Network Structure Identification for Medium Transport in a Virtual

Reality Environment

Linh Tuan Mai

a

and Heiko Werdin

Chair of Building Energy Services, Faculty of Mechanical Engineering,

University of Applied Sciences Dresden, Dresden, Germany

Keywords:

Building Energy Service Simulation, Virtual Reality, Smart Education.

Abstract:

Building Information Modelling (BIM) in the Architecture, Engineering, and Construction(AEC) sector al-

lows for significant improvements in working efficiency throughout the entire life cycle of a building and has

become mandatory in many countries. This process necessitates a greater understanding of the entire system

from engineers, technicians, and facility managers, resulting in a greater demand for appropriate educational

methods involving system simulation. The simulation of building energy services includes determining the

network structure for medium transport, which is often not included in the BIM-model. This paper describes a

workflow for determining the structure of a component-based geometrical model of a building energy service

involving medium transport automatically. The workflow can be divided into three stages: identifying con-

nected components, determining valid connection paths from a starting point to an end point, and determining

the initialized flow direction of the transport medium within the system as well as the network structure. The

depicted solution includes the workflow’s implementation and integration into a virtual reality environment

for educational purposes. This approach has been validated through various exemplary generated test systems

and allows for the realization of flexible educational use cases.

1 INTRODUCTION

1.1 Simulation as Tool for a Better

Understanding of Building Energy

Services

Building energy services (BES) include technical sys-

tems in a building, such as shading, heating, cool-

ing, ventilation, and air conditioning (HVAC), and are

responsible for creating a suitable living and work-

ing environment for its residents (Hall and Greeno,

2017). BES are an important component of any mod-

ern building, contributing significantly to the fulfill-

ment of requirements for user comfort and the overall

energy efficiency of the structure.

Different building usages necessitate different

BES, ranging from simple BES in an apartment build-

ing to much more complex BES in functional build-

ings. The number of components (e.g., radiators,

pumps, pipes, air ducts) as well as the dimension and

specific component types vary between BES. The be-

haviors of different BES differ accordingly, resulting

a

https://orcid.org/0000-0001-8265-534X

in increased demand for experts (technicians, engi-

neers, and facility managers) in this domain with ex-

tensive system knowledge.

The widespread use of Building Information Mod-

elling (BIM) in the Architecture, Engineering, and

Construction (AEC) sector (Milyutina, 2018) enables

the availability of a building model, including its

BES, that is created and improved throughout the

building’s life cycle. This opens the door to the use of

building simulations, which improves the quality of

digital twins of building systems (Lydon et al., 2019).

The ability to simulate various system behaviors dur-

ing runtime or even before the building exists leads

to a wide range of important applications that signif-

icantly improve a building’s sustainability. Early in

the planning process, the design quality can be eval-

uated and improved. Anomalies caused by runtime

degradation can be identified in real time by compar-

ing measured data in the real building to simulated

data.

The benefits of system simulation mentioned

above also apply to educational use. Students and

trainees can use simulation software such as MatLab

Simulink to simulate the runtime behavior of techni-

456

Mai, L. and Werdin, H.

Network Structure Identification for Medium Transport in a Virtual Reality Environment.

DOI: 10.5220/0012146900003546

In Proceedings of the 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2023), pages 456-463

ISBN: 978-989-758-668-2; ISSN: 2184-2841

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

cal devices and systems. The resulting data indicates

how the system functions given the working condi-

tions defined by the users. Despite the low effort re-

quired to adapt the system model, the limitation of

using traditional simulation software in education is

the simplicity of the result presentation, which limits

learning cognition.

1.2 Application of Virtual Reality for an

Immersive Learning Experience

The development of Extended Reality (XR) (Kaplan

et al., 2021) allows for innovative forms of informa-

tion presentation. XR includes a variety of spatial in-

terface technologies and conceptual propositions that

provide varying degrees of immersion. These con-

cepts, which are Augmented reality (AR), Mixed re-

ality (MR), Augmented Virtuality (AV), Virtual re-

ality (VR), are parts of the reality-virtuality contin-

uum (Milgram and Kishino, 1994).

Among these concepts, VR uses head-mounted

displays to provide a fully immersive experience in a

virtual environment and has a high potential for sup-

porting immersive learning experiences (Lau and Lee,

2021). An application for fault diagnosis in offshore

wind turbines (Kapp et al., 2022), or VR-approaches

that offer practical and clinical emergency medical

education (Behmadi et al., 2022) (Rad et al., 2022),

are examples of VR training tools.

XR education applications in the AEC sector pri-

marily aim to improve learners’ learning ability re-

garding complex spatial arrangements. XR training

tools are used for operation guidance (for example,

drilling operation training) and safety training for haz-

ard identification and accident prevention (Tan et al.,

2022).

In terms of comprehensive BES-knowledge, VR-

Lab4BES is the only publicised education research

using XR.

VRLab4BES (Mai and Werdin, 2022) is a VR tool

for educational purposes that provides immersive and

interactive learning experiences. This tool’s primary

application domain is training programmes for engi-

neers and technicians in the AEC sector. The learn-

ing units in VRLab4BES are based on a simple sim-

ulated BES system. Each learning unit involves one

or more building trades (for example, cooling or heat-

ing) (fig. 1).

Every learning unit is designed as a closed sys-

tem with interactable components. An example of a

learning unit is seen in fig. 2, which consists of a sim-

ple heating circuit. Using an interactive hand panel,

the learner can reconfigure the various components

(a pump, a sensor, a PI-controller, and a two-way

Figure 1: Concept of VRLab4BES (Mai and Werdin, 2022).

valve). The adapted behaviour of individual compo-

nents and their impact on the overall system are re-

layed to learners via various diagrams, informational

panels, or other visual effects, such as the colours of

the pipe’s sectors, which depict the temperature of

each sector.

Figure 2: Example of a VR learning unit from VR-

Lab4GST (Mai and Werdin, 2022).

Despite the successful application of the approach

in practise (Mai and Werdin, 2022), which shows the

advantages in improving learning motivation and cog-

nition over traditional simulation programmes, there

is still a lot of potential VRLab4BES. The learners’

ability to adapt newly acquired knowledge from a

learning unit is limited by the inability to reconstruct

or create a BES system from scratch within the learn-

ing environment during runtime. Importing and ap-

plying the simulation to an existing BIM-Model of a

BES is also not possible.

Aside from the difficulties in developing neces-

sary user functions for usability (e.g., a snap function

to correctly connect the geometry of different com-

ponents in a VR-environment), one very important

reason for the absence of the aforementioned func-

tions in VRLab4BES is the difficulty in automatically

identifying the network structure of a given connected

geometry model of a BES. While BIM models can

provide information about connectors of various com-

ponents (for example, air ducts), there is no solution

approach that discusses the identification of medium

transport systems in general and BES in particular.

Network Structure Identification for Medium Transport in a Virtual Reality Environment

457

1.3 Automated Identification of

Network Structure for Medium

Transport

This paper introduces a workflow for automatically

determining a BES model’s network structure as well

as the direction of the corresponding medium trans-

port throughout the entire system. This method is

the foundation for simulating various building trades

such as heating, cooling, air conditioning, and sani-

tary. The workflow is integrated into the education

platform VRLab4BES for validation purposes, and it

supports the simulation of heating systems as part of

various learning units.

Although the workflow is applicable to other sim-

ilar usecases and is independent of development en-

vironments, the details of its implementation in a VR

environment are depicted as a contribution to the re-

search on simulation in XR applications.

2 NETWORK STRUCTURE

IDENTIFICATION AS AN

ESSENTIAL PART OF BES

SIMULATION

2.1 Network Components

A heating system will be used as an example to iden-

tify the usage and challenges of network structure

identification. A heating system consists of various

components of different functions, such as heat source

(furnace or heat pump); water circulation system in-

cluding pipes, bow, T-pieces and crosses; thermostat;

heat exchanger; valves as well as other aggregates

for safety (e.g. expansion chamber) or the monitor-

ing and system controls (e.g. controller, sensors and

operating devices).

Components related to medium transport in a

heating system can be classified based on their in-

fluence on the medium transport and their number of

openings. We use the term connector to describe the

openings in the scope of this paper. A connector does

not only represent a specific geometrical form on the

components but also support the parameter exchange

between component models as part of the system sim-

ulation. Fig. 3 depicts the roles of connectors in terms

of medium transport. Each connector can be identi-

fied as input, output or unidentified. The unidentified

status of a connector indicates that the identification

process (sec. 3) has not determined this connector’s

role in the network structure.

Figure 3: Different roles of component connectors for

medium transport.

As a result, the medium transport components can

be classified as follows:

• Pumps are vital parts of a heating system because

they regulate mass flow within the water circu-

lation system. Other building services also have

comparable components, such as fans for the air

conditioning. Each pump has two connectors,

one for water input and the other for water out-

put. Different pumps in a heating system can

correspond to different subsystems and functions

(e.g. medium transport to heat exchangers or wa-

ter exchange between the furnace and water tank).

Within the scope of this paper, we define a main

pump as the device in charge of delivering heated

water into the system. The main pump is fre-

quently integrated into the heat source. The func-

tion of the heat source will be incorporated into

the main pump to simplify the description of the

workflow in this paper.

• Circulation components with two connectors are

all non-pump components of the medium trans-

port system with one input and one output. This

category includes pipes, bows, heat exchangers,

and valves. While valves can have a direct impact

on regulating mass flow in the system, they can

also be included in this category due to their roles

in the yet-to-be-identified network structures.

• Distributors are made up of more than two con-

nectors. Aside from water distributors with valves

for regulating the flow of water in various heat-

ing circuits, aggregates such as T-pieces and pipe

crosses can be included in this category.

Aside from the previously mentioned compo-

nents, there are additional components such as water

expansion chambers where water can be delivered to

or extracted from. They are part of the heating sys-

tem’s safety components. They will not be included

further in the analyses in this paper due to their pas-

sive role in medium transport in heating circuits.

SIMULTECH 2023 - 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

458

2.2 Network Structure and System

Simulation

In general, medium transport in a heating system can

be described as a closed loop in which the medium

begins at the main pump (which in this paper also in-

cludes the heat source as depicted in sec. 2.1), moves

through circulation components with two connectors,

and returns to the main pump. Figure 3-b depicts an

example of a simple heating system. The heated wa-

ter is transported from the pump to the heat exchanger

(HE 1) via multiple pipes and bows, and then back to

the pump via additional pipes and bows.

In practise, BES is made up of much more com-

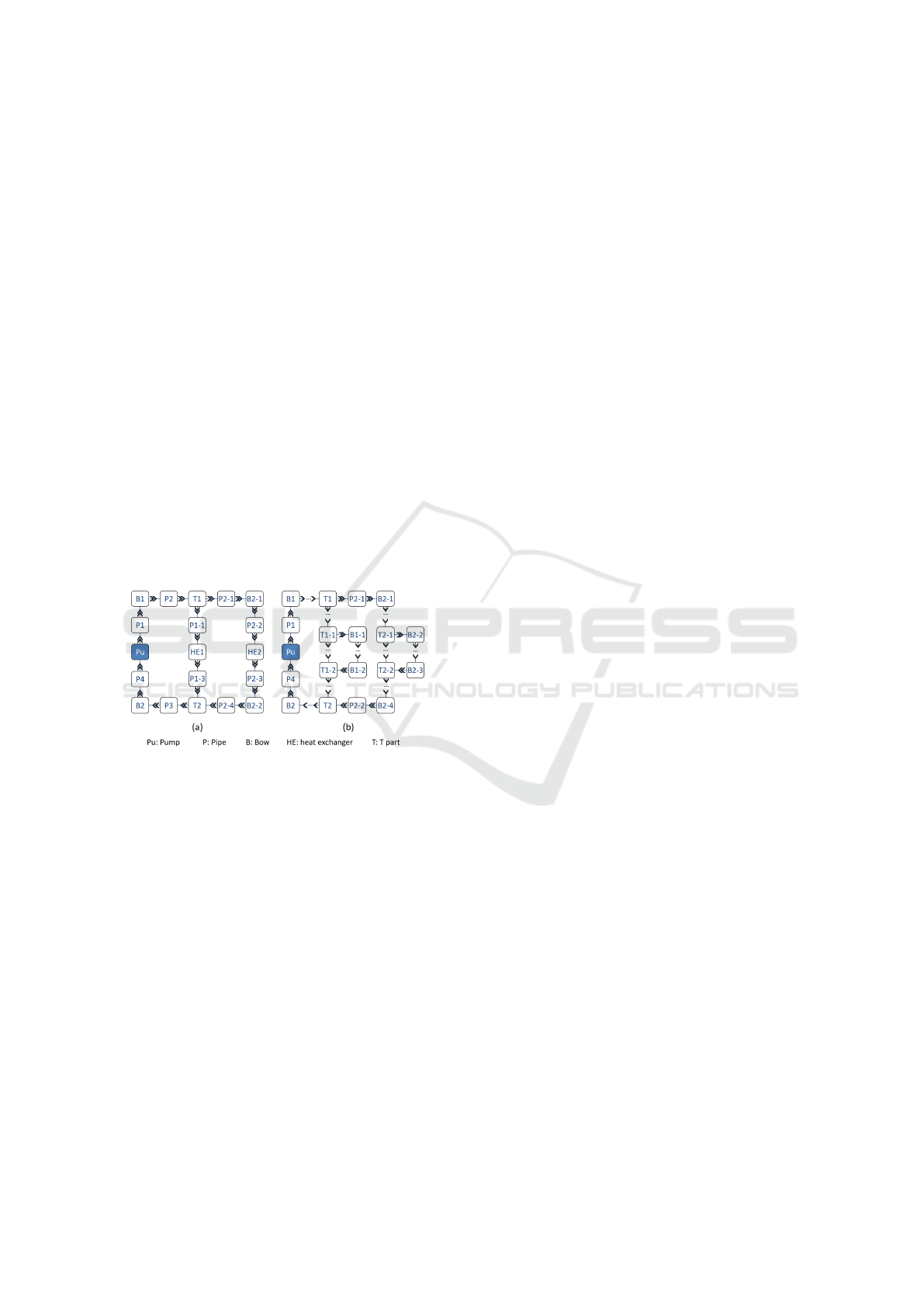

plex network structures. Instead of a single loop, a

BES can contain parallel structures, as illustrated in

fig. 4-a. It is possible to distribute the medium to

multiple subsystems by using T-pieces (T1 and T2

in this example). T1 in this example has the func-

tion of diverting, while T2 has the function of mix-

ing. Figure 4-b depicts a more complex system struc-

ture using T-pieces with multiple subsystems and sub-

subsystems. Other distributors with more connectors

can transport the medium to multiple subsystems.

Figure 4: Different network structure in a medium transport

system.

A heating system simulation consists of two parts:

hydraulic simulation and thermic simulation. All

components involved in the medium transport pro-

cess are simulated. Both simulations are performed in

separate loops, beginning with the main pump. The

hydraulic simulation determines the hydraulic resis-

tances and other hydraulic parameters. Thermic sim-

ulation calculates the temperature in each component

or part of a component (e.g. pipe sections) based on

the results of the hydraulic simulation and other ther-

mic parameters of the components (e.g. start temper-

ature from the water leaving the main pump, ambient

temperature, or the isolation of the components’ sur-

face).

The calculation for each component in both sim-

ulation loops requires the calculated results from the

component(s) before this component in the medium

flow direction and delivers data to the calculation for

the next components. As a result, the information

about the medium flow is critical to the accuracy of

the simulation result.

The goal of network structure identification for

medium transport in BES is thus to identify all con-

nected components in the system and determine the

medium’s initialised flow direction through the sys-

tem given the pump direction. Components such as

valves that can be reconfigured during simulation run-

time to influence flow direction will be counted as

fully opened during the identification process.

BES simulations (for example, in the VR educa-

tional environment VRLAb4BES) frequently require

this information directly from users. This restricts

learning use cases in which learners can import BES’

BIM models and simulate them. This limitation also

prevents learners from freely modifying the compo-

nents and structure of a given system and restarting

the simulation during a virtual reality learning unit.

3 MODELLING AND

IDENTIFICATION OF

NETWORK STRUCTURE FOR

MEDIUM TRANSPORT

SYSTEM

3.1 Modelling of Generic Components

in a Medium Transport Network

The modelling of BES components is depicted in

fig. 5. Each BES component consists of connectors,

each has one of the three possible connector types in-

put, output or unidentified. Each connector can have

a reference of another connector, which this connec-

tor is connected to. This concept is used to support

the modelling of the network structure consisting of

connected components.

Figure 5 depicts the modelling of BES compo-

nents. Each BES component is made up of connec-

tors, each with one of three possible connector types:

input, output, or unidentified. Each connector can

have a reference to another connector to which it is

connected. This concept is used to aid in the mod-

elling of network structures made up of connected

components.

Specific classes describing trade-related proper-

ties of a component inherit the generic class BES com-

ponent. To support the ordered execution of the simu-

lation of system components, the concepts hydraulic

component and thermic component are defined for

heating system components. The water connector in-

Network Structure Identification for Medium Transport in a Virtual Reality Environment

459

Figure 5: Modeling BES components.

herits the generic connector and is used specifically

for heating simulation. Also shown in fig. 5 are hy-

draulic behaviour and thermic behaviour, where the

specific behaviour of each component is calculated

based on its own parameters and environment param-

eters (including the simulation results of its predeces-

sors). The connectors also serve to transfer simula-

tion data between connected components. Because of

the focus of this paper, these concepts for behaviour

simulation will be described in greater detail in a sub-

sequent publication.

3.2 Generic Workflow to Identify the

Network Structure

In terms of network identification, each BES sys-

tem can be described as a collection of BES com-

ponents B = {b

i

}. Each component b

i

is made up

of a series of connectors C

i

= {c

i

j

}. Each connec-

tor c

i

j

= (c

h

k

,t

i

j

) contains a reference to its connected

connector c

h

k

belonging to component b

h

and a type

t

i

j

∈ T = {input,out put, unidenti f ied}

c

i

j

= (null,unidenti f ied)∀i, j is the generic start-

ing point for network identification. The goal of the

identification workflow is to determine which connec-

tors are connected and whether they are input or out-

put.

This approach presents a three-steps-workflow,

which will be detailed in the following sections.

3.2.1 Identification of Connected Components

The connected connectors will be determined during

this step. This information may already be included

in a BIM model or must be derived from the BES

system’s 2D or 3D geometry model. In the case of

VRLab4BES, each component has its own 3D model,

and a connector is an invisible object positioned in

the middle of the 3D model’s corresponding opening.

Object colliders can be added to each connector to de-

termine this connected-relationship between connec-

tors. Each collider is a volume centred on the connec-

tor object. The collider of one connector can then be

compared to the collider of another, resulting in the

assignment of connected connectors as references in

each connector.

Figure 6 shows a simplified example of this step.

The components with their connectors are shown on

the left side at the start of this step. The existing con-

nections between connectors of all components are

determined at the end of this step. With the exception

of the main pump b

0

, all connectors have unidentified

as connector type.

Figure 6: Identification of connected components.

3.2.2 Determine Valid Medium Transport Paths

Given that b

0

is the main component generating mass

flow in the system (e.g., the main pump in the heating

system), the second step of the workflow will deter-

mine all possible valid paths between the output con-

nector c

0

0

and the input connector c

0

1

of b

0

. Each

path p

i

between two connectors is defined as an or-

dered list of connectors, with the first and last objects

of the list being these two connectors. A valid path

is defined as one that has (i) no duplication of its ele-

ments and (ii) does not return to the same component

after leaving it, with the exception of the main pump.

The second condition is met when fewer than three

connectors of the same component are found next to

each other in a specified path and no other connec-

tor of the same component is found else where on the

same path.

Algorithm 1 describes the algorithm for determin-

ing all possible valid paths within the system. The

procedure is carried out using a recursive function

GETPATHS which takes as parameters any start con-

nector c

i

j

, any end connector c

h

k

6= c

i

j

, the current

tracked path p

cu

, the list B

0

∈ B of components dis-

covered on the current path and the set of paths P.

When the function is executed, it moves along

the network through the connected connectors (c.next

represents the connected connector of connector c),

updates the current path p

cu

and the list B

0

. The

function distinguishes between (i) the start of the pro-

cess (L4-L7), (ii) moving from a connector to another

within the same component (L9-L11), (iii) moving

from one connector to its connected connector (L16-

19) and (iv) registering a complete path as an element

of P when the algorithm reaches the end connector c

h

k

(L13-L14).

This step’s procedure (L20-L25) includes calling

SIMULTECH 2023 - 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

460

Algorithm 1: Determine available medium transport paths.

1: Inputs:

(i)B : a set of BES components b

i

(ii)b

0

: main component generating mass flow

2: Result:

P: a set of valid paths p

k

from output

connector c

0

0

to input connector c

0

1

of b

0

3: function GETPATHS(c

i

j

, c

h

k

, p

cu

, B

0

, P

result

)

4: if c

i

j

= c

0

0

then

5: c

m

n

= c

i

j

.next

6: B

0

← B

0

∪ {b

m

}

7: GETPATHS(c

m

n

,c

h

k

, p

cu

,B

0

,P

result

)

8: else

9: if c

start

.next = p

current

[p

cu

.length − 2] then

10: for all c

i

x

! = c

i

j

do

11: GETPATHS(c

i

x

,c

h

k

, p

cu

,B

0

P

result

)

12: else

13: if c

i

j

.next = c

h

k

then

14: P

result

← P

result

∪ p

cu

15: else

16: c

m

n

= c

i

j

.next

17: if b

m

/∈ B

0

then

18: B

0

← B

0

∪ {b

m

}

19: GETPATHS(c

m

n

,c

h

k

, p

cu

,B

0

,P

result

)

20: procedure DETERMINE SET P OF VALID PATHS

21: Initialize:

P ← ∅

22: B

0

← {b

0

}

23: p

cu

← {c

0

0

}

24: GETPATHS(c

0

0

,c

0

1

, p

cu

,B

0

,P)

25: return P

GETPATHS with c

0

0

and c

0

1

as the start and end con-

nector, respectively. The resulting set P is made up of

valid network paths.

Four valid paths can be identified and illustrated

in fig. 7 for the example in fig. 6. The number for

each connector represents the calculated value for the

shortest distance to the start connector, which is part

of the following step.

Figure 7: Determine available medium transport paths.

3.2.3 Determining Correct Initialized Medium

Transport Direction

Each path identified in the second step represents a

potential route for the medium through the system.

However, there are paths that contradict each other.

In the example in fig. 7, p

3

requires the medium to

be transported from b

8

to b

10

whereas p

4

requires the

medium to be transported in the opposite direction.

To address this issue, a function f (c

i

j

) is intro-

duced to calculate the minimal distance from any con-

nector c

i

j

in the system to c

0

0

. While the distance

between connected connectors is defined as zero, the

flow distance between connectors of each specific

component must be defined or calculated in the 3D

model beforehand. Another approach to determining

distance is to count the fewest number of connectors

between any connector and the c

0

0

in any path.

During the final step, f will be applied to all con-

nectors in every identified valid path in both cases.

The calculated values for the simplified example are

shown in Fig. 7. The outcome will be saved as a con-

nector’s temporal attribute. If a new value of f (c

i

j

)

is found that is less than the current stored value, the

stored value will be replaced.

Following this, the stored values of connectors

from each component with two connectors will be

compared (fig. 8-a). The lower-valued connector will

be input, while the other will be output. Afterwards,

the types of distributors’ connectors will be deter-

mined based on the type of the connectors connected

to them. If a connector connects to an input connector,

it will be an output connector, and vice versa (fig. 8-

b). Because there are no direct connections between

distributors in BES, a distributor’s connector always

connects to another connector that is not unidentified.

Figure 8: Determining correct initialized medium transport

direction.

4 PROTOTYPE

IMPLEMENTATION AND

VALIDATION

The object model from sec. 3.1 and the workflow from

sec. 3.2 to identify the network structure were imple-

mented as part of the VR environment VRLab4BES

Network Structure Identification for Medium Transport in a Virtual Reality Environment

461

using the Unity 2020.3.28f1 game engine.

Existing VR learning units for heating have been

modified for validation purposes, so that no manual

definition of the execution order for the hydraulic and

thermic scripts, manual definition of connector type

for each connector, or manual assignment of the con-

nected connectors is required.

The approach was evaluated on exemplary sys-

tems used in VRLab4BES’s various educational units.

A test system with a primary pump, one heat ex-

changer, many valves, and various medium circula-

tion components is depicted in fig. 9. The tests con-

firmed that the steps in the workflow provided in

sec. 3.2 were completed in the right order.

Figure 9: Examplary system for validation test.

The new method produces correct results in sys-

tems with parallel subsystems. Systems with other

network structures, such as bridges between parallel

systems, were built for the testing, despite the fact that

these structures in BES are not typical. The network

identification validation results are correct, reaffirm-

ing the approach’s applicability in BES simulation

and medium transport systems in other domains.

Various test systems were developed to determine

the scalability of the approach, varying in: (a) the

number of components with two connectors, (b) the

number of distributors, and (c) the number of alterna-

tive paths from the pump’s output to the pump’s in-

put. While the number of distributors influences the

number of viable paths, the latter aspect is heavily in-

fluenced by network topology. As a result, these two

aspects should be examined individually. Because the

trade-specific duties of each component (e.g., valve,

pipe, or heat exchangers) have no effect on the ap-

proach’s performance, we restricted the components

used for the scalability test to a pump, pipes, bows,

and T-pieces.

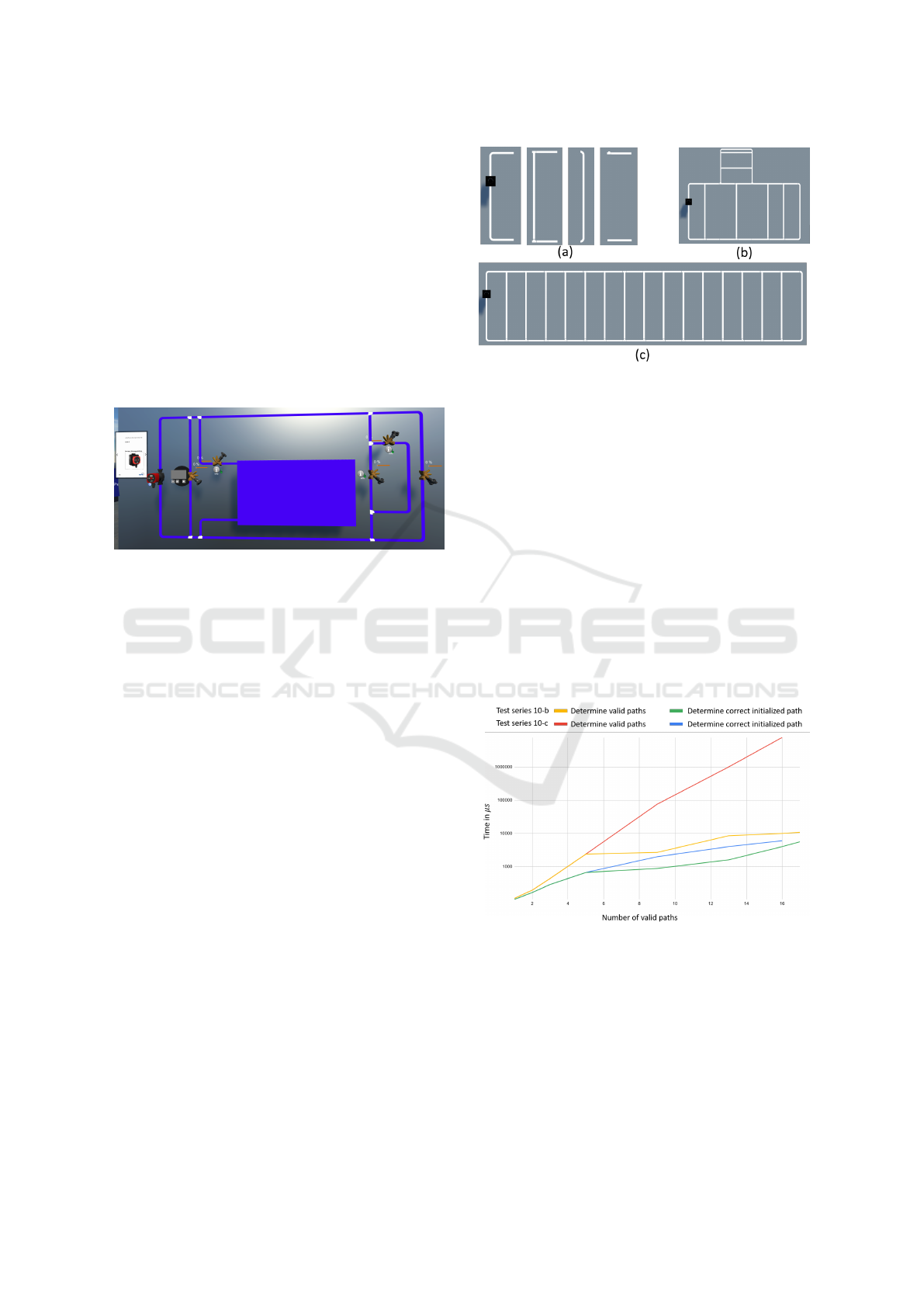

Figure 10-a depicts component blocks made up of

several system components that are used to build test

systems. Figures 10-b and 10-c show examples of test

systems developed for the evaluation.

The method for identifying network structure was

run 100 times for each test system. The time it took to

complete each loop’s various steps was measured and

documented. The mean value of the time measured

Figure 10: Creating evaluation tests.

for each step is used in the evaluation.

The analysis reveals a linear relationship between

the time required to identify connected elements

(sec. 3.2.1) and the total number of connectors, which

is a combined factor of the number of components

with 2 connectors and number of distributors.

The time required to determine the valid medium

transport paths (sec. 3.2.2) and the correct initialised

medium transport direction (sec. 3.2.3) is affected by

a variety of factors. We build many versions for each

of the systems in fig. 10-b and fig. 10-c by adding or

removing a number of middle-blocks (the second and

fourth blocks from the left in fig. 10-a). The time re-

quired for each of the two steps mentioned above is

shown in fig 11, which varies depending on the num-

ber of valid paths for the two test series.

Figure 11: Time measured for the test series.

The variations of both test series with the identical

structure and components are shown in the left part of

the diagram where the lines overlap. For variations

with similar number of valid paths and different num-

ber of components, it is demonstrated that the time

necessary for the test series 10-b is significantly less

than that required for the test series 10-c, particularly

for the determination of the valid path.

In general, the workflow duration is related to the

SIMULTECH 2023 - 13th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

462

number of components, especially the number of dis-

tributors that define new branches in the system, as

well as the length of the longest feasible valid path.

The application of this approach allows a time and

effort reduction in configuring learning units in VR-

Lab4BES.

5 CONCLUSION

As a groundwork for BES simulation, this paper in-

troduced a workflow for automatically identifying the

network structure of medium transport systems as part

of BES models. The approach includes a suitable

object model with model elements required to de-

scribe the network structure and medium flow direc-

tion. The workflow is divided into three steps: (i)

identifying connected components, (ii) determining

valid medium transport paths, and (iii) determining

the correct initialised medium transport direction.

For validation, this approach was deployed as a

functional extension of the VR educational environ-

ment VRLab4BES and evaluated with multiple test

heating systems varying in device count and network

complexity. The tests show a positive outcome and a

significant reduction in effort in developing new vir-

tual reality learning units based on BES simulation.

This approach allows learners to freely create

and modify BES systems and apply simulation to

each component, rather than dealing with the time-

consuming and error-prone manual definition of

medium transport direction. For these use cases, re-

search into suitable interacting mechanisms in vir-

tual reality to ensure user-friendliness (e.g. 3D-grid

for auto-snap component placement) and the balance

between immersiveness and handiness of component

placement mechanism during complex system defini-

tion is required. Furthermore, due to the scope of this

paper, additional details about the hydraulic and ther-

mic simulation of a heating system in VR will be dis-

cussed in a subsequent publication.

The procedure of determining medium transport

direction based on the shortest distance to the network

starting point presented in this paper can be used to

other systems using other medium such as air, refrig-

erant, or electrical energie. Specific implementation

and considerations will be required depending on the

chosen trade.

REFERENCES

Behmadi, S., Asadi, F., Okhovati, M., and Sarabi, R.

(2022). Virtual reality-based medical education versus

lecture-based method in teaching start triage lessons

in emergency medical students: Virtual reality in med-

ical education. Journal of Advances in Medical Edu-

cation and Professionalism, 10(1), page 48.

Hall, F. and Greeno, R. (2017). Building services handbook.

Routledge, 9 edition.

Kaplan, A. D., Cruit, J., Endsley, M., Beers, S. M., Sawyer,

B. D., and Hancock, P. A. (2021). The effects of vir-

tual reality, augmented reality, and mixed reality as

training enhancement methods: A meta-analysis. Hu-

man factors, 63(4), pages 706–726.

Kapp, F., Matthes, N., Kruse, L., Niebeling, M., and

Spangenberger, P. (2022). Fehlerdiagnose mit virtual

reality trainieren–entwicklung und erprobung einer

virtuellen offshore-windenergieanlage. Zeitschrift f

¨

ur

Arbeitswissenschaft, pages 1–10.

Lau, K. and Lee, P. (2021). Using virtual reality for pro-

fessional training practices: exploring the factors of

applying stereoscopic 3d technologies in knowledge

transfer. Virtual Reality, 25(4), pages 985–998.

Lydon, G., Caranovic, S., Hischier, I., and Schlueter, A.

(2019). Coupled simulation of thermally active build-

ing systems to support a digital twin. Energy and

Buildings 202 (2019).

Mai, L. T. and Werdin, H. (2022). Vrlab4bes-a virtual real-

ity implementation approach of building service sim-

ulation for educational purposes. 2022 8th Interna-

tional Conference on Virtual Reality (ICVR), pages

82–89.

Milgram, P. and Kishino, F. (1994). A taxonomy of mixed

reality visual displays. IEICE TRANSACTIONS on In-

formation and Systems, 77(12), pages 1321–1329.

Milyutina, M. A. (2018). Introduction of building infor-

mation modeling (bim) technologies in construction.

Journal of Physics: Conference Series (Vol. 1015, No.

4, p. 042038). IOP Publishing.

Rad, R., Sadrabad, A., Nouraei, R., Khatony, A., Bashiri,

H., Bozorgomid, A., and Rezaeian, S. (2022). Com-

parative study of virtual and face-to-face training

methods on the quality of healthcare services provided

by kermanshah pre-hospital emergency staff (ems):

randomized educational intervention trial. Compar-

ative study of virtual and face-to-face training meth-

ods on the quality of healthcare services provided

by Kermanshah pre-hospital emergency staff (EMS):

randomized educational Intervention trial., pages 1–

7.

Tan, Y., Xu, W., Li, S., and Chen, K. (2022). Augmented

and virtual reality (ar/vr) for education and training in

the aec industry: A systematic review of research and

applications. Buildings 12, no. 10, page 1529.

Network Structure Identification for Medium Transport in a Virtual Reality Environment

463