Integration of Heterogeneous Components for Co-Simulation

Jawher Jerray

a

, Rabea Ameur-Boulifa

b

and Ludovic Apvrille

c

LTCI, T

´

el

´

ecom Paris, Institut Polytechnique de Paris, Sophia-Antipolis, France

Keywords:

Heterogeneous Models, Simulation, Formal Verification, Integration, System Design.

Abstract:

Because of their complexity, embedded systems are designed with sub-systems or components taken in charge

by different development teams or entities and with different modeling frameworks and simulation tools,

depending on the characteristics of each component. Unfortunately, this diversity of tools and semantics makes

the integration of these heterogeneous components difficult. Thus, to evaluate their integration before their

hardware or software is available, one solution would be to merge them into a common modeling framework.

Yet, such a holistic environment supporting many computation and computation semantics seems hard to settle.

Another solution we investigate in this paper is to generically link their respective simulation environments

in order to keep the strength and semantics of each component environment. The paper presents a method to

simulate heterogeneous components of embedded systems in real-time. These components can be described at

any abstraction level. Our main contribution is a generic glue that can analyze in real-time the state of different

simulation environments and accordingly enforce the correct communication semantics between components.

1 INTRODUCTION

Complex embedded systems are commonly designed

using several modeling approaches and tools, because

of the different nature of sub-systems, and because

of the use of tiers to provide equipments. Integrat-

ing such heterogeneous is known as complex because

of the diversity of models. Yet, ideally, this integra-

tion stage should be done as early as possible in the

development process of these systems to verify, e.g.,

that the interfaces and main data exchanged are as

expected, and can provide the expected overall func-

tions.

Since forcing all partners of a product to use the

same modeling languages or simulation techniques

is a too hard constraint, integration of components

designed within disparate formalisms necessitates a

methodology for interconnecting these varying for-

malisms. A first way to do would be to glue the differ-

ent meta-models of the components in order to build a

unique (meta-)model from which integration verifica-

tions can be performed. This has already been shown

in the scope of components for which their models

of computation are quite similar (Zhao et al., 2020).

Yet, when they are too different, a second approach

a

https://orcid.org/0000-0001-6170-7489

b

https://orcid.org/0000-0002-2471-8012

c

https://orcid.org/0000-0002-1167-4639

can be used: connecting these components at simula-

tion level. This paper aims to address this challenge,

concentrating specifically on data exchanges between

components. The objective is to guarantee the en-

forcement of the correct communication semantics.

In this paper, we define a method and techniques

to allow to integrate a set of models designed with dif-

ferent frameworks and simulated using their own sim-

ulator, with no modification on their simulation en-

gine. To maintain a real-time co-simulation of these

different simulators where they interoperate in realis-

tic scenarios, we propose a generic ”simulation glue”

based on a distributed event streaming platform to

join heterogeneous simulators together. . After hav-

ing defined this glue, the paper illustrates in a more

concrete way how SystemC and TTool components

can be co-simulated, using Apache Kafka as the dis-

tributed event streaming platform.

2 RELATED WORK

In the area of heterogeneous distributed systems anal-

ysis, e.g., (Basu et al., 2006; Liboni and Deantoni,

2020), most of the works are based on co-simulation,

but not many of them can support both simulation and

formal validation in the same framework.For coupling

two or more simulation tools in a co-simulation envi-

Jerray, J., Ameur-Boulifa, R. and Apvrille, L.

Integration of Heterogeneous Components for Co-Simulation.

DOI: 10.5220/0012134800003538

In Proceedings of the 18th International Conference on Software Technologies (ICSOFT 2023), pages 637-644

ISBN: 978-989-758-665-1; ISSN: 2184-2833

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

637

ronment, most of the approaches (e.g., (Neema et al.,

2014; Tavella et al., 2016; Mugombozi et al., 2019))

rely on the Functional Mockup Interface (FMI) Stan-

dard (Blochwitz et al., 2011) to bundle, in a single

black-box, the internal computations and the interface

descriptions of the simulation units. One of the most

difficult challenges these approaches face is dealing

with the gap between the different semantics (Tri-

pakis, 2015) of simulation units such as the various

semantics of the coordination, which can refer to con-

tinuous time or discrete events. In (Liboni and Dean-

toni, 2020), the authors have defined a language for

describing model coordination interfaces. The inter-

face is dedicated to share the elements necessary to

coordinate the execution and communication among

the simulation units. There also exist dedicated plat-

forms for the modelling and the simulation of hetero-

geneous component-based systems, examples include

(Balarin et al., 2003; Eker et al., 2003; Basu et al.,

2006). These platforms support several modeling lan-

guages with a variety of component semantics. How-

ever, they offer a general and unified framework for

the design and simulation, even for hybrid systems.

Among existing co-simulation solutions for integrat-

ing complex systems, the model transformation from

a high-level language to SystemC is proposed in the

scope of UML or SysML (Raslan and Sameh, 2007;

?; ?). In (Atitallah et al., 2008), the authors propose a

tool to transform a high level MARTE description into

an executable platform via a chain of model transfor-

mations. These solutions are relatively tedious since

the transformation of high-level languages into tradi-

tional simulation or verification must preserve the se-

mantics, which is commonly tedious for supporting

correctly communication and computation semantics.

Moreover, all modeling environments must propose

a model transformation to the same target language

(e.g., SystemC) and the simulation specifications ob-

tained from high-level languages must still be inte-

grated together.

3 SIMULATING

HETEROGENEOUS MODELS

This section presents our contribution: a new frame-

work for the integration of heterogeneous components

using a simulation integration platform. This integra-

tion platform is agnostic to the simulation technology,

as long as it supports the communication semantics

described in this section.

Model

M

1

I

1

I

′

1

I

′

2

O

1

O

′

1

O

′

2

Model

M

2

I

1

I

′

1

I

′

2

O

1

O

′

1

Model

M

3

I

1

I

′

1

O

1

O

′

1

O

′

2

Glued models

Distributed event

streaming platform

Figure 1: Communication between models and the dis-

tributed event streaming platform.

3.1 Component Model

A model defines components interconnected with

ports. A model supports 4 types of ports: internal

input ports I

i

, external input ports I

′

j

, internal output

ports O

k

and external output ports O

′

l

. A model M

has m internal input ports, n external input ports, p

internal output ports and q external output ports as

shown in Fig. 1. We assume that the objective is to

co-simulate a set of components C . We assume that

the simulation engine of each c ∈ C can already han-

dle communications internal to c. Thus, in this paper,

we focus on external input ports I

′

j

and external output

ports O

′

l

.

In this paper, we consider two modeling

frameworks and their corresponding meta-models:

TTool (TTo, 2023) and SystemC. The former can be

used to capture SysML components that can be sim-

ulated with the internal simulator (Knorreck et al.,

2009) of TTool to prove safety and performance prop-

erties. The latter uses components written in C++ and

simulated with the SystemC simulation engine.

3.2 Distributed Event Streaming

Platform

We assume that a facility, part of our contribution,

can stream events to distributed senders/receivers so

as to ensure data can be sent and received, in real-

time, by the simulation engines of components.

Apache Kafka. Apache Spark, Apache Kafka,

Apache Flink and Spring Cloud Data Flow are ex-

ample of streaming platforms. We decided to rely

on Apache Kafka to forward messages between sim-

ulation engines. Indeed, Kafka supports many com-

puting platforms and can also handle distributed and

event-based communications. Yet, Kafka cannot na-

tively support the communication semantics usually

found in modeling frameworks for embedded sys-

tems, for instance the exchange of values via FIFOs.

Yet, Kafka supports the notion of broker: a broker

ICSOFT 2023 - 18th International Conference on Software Technologies

638

contains a set of topics, and each topic has a set of

partitions that can be considered as an infinite FIFO

buffer.To send messages to a partition, we rely on pro-

ducers. A producer can send messages to different

partitions in different topics. Consumers can receive

messages from partitions. Partitions are configured at

co-simulation setup.

3.3 Communication

In Fig. 1, we give an example of the simulation in-

tegration between 3 models via a distributed event

streaming platform, where:

• Model M

1

has 2 external input ports I

′

1

and I

′

2

and

2 external output ports O

′

1

and O

′

2

.

• Model M

2

has 2 external input ports I

′

1

and I

′

2

and

1 external output port O

′

1

.

• Model M

3

has 1 external input port I

′

1

and 2 exter-

nal output ports O

′

1

and O

′

2

.

The distributed event streaming platform must ensure

communications, for example from external output

O

′

1

of M

1

to external input I

′

1

of M

2

.

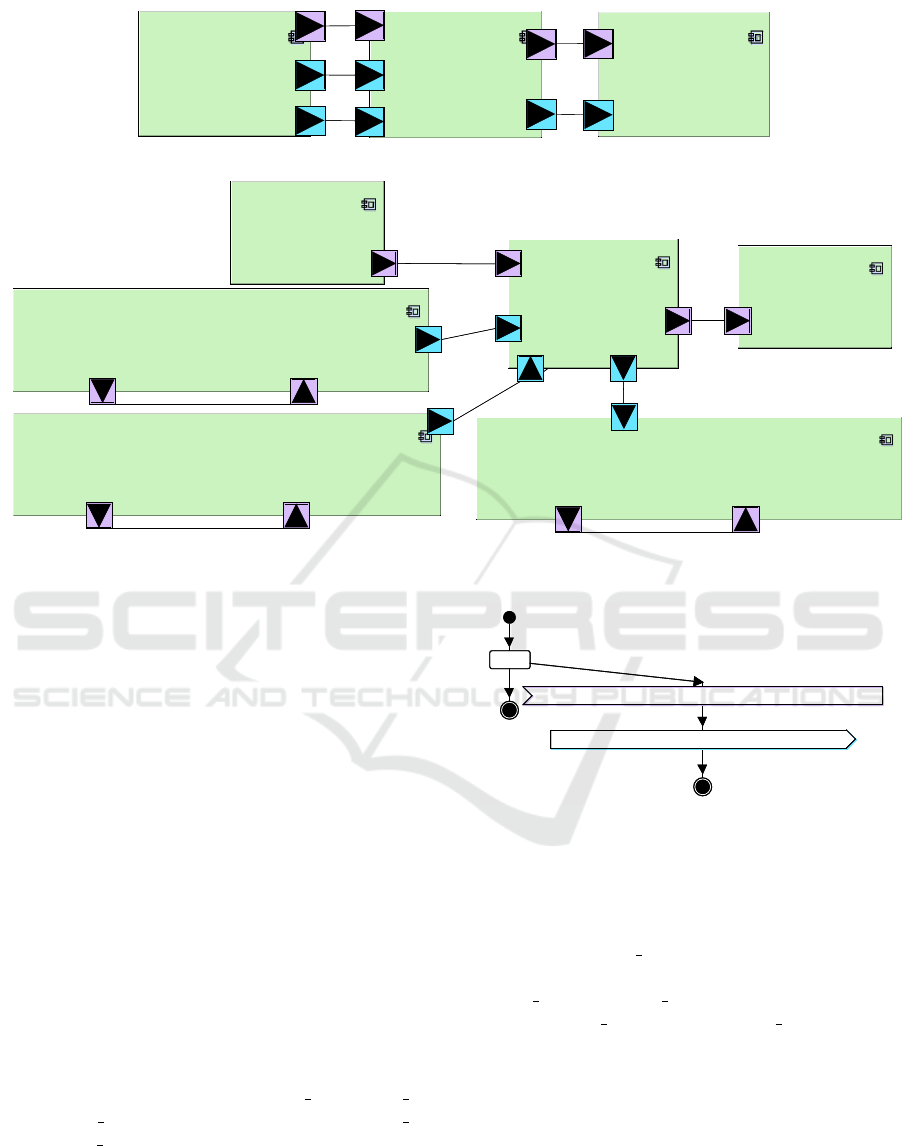

Fig. 2 depicts the general approach of our con-

tribution. First, we assume that a user wants to co-

simulate at least two models having possibly different

meta-models. From those models, our contribution

automatically updates these models to allow them to

interact with our co-simulation framework. Then, us-

ing these Co-simulation models, we start the corre-

sponding simulation of each model at the same time.

We assume we can access to the simulation trace of

each simulation when they are running: what is of in-

terest for us is obviously to identify all the potential

read or write transactions on external ports. Indeed,

the co-simulator retrieves information that being sent

or received on each port. When data is ready to be

sent on an external output port, our co-simulator en-

sures data are forwarded to the corresponding external

input port while enforcing the communication seman-

tics, e.g., finite or infinite FIFO, exchange of values or

exchange of a quantity of information.

Fig. 3 zooms on the co-simulation box shown

in Fig. 2. The co-simulator is in charge of stream rout-

ing. For each model, the co-simulator manages the

sending and receiving of data from the event stream-

ing platform depending on the port type and the cur-

rent status of ports.

3.4 Co-Simulation Models

The purpose of modifying the original models is to

facilitate communication between the simulation of a

model and the co-simulation. Co-simulation models

are automatically generated from the original model.

The Co-simulation models are automatically gener-

ated from a given model.

Algorithm 1: Algorithm of the creation of the Co-simulation

TTool model.

1 for each

i input channel in list input channels do

2 disconnect port from origin side

(i input channel); /* Disconnect the external

port from its origin. */

3 create new task(); /* Create new task for the

external input channel. */

4 connect port to new task(i input channel);

/* Connect the external port to the new task. */

5 add event(i input channel); /* Add an event

to the new task, this event will retrieve data from

the co-simulator using the avs command that allows

to add signals to a given event. */

6 associate activity diagram to task

(i input channel); /* Create the activity

diagram of the new task that contains an infinite

loop with a read event to get the data sent by the

co-simulator followed by a write channel to insert

the data to the model. */

7 add CPU in architecture(i input channel);

/* Add a new CPU in the architecture and associate

the created task to it. */

8 link CPU to bus(i input channel); /* Link

the new CPU to the main Bus. */

9 end

10 for each

i out put channel in list out put channels do

11 disconnect port from destination side

(i output channel); /* Disconnect the

external port from its destination. */

12 create new task(); con-

nect port to new task(i output channel);

add event(i output channel);

13 associate activity diagram to task

(i output channel); /* Create the activity

diagram of the new task that contains an infinite

loop with a read event, followed by a read channel

to remove samples from the channel. */

14 add CPU in architecture(i output channel);

link CPU to bus(i output channel);

15 end

Algorithm to Create a Co-Simulation TTool

Model, as Shown in Fig. 2. A TTool model con-

sists of two views: a functional view and a hard-

ware view. In the functional view, SysML blocks are

used to describe the functions and their communica-

Integration of Heterogeneous Components for Co-Simulation

639

<<component>>

Co-simulation

<<component>>

Simulation of Model 1

<<component>>

Model 1

<<component>>

Trace of Model 1

<<component>>

Co-simulation Model 1

Text

Automatic adjustment

<<component>>

Model 2

<<component>>

Co-simulation Model 2

Automatic adjustment

<<component>>

Model n

<<component>>

Co-simulation Model n

Automatic adjustment

run

<<component>>

Simulation of Model 2

run

<<component>>

Simulation of Model n

run

<<component>>

Trace of Model 2

generate generate

<<component>>

Trace of Model n

generate

parse

parse

parse

retrieve informationretrieveinformation

retrieveinformation

Figure 2: An overview of the proposed approach.

Figure 3: Zoom in the ”Co-simulation” box.

tion. The behaviour of each function is given with

an Activity Diagram. Functions can communicate to-

gether using two different facilities: event and data

channels. Events can be used to exchange control val-

ues. Data channels are used to capture the exchange

of a quantity of information. In the hardware view,

functional blocks are allocated to blocks representing

hardware components: processors, buses and memo-

ries. Functions are to be allocated to execution com-

ponents (e.g., processors), and data communication

are mapped to buses and memories. Events are not

mapped since the traffic induced by control signals

is usually considered as negligible. Events and data

channels support different semantics, such as finite

FIFO, infinite FIFO, etc.

Handling a communication (events, data) with a

model external to TTool means that the hardware plat-

form modeled in TTool must contain a input/output

hardware device from which all system components

can be reached. This is how this is achieved in em-

bedded systems: a communication interface must be

used for input and output operations with the environ-

ment.

As a consequence, sending information to a com-

ponent external to the TTool’s model means that

transactions on memories and on buses leading to the

communication interface device must be taken into

account when simulating the TTool model. Thus,

when connecting TTool’s simulator with another sim-

ulator, we decided to add one hardware I/O device per

output or input channel, and the necessary connection

to buses and memories of the hardware part of the

TTool model. Moreover, we map to each hardware

device one function f

c

e

. The activity diagram of f

c

e

features a main loop, which is infinite. In the case of

an input device, the loop contains a wait event oper-

ICSOFT 2023 - 18th International Conference on Software Technologies

640

Input

comm_2

evt_1

comm_1

Output

evt_2

comm_3

comm_3

comm_1

evt_1

comm_2

evt_2

Component

evt_1

comm_2

comm_3

evt_2

comm_1

Input

comm_2

evt_1

comm_1

Output

evt_2

comm_3

comm_3

comm_1

evt_1

comm_2

evt_2

Component

evt_1

comm_2

comm_3

evt_2

comm_1

—————————————————————————————————————

evt_2

Input

evt_1

TASK_INP_COMMUNIC_CHANNEL_comm_2

- nbr_samples_input_from_kafka_comm_2 = 0 : Natural;

comm_2

goTM_IN_comm_2 goTM_IN_comm_2

TASK_INP_COMMUNIC_CHANNEL_comm_1

- nbr_samples_input_from_kafka_comm_1 = 0 : Natural;

comm_1

goTM_IN_comm_1 goTM_IN_comm_1

goTM_OUT_comm_3

goTM_IN_comm_2

goTM_IN_comm_1

evt_1

comm_3

Output

evt_2

TASK_OUTP_COMMUNIC_CHANNEL_comm_3

- nbr_samples_output_from_kafka_comm_3 = 0 : Natural;

comm_3

goTM_OUT_comm_3 goTM_OUT_comm_3

comm_1

comm_2

Component

comm_1

comm_2 comm_3

evt_1

evt_2

evt_2

Input

evt_1

TASK_INP_COMMUNIC_CHANNEL_comm_2

- nbr_samples_input_from_kafka_comm_2 = 0 : Natural;

comm_2

goTM_IN_comm_2 goTM_IN_comm_2

TASK_INP_COMMUNIC_CHANNEL_comm_1

- nbr_samples_input_from_kafka_comm_1 = 0 : Natural;

comm_1

goTM_IN_comm_1 goTM_IN_comm_1

goTM_OUT_comm_3

goTM_IN_comm_2

goTM_IN_comm_1

evt_1

comm_3

Output

evt_2

TASK_OUTP_COMMUNIC_CHANNEL_comm_3

- nbr_samples_output_from_kafka_comm_3 = 0 : Natural;

comm_3

goTM_OUT_comm_3 goTM_OUT_comm_3

comm_1

comm_2

Component

comm_1

comm_2 comm_3

evt_1

evt_2

Figure 4: Top: The original Task diagram of the initial model. Bottom: The auto-generated task diagram of the Co-simulation

model.

ator that makes it possible to receive the number of

samples to be read (i.e., the quantity of information).

The wait event is followed by a read channel opera-

tor. In the case of an output device, the infinite loop

had a send event to send to the destination the num-

ber of samples to be read, and then a write operator.

Algorithm 1 formalizes the different steps necessary

to prepare a TTool model for external co-simulation:

this includes creating the new functions f

c

e

and their

behavior, creating the hardware I/O devices p

c

e

, con-

necting them to the corresponding bus, and connect-

ing the new ports (ports of f

c

e

) to the corresponding

sending ou receiving functions.

4 IMPLEMENTATION OF OUR

APPROACH

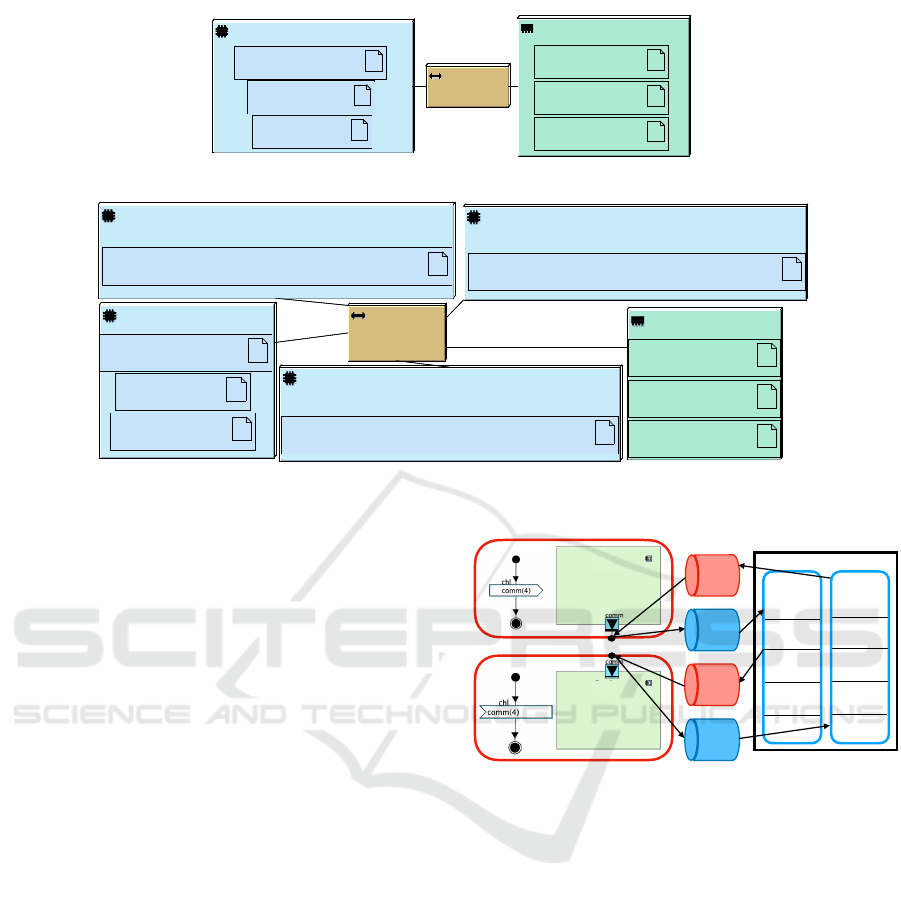

An Example of Generating Automatically a Co-

Simulation TTool Model. Let’s consider an exam-

ple with 3 external input ports (”evt 1”, ”comm 1”

and ”comm 2”) and 2 external output ports (”evt 2”

and ”comm 3”). The top part of the functional view

in Fig. 4 and the top part of the architecture in Fig. 6

depict functional components and the allocation of

components to the related architecture, respectively.

The application of Algorithm 1 to this model au-

chl

comm_1(nbr_samples_input_from_kafka_comm_1)

evt

goTM_IN_comm_1(nbr_samples_input_from_kafka_comm_1)

for(;;)

inside loop

exit loop

chl

comm_1(nbr_samples_input_from_kafka_comm_1)

evt

goTM_IN_comm_1(nbr_samples_input_from_kafka_comm_1)

for(;;)

inside loop

exit loop

Figure 5: The auto-generated activity diagram for Channel

comm

1

.

tomatically transforms the component view to the

one given at the bottom of Figure Fig. 4. Similarly,

the activity diagram of the new task of the exter-

nal channel ”comm 1” is shown in Fig. 5, the ac-

tivity diagrams of the tasks of the external channels

”comm 2” and ”comm 3” are similar to that of the

channel ”comm 1”, but its of ”comm 3” has a chan-

nel read operator instead of the channel write opera-

tor. Also, bottom part of Figure Fig. 6 depicts the new

hardware architecture.

Automatic Handling of Communication Semantics

via Kafka. The general idea behind our contribu-

tion is to automatically create the necessary Kafka

partitions to handle the communication semantics,

e.g., to manage the number of events or data samples

Integration of Heterogeneous Components for Co-Simulation

641

<<CPURR>>

CPU0

Application::Component

Application::Output

Application::Input

<<BUS-RR>>

Bus0

<<MEMORY>>

Memory0

Application::comm_2

channel

Application::comm_1

channel

Application::comm_3

channel

<<CPURR>>

CPU0

Application::Component

Application::Output

Application::Input

<<BUS-RR>>

Bus0

<<MEMORY>>

Memory0

Application::comm_2

channel

Application::comm_1

channel

Application::comm_3

channel

—————————————————————————————————————

<<CPU>>

CPU_TASK_OUTP_COMMUNIC_CHANNEL_comm_3

Application::TASK_OUTP_COMMUNIC_CHANNEL_comm_3

<<CPU>>

CPU_TASK_INP_COMMUNIC_CHANNEL_comm_2

Application::TASK_INP_COMMUNIC_CHANNEL_comm_2

<<CPU>>

CPU_TASK_INP_COMMUNIC_CHANNEL_comm_1

Application::TASK_INP_COMMUNIC_CHANNEL_comm_1

<<CPU>>

CPU0

Application::Input

Application::Output

Application::Component

<<MEMORY>>

Memory0

Application::comm_3

channel

Application::comm_1

channel

Application::comm_2

channel

<<Bus>>

Bus0

<<CPU>>

CPU_TASK_OUTP_COMMUNIC_CHANNEL_comm_3

Application::TASK_OUTP_COMMUNIC_CHANNEL_comm_3

<<CPU>>

CPU_TASK_INP_COMMUNIC_CHANNEL_comm_2

Application::TASK_INP_COMMUNIC_CHANNEL_comm_2

<<CPU>>

CPU_TASK_INP_COMMUNIC_CHANNEL_comm_1

Application::TASK_INP_COMMUNIC_CHANNEL_comm_1

<<CPU>>

CPU0

Application::Input

Application::Output

Application::Component

<<MEMORY>>

Memory0

Application::comm_3

channel

Application::comm_1

channel

Application::comm_2

channel

<<Bus>>

Bus0

Figure 6: Top: The original architecture of the initial model linked to the top task diagram in Fig. 4. Bottom: The auto-

generated architecture of the Co-simulation model linked to the bottom task diagram in Fig. 4.

in transit between two external ports. We associate

to each component ports consumers and producers.

A consumer intends to collect values from partitions,

while a producer add information to partitions. Fi-

nally, our co-simulation framework is based on a set

of partitions handled by Kafka and a set of producers

and consumers.

We now review how the different communication

semantics of data channels and events can be handled

by the co-simulation framework (”Co-simulation”

box in Fig. 2). For space reason, the paper focuses on

one data channel communication semantics: Blocking

Read Blocking Write (BRBW). An other communica-

tion sematics of type: Block Read Non Blocking Write

with finite FIFO for events (BRNBW) can be found in

section 4 of (Jerray et al., 2023).

Blocking Read, Blocking Write Channel. Let’s

consider a model built upon two components c

1

and

c

2

exchanging data with an external communication.

c

1

has an ”external output” port comm of type ”block-

ing write channel”, c

2

has an ”external input” port

comm of type ”blocking read channel”. Because they

are external, these two ports must exchange data via

our approach to provide a blocking-read blocking-

write channel communication. The approach is con-

figured as follows.

Fig. 7 depicts the communication between c

1

and

c

2

and presents the different producers and consumers

that are used to enforce the correct communication

semantics between them.

T

pr

1

c

1

co

2

p

1

pr

2

co

1

p

2

.!

."

.

.!

."

.

c

2

Figure 7: External communication between c

1

and c

2

via a

BRBW channel.

First of all, a topic denoted T with two partitions

p

1

and p

2

is created to apply the correct communi-

cation semantics between c

1

and c

2

. p

1

indicates the

current number of samples that can be consumed by

c

2

while p

2

contains the number of samples that has

been already read by c

2

.

For c

1

, we create a producer pr

1

that puts in p

1

the number of samples that have been written. The

producer pr

1

detects the written samples by analyz-

ing in real-time the simulation trace of c

1

. c

1

relies

on p

2

via consumer co

1

to know how many samples

have been already read by c

2

to figure out how many

samples can be transmitted to p

1

.

For c

2

, we create a consumer co

2

to get from p

1

the number of samples that has been written by pr

1

,

and we use a producer pr

2

to send in p

2

the number of

samples that have been read based on the simulation

trace of c

2

. So, the consumer co

2

is blocked until a

new element is added to p

1

or a read is performed by

ICSOFT 2023 - 18th International Conference on Software Technologies

642

c

2

.

Algorithm 2 features how the channels at output

side (component c

1

) are handled for a BRBW chan-

nel and Algorithm 3 shows how to handle channels at

input side (component c

2

) for a BRBW channel.

Algorithm 2: Algorithm of the output side (component c

1

)

for a BRBW channel.

1 search ←

search write trans in trace(channel name);

/* Check if there is a write transaction of

this output channel in the trace. */

2 if search is True then

3 nb samples written ←

get from trace number of samples written

(channel name); /* Parse, from the

trace, the number of samples of the

external output channel that has been

written. */

4 send message(pr

1

, T , 0,

nb samples written); /* Send the number

of samples in p

1

of T created for this

channel using its producer pr

1

. */

5 end

6 nb samples read by c2 ←

read first message no blocking (co

1

);

/* Check if there is a new message in p

2

since

the last consumption and return the value of the

first new message (element). */

7 if nb samples read by c2 != ”” then

8 exec command(”avs ”+

name of event created for channel output

+ ” 1 ” + nb samples read by c2);

/* Add the number of samples obtained from

p

2

to the event of the new task that was

created for the output external channel.

Thanks to the avs command of the simulator

that allows to add virtual signals for a

given event. By adding the number of the

samples read by c

2

to the event a read

transition will be succeeded to remove the

obtained number of samples from the output

channel buffer. */

9 end

Co-simulation of TTool SysML and SystemC mod-

els. We show how our approach can be used to co-

simulate components designed in TTool (SysML) and

others designed in SystemC. A ZigBee decoder serves

as case study: we use the version described in (Enrici

et al., 2017). ZigBee is a wireless communication

scheme adapted to low-power devices.

Algorithm 3: Algorithm of the input side (component c

2

)

for a BRBW channel.

1 check new data ←

check new data in topic(channel name);

/* Check if there is new data since the last

consumption in p

1

of the topic T that was

created for this channel. */

2 if check new data is True then

3 nb samples ←

read first message blocking(co

2

);

/* Consume the first new message since the

last consumption and return the number of

samples found in p

1

using the consumer co

2

created for this input channel. */

4 exec command(”avs ”+

name of event created for channel input

+ ” 1 ” + nb samples); /* Add the number

of the new samples obtained from p

1

to the

event of the new task that was created for

the input external channel (for example the

event goTM OUT comm 1 in Fig. 5). By adding

the number of the samples written by c

1

to

the event, a write transition will be

succeeded to add the obtained number of

samples to the input channel buffer. */

5 end

6 search ←

search read trans in trace(channel name);

/* Check if there is a read transaction of this

input channel in the trace. */

7 if search is True then

8 nb samples read ←

get from trace number of samples read

(channel name); /* Parse, from the

trace, the number of samples of the

external input channel that has been read.

*/

9 send message(pr

2

, T , 1,

nb samples read); /* Send the number of

read samples in p

2

of the topic T using the

producer pr

2

. */

10 end

In this example, we have divided the ZigBee de-

coder into 5 components (Souce, symbol2ChipSeq,

Chip2Octet, CW, and Sink) where Souce, Chip2Octet

and Sink are modeled and simulated by TTool while

symbol2ChipSeq and CW are modeled and simulated

using SystemC. All the external channels, in this ex-

ample, are of type blocking read blocking write (FIFO

of size 2) and the external events are of type blocking

read, no blocking write with infinite FIFO. Also, we

set the size of samples to 13.

After model improvement, our approach starts all

Integration of Heterogeneous Components for Co-Simulation

643

five simulation engines (one for each component),

thus including all the necessary Kafka consumers and

producers.

The description of case study and the results can

be found in section 5 of (Jerray et al., 2023).

5 CONCLUSION

In this paper, we highlighted the need to integrate

components together without common modeling lan-

guages nor heavy model transformations. Thus, we

presented a method that allows to co-simulate, in real-

time, embedded systems with heterogeneous compo-

nents while respecting usual communication seman-

tics between the components to be integrated. Our ap-

proach is based on simple model updates, on Kafka,

and on the use of consumers and producers.

We have applied our method applies to mid-size

systems such as Zigbee.

Having a distributed co-simulation has a cost in

term of simulation time: we intend to lower the extra

latency as much as possible: an option is to experi-

ment with other brokers, even if Kafka has the advan-

tage to be a recognized platform for distributed data

exchange and is platform agnostic. We also intend to

experiment with more modeling and simulation envi-

ronments like AADL.

REFERENCES

(2023). TTool. https://ttool.telecom-paris.fr. [Online].

Atitallah, R. B., Marquet, P., Piel,

´

E., Meftali, S., Niar,

S., Etien, A., Dekeyser, J.-L., and Boulet, P. (2008).

Gaspard2: from MARTE to SystemC Simulation. In

Workshop on Modeling and Analyzis of Real-Time and

Embedded Systems with the MARTE UML.

Balarin, F., Watanabe, Y., Hsieh, H., Lavagno, L.,

Passerone, C., and Sangiovanni-Vincentelli, A.

(2003). Metropolis: an integrated electronic system

design environment. Computer, 36(4):45–52.

Basu, A., Bozga, M., and Sifakis, J. (2006). Modeling het-

erogeneous real-time components in BIP. In Software

Engineering and Formal Methods (SEFM), pages 3–

12. IEEE Computer Society.

Blochwitz, T., Otter, M., Arnold, M., Bausch, C., Elmqvist,

H., Junghanns, A., Mauss, J., Monteiro, M., Neidhold,

T., Neumerkel, D., Olsson, H., Peetz, J. V., Wolf, S.,

and Claub, C. (2011). The Functional Mockup In-

terface for Tool independent Exchange of Simulation

Models. In Proceedings of the 8th International Mod-

elica Conference, pages 105–114.

Eker, J., Janneck, J., Lee, E., Liu, J., Liu, X., Ludvig, J.,

Neuendorffer, S., Sachs, S., and Xiong, Y. (2003).

Taming heterogeneity – the Ptolemy approach. Pro-

ceedings of the IEEE, 91(1):127–144.

Enrici, A., Apvrille, L., and Pacalet, R. (2017). A model-

driven engineering methodology to design parallel and

distributed embedded systems. ACM Trans. Des. Au-

tom. Electron. Syst., 22(2):34:1–34:25.

Jerray, J., Rabea, A.-B., and Apvrille, L. (2023). Integra-

tion of heterogeneous components for co-simulation.

working paper or preprint.

Knorreck, D., Apvrille, L., and Pacalet, R. (2009). Fast

Simulation Techniques for Design Space Exploration,

pages 308–327. Springer Berlin Heidelberg, Berlin,

Heidelberg.

Liboni, G. and Deantoni, J. (2020). CoSim20: An In-

tegrated Development Environment for Accurate and

Efficient Distributed Co-Simulations. In ICISE 2020 -

5th International Conference on Information Systems

Engineering, Manchester/Virtual, United Kingdom.

Mugombozi, C. F., Zgheib, R., Roudier, T., Kemmeugne,

A., Rimorov, D., and Kamwa, I. (2019). Collaborative

Simulation of Heterogeneous Components as a Means

Toward a More Comprehensive Analysis of Smart

Grids. In 2019 7th Workshop on Modeling and Simu-

lation of Cyber-Physical Energy Systems (MSCPES),

pages 1–6.

Neema, H., Gohl, J., Lattmann, Z., Sztipanovits, J., Karsai,

G., Neema, S., Bapty, T., Batteh, J., and Tummescheit,

H. (2014). Model-Based Integration Platform for

FMI Co-Simulation and Heterogeneous Simulations

of Cyber-Physical Systems. In Lund University, pages

235–245.

Raslan, W. and Sameh, A. (2007). Mapping sysml to sys-

temc. In Forum on specification & Design Languages

FDL, pages 225–230. ECSI.

Tavella, J.-P., Caujolle, M., Tan, C., Plessis, G., Schumann,

M., Vialle, S., Dad, C., Cuccuru, A., and Revol, S.

(2016). Toward an Hybrid Co-simulation with the

FMI-CS Standard. Research Report.

Tripakis, S. (2015). Bridging the semantic gap between het-

erogeneous modeling formalisms and FMI. In Embed-

ded Computer Systems: Architectures, Modeling, and

Simulation SAMOS, pages 60–69. IEEE.

Zhao, H., Apvrille, L., and Mallet, F. (2020). A model-

based combination language for scheduling verifica-

tion. In Hammoudi, S., Pires, L. F., and Seli

´

c, B., ed-

itors, Model-Driven Engineering and Software Devel-

opment, pages 27–49, Cham. Springer International

Publishing.

ICSOFT 2023 - 18th International Conference on Software Technologies

644