Design of a Logistics Allocation Scheme Based on the Approximate:

Relaxed Approach to Batching Algorithm

Xingzou Liu

*

, Jie Yao, Xinyu Zhao, Zhuo Li and Kun Jiang

Information Engineering University, Zhengzhou, Henan, China

Keywords: Relaxationt, Optimization, Logistics.

Abstract: The Ministry of Commerce, the Central Internet Information Office and the Development and Reform

Commission jointly released the "14th Five-Year Plan" for the development of e-commerce, whih provides a

top-level design for the development of e-commerce in China during the 14th Five-Year Plan period. With

the deepening impact of e-commerce on the social economy, the role of e-commerce on the industrial chain

and supply chain is becoming stronger and stronger, and the innovative functions proposed in the industrial

chain and supply chain will enable e-commerce to better support the industrial chain and supply chain. As

online shopping gradually becomes an important consumption mode in today's market. Efficient logistics and

transportation gradually become a concern. The warehouse, as the starting point for the discharge of goods,

has a significant impact on the efficiency of logistics and transportation. In this paper, for a simplified sorting

system, the batching algorithm is designed using the approximate system-relaxation algorithm, the goods

placement problem is optimised using the simulated annealing algorithm, and the assignment of sorting tasks

is finally completed by cross-referencing specific scenarios. (No effect of the paper was seen, i.e. whether

there was any improvement in the data, or whether anything new was proposed).

1 INTRODUCTION

This template, modified in MS Word 2007 and saved

as a “Word 97-2003 Document” for the PC (Yao,

2022), provides authors with most of the formatting

specifications needed for preparing electronic

versions of their papers (Huang, 2017). In recent

years, online shopping has developed very rapidly in

China. The convenience and affordability of e-

commerce has made it rapidly popular in China (Yao,

2022). As the logistics support for the e-commerce

industry, the express delivery industry is also growing

rapidly with the development of the e-commerce

market scale (Huang, 2017; Zhao, 2021; Li, 2022). At

the same time, China's governments at all levels also

attach great importance to the development of e-

commerce and express industry, in the "express into

the village" and many other people-friendly policies,

the development of China's express industry has

expanded rapidly, the number of major courier

companies handle more and more express every day.

2016 is already expected to exceed 40 billion express

business volume in China (Reports, 2017). And

according to the "2021 China Express Development

Index Report" released by the State Post Bureau, the

national express business volume in 2021 completed

108.3 billion pieces, with an average daily express

mail handling volume of nearly 300 million pieces.

Among them, Jinhua City's annual express business

volume exceeded 10 billion pieces, becoming the first

city in the country to move into the 10 billion scale

(Xu, 2021). In the face of so many express, how the

courier companies in the accurate and safe premise,

as soon as possible to the hands of customers express

is a widely concerned about the issue. And speeding

up the sorting speed is undoubtedly the most

important part of speeding up the logistics speed, and

is also an important means for major courier

companies to improve their market competitiveness.

Sorting is the process of stacking couriers by order,

type and order of entry and exit. In the beginning, the

most primitive manual sorting was used. At that time,

the flow of goods was small and manual sorting was

sufficient to meet demand, but as the economy

became more global and the number of goods in

circulation grew, manual sorting became difficult to

meet. In the 1920s the Dutch company Erma

developed the world's first letter sorting machine,

which marked the birth of automatic sorting

equipment. After the Second World War a number of

developed countries began to work on automatic

Liu, X., Yao, J., Zhao, X., Li, Z. and Jiang, K.

Design of a Logistics Allocation Scheme Based on the Approximate: Relaxed Approach to Batching Algorithm.

DOI: 10.5220/0012142300003562

In Proceedings of the 1st International Conference on Data Processing, Control and Simulation (ICDPCS 2023), pages 17-22

ISBN: 978-989-758-675-0

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

17

sorting techniques and equipment and applied them in

practice (Li, 2013). With the popularisation and

development of computers and the subsequent

application of technologies such as big data and the

internet in automatic sorting, logistics sorting systems

in foreign countries became increasingly

sophisticated (Le, 2022). Although China's logistics

industry has made good progress since the reform and

opening up, especially in the 21st century, not only in

land logistics, but also in air logistics and water

logistics (Li, 2022; Huang, 2021), automated sorting

in China started very late, so there is still a certain

distance between the overall level and the world's

advanced level, especially in the area of sorting speed.

However, China has a great demand for the

development of the express delivery industry, and the

modern logistics industry plays an important

fundamental and pioneering role in the national

economy and social development (Xu, 2022). The

scale of China's express business continues to rank

first in the world, accounting for more than 40% of

the global share, and contributing 60% to the growth

of the world's express business, which has become a

new engine for the development of the global express

market (Yang, 2017). The 14th Five-Year Plan and

the 20th Five-Year Plan are the most important and

most important of all. The Outline of the 14th Five-

Year Plan and Vision 2035 proposes to "optimise

international logistics channels and accelerate the

formation of a safe and efficient logistics network

with internal and external connections" (Li, 2021;

Wang, 2022). Sorting efficiency is a major focus on

the competitiveness of the express industry. In order

to enable the rapid development of China's express

industry, to achieve efficient automated sorting as

early as possible, to promote the mechanisation and

modernisation of the entire industry and to improve

the competitiveness of enterprises internationally, it

is essential to study and analyse sorting algorithms. In

response to this call, and also out of practical

considerations, major logistics companies are striving

to find faster and more efficient sorting methods.

2 PREVIOUS WORK

2.1 Problem Analysis

In order to improve the sorting efficiency of e-

commerce systems and provide algorithmic support

and theoretical basis for the next step of e-commerce

automation, we select three steps: goods aggregation,

goods on shelves, and assigned sorting according to

the existing courier delivery workflow, refine the

objective functions for these three steps, and carry out

modelling and optimisation respectively. The optimal

solution for the three steps in the target scenario is

finally derived, forming an optimal courier picking

solution for existing e-commerce conditions.

2.2 Introduction to the Approximate,

Relaxation Algorithm

Constraint and relaxation algorithms are common

algorithms for making abstract problems concrete,

and initially researchers put this idea into practice in

order to find better transfer equations and to ensure

that the resulting solution is optimised in an attempt

to transfer the equation. The 'constraint' approach is

generally described as adding conditions and

restrictions that are appropriate and more realistic to

ensure that the solution is still obtained after the

addition of these conditions and restrictions. The

'relaxation' approach, on the other hand, relaxes the

harsh and unreasonable conditions and restrictions of

the abstract problem and ensures that the solution is

still found after relaxing these conditions and

restrictions. The current constraint and relaxation

algorithm is very effective in optimising known

solutions to reasonable problem constraints. Figure 1

is the flow chart of the restriction relaxation

algorithm.

2.3 Constraint, Relaxation Algorithm

Implementation Steps

Step 1: add appropriate constraints, compare the

initial solution with the new solution and update the

values of the more optimal solution.

Step 2: Remove some of the stringent conditions,

compare the initial solution with the new solution, the

increment of the objective function and update the

values of the more optimal solution.

Step 3: If the solution is still obtained by

modifying the constraints, repeat steps 1 and 2 until

the more optimal solution no longer changes.

2.4 Introduction to the Simulated

Annealing Algorithm

The simulated annealing algorithm is a commonly

used optimization algorithm based on Monte-Carlo

iterative solving. Initially, researchers combined the

general combinatorial optimization problem in

optimal combinatorial problems with the solid

annealing process in thermodynamics, trying to break

through the local optimum and find the global

optimum with a certain probability. Today, this

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

18

algorithm has become the classical algorithm for

finding globally optimal patterns.

2.5 Simulated Annealing Algorithm

Model Construction Steps

Step 1: Generate the initial solution randomly, update

the optimal solution as the initial solution and

calculate the corresponding objective function taking

values.

Step 2: generate new solutions randomly in the

domain of the optimal solution, calculate the

increment of the objective function between the

optimal solution and the new solution, and update the

optimal solution when the increment of the objective

function is greater than zero.

Step 3: Repeat step 2 until the optimal solution no

longer changes.

Start

End and print y

Generate random

vector ď vĐ

The probability of

producing ď 1Đ gose

down

Is ď vĐ selected

Reduce the

requir em ents for s helf

utilization

Whether ď vĐ make the

shelf utilization to meet the

the requirements

Have all orders been

completed

The sele cted order

completes inď vĐ

Outputď vĐ

N

Y

Y

N Y

N

3 METHODOLOGY

3.1 Design of Batching Algorithms

Using the Approximate - Relaxed

Approach

First create a matrix representing the orders of the day.

𝐴=

𝑎

𝑎

⋯𝑎

𝑎

𝑎

⋯𝑎

⋮

𝑎

⋮

𝑎

⋱⋮

⋯𝑎

where the rows represent the order number and the

columns represent the type of goods, so that

𝑚=

932, 𝑛= 1941 , and

𝑎

=

0 𝑁𝑜 item j in the 𝑖

order

1 The 𝑗

item in the 𝑖

order

Next, construct the selection matrix:

𝑋=

𝑥

𝑥

⋯𝑥

𝑥

𝑥

⋯𝑥

⋮

𝑥

⋮

𝑥

⋱⋮

⋯𝑥

where the rows represent order batches and the

columns represent order numbers, i.e. 𝑚= 932 , and

𝑥

=

0 𝐵𝑎𝑡𝑐ℎ 𝑖 𝑛𝑜𝑡 𝑠𝑒𝑙𝑒𝑐𝑡𝑒𝑑 𝑗

order

1 B𝑎𝑡𝑐ℎ 𝑖 𝑛𝑜𝑡 𝑠𝑒𝑙𝑒𝑐𝑡𝑒𝑑 𝑗

order

where the rows represent order batches and the

columns represent order numbers, i.e. 𝑚= 932 , and

𝑥

=

0 𝐵𝑎𝑡𝑐ℎ 𝑖 𝑛𝑜𝑡 𝑠𝑒𝑙𝑒𝑐𝑡𝑒𝑑 𝑗

order

1 B𝑎𝑡𝑐ℎ 𝑖 𝑛𝑜𝑡 𝑠𝑒𝑙𝑒𝑐𝑡𝑒𝑑 𝑗

order

Let the matrix 𝑌= 𝑋× 𝐴 , then it is easy to see that

𝑦

=

0 There are no j goods in 𝑖

the batch

else There are j goods in 𝑖

the batch

To facilitate the calculation, the numbers in 𝑌 all

numbers greater than 1 are set to 1, i.e.

𝑦

=

0 There are no j goods in 𝑖

the batch

1 There are j goods in 𝑖

the batch

In this way, the objective translates into

minimizing the value of𝑔 the minimum value of the

constraint as follows:

𝑠

∙

𝑡

∙

=

⎩

⎪

⎨

⎪

⎧

𝑌

𝑖𝑗

𝑛

𝑗=1

≤200 (1)

𝑋

𝑖𝑗

𝑔

𝑖=1

= 1 (2)

Thus, it is sufficient to find such a matrix𝑋 The

problem can be solved by finding such a matrix that

satisfies the above conditions and has the minimum

number of rows, but such a matrix is not easy to find

because, firstly, the number of rows is unknown and

the matrix cannot be set up in the first place. Secondly,

the number of columns in the matrix is too large to

traverse to find the optimal matrix.

Therefore, abandoning the search for the optimal

solution and moving to an approximate solution, one

can split𝑋 splitting each row of the0 −1 matrix of

rows and solving for them separately.

𝑣

=

0 The 𝑖

order is not selected in this selection

1 The 𝑖

order is selected in this selection

such that 𝑣 its multiplication with the matrix

𝐴 multiply it with the matrix and make the result

satisfy the constraint (1) so that this row matrix is said

to 𝑣 is a correct choice, otherwise it is an incorrect

choice.

Each correct selection is saved in a row of the

matrix 𝑋 in one row of the matrix, and subsequent

selections are made without reselecting 𝑋 the orders

already selected in the matrix. When the matrix 𝑋

satisfies the constraint (2) the selection is complete,

Design of a Logistics Allocation Scheme Based on the Approximate: Relaxed Approach to Batching Algorithm

19

at which point the 𝑋 can be used as a solution to this

problem.

The solution sought for this question 𝑋 The

number of rows should be as small as possible, and for

this reason, as many orders as possible should be

selected for each choice.

Adjusting0 −1 The probability of the random

number being generated is initially set to 1 with a

probability of 1 and when a loop of 100 When the

correct choice is not found after several attempts,

reduce this probability by 0.005. In this way, the final

choice generated has as many orders selected each

time as possible. The solution found is also better than

before.

To further optimise the solution, a further

condition can be added, requiring the highest possible

utilisation of the shelves, in a similar way to before,

setting the minimum number of shelves to be utilised

initially as 200, and discard if the found choice cannot

be satisfied. If the number of consecutive 10 is not

satisfied, then the minimum utilisation number is set

to −1 . After using this method of calculation, the

approximate solution to the problem is eventually

found, using 92 The order is processed in batches.

3.2 Optimising the Placement of Goods

Using Simulated Annealing

Algorithms

The equations are an exception to the prescribed

specifications of this template. You will need to

determine whether or not your equation should be

typed using either the Times New Roman or the

Symbol font (please no other font). To create

multileveled equations, it may be necessary to treat the

equation as a graphic and insert it into the text after

your paper is styled.

Based on the results obtained in the previous

section, it is possible to obtain the number of orders

completed in each batch and to calculate the types of

goods contained therein according to the previous

method. The objective is to find a sequence of goods

that minimises the total picking distance of a batch of

orders. That is, to find a sequence of equal length to

the number of goods in a batch, so that when the goods

are arranged according to this sequence, the total

picking distance is minimised.

In this way, the problem is transformed into

finding a sequence that minimises the objective

function, which can be equated to TSP problem. Let

the first 𝑚 order contains the set of item numbers

as 𝑔

and the total picking distance for all orders

is𝑆

(

𝑚

)

, then use the following formula.

𝑆

(

𝑚

)

= 𝑑

(

𝑂

)

∈

(

3

)

In this way𝑆

(

𝑚

)

is the total picking distance to

be found, which should next be minimized.

For each batch of orders obtained from the

previous results, the number of occupied shelves is

relatively large and it is not computationally feasible

to traverse the entire arrangement, so a simulated

annealing algorithm is used to find an approximate

solution.

with 𝑆

(

𝑚

)

as the main function, the 𝑚 The order

of the goods contained in the batch of orders is the

input, and the inverse order and the pair of orders are

used to find the proximity solution, and the initial

temperature is set to 1000 and the end temperature is

set to 8 and the cooling rate is set to 0.94 The results

obtained by the two methods are compared and the

better one is used as the best order for this batch of

orders.

From the results, it can be seen that the solution

sequences obtained by both the pairwise and inverse

order methods of finding proximity solutions are each

good or bad in different orders but do not differ much,

so the solution sequence with the smallest total

picking distance is taken directly as the final solution

sequence.

3.3 Assignment of Sorting Tasks

The equations are an exception to the prescribed

specifications of this template. You will need to

determine whether or not your equation should be

typed using either the Times New Roman or the

Symbol font (please no other font). To create

multileveled equations, it may be necessary to treat

the equation as a graphic and insert it into the text

after your paper is styled.

In this question there are 5 sorters, initially

located on 1 shelf number, and based on the results in

(2) the results in this question, calculate the number

of orders to be picked from the current position after

picking the first 𝑖 after picking the first order, from

the current position P

The picking of the next order

starts at the current position. At this point there are

four scenarios. The following is the first case:

𝑃

<min

∈

(

𝑖

)

(

4

)

At this point the sorter simply moves from the

current position to the highest numbered shelf position

where the goods in the order are located, moving a

distance of max

∈

𝑆

(

𝑖

)

−𝑃

.

This is the second case:

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

20

𝑃

>max

∈

𝑆

(

𝑖

)

(

5

)

At this point the sorter simply moves from the

current position to the lowest numbered shelf position

where the goods in the order are located, moving a

distance of 𝑃

−minS

∈

(

𝑖

)

.

This is the third case:

minS

∈

(

𝑖

)

< 𝑃

<

∈

(

)

∈

(

)

(

6

)

The shortest distance the sorter can move is from

the current position to the mini∈O k S(i) position and

then to the maxi∈O k S(i)

position, the total distance moved is 𝑃

−

minS

∈

(

𝑖

)

+ maxS

∈

(

𝑖

)

−min

∈

𝑆

(

𝑖

)

This is the forth case:

∈

(

)

∈

(

)

< 𝑃

<max

∈

𝑆

(

𝑖

)

(

7

)

The shortest distance the sorter can move at this

point is from the current position to positionmaxS

∈

(

𝑖

)

and then to minS

∈

(

𝑖

)

The total distance travelled is

𝑃

−minS

∈

(

𝑖

)

+ maxS

∈

(

𝑖

)

−min

∈

𝑆

(

𝑖

)

Initially, any

sorter is first asked to complete the first batch of orders

and the distance travelled is calculated, and

subsequent orders are picked by the sorter who has

travelled the least distance, so that the picking task is

as even as possible.

4 RESULT AND DISCUSSION

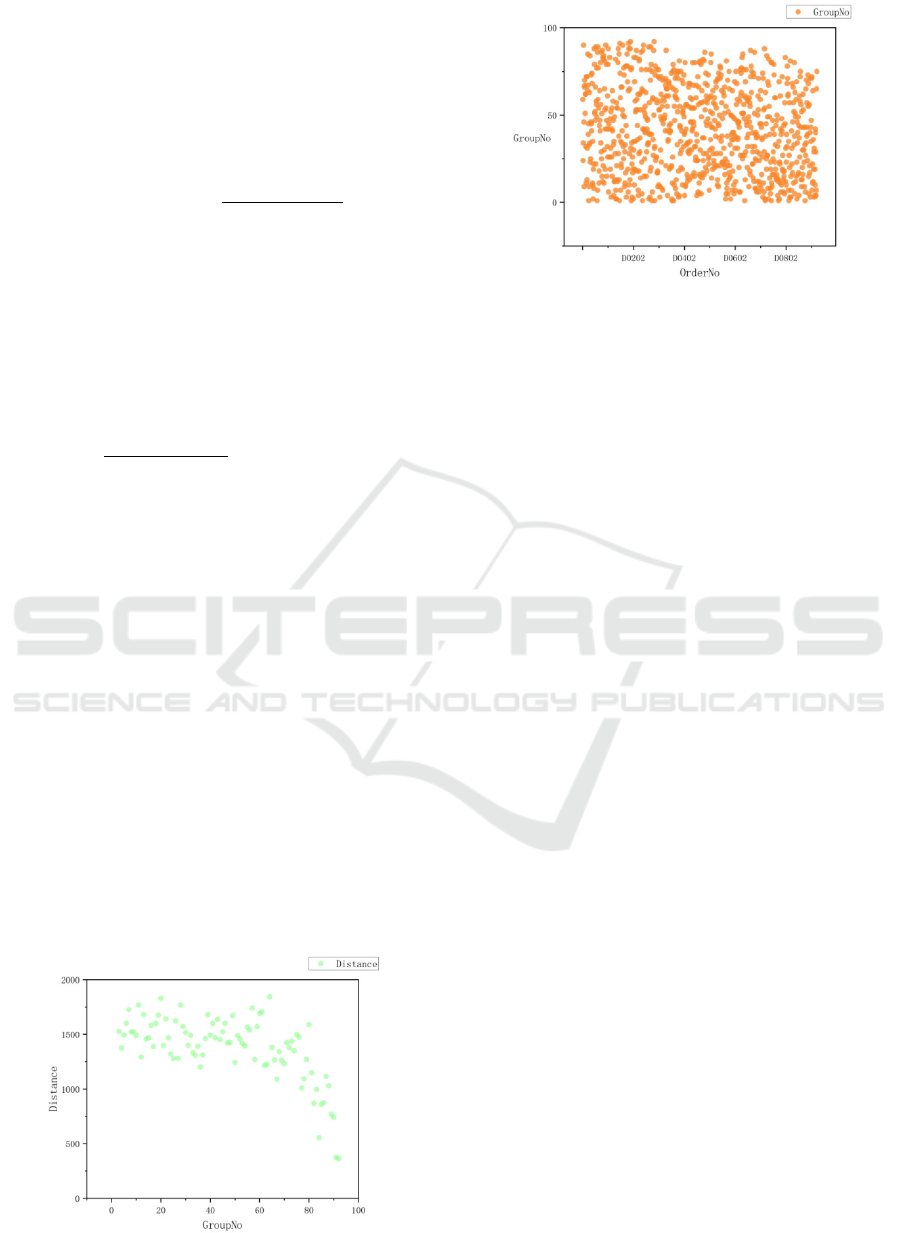

The following two results are scatter plots of the

distance of the express sorting system and the sorting

results between different groups after using the

annealing algorithm and the restriction relaxation

algorithm.

4.1 Analysis of Results

This paper provides a model for the order batching

method, the order in which different goods are placed

and the task allocation of pickers in the courier

distribution process, and tests this model in one case.

And as can be seen from these results, this model

solves the problem of determining the batching

method in order batch processing very well, resulting

in high shelf utilisation and the ability to process a

large number of orders at once.

In solving the problem of how goods are placed

on the shelves, the diagram below shows that

individual goods of the same order are placed in

relatively centralised locations, which greatly

facilitates the picking process for the pickers. When

assigning picking tasks, this paper provides a more

general model that can be used to adjust the weights

between distance travelled and mutual averaging, or

even add new judgement factors, according to specific

business needs, without affecting the normal use of the

model. The results are obtained to meet the specific

situation. The shortcomings of the model in this paper

are as follows:

A. When dealing with order batching problems

for orders containing fewer types of goods have good

results, but for large orders, there is a certain

probability of low shelf utilisation and fewer orders

being processed in a single run.

B. In solving the goods placement problem, the

speed of computing is sacrificed to get better results,

and the practical application still requires more

computer arithmetic.

C. The models shown in this paper are

approximate solutions and should not be used when

the number of orders is small and optimal solutions are

available.

Design of a Logistics Allocation Scheme Based on the Approximate: Relaxed Approach to Batching Algorithm

21

REFERENCES

Yao Hanfang. Analysis of the role of e-commerce

development in promoting logistics economy. Modern

Business, 2022(11):47-49. DOI:10.14097/j.cnki.5392/

2022.11.048.

Huang Qiang. Analysis of the development situation of

express delivery industry and intelligent logistics.

Logistics Technology and Applications, 2017,

22(01):126-128.

Zhao Saijian. Current situation and countermeasures of

China's shipping logistics development in the

information era. Ship Materials and Markets,

2021,29(09):7-8. DOI:10.19727/j.cnki.cbwzysc.2021.

09.004.

Li Chengchen,Gao Peng. Analysis of the current situation

and operation mode of cross-border e-commerce

logistics under logistics development. China Storage

and Transportation, 2022(05):138-139.

DOI:10.16301/j.cnki.cn12-1204/f.2022.05.073.

China's express business volume is expected to reach 42.3

billion pieces this year. Transportation and Port and

Maritime, 2017,4(02):76.

Xu Zhaohui. Jinhua's annual express volume exceeds 10

billion pieces and ranks first in the country. Jinhua

Daily, 2021-11-18(A01). DOI:10.28413/n.cnki.njhrb.

2021.004425.

Li, Binshan. Research on the application of automatic

sorting system in express delivery industry. Journal of

Economic Research, 2013(31):43-44.

Le, J. E-commerce logistics and distribution development

strategy under the vision of big data. Business Watch,

2022(11):37-40.

Li Chunyu. Research on modern water transport logistics

management based on sustainable development.

Zhujiang Water Transport, 2022(07):29-31. DOI:

10.14125/j.cnki.zjsy.2022.07.002.

Huang Wenbo, Chen Zishuo. Current situation and

suggestions for the development of air logistics in

China. China Storage and Transportation, 2021(06):

82-83.DOI:10.16301/j.cnki.cn12-1204/f.2021.06.030.

Xu Jing. Research on the high-quality development of

modern logistics in the context of digital economy.

Business and Economic Research, 2022(08):115-117.

Yang Y. China becomes the engine of global express

development. Railway procurement and logistics,

2017,12(04):69.

Ding Guihua. Building an integrated global express hub to

promote the national strategy of Yangtze River Delta

integration. China Logistics and Purchasing,

2019(24):108-109. doi:10.16079/j.cnki.issn1671-

6663. 2019.24.070.

Yu Jiaxiang, Suo Xin, Wang Xun, Feng Junqing, Xiao

Kangyan, Kuang Zijun. Wuhan practice of multi-party

collaborative urban emergency logistics system

construction. Comprehensive Transport,

2022,44(04):111-115.

Li Ran, Huang Lina, Li Xin. The experience and inspiration

of global express giants in building logistics system--

Analysis of the latecomer advantages of China's

express logistics industry. Price Theory and Practice,

2021(11):75-78+197. DOI:10.19851/j.cnki.cn11-

1010/ f.2021.11.404.

Wang Ming, Lu Chengyun, Liu Wenhua. "New

requirements and patterns of logistics development in

the 14th Five-Year Plan. Journal of Beijing Jiaotong

University (Social Science Edition), 2022,21(01):11-

17. DOI:10.16797/j.cnki.11-5224/c.20220107.014.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

22