to improve production efficiency and reduce operating

costs. Continuous operations improvement efforts have motivated researchers to find a method that is suitable

for SMEs. In this context, Green Lean has emerged as an integral part. The Green Lean debate in midsize

manufacturing is still in its infancy and needs attention. Therefore, the main objective of this study is to use

systematic data to identify and analyze the success factors, framework conditions and advantages of Green

Lean in medium-sized manufacturing industry. A systematic model shows the relationships between the

determinants of implementing green and lean initiatives for SME manufacturing. Lack and performance

measurement are the main challenges in implementing Green-Lean. Additionally, most frameworks are

designed for specific industries rather than general frameworks to reduce and eliminate various wastes.

However, this framework has lost its social dimension. The main contribution of this paper is the integration

framework lean six sigma - green productivity for SMEs in manufacturing. These results will help institutions,

owners, and small businesses take action for improvement.

1 INTRODUCTION

Organizations are under constant pressure to improve

their performance in today's competitive environment

(Hang et al., 2022). One way to improve

organizational performance is to implement an

improvement strategy (Rehman Khan et al., 2022).

Existing resources can mobilize operational problems

through continuous improvement strategies (Bernal

Torres et al., 2021). Moreover, the development

method considers that all companies are not

homogeneous. SMEs have their very own demanding

situations because of a loss of size and sources

compared to large companies (Albats et al., 2021).

However, SMEs are dynamic and growing businesses

have unique characteristics and fitures(Miller et al.,

2021). It is widely recognized that SMEs generally

differ from large companies in that they have less

debt, and scale and resource constraints (both human

and financial) impact core competencies and

skills(Miller et al., 2021).

One of the most popular approaches to improving

operational performance in manufacturing

organizations is lean six sigma. Continuous

improvement is believed to be a method for

identifying and eliminating waste and optimizing the

use of resources (Gaikwad & Sunnapwar, 2020).

Current concerns about the environmental impact that

has occurred in the company, changing the

company`s operational approach to complying with

environmental regulations and responding to growth

in customer demands for sustainable products and

services (Siegel et al., 2019). Thus, the "green"

paradigm emerged, as an operational philosophy and

approach that improves an operation's ecological

efficiency, reducing the negative impact of services

or products on the environment while maintaining or

improving financial performance (Bhattacharya et al.,

2019).

Many studies have examined the natural

alignment of lean and green through similar

operational management approaches. Therefore,

researchers suggest compatibility between lean and

Riyanto, O., Setiawan, M., Hariyanto, K., Suwondo, A., Hindratmo, A., Oktavia, C., Purnamayudhia, O., Subaderi, ., Dewi, F., Abdullah, M., Endarto, B. and Widhiyanta, N.

Integration of Lean Six Sigma and Green Productivity for Manufacturing SMEs.

DOI: 10.5220/0012117500003680

In Proceedings of the 4th International Conference on Advanced Engineering and Technology (ICATECH 2023), pages 273-280

ISBN: 978-989-758-663-7; ISSN: 2975-948X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

273

green and that the two can work together effectively

to positively impact the environment and operational

performance (Teixeira et al., 2022). As such,

researchers have proposed compatibility between

lean and green so that they can work together

effectively to positively impact the environment and

operational performance (Inman & Green, 2018).

According to (Siegel et al., 2019), both lean and green

will sustainably increase the competitiveness of

SMEs. Available survey data show that SMEs are

responsible for most of the industrial pollution and

contribute significantly to environmental degradation

(Hasan et al., 2020). To achieve this, SMEs should

consider economic, environmental and social issues

by starting green and lean adoption. The literature

extensively shows that lean practices positively

impact green performance (Touriki et al., 2022).

However, little research has been done on SMEs

(Touriki et al., 2022). Moreover, implementation in

the SME context remains challenging as it requires

substantial financial resources, skills, and time

(Alexander et al. 2021). Moreover, according to

various experts, no clear research definition of lean

green in SMEs has been established. The literature on

this topic is still incomplete and needs to be

reconstructed. SMEs face many obstacles in

mobilizing the resources required to implement lean

green strategies (Yadav and Gahlot 2022). SMEs

need multiple guidelines, including identifying

challenges, benefits, frameworks, and critical success

factors to encourage SMEs to implement lean and

green projects to improve sustainable performance.

The lack of research to develop a lean-green

implementation framework for SMEs is an important

motivation to take up this research area (Siegel et al.,

2022). This study aims to develop a conceptual

framework for the application of lean green in SME

manufacturing. Therefore, starting from this lack of

knowledge, we propose strategies for sustainable

approaches in the context of SMEs through a

theoretical framework, systematically collecting and

analyzing relevant lean and green areas. A literature

search was conducted. Against this background, the

research objectives are formulated as follows:

(1) Identify and explore the characteristics and

relationships of Lean Six Sigma with Green

Productivity;

(2) Identify operational practice gaps and

opportunities to integrate Lean Six Sigma linkages

with Green Productivity, focusing on SME operations

in the manufacturing sector;

(3) Propose an integrated strategy for Lean Six Sigma

- green productivity in the context of SMEs through a

theoretical framework.

The rest of the paper is organized as follows. Section

2 presents the research methodology. Section 3

provides detailed findings and considerations.

Finally, Section 4 contains the study conclusions.

2 METHODOLOGY

This research framework uses systematic literature

reviews (SLR) compiled to categorize common data

and information sources examined in this study. A

systematic literature review (SLR) is about lean green

conducted through a structured process by reviewing

selected articles from various databases and sources.

SLR provides a comprehensive, transparent and

explicit approach to rigorously enforcing the process

(Thomé et al., 2016). SLR is a method of identifying,

discovering, and synthesizing research results

completed and produced by researchers and

practitioners (Lima et al., 2020).

Search engines, Elsevier

(www.sciencedirect.com), Emerald

(http://www.emeraldinsight.com), Springer

(http://www.springerlink.com), Taylor & Francis

(http://www.taylorandfrancis.com) and online

libraries Google Scholar database or library services

such as Wiley (www.wiley.com), Ebsco

(www.ebsco.com), Scopus (www.scopus.com),

where relevant find Journal article for this study.

Strings include (Lean), (Green), (Green and Lean),

(Lean Green), (SME), (Small and Medium Business),

(Manufacturing), and (Sustainability). As a result,

these search terms are combined with Boolean

operators (AND and OR) when searching keywords,

titles, abstracts, and full article text. This approach is

very important for a complete and thorough literature

investigation. The search is considered complete

when the same article continues to appear.

All article summaries in your search string are

manually checked for maximum consistency. A final

sample of 35 items was identified. As research in this

area is still in its infancy, the amount of referenced

literature is relatively limited, especially when

compared to the vast amount of research in the lean

environment field. It can therefore be argued that the

literature lacks a clear and structured research

definition of Greenlean. Articles with irrelevant

abstracts were not used in this research report due to

a strict search for terms used to identify relevant

articles.

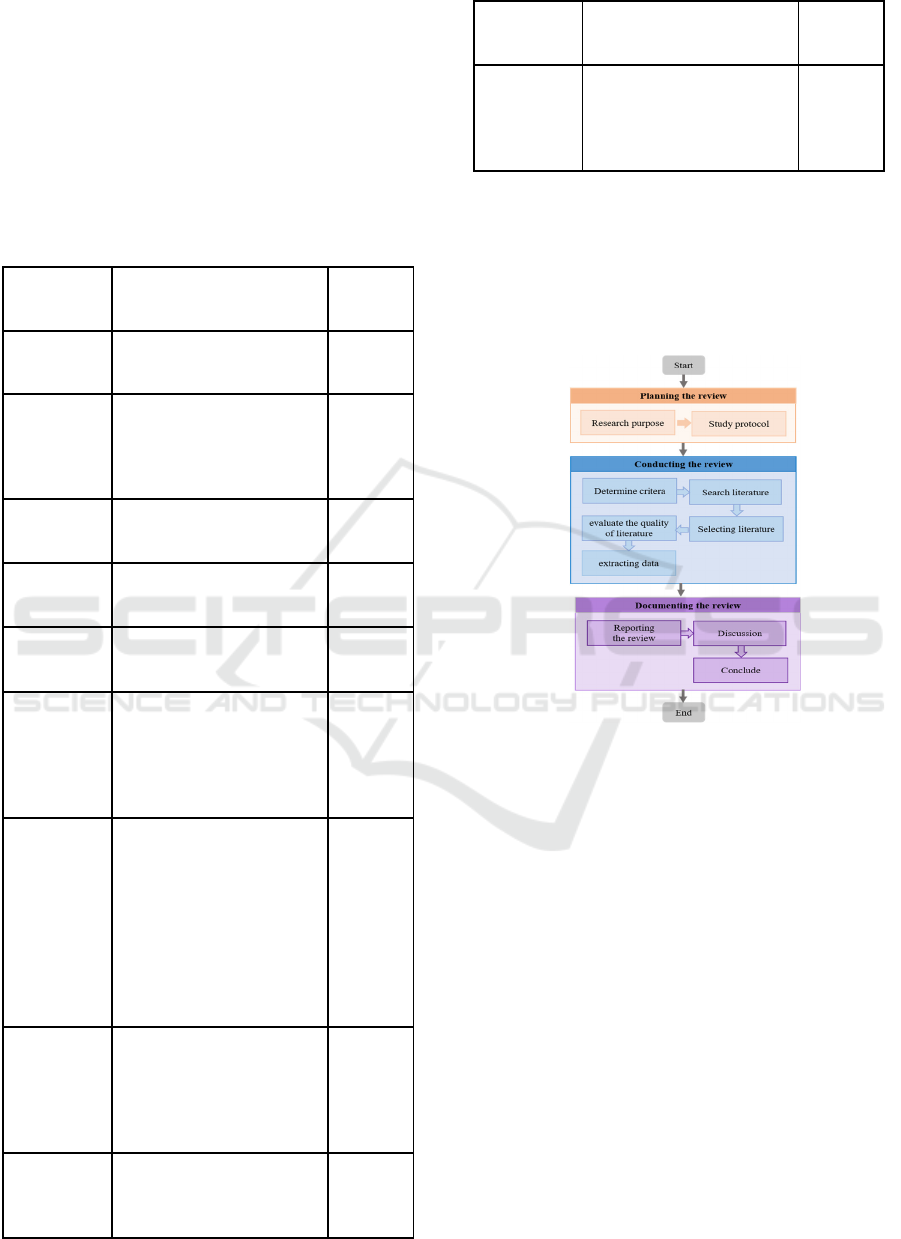

The SLR approach is shown as in figure 1. While

the literature review process is shown in table 1.

Photovoltaic is a technological innovation

designed to capture solar energy to convert it into

ICATECH 2023 - International Conference on Advanced Engineering and Technology

274

electrical energy that is greater than battery energy.

Although the SCC regulates the power that comes out

of the PV, the SCC is to control the voltage that will

enter the battery (Setyono et al., 2022). In this

research, a 100WP capacity solar panel will be

explored. The PV specification data used is in table 1.

When testing PV, several parameters are taken,

including temperature, solar radiation, voltage, and

electric current.

Table 1: Systematic literature review process.

Process Defintion

Number

of

articles

Research

purposes

Identify the intent and

purpose of the review

Develop

research

protocol

Asking research questions

in advance, including

evaluation scope, criteria,

quality and data

extraction.

Determine

the relevant

criteria

Establish research criteria

that are only relevant

articles

Search and

collect

literature

Search for relevant articles

from indexed journal

sources

Total

220

articles

Selection

and study

The definition of criteria

does not include articles

that are irrelevant

95

relevant

articles

Evaluate

the quality

of relevant

studies

Depending on the research

method used, rate the

quality of each article.

Articles that are not

qualified should be

remove

d

Data

extraction

Extract data systematically

from each study in the

overview. This stage can

be divided into several

steps, starting from

finding the title of the

article, abstracting it to

then reviewing the article

in full to analyze the

content of the article topic

Analyze

(synthesize)

data.

Using quantitative and/or

qualitative techniques,

combining the facts

obtained and illustrating

the main conclusions of

the anal

y

sis

35

articles

were

analyzed

Write a

review

result

A detailed report on the

process and results of a

systematic literature

search

Process Defintion

Number

of

articles

Discuss and

conclude

Contribute to knowledge

by publishing the results

of a systematic literature

review in academic

scientific

j

ournals.

In this sense, only articles published between 2002

and 2020 are included. Finally, all books, websites,

conference papers, and grey literature, such as

reports and working papers, were excluded from the

research review, and only papers published in high-

quality journals were considered

Figure 1: Research process.

3 RESULT AND DISCUSSION

Lean and Green have become very popular in recent

years (Leong et al., 2019). Lean and Green are two

approaches to develop in different contexts. Both are

synergistic and compatible strategies as they share a

common focus on waste reduction and efficient use

of resources (Gaikwad and Sunnapwar 2020). As a

result, the principles and tools of both approaches

have been combined into an improvement approach

known as “lean green” to achieve operational

excellence and sustainability (Gaikwad and

Sunnapwar 2020).

Green Lean is an integrated approach to achieving

environmental, financial and operational

improvements (Gholami et al., 2021). Integrating

green and lean can be seen as a new way for

companies to improve their sustainability

performance. According to (Lim et al., 2022), an

Integration of Lean Six Sigma and Green Productivity for Manufacturing SMEs

275

organization that has implemented lean and green

practices simultaneously achieves better results than

an organization that focuses on just one of these

initiatives.

After demonstrating the limitations of the lack of

a complete and structured lean and green framework

in the context of SMEs, we apply two approaches

based on a combination of theoretical elements from

the literature review. We propose a specific

integration framework for a framework for

Integrating lean six sigma - green productivity

methods to increase the productivity of small and

medium enterprises (SMEs) in manufacturing. The

framework illustrated in Figure 2 describes the

critical elements needed for SMEs to be

environmentally friendly, socially conscious and

ensure sustainable profitability through cost savings.

Figure 2: Lean Six Sigma - Green Productivity Integration

Framework for Manufacturing SMEs

Green Lean integration is a critical phenomenon in

the the framework. Success factors act as inputs to

critical phenomena, and SME performance is viewed

as output. Green Lean integration challenges in the

context of SMEs are guided, and efforts to improve

organizational performance are guided. Below is a

discussion of the theoretical elements that emerge

from the literature.

We describe the success factors for some areas

that organizations need to pay more attention to

effectively implement and sustain their Green Lean

efforts (see Table 2). Small business owners or

managers should encourage industry policymakers to

focus on key factors for implementing integrated lean

and green production in resource-constrained small

businesses.

We support. SME managers can prioritize

resources for the successful implementation of Lean

Green initiatives. Every article, without exception,

involves SME owner/manager commitment as an

essential factor for success (Baumer-Cardoso et al.

2020; Gandhi et al., 2018; Khana et al., 2020; Thanki

et al., 2019; Yadav et al., 2018; Fatoki 2019;

Aboelmaged & Hashem, 2019 ; Yuik et al., 2020;

Aboelmaged et al., 2018).

Employee motivation is involved in integration,

company goals and strategies, reviews and audits,

vision and guidance by a lean, green and sustainable

framework. Every article, without exception,

involves employee engagement as an essential factor

for success (Thanki and Thakkar 2018; Khana et al.,

2020; Gandhi et al., 2018; Siegel et al., 2022; Caldera

et al., 2019).

Within this group, various development processes

have been identified that enable current technologies

to address the unmet needs of new customers.

Managers must enable cross-functional teams to

discover new technologies with numerous pioneering

partners.

The ideal sequence suggested to them is to

achieve this by organizing the project learnings and

structuring the development process to meet the

changing market needs. Every article, without

exception, involves market adaptation as an essential

factor for success (Kasalı, Ö. 2010; Mosey, S. 2005;

Kumar, K. et al., 2012; Sui, S. et al., 2014;

Bourletidis, K et al., 2013; Hussain et al., 2015;

Fuchs et al., 2016; Neirotti et al., 2017).

The most straightforward approach is to think of

lean as the activity of identifying and eliminating

waste to add value to the organization and customers.

Six sigma is a robust statistical methodology for

reducing variation and improving quality and

customer satisfaction. When lean, green, and safe are

aligned, the organization, its customers and the

environment all benefit. Every article, without

exception, involves focus on customer as an essential

factor for success (Nabhani & Shokri, 2009;

Alhuraish et al., 2014; McAdam et al., 2019; Sharma

et al., 2015; Amar & Davis, 2008; Nallusamy, 2016;

Mustapha et al., 2018).

ICATECH 2023 - International Conference on Advanced Engineering and Technology

276

Table 2: Success factors for green-lean

Article Success factor

(Baumer-Cardoso

et al. 2020;

Gandhi et al.,

2018; Khana et

al., 2020; Thanki

et al., 2019;

Yadav et al.,

2018; Fatoki

2019;

Aboelmaged &

Hashem, 2019 ;

Yuik et al., 2020;

Aboelmaged et

al., 2018)

SME owner/manager

commitment. Small

business owners or

managers should encourage

industry policymakers to

focus on some key factors

for implementing integrated

lean and green production in

resource-constrained small

businesses. We support.

SME managers can

prioritize resources for the

successful implementation

of Lean Green initiatives.

(Thanki and

Thakkar 2018;

Khana et al.,

2020; Gandhi et

al., 2018; Siegel

et al., 2022;

Caldera et al.,

2019)

SME employee engagement.

Employee motivation is

involved in integration,

company goals and

strategies, reviews and

audits, vision and guidance

by a lean, green and

sustainable framework.

(Kasalı, Ö. 2010;

Mosey, S. 2005;

Kumar, K. et al.,

2012; Sui, S. et

al., 2014;

Bourletidis, K et

al., 2013; Hussain

et al., 2015; Fuchs

et al., 2016;

Neirotti et al.,

2017)

To adapt to the market,

managers should empower

cross-functional teams to

discover new technologies

and systematize project

learning to meet changing

market needs.

(Nabhani &

Shokri, 2009;

Alhuraish et al.,

2014; McAdam et

al., 2019; Sharma

et al., 2015; Amar

& Davis, 2008;

Nallusamy, 2016;

Mustapha et al.,

2018)

Focus on customer. The

simplest approach is to

identify and eliminate waste

and think of lean as an

activity that creates value for

your business and your

customers. Six sigma is a

robust statistical

methodology for reducing

variation and improving

quality and customer

satisfaction. When lean,

green, and safe are aligned,

the organization, its

customers and the

environment all benefit.

4 CONCLUSIONS

The details of the results of the proposed integration

framework for the Lean Six Sigma – Green

Productivity method for SMEs are as follows:

1. Provide a positive influence on people (leaders

and employees such as motivating, empowering,

energizing, compensating, and educating. It will

have a positive impact on the level of satisfaction

and commitment of leaders/managers and

employees.

2. Save time and flexibility in the production process

flow, improve process management

improvements, and increase customer loyalty and

satisfaction.

3. Cost savings, productivity gains, increased market

share, customer retention (maintaining long-term

sustainable business relationships with

customers), reduced cycle times, reduced errors,

cultural change, and product/ Development of

services.

4. The strong positive influence of SME

owners/managers on employees will create an

adaptive management hierarchy layer so that

internal organizational communication becomes

faster and more effective. It will promote more

substantial and better relationships with

customers.

5. Identify and reduce waste and hidden costs and

eliminate the level of defective products, thereby

reducing operational costs. It positively impacts

profit margins, SME business

growth/development, and customer value.

ACKNOWLEDGEMENTS

The author would also like to thank the LPPM-UWP,

Faculty of Engineering, Universitas Wijaya Putra, for

the support and facilities for conducting this research.

We hope this research to emplemented on SMEs.

REFERENCES

Hang, Y., Sarfraz, M., Khalid, R., Ozturk, I., & Tariq, J.

(2022). Does corporate social responsibility and green

product innovation boost organizational performance?

a moderated mediation model of competitive advantage

and green trust. Economic Research-Ekonomska

Istraživanja, 1-21.

https://doi.org/10.1080/1331677X.2022.2026243

Integration of Lean Six Sigma and Green Productivity for Manufacturing SMEs

277

Rehman Khan, S. A., Yu, Z., Sarwat, S., Godil, D. I., Amin,

S., & Shujaat, S. (2022). The role of block chain

technology in circular economy practices to improve

organisational performance. International Journal of

Logistics Research and Applications, 25(4-5),605-622.

https://doi.org/10.1080/13675567.2021.1872512

Bernal Torres, C. A., Paipa Galeano, L., Jarrah Nezhad, Y.,

Agudelo Otálora, L. M., & Millán, J. (2021).

Continuous improvement and business sustainability in

companies of an emerging market: Empirical analysis.

Journal of Industrial Engineering and Management,

14(4), 771-787. http://dx.doi.org/10.3926/jiem.3610

Albats, E., Podmetina, D., & Vanhaverbeke, W. (2021).

Open innovation in SMEs: A process view towards

business model innovation. Journal of Small Business

Management, 1-42.

https://doi.org/10.1080/00472778.2021.1913595

Miller, K., McAdam, M., Spieth, P., & Brady, M. (2021).

Business models big and small: Review of

conceptualisations and constructs and future directions

for SME business model research. Journal of Business

Research, 131, 619-626.

https://doi.org/10.1016/j.jbusres.2020.12.036

Gaikwad, L., & Sunnapwar, V. (2020). An integrated Lean,

Green and Six Sigma strategies: A systematic literature

review and directions for future research. The TQM

Journal. https://doi.org/10.1108/TQM-08-2018-0114

Siegel, R., Antony, J., Garza-Reyes, J. A., Cherrafi, A., &

Lameijer, B. (2019). Integrated green lean approach

and sustainability for SMEs: From literature review to

a conceptual framework. Journal of cleaner production,

240, 118205.

https://doi.org/10.1016/j.jclepro.2019.118205

Bhattacharya, A., Nand, A., & Castka, P. (2019). Lean-

green integration and its impact on sustainability

performance: A critical review. Journal of Cleaner

Production, 236, 117697.

https://doi.org/10.1016/j.jclepro.2019.117697

Teixeira, P., Ribeiro, P., Nunes, E., & Machado, V. (2022).

Combining lean and green practices to achieve a

superior performance: The contribution for a

sustainable development and competitiveness—An

empirical study on the Portuguese context. Corporate

Social Responsibility and Environmental Management,

29(1), 436-447. https://doi.org/10.1002/csr.2242

Inman, R. A., & Green, K. W. (2018). Lean and green

combine to impact environmental and operational

performance. International Journal of Production

Research, 56(14), 4802-4818.

https://doi.org/10.1080/00207543.2018.1447705

Siegel, R., Antony, J., Garza-Reyes, J. A., Cherrafi, A., &

Lameijer, B. (2019). Integrated green lean approach

and sustainability for SMEs: From literature review to

a conceptual framework. Journal of cleaner production,

240, 118205.

https://doi.org/10.1016/j.jclepro.2019.118205

Hasan, M. N., Anastasiadis, S., Spence, L. J., & Uba, C. D.

(2020). Environmental attitudes of polluting SMEs:

Qualitative insights from a low‐income developing

country. Business Strategy & Development, 3(4), 554-

566. https://doi.org/10.1002/bsd2.121

Touriki, F. E., Belhadi, A., Kamble, S., & Benkhati, I.

(2022). Achieving Environmental Excellence Through

Lean and Green in SMEs. In A. Hussain (Ed.),

Sustainable Excellence in Small and Medium Sized

Enterprises (pp. 41-83). Springer, Singapore.

https://doi.org/10.1007/978-981-19-0371-7_3

Alexander, P., Antony, J., & Cudney, E. (2021). A novel

and practical conceptual framework to support Lean Six

Sigma deployment in manufacturing SMEs. Total

Quality Management & Business Excellence, 1-31.

https://doi.org/10.1080/14783363.2021.1945434

Yadav, V., & Gahlot, P. (2022). Green Lean Six Sigma

sustainability-oriented framework for small and

medium enterprises. International Journal of Quality &

Reliability Management.

https://doi.org/10.1108/IJQRM-08-2021-0297

Siegel, R., Antony, J., Govindan, K., Garza-Reyes, J. A.,

Lameijer, B., & Samadhiya, A. (2022). A framework

for the systematic implementation of Green-Lean and

sustainability in SMEs. Production Planning & Control,

1-19. https://doi.org/10.1080/09537287.2022.2052200

Thomé, A. M. T., Scavarda, L. F., & Scavarda, A. J. (2016).

Conducting systematic literature review in operations

management. Production Planning & Control, 27(5),

408-420.

https://doi.org/10.1080/09537287.2015.1129464

Lima, R. M., Dinis-Carvalho, J., Souza, T. A., Vieira, E., &

Gonçalves, B. (2020). Implementation of lean in health

care environments: an update of systematic reviews.

International Journal of Lean Six Sigma.

https://doi.org/10.1108/IJLSS-07-2019-0074

Leong, W. D., Lam, H. L., Ng, W. P. Q., Lim, C. H., Tan,

C. P., & Ponnambalam, S. G. (2019). Lean and green

manufacturing—a review on its applications and

impacts. Process Integration and Optimization for

Sustainability, 3(1), 5-23.

https://doi.org/10.1007/s41660-019-00082-x

Gaikwad, L., & Sunnapwar, V. (2020). An integrated Lean,

Green and Six Sigma strategies: A systematic literature

review and directions for future research. The TQM

Journal. https://doi.org/10.1108/TQM-08-2018-0114

Gholami, H., Jamil, N., Mat Saman, M. Z., Streimikiene,

D., Sharif, S., & Zakuan, N. (2021). The application of

green lean Six Sigma. Business Strategy and the

Environment, 30(4), 1913-1931.

https://doi.org/10.1002/bse.2724

Lim, M. K., Lai, M., Wang, C., & Lee, Y. (2022). Circular

economy to ensure production operational

sustainability: A green-lean approach. Sustainable

Production and Consumption, 30, 130-144.

https://doi.org/10.1016/j.spc.2021.12.001

Baumer-Cardoso, M. I., Campos, L. M., Santos, P. P. P., &

Frazzon, E. M. (2020). Simulation-based analysis of

catalyzers and trade-offs in Lean & Green

manufacturing. Journal of Cleaner Production, 242,

118411. https://doi.org/10.1016/j.jclepro.2019.118411

Gandhi, N. S., Thanki, S. J., & Thakkar, J. J. (2018).

Ranking of drivers for integrated lean-green

ICATECH 2023 - International Conference on Advanced Engineering and Technology

278

manufacturing for Indian manufacturing SMEs. Journal

of Cleaner Production, 171, 675-689.

https://doi.org/10.1016/j.jclepro.2017.10.041

Khana, M. P., Talibb, N. A., & Kowangc, T. O. (2020). The

development of a sustainability framework via lean

green six sigma practices in SMEs based upon RBV

theory. Development, 12(5), 135-156.

Thanki, S., & Thakkar, J. J. (2019). An investigation on

lean–green performance of Indian manufacturing

SMEs. International Journal of Productivity and

Performance Management, 68(6), 1046-1063.

https://doi.org/10.1108/IJPPM-11-2018-0424

Yadav, N., Gupta, K., Rani, L., & Rawat, D. (2018). Drivers

of sustainability practices and SMEs: A systematic

literature review. European Journal of Sustainable

Development, 7(4), 531-548.

https://doi.org/10.14207/ejsd.2018.v7n4p531

Fatoki, O. (2019). Drivers and barriers to sustainability

manufacturing practices by small and medium

enterprises in South Africa. Academy of

Entrepreneurship Journal, 25(3), 1-12.

Aboelmaged, M., & Hashem, G. (2019). Absorptive

capacity and green innovation adoption in SMEs: The

mediating effects of sustainable organizational

capabilities. Journal of Cleaner Production, 220, 853-

863. https://doi.org/10.1016/j.jclepro.2019.02.150

Yuik, C. J., Perumal, P. A., & Feng, C. J. (2020). Exploring

critical success factors for the implementation of lean

manufacturing in machinery and equipment SMEs.

Engineering Management in Production and Services,

12(4), 77-91. https://doi.org/10.2478/emj-2020-0029

Aboelmaged, M. (2018). The drivers of sustainable

manufacturing practices in Egyptian SMEs and their

impact on competitive capabilities: A PLS-SEM model.

Journal of Cleaner Production, 175, 207-221.

https://doi.org/10.1016/j.jclepro.2017.12.053

Thanki, S. J., & Thakkar, J. (2018). Interdependence

analysis of lean-green implementation challenges: A

case of Indian SMEs. Journal of Manufacturing

Technology Management, 29(2), 355-383.

https://doi.org/10.1108/JMTM-04-2017-0067

Khana, M. P., Talibb, N. A., & Kowangc, T. O. (2020). The

development of a sustainability framework via lean

green six sigma practices in SMEs based upon RBV

theory. Development, 12(5), 135-156.

Gandhi, N. S., Thanki, S. J., & Thakkar, J. J. (2018).

Ranking of drivers for integrated lean-green

manufacturing for Indian manufacturing SMEs. Journal

of Cleaner Production, 171, 675-689.

https://doi.org/10.1016/j.jclepro.2017.10.041

Siegel, R., Antony, J., Govindan, K., Garza-Reyes, J. A.,

Lameijer, B., & Samadhiya, A. (2022). A framework

for the systematic implementation of Green-Lean and

sustainability in SMEs. Production Planning & Control,

1-19. https://doi.org/10.1080/09537287.2022.2052200

Caldera, H. T. S., Desha, C., & Dawes, L. (2019).

Evaluating the enablers and barriers for successful

implementation of sustainable business practice in

‘lean’SMEs. Journal of Cleaner Production, 218, 575-

590. https://doi.org/10.1016/j.jclepro.2019.01.239

Kasalı, Ö. (2010). Visualizing Motivations, Strategies and

Activities of Green Marketing in Organizations: A

Descriptive Study in Electronics/Battery Industry

(Doctoral dissertation, Marmara Universitesi (Turkey).

Mosey, S. (2005). Understanding new‐to‐market product

development in SMEs. International Journal of

Operations & Production Management, 25(2), 127-149.

https://doi.org/10.1108/01443570510576994

Kumar, K., Boesso, G., Favotto, F., & Menini, A. (2012).

Strategic orientation, innovation patterns and

performances of SMEs and large companies. Journal of

Small Business and Enterprise Development, 19(1),

132-145. https://doi.org/10.1108/14626001211196442

Sui, S., & Baum, M. (2014). Internationalization strategy,

firm resources and the survival of SMEs in the export

market. Journal of International Business Studies,

45(7), 821-841. https://doi.org/10.1057/jibs.2014.11

Bourletidis, K. (2013). The strategic management of market

information to SMEs during economic crisis. Procedia-

Social and Behavioral Sciences, 73, 598-606.

https://doi.org/10.1016/j.sbspro.2013.02.096

Hussain, J., Ismail, K., & Akhtar, C. S. (2015). Market

orientation and organizational performance: case of

Pakistani SMEs. Arabian Journal of Business and

Management Review, 5(5), 1-6.

Fuchs, M., & Köstner, M. (2016). Antecedents and

consequences of firm’s export marketing strategy: An

empirical study of Austrian SMEs (a contingency

perspective). Management Research Review, 39(3),

329-355. https://doi.org/10.1108/MRR-07-2014-0158

Neirotti, P., & Raguseo, E. (2017). On the contingent value

of IT-based capabilities for the competitive advantage

of SMEs: Mechanisms and empirical evidence.

Information & Management, 54(2), 139-153.

https://doi.org/10.1016/j.im.2016.05.004

Nabhani, F., & Shokri, A. (2009). Reducing the delivery

lead time in a food distribution SME through the

implementation of six sigma methodology. Journal of

manufacturing technology Management, 20(7), 941-

960. https://doi.org/10.1108/17410380910984221

Alhuraish, I., Robledo, C., & Kobi, A. (2014, August). Key

success factors of implementing lean manufacturing

and Six Sigma. In Proceeding of 17th Toulon-Verona

International Conference, Liverpool John Moores

University.

McAdam, R., Miller, K., & McSorley, C. (2019). Towards

a contingency theory perspective of quality

management in enabling strategic alignment.

International Journal of Production Economics, 207,

195-209. https://doi.org/10.1016/j.ijpe.2016.07.003

Sharma, V., Dixit, A. R., & Qadri, M. A. (2015). Impact of

lean practices on performance measures in context to

Indian machine tool industry. Journal of Manufacturing

Technology Management, 26(1), 2-25.

https://doi.org/10.1108/JMTM-11-2014-0118

Amar, K., & Davis, D. (2008, March). A review of Six

Sigma implementation frameworks and related

literature. In proceedings of the international

multiconference of engineers and computer scientists

(Vol. 2).

Integration of Lean Six Sigma and Green Productivity for Manufacturing SMEs

279

Nallusamy, S. (2016). A proposed model for sustaining

quality assurance using TQM practices in small and

medium scale industries. International Journal of

Engineering Research in Africa, 27, 184-190.

https://doi.org/10.4028/www.scientific.net/JERA.22.1

84

Mustapha, M. R., Hasan, F. A., & Muda, M. S. (2018). Lean

Six Sigma implementation: multiple case studies in a

developing country. International Journal of Lean Six

Sigma, 9(1), 2-18. https://doi.org/10.1108/IJLSS-10-

2016-0086

ICATECH 2023 - International Conference on Advanced Engineering and Technology

280