Special Vehicle Collision Safety Analysis

Ruoyu Ren, Yi Jiang

*

, Baosheng Yang, Yunlong Cai and Yuchen Zhao

School of Aerospace Engineering, Beijing Institute of Technology, Beijing, China

Keywords: Vehicle Collision, Finite Element, Explicit Dynamics, Element Deletion Method, Particle Method.

Abstract: Special vehicles have the characteristics of large volume, high center of gravity, and high quality. At the

same time, the driver 's field of vision is low, making special vehicles prone to collision safety accidents. In

order to improve the collision safety of special vehicles, based on the finite element method of numerical

simulation, this paper innovatively establishes the finite element model of the whole vehicle including the

front windshield of the vehicle simulated by the element deletion method and the tire of the vehicle

simulated by the particle method. According to the collision regulation C-NCAP, two collision conditions of

50 km/h frontal 100% collision with rigid wall and 50 km/h frontal 40% offset collision with rigid wall are

built. The collision process simulation is realized by explicit dynamic algorithm, and the collision safety of

special vehicles is studied. The results show that the basic shape of the cab of the vehicle model remains

unchanged in the two collision conditions, which can meet the needs of occupant living space. Further

research results show that the front windshield of the vehicle will not break or break away from the window,

and only small cracks will occur in some positions.

1 INTRODUCTION

Special vehicles are special purpose vehicles that

exceed the design limits of general vehicles in terms

of shape and size. They are equipped with special

equipment and special tasks. Common special

vehicles include oil tanker cars, aerial work vehicles,

radar vehicles, etc. Special vehicles have the

characteristics of difficult driving, large vehicle

volume, high center of gravity, high quality, precise

internal structure, equipped with special equipment

dedicated to the implementation of a task, while the

driver 's field of vision is low, making special

vehicles prone to collision safety accidents. However,

due to the small number of special vehicles, the

safety research of special vehicles lags behind that

of normal passenger vehicles. Therefore, it is

particularly important to study the collision

phenomenon and provide theoretical basis for

improving the collision safety of special vehicles.

In the evaluation of vehicle collision safety, in

addition to the safety regulations issued by the

government, there is a more stringent standard based

on social organizations, namely the star standard

NCAP for vehicles. The C-NCAP standard

applicable to China has made the standard

requirements for collisions in accident scenarios

such as frontal collision, frontal offset collision, side

collision and heavy hammer impact.

In C-NCAP, frontal collision refers to the

collision speed of 50 km/h, and four Hybrid III

dummy are placed on the four seats of the vehicle.

The front dummy is used to test the collision injury

of the front occupant, and the rear dummy is used to

detect the protection performance of the restraint

system.

Frontal offset collision is a collision with a

front-end collision surface overlap rate of 40% of

the vehicle width, which is used to simulate the

collision between the vehicle and the frontal vehicle

or frontal obstacle.

34

Ren, R., Jiang, Y., Yang, B., Cai, Y. and Zhao, Y.

Special Vehicle Collision Safety Analysis.

DOI: 10.5220/0012144800003562

In Proceedings of the 1st International Conference on Data Processing, Control and Simulation (ICDPCS 2023), pages 34-45

ISBN: 978-989-758-675-0

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Vehicle frontal collision diagram.

Figure 2: Vehicle frontal offset collision diagram.

For the study of vehicle collision safety, there are

three main methods: empirical method, real vehicle

test method and numerical simulation method. The

empirical method is the initial use of the method,

based on the results of previous vehicle collisions,

the structure and components of the vehicle redesign

to improve vehicle collision safety. (Lei, 2004) The

real vehicle test method is a method to test the

completed vehicle products according to the standard

experimental regulations, but the real vehicle test

method has the disadvantages of long time, high cost

and poor repeatability (Li, 2015). With the

development of computer numerical simulation

technology, the finite element method is now used to

study the collision of vehicles. The research on

vehicle simulation collision at home and abroad

started earlier and developed more comprehensively.

In this field, domestic and foreign scholars have

developed computer simulation of vehicle collision

test conditions and simulation methods with the help

of computer simulation software.

In 1987, D. V. Lugt et al. used the explicit finite

element program to simulate on the CRAY X-MP

supercomputer, studied the results of 30 miles per

hour bus in frontal barrier collision, and compared

the deformation shapes in simulation and experiment

(Lugt, 1987). In 1993, Jesse S. Ruan et al. first

established a three-dimensional head model to study

the dynamic response of the human head when the

human head is impacted by a vehicle collision (Ruan,

1993). In 1998, Lu Bin of Chongqing University

wrote the first domestic red flag car collision

simulation process carried out by Changchun

Automobile Institute (Lu, 2008). In 2001, Gao

Weimin of Tongji University used PAM.CRASH to

build a full-width frontal collision platform of a car

Special Vehicle Collision Safety Analysis

35

and carried out a collision computer simulation (Gao,

2001). In 2011, Liu Qi simulated the establishment

of a three-layer structure of the vehicle front glass,

and simulated the contact between the occupant 's

head and the front glass during the collision, which

verified the rationality of the three-layer structure

glass simulation (Liu, 2011). In 2015, KA Danelson

et al. used the dummy model to evaluate the effects

of different safety restraint systems on chest injuries,

including three-point seat belts, frontal airbags, and

buckle pretensioners (Kerry, 2015).

In summary, the previous finite element

simulation of vehicle collision began earlier.

However, with the development of computer

technology, new theories and methods have been

applied to the field of finite element simulation.

However, there are few studies on the application of

these new methods to the field of vehicle collision.

This paper uses new research methods such as CPM

particle method to simulate vehicle collision, which

can provide a theoretical basis for improving vehicle

safety.

2 NUMERICAL SIMULATION

METHOD

In 2007, Lars Olovsson et al. proposed the particle

method based on molecular dynamics theory. The

particle method discretizes the gas into particles. The

gas molecule cluster containing multiple gas

molecules is simplified as a rigid particle. The

macroscopic physical quantities such as temperature

and pressure of the gas are calculated by counting

the collisions between the rigid particles and the wall

and the collisions between the particles. According

to the molecular dynamic theory, the pressure is the

function of the molecular specific kinetic energy, and

the gas static pressure in the particle method is

calculated by counting the average kinetic energy of

the particles. At the inlet of the flexible cylinder, the

particle method injects a large number of particles

into the flexible cylinder according to the mass flow

rate curve. The particle direction is arbitrary. The

average velocity of the newly created particles is

determined by its temperature and mass. The particle

rate obeys the Maxwell-Boltzmann rate distribution

and enters the flexible cylinder (Yang, 2022).

The element deletion method means that when

the elements in the model meet the preset failure

criteria, the program will automatically delete the

corresponding elements and nodes. When a series of

elements and nodes are deleted and connected to

each other, a visual crack path is formed. Among

them, the most commonly used method is to add

failure criteria such as maximum principal stress,

maximum principal strain or maximum tensile stress.

If any preset failure criterion is satisfied during the

loading process, the material is destroyed; another

way is to use the material model with failure

criterion in the finite element software, and embed

the failure criterion into the corresponding material

constitutive without adding additional failure

criterion. The element deletion method is simple in

theory and efficient in calculation. It is often used to

calculate the damage of glass materials. The deleted

elements can be regarded as cracks (Wang, 2022).

3 ESTABLISHMENT OF

VEHICLE FINITE ELEMENT

MODEL

The vehicle model is shown in Figure 4. It is a two-

axle special vehicle with a bucket. The length of the

vehicle is 8.06 m, the width of the vehicle is 2.46 m,

the height of the vehicle is 2.88 m, and the length of

the head is 1.95 m. The 3D model of the vehicle

consists of 128 components, and the head model

consists of 48 components.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

36

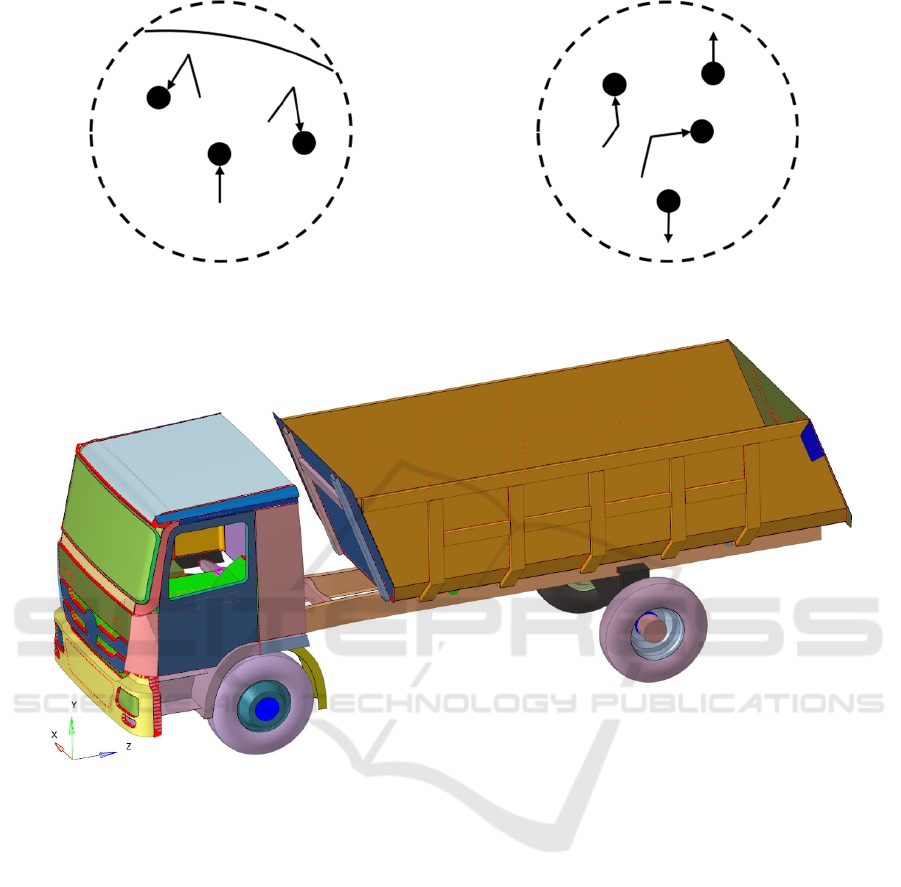

(

a

)

p

article-to-wall collision

(

b

)

p

article-to-

p

article collision

Figure 3: Principle schematic diagram of particle method.

Figure 4: Special vehicle model.

The materials used in the finite element

simulation of vehicles can be divided into metal

materials and non-metallic materials. Non-metallic

materials such as rubber, plastics, etc., metal

materials are used more in vehicles, such as low

carbon steel, composite aluminum, etc. For the front

panel of the vehicle, some sheet metal parts, etc. will

produce large deformation of the material, the use of

linear elastic material

(PIECEWISE_LINEAR_PLASTICITY) simulation,

and according to the actual situation to give

aluminum, steel and other material data. For rigid

bodies that are not easily deformed in vehicles, such

as engines, vehicle reducers, etc., rigid materials

(RIGID) are used for simulation, giving material

data to Q235 steel with great stiffness. For rubber

materials such as tires in vehicles, elastic material

(ELASTIC) simulation is used. For brittle materials

such as vehicle front windshield, the piecewise

elastic-plastic

(MODIFIED_PIECEWISE_LINEAR_PLASTICITY)

material is used for simulation, and the unit is

deleted after failure. The material parameters of the

main components of the vehicle are shown in Table 1.

The particle method is used to simulate the

vehicle tires to see the movement and deformation of

the head and body parts during the collision. Set the

initial environmental conditions and tire internal

conditions, and set the particle number to 200,000.

The data setting of the tire control panel is shown in

Table 2.

Special Vehicle Collision Safety Analysis

37

Table 1: Material parameters of vehicle main parts.

Rho

(density)

E

(young’s

modulus)

PR

(poisson

ratio)

SIGY

(yield

strength)

ETAN

(tangent

modulus)

FAIL

(maximum

strain failure)

Q235 steel 7.86e3 kg/m

3

2.1e5 MPa 0.3 235 MPa 6100 MPa /

Aluminium 2.7e3 kg/m

3

7.2e4 MPa 0.3 200 MPa 1130 MPa /

Rubber 6.88e3 kg/m

3

2.61e4 MPa 0.3 / / /

Glass 2573 kg/m

3

7e3 MPa 0.22 30 MPa 1000 MPa 0.025

Table 2: Tire parameter control.

Parameter Ambient atmosphere Tire

TATM (temperature) 293 K 293 K

RPATM (pressure) 101325 Pa 8e6 Pa

XMAIR (molar mass of gas) 29 g/mol 29 g/mol

AAIR (constant heat capacity) / 25 J/(mol·K)

BAIR (linear heat capacity) / 4.2e-3 J/(mol·K)

CAIR (quadratic heat capacity) / 0

Figure 5: Tire simulation diagram.

The finite element model of the tire simulated by the

airbag is shown in Figure 5. The blue radial line

segment is a schematic diagram of the revolute pair

of the wheel.

The previous simulation of glass mostly used the

PVB multi-layer glass structure similar to the actual

vehicle front windshield. The PVB film simulated by

the hyperelastic material was added between several

layers of glass simulated by the piecewise elastic-

plastic material, and the maximum failure principal

strain of the piecewise elastic-plastic material was

set. When the principal strain of the element exceeds

the limit value, it is judged as the element failure,

which is manifested as the element deletion.

This paper mainly studies the deformation results

of the car body itself in the collision process, so the

simulation of glass is simplified, using piecewise

elastic-plastic material to simulate single-layer glass.

The maximum principal strain failure criterion is set

to 2.5% in the control panel of the glass. When the

principal strain of the grid reaches 2.5%, the grid

failure is determined, which is shown as the removal

of the grid from the model. A simple simulation of

the rupture of the glass is performed. The parameter

settings of the front windshield are shown in Table 1.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

38

Figure 6: Acceleration sensor diagram.

In the real vehicle collision test, the acceleration

sensor needs to be installed and placed at the B-pillar

on both sides of the vehicle. This is because the

stiffness of the vehicle at this location is larger and

the deformation is smaller. It is more reasonable to

represent the acceleration of the vehicle with the

acceleration at this location. At the same time, it is

close to the driver's seat, which can reflect the driver

's acceleration overload feeling in the collision as

much as possible. Therefore, the acceleration sensor

is placed inside the B-pillar of the vehicle in the

simulation. The acceleration sensor at the B-pillar of

the vehicle is shown in Figure 6.

4 VEHICLE COLLISION SAFETY

ANALYSIS

Based on a special vehicle model, the finite element

model of vehicle collision with rigid wall is

established, and the frontal 100% collision and

frontal 40% offset collision simulation of vehicle are

realized. The collision safety of vehicle is analyzed

based on the results of vehicle energy change and

vehicle body deformation.

4.1 Vehicle 100% Frontal Collision

This part simulates the vehicle's 100% frontal impact

on the rigid wall at a speed of 50 km/h, and views

the data of vehicle deformation, overall energy

change, and acceleration change during the collision.

Figure 7 shows the deformation of the vehicle

at different times during the 100% frontal collision

from 0 to 0.1 s. Because the front end of the vehicle

energy absorption deformation part is less, so the

deformation of the vehicle in the collision process is

not obvious, the basic shape of the cab is not

destroyed, the collision deformation time mainly

occurs in the first 20 ms. In addition to the vehicle

longitudinal beam has a slight bending, bucket

before and after the panel has a small bending

deformation, the basic framework of the vehicle little

change. At the same time, the deformation of the tire

was observed. At 40 ms, the deformation of the

vehicle tire basically reached the maximum, and then

rebounded.

Vehicle collision is a process involving the

collision of multiple objects in contact with each

other, with momentum and energy exchange. Figure

8 is the curve of vehicle energy changing with time

during the collision process. The energy change of

the whole process is coherent, the curve is smooth

and smooth, and the simulation process is reasonable.

The decrease in total energy is due to the fact that the

rigid wall still retains part of the contact energy

during the collision, which is dissipated to the

outside in the form of thermal energy, and that the

deleted element also consumes part of the energy

due to the use of the element deletion method to

simulate the deformation of the glass. Vehicle energy

change for kinetic energy becomes smaller, internal

energy becomes larger, in line with the objective law

of kinetic energy to internal energy conversion. It

can be seen from the diagram that the kinetic energy

and internal energy are basically stable at 0.04 s, and

the increase or decrease is not large. It can be

considered that the collision is basically over, and

basically at 0.04 s, the internal energy of the vehicle

basically reaches the final value, and the deformation

degree basically reaches the maximum.

Special Vehicle Collision Safety Analysis

39

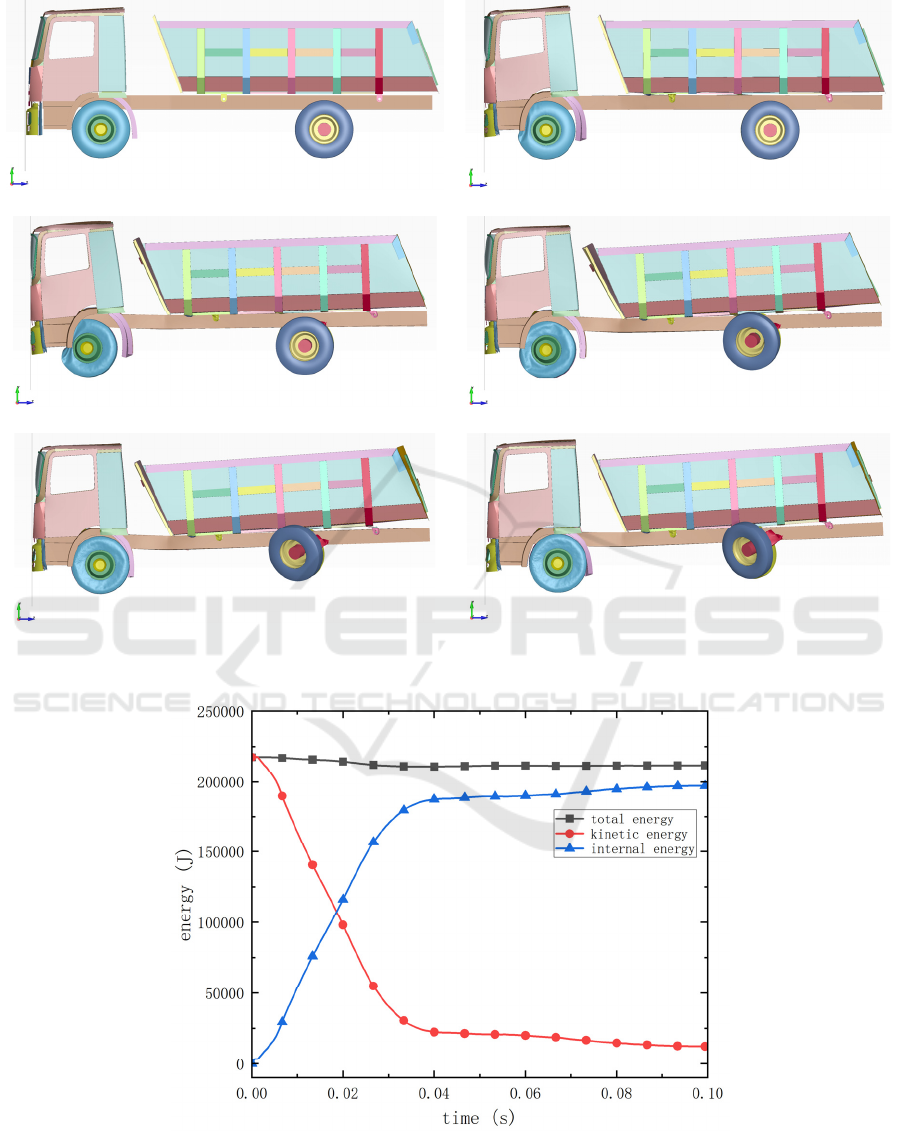

(a) t = 0 s (b) t = 0.02 s

(c) t = 0.04 s (d) t = 0.06 s

(e) t = 0.08 s (f) t = 0.1 s

Figure 7: Vehicle frontal collision deformation diagram at different times.

Figure 8: Energy change in collision process.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

40

Figure 9: Vehicle acceleration curve.

Figure 10: Deformation of vehicle front windshield at 0.04 s.

Acceleration curve is obtained by deriving the speed

of vehicle acceleration sensor unit to study the

change of vehicle acceleration during collision. The

acceleration curve obtained by the acceleration

sensor units on both sides of the vehicle B-pillar is

shown in Figure 9.

Due to the asymmetry of the established vehicle

cab model, the acceleration of the B-pillars on both

sides is not exactly the same. It can be seen that the

acceleration increases from negative to about 1038

m/s

2

, then decreases to about-233 m/s

2

, and then

oscillates near zero. The maximum acceleration is

about 105g and the acceleration is about 13g at 0.04

s after the collision.

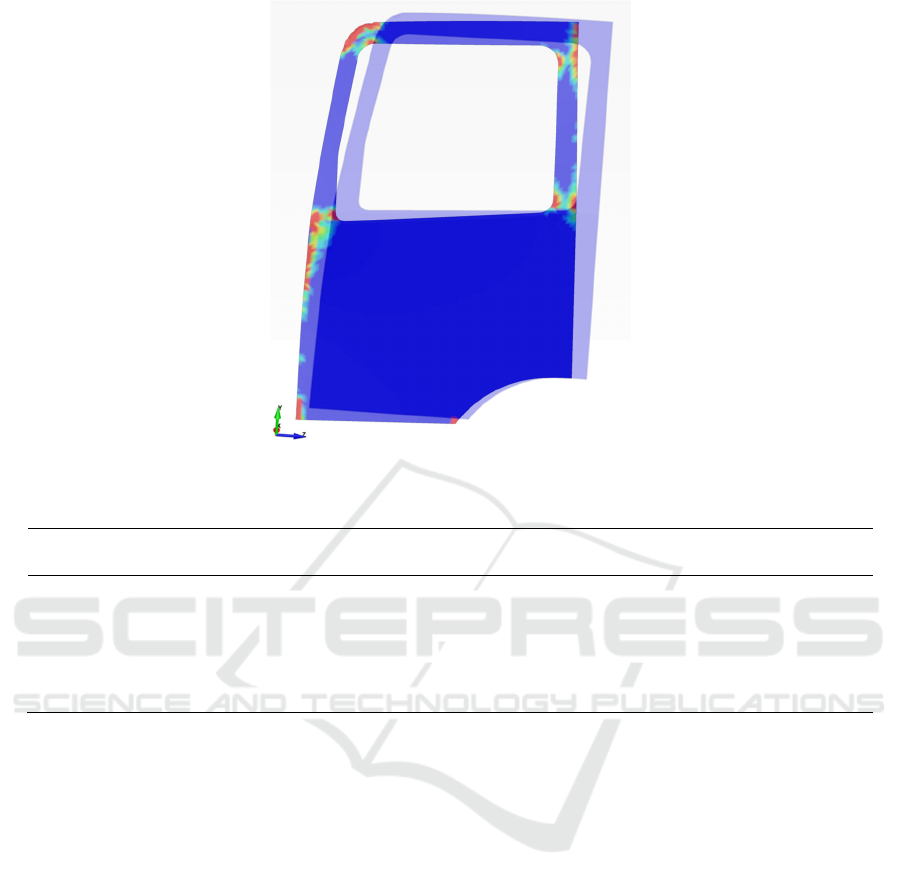

Figures 10 show the deformation of the

vehicle's front windshield and window frame at 0.04

s. It can be seen that the vehicle 's front windshield

and window frame are still connected at 0.04 s, and

there is no glass falling off the window. And the

failure unit mainly occurs at the connection, and

there will be no splash of glass debris; therefore, it

can be judged that the deformation of the front

windshield of the vehicle during the collision does

not threaten the safety of the occupants.

After the collision of the vehicle, whether the

door can open normally without external force plays

an important role in the timely escape and treatment

of the occupants after the accident. However, it is

difficult to directly judge whether it can be opened,

and it can be indirectly judged by observing the

deformation of the door. The deformation of the left

door is shown in Figure 11.

Special Vehicle Collision Safety Analysis

41

Figure 11: Car door deformation diagram.

Table 3: Coordinate change of y-axis and z-axis at four corners of door.

node

z-axis

coordinates

y-axis

coordinates

z-axis coordinates

(0.04 s)

y-axis coordinates

(0.04 s)

Upper left corner 674.278 2723.523 403.548 2740.413

Bottom left corner 1548.325 1306.621 1440.063 1423.892

Upper right corner 1548.858 2768.338 1268.210 2874.717

Lower right corner 470.285 1104.993 389.409 1110.424

Figure 11 shows the deformation of the door at

0 s and 0.04 s. It can be seen that the basic shape of

the door has not changed. In order to measure the

deformation of the door, the output point is set at the

four corner nodes of the door, and the change of the

diagonal length of the door at 0s and 0.04 s is

calculated.

According to Table 3, the two diagonal lines of

the door do not change much at 0 s and 0.04 s, and

basically only change by 11 mm. Therefore, it can be

considered that the door does not deform much

during the collision.

4.2 Vehicle 40% Frontal Offset

Collision

This part simulates the vehicle hitting the offset rigid

wall at a speed of 50 km/h. The simulation time is

0.1 s. In the post-processing, the vehicle deformation,

the overall energy change and the deformation

energy absorption of each component are viewed.

Since the vehicle tire is more crushed during the

offset collision, an analysis of the tire is added to the

offset collision.

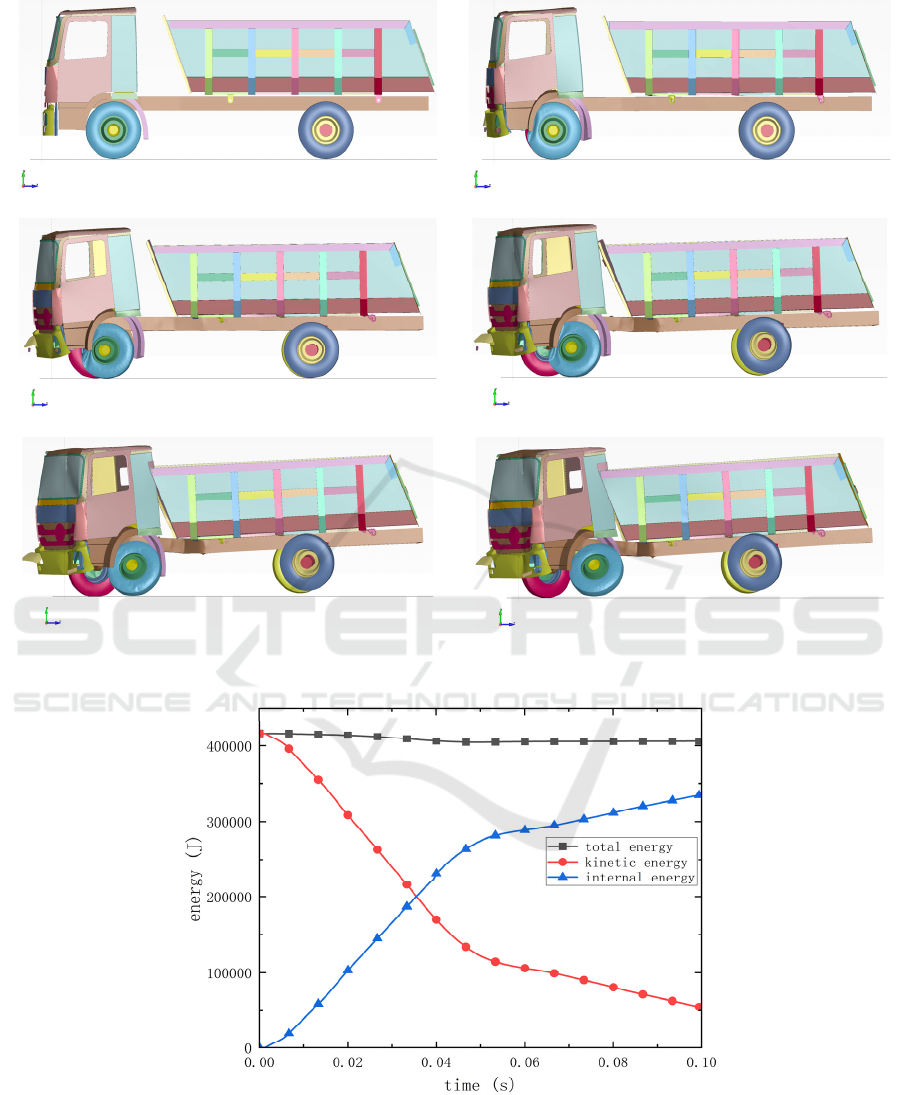

Figure 12 shows the deformation of the vehicle

in the period of 0 to 0.1 s. It can be seen that the

front of the vehicle began to turn to the offset side

from 0.02 s, and the front beam began to bend at

0.04 s, which lasted until 0.1 s at the end of the

simulation. At the same time, it can be seen that the

rear panel of the vehicle cab collided with the front

of the vehicle at 0.06 s, and the rear of the vehicle

began to rise at 0.06 s and continued until the end of

the simulation. The deformation of the tire is more

obvious on the left side, and the maximum

deformation of the left tire occurs at about 0.4 s, and

then the tire rebounds.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

42

(a) t = 0 s (b) t = 0.02 s

(c) t = 0.04 s (d) t = 0.06 s

(e) t = 0.08 s (f) t = 0.1 s

Figure 12: Vehicle frontal offset collision deformation diagram at different times.

Figure 13: Frontal offset collision energy change.

Figure 13 reflects the overall energy change in the offset collision. The curves are coherent and

Special Vehicle Collision Safety Analysis

43

smooth, and the simulation calculation is reasonable.

The decrease of the total energy curve is due to the

contact energy between the vehicle and the rigid wall

and the energy consumption after the element

removal is not included.

It can be seen that the kinetic energy of the

vehicle decreases and the internal energy increases.

The kinetic energy and internal energy of the vehicle

change at a faster rate in the first 0.05 s, and still

increase or decrease after 0.05 s, but the change rate

decreases. The deformation of the vehicle before

0.05 s is mainly compressive deformation along the

speed direction; the deformation of the vehicle after

0.05 s is mainly due to the slow increase of the

internal energy of the beam bending caused by the

compression of the offset rigid wall and the slow

decrease of the kinetic energy of the head deflection.

The deformation of the front windshield of the

vehicle at 0.1 s is shown in Figure 14. It can be seen

that under the extrusion of the offset rigid wall, the

glass produces an indentation at the edge of the rigid

wall and the position where the glass contacts, and

there is a partial unit failure at the indentation. There

are a small number of unit failures at the connection

between the window and the glass, and it is judged

that the front windshield of the vehicle will not be

detached from the window in the collision

simulation.

The particle method is used to simulate the tire.

By counting the collisions between a large number

of particles and the collisions between particles and

the wall, the macroscopic physical quantities of the

gas inside the tire are calculated. The curves of tire

pressure and volume with time are shown in Figure

14 and Figure 15.

From Figure 15, it can be seen that the pressure

of the left front wheel squeezed by the collision

increases first and then decreases, from the initial

Figure 14: Deformation of vehicle front windshield at 0.1 s.

Figure 15: Tire pressure time curve. Figure 16: Tire volume time curve.

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

44

0.8 MPa to about 0.89 MPa, and the pressure

continues to decrease to 0.68 MPa after fluctuation.

As the volume of the airbag inside the tire increases

gradually during the collision, the gas pressure inside

the tire decreases. The pressure of right rear wheel

decreases from 0.8 MPa to 0.76 MPa, and the

pressure of right front wheel and left rear wheel

increases from 0.8 MPa to 0.87 MPa and 0.86 MPa

respectively. The volume curve of the tire basically

shows a trend opposite to the pressure curve.

5 CONCLUSION

In this paper, the finite element method is used to

simulate the vehicle collision process. The vehicle

front windshield simulated by element deletion

method and the vehicle tire simulated by particle

method are applied to the collision of the vehicle

model to improve vehicle safety. It is found that the

basic shape of the cab remains unchanged under two

collision conditions, and the vehicle safety is high.

And the cab deformation occurs mainly in 50 ms,

deformation time is short. The front windshield of

the vehicle will only crack in some parts, and there

will be no large area out of the window. The tire of

the vehicle will produce large deformation in the

offset collision, and the pressure in the tire will also

change to a certain extent, but the pressure change is

small, and the vehicle is safer.

REFERENCES

Lei, Z. B. (2004). Crashworthiness of Large Deformed

Structures. The Crashworthiness of Structure with

Large Displacement and Large Deformation. Hunan:

Central South University.

Li, G. T. (2015). Introduction. Analysis and improvement

of commercial vehicle cab's frontal crash safety.

Hunan: Hunan University.

Lugt, D. A. V., Chen, R. J., & Deshpande, A. S. (1987).

Passenger Car Frontal Barrier Simulation Using

Nonlinear Finite Element Methods. SAE Transactions,

96, 1083–1087.

Ruan, J., Khalil, T., & King, A. (1993). Finite Element

Modeling of Direct Head Impact. https://saemobilus.

sae.org/content/933114/.

Lu, B. (2008). Introduction. Research on the C-NCAP

Collision Test for Passenger Car. Chongqing:

Chongqing University.

Gao, W. M., Wang, H. Y., & Xu, D. K. (2001). Effect of

spotweld in simulations of vehicle crash. Journal-

Tongji University, 29(7), 870-872.

Liu, Q., Liu, J. Y., & M, Q. (2011). Simulation and test

validation of windscreen subject to pedestrian head

impact. Journal of Automotive Safety and Energy,

2(2), 128.

Kerry A. D., Adam J. G., & Andrew R. K. (2015). Finite

element comparison of human and Hybrid III

responses in a frontal impact. Accident Analysis &

Prevention, 85, 125-156.

Yang, B. S, Jiang, Y., & Yang, L. N. (2022). Research on

Universal Flexible Cylinder Ejection. http://kns.cnki.

net/kcms/detail/61.1234.TJ.20221026.1947.002.html.

Wang, M., Li, Y., Luo, H., Zheng, X., & Li, Z. (2022).

Experiment and Numerical Simulation of Damage

Progression in Transparent Sandwich Structure under

Impact Load. Materials, 15(11), 3809.

Special Vehicle Collision Safety Analysis

45