Construction of Big Data Monitoring Cloud Platform for New

Energy Industry Chain

Wenhe Zhang, Haixiu Liu, Tingrui Liu

*

and Ailing Gong

*

College of Mechanical & Electronic Engineering, Shandong University of Science & Technology, Qingdao 266590, China

Keywords: Energy Industry, Big Data, Monitoring Cloud Platform.

Abstract: In order to solve the problems related to the lack of coordination of production process, production

process safety, industrial management confusion, inefficient operation and promotion and safety of new

energy industry chain, with the help of the artificial neural network algorithm of reinforcement learning,

the bus transmission technology of the Internet of things, big data and cloud platform and other high and

new technologies, the big data monitoring cloud platform of the new energy industry chain is constructed,

to enhance the capacity of the new energy industry chain for safe production, operational control and

sustainability based on technological innovation and promotion, thereby reducing costs and increasing

productivity, and based on user demand, prediction and control of power and dual-carbon targets.

1 INTRODUCTION

New Energy sources such as wind energy and light

energy are entering the production process and

living environment of human beings with a large

proportion and on a large scale. Except that the

small industries with wind-solar hybrid can be used

in densely populated areas, most of the wind,

photovoltaic and other new energy power stations

(including yard and grid) locate in sparsely

populated area. Therefore, there are some problems,

such as the lack of coordination of production

process, the safety of production process, the

confusion of industrial management, the low

efficiency of operation and maintenance, and the

related problems of promotion and safety. At the

same time, there are many problems in new energy

data, such as massive multi-source heterogeneity,

isolated data island, hidden fault data, dominant

fault, imbalance of energy dissipation and storage,

low level of intelligent control, etc. (Wang, 2021)

In order to solve these problems, a series of new

energy big data platforms have been developed by

domestic and foreign new energy industry chain

manufacturers. For example, the world’s largest

energy IoT platform EnOS, UP-WindEYE system

platform integrating high-speed real-time

communication and super-grid support,

“wind-gathering control ABC distributed system

platform” built by Shanghai Electric Company of

China, they are all the best at what they do. The

data collection strategy of new energy big data

platform is an important part of cloud platform

construction (Wang, 202; Yang, 2019). Reference

(Shi, 2017) based on R, Python, H2o, Spark

methods, data mining and full data model training

and verification are realized, and a large data

platform for new energy of wind power is

constructed. Reference (Liu, 2021) based on

massive data, a new method for large-scale access

state estimation of new energy distribution network

is proposed, and the constraints of new energy

platform after grid-connected are established. Most

of the new energy platforms use the cloud to acquire

multi-source data, perform massive parallel

computation in the distributed cluster, and feed back

the information to the field and the client to realize

the reasonable dispatch and allocation of resources

(Sun, 2021). When it comes to cloud computing,

reference (Zhang, 2022) presents a hybrid algorithm,

a parallel residual convolutional neural network

(HPR-CNN) model for RUL prediction, by fusing

multi-period data, the hidden features are used to

extract different depth information effectively

through residual network, and the on-line cloud

prediction is realized in practical application.

Reference (Zhang, 2021) based on the basis of

Personal Computer technology, using HADOOP big

Gong, A.

Construction of Big Data Monitoring Cloud Platform for New Energy Industry Chain.

DOI: 10.5220/0012150000003562

In Proceedings of the 1st International Conference on Data Processing, Control and Simulation (ICDPCS 2023), pages 95-101

ISBN: 978-989-758-675-0

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

95

data management platform, a new distributed data

cluster management system is adopted, and the

basic design features and implementation of

Hadoop big data platform are described in detail. In

data optimization, dynamic prediction and

scheduling, artificial intelligence algorithms have

been applied more and more widely and mature.

In the aspect of data collection, this study adopts

multi-source data fusion technology based on

industrial company’s Internet of things platform and

cloud resource layer utilizing Siemens bus

communication, and develops distributed file

storage technology, with the functions of high

compression ratio, real-time I/O, support vector

operation and high scanning performance, it can

realize multi-level index and instant retrieval of

mass data. In cloud computing, data optimization

and dynamic prediction, the cloud platform adopts

an enhanced depth q network training algorithm

(Huawei, 2022) to make full use of the advantages

of the elastic cloud server, and Integration of

multi-professional computing and performance

analysis software to achieve dynamic optimization

and scheduling adjustment.

2 CONSTRUCTION OF BIG

DATA MONITORING CENTER

PLATFORM FOR NEW

ENERGY INDUSTRY CHAIN

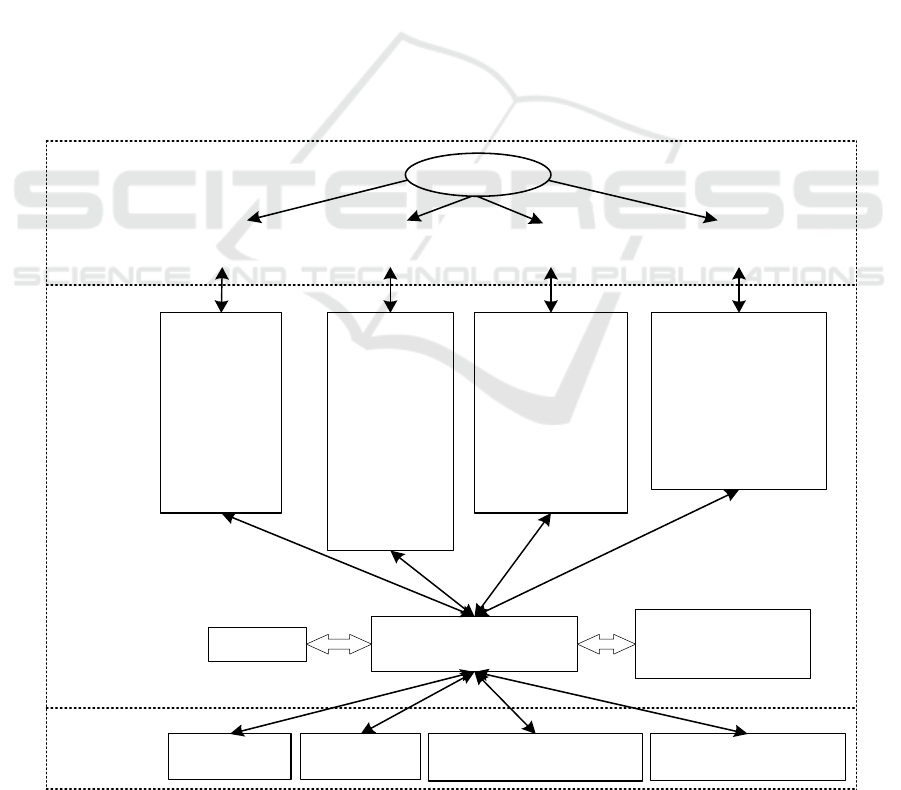

The platform of big data center is based on the elastic

cloud platform of deep learning ANN Technology

and multi-source data fusion, communicating

decision-making layer, big data institute, and

Industrial Company chain. Through the Operation

Management Center management and achieve

efficiency analysis, data management, sales

management, energy dissipation, scheduling

coordination and other multi-channel coordination.

Through the supporting business center to achieve

fault diagnosis, disaster forecasting, weather

environment, solve the hidden danger, supporting

industries and other supporting industrial chain

Figure 1: Big data business architecture.

Production process

monitoring

Operation

management

Business

center

Prediction and

promotion

Operation

monitoring,

Equipment

status,

Statistical

report,

Process

control,

Fault alarm

Efficiency

analysis,

Data

management,

Sales

management,

Energy

consumption

and storage,

Dispatching

coordination

Fault diagnosis,

Disaster

prediction,

Weather

environment,

Solving hidden

dangers,

Supporting

industry

Power prediction,

User demand,

Critical equipment

health,

Dual carbon target

predictive control,

Technological

innovation

Big data center

platform

Elastic cloud

platform for multi-

source data fusion

R D L A

Wind power

industry

Photovoltaic

industry

Wind-photovoltaic

complementary industry

Supporting

manufacturer industry

Business Center

Big data

research

institute

Decision-making level

Industrial

Company

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

96

operations. The forecast and control of the future

target is realized through the forecast and extension

center, including power forecast, user demand

forecast, key equipment health condition

assessment, double carbon target forecast control,

and technology innovation and so on. Big Data

Centers Exchange data with the IoT platform of

industrial companies through the elastic cloud

platform of multi-source data fusion. The industrial

companies not only include the conventional wind

power and photovoltaic industries, but also in this

design, in particular, include the small-scale

industries with complementary scenery and the

relevant supporting manufacturers, because the

supporting industries, especially the industries with

supporting key components, it is of great

significance to the sustainable operation of the new

energy system. New Energy Industry Chain Big

Data Monitoring Center platform functional

structure and data flow, as shown in Figure 1.

2.1 Cloud Management Interface

Between Big Data Center Platform

and Multi-Source Data Fusion

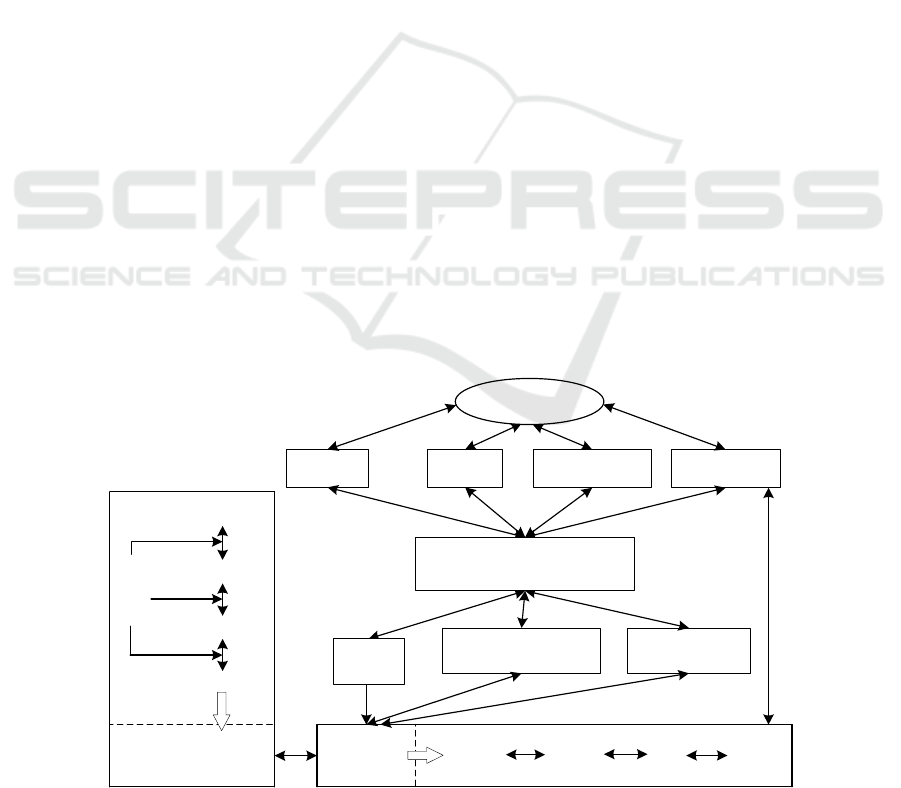

Elastic cloud platform API service and cloud

resource layer are the technical elements and

physical carriers of cloud management interface

between big data center platform and multi-source

data fusion respectively. Elastic cloud server has

rich specification types, rich mirror types and disk

types, reliable data security and efficient operation

and maintenance, real-time cloud monitoring and

load balancing functions.

The platform of Internet of things based on data

collection of Industrial Company realizes data

interchange with data source through Siemens bus.

The Siemens bus, which is the basis of Industry 4.0,

seamlessly integrates with the ECS and OpenStack

native interfaces provided by the elastic cloud

server, allowing it to adjust the specifications of the

elastic cloud server as needed, build a reliable, safe,

flexible and efficient computing environment.

Flexible cloud platform API services allow for

interface switching and debugging in the API

Explorer. The core of the “Remote management”

module of the IoT platform is the construction of

the network transport layer (Li, 2020). In this

design, the network transport layer is constructed by

using Intel Virtualization Technology, using Intel

Virtualization Technology to build a part of virtual

machine in Lan, Internet, fiber ring network and so

on, to improve the network transmission speed,

provide a smooth network environment for data

transmission. It also takes advantage of the Intel

Virtualization Technology’s flexible deployment

capabilities to receive and process data from the bus

based perceptual control layer, and to convert the

data into structured data that can be distributed to a

nearby virtual machine. As an important part of the

transition between the sensing control layer and the

elastic cloud computing service layer, the network

transport layer uses Intel Virtualization Technology

to receive the data first, then process the data,

finally, the processed data is transferred to the cloud

Figure 2: Cloud management interface between big data center platform and multi-source data fusion.

Operation

monitoring

Predictive

diagnosis

Safe operation

and maintenance

Multi-source

data fusion

Big data center

Data analysis and

mining

Cloud

resource layer

network

The

server

Cloud

method

Portal and

authentication

Elastic cloud platform

API service

Asset

center

storage

IOT platform based on

data acquisition of

industri al companies

Data source

Data routing

Application routing

Remote management

Siemens

bus

Construction of Big Data Monitoring Cloud Platform for New Energy Industry Chain

97

resource layer, which can greatly reduce the data

computation of the cloud computing service layer,

and make the cloud computing service layer

concentrate the computing power resources on the

big data analysis, data mining and so on.

A cloud management interface for large data

center platforms and multi-source data fusion, as

shown in Figure 2.

2.2 Dynamic Optimization Strategy of

Cloud Computing and Data

With the rise of deep learning, the combination of

deep learning and reinforcement learning has

received a lot of attention. Deep reinforcement

learning integrates the powerful perceptive ability

of deep learning into the traditional reinforcement

learning algorithm, which forms a new research

hotspot in the field of artificial intelligence. In this

design, an intelligent algorithm based on reinforce

deep learning ANN (RDLA) is used in cloud

computing, data optimization and dynamic

prediction, which can not only be used in the related

business of the big data center platform, and it can

be directly used in the process of multi-source data

fusion. The principles of fast transmission, high

speed calculation, high-cost performance and

reliability, and meeting double carbon targets are

emphasized in the calculation and implementation.

The depth q network learning method in

reinforcement learning is the foundation of the

Algorithm. It uses the idea of “Value function”

approximation to fit the long-term value of each

“Action” under the current state through a strategy

value network, in the decision-making directly

using the highest value of the “Action”, the use of

neural network strong nonlinear processing capacity,

to achieve the state dimension reduction. At the

same time, the “small step” reinforcement learning

method is adopted in the rigid system processing

link to improve quality and control accuracy, while

the “Large step” artificial neural network simplified

learning method is adopted in the non-rigid system

processing link (Liu, 2020), to get better cost

performance.

The core process of cloud computing and data

dynamic optimization strategy RDLA, are described

and illustrated in Figure 3.

3 APPLICATION CASE:

STABILIZE THE POWER

GENERATION THROUGH THE

PREDICTION AND

PROCESSING OF EXTREME

WORKING CONDITION DATA

Taking the real-time monitoring of large-scale wind

turbine blades in the wind power field of a wind

power company as an example, the power generation

Figure 3: The core process of cloud computing and data dynamic optimization strategy RDLA.

Agent

Decision-making

modules

Software simulation

environment

Historical

memory

ANN Policy

Net

Target Net

Current action,

One-step return

Next state,

highest value

Long term value of current

action

ANN continuous feedback

optimization

Current status, action return

+

Store to

memory

Status

Action

Periodic

synchronization

parameters

One-step

return,

Next step

status

Training,

updating

Output optimal

action

Strengthen deep Q network training module

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

98

is stabilized by predicting and processing the data of

extreme working conditions. The company's large

wind turbine blades adopt flap structure and

hydraulic pitch system to jointly deal with the

aerodynamic instability excitation under extreme

working conditions. Under normal working

conditions, the flap is in the initial and

non-excitation state, and the maximum power is

obtained only by pitch driving. Under extreme

operating conditions, such as the blade is in stall

state, the power is attenuated, and the blade is in a

pneumatically excited hazardous state with potential

damage. In mild and moderate stall states, the

power will be attenuated, and with the continuation

of stall state, the blade may produce potential

invisible faults and affect the blade life. In the

severe stall state, if the stall state continues to

extend, not only the power will be extremely

attenuated, but also the blade may produce an

instantaneous dominant fault-fracture failure.

In the "on-site real-time monitoring" link of

production process monitoring of the big data

platform, the fully distributed optical fiber sensing

differential pressure feedback measurement system

installed in the blade finds that the blade is in stall

state, and directly transmits the on-site wind

condition data and stall state to the cloud resource

layer through Siemen’s bus and remote managed

virtual machine system. The elastic cloud APP pulls

out the NA63215 airfoil structure data chord length

c and density

𝜌

b

stored in the big data center, and

uses the Xfoil software and AirfoilPrep software in

the built-in software environment to obtain the lift

and drag aerodynamic coefficients C

L

and C

D

,for

angle of attack α in the range of -90

o

~90

o

, and

likewise fits them to the sixth-order Taylor series

curve. Combined with the continuous integration of

multi-source data, the elastic cloud server invokes

the RDLA system for the optimization process. The

sixth-order Taylor series expression of the invoked

original data and the optimized aerodynamic

coefficient is as follows:

() ( )

6

1

sin

iii

i

f

wabwc

=

=+

(1)

where w is the ratio of airfoil position vector to

blade span, when f(w) represents c and

𝜌

b

; w is the

instantaneous angle of attack of the airfoil, when

f(w) represents C

L

and C

D

.

Table 1: Parameters of aerodynamic Coefficients in six-order Taylor series.

Items c

𝜌

b

C

L

C

D

a

1

5.5609 21.659 0.8687 3.3091

b

1

3.9432 4.6555 2.0731 0.3508

c

1

-0.3823 0.2601 0.0412 1.4879

a

2

141.88 25.485 0.3071 0.7147

b

2

8.5757 8.5638 4.0132 2.0368

c

2

-0.3955 -0.2688 -0.0581 -1.5801

a

3

139.09 12.477 0.1990 2.6581

b

3

8.6264 12.522 5.8919 0.4023

c

3

2.7111 0.7951 -0.0509 -1.6633

a

4

0.3314 4.0963 0.1711 -0.0180

b

4

18.433 21.243 0.7129 2.9866

c

4

-0.4111 -1.8908 0.8469 -1.5277

a

5

0.2577 2.2964 0.1375 0.0201

b

5

24.511 25.077 7.6131 3.9489

c

5

-1.3026 -1.4001 -0.1191 1.5861

a

6

0.1405 0.3705 0.0856 0.0003

b

6

30.595 36.386 9.2975 4.8155

Construction of Big Data Monitoring Cloud Platform for New Energy Industry Chain

99

c

6

-1.1844 -5.5199 -0.1929 -1.5748

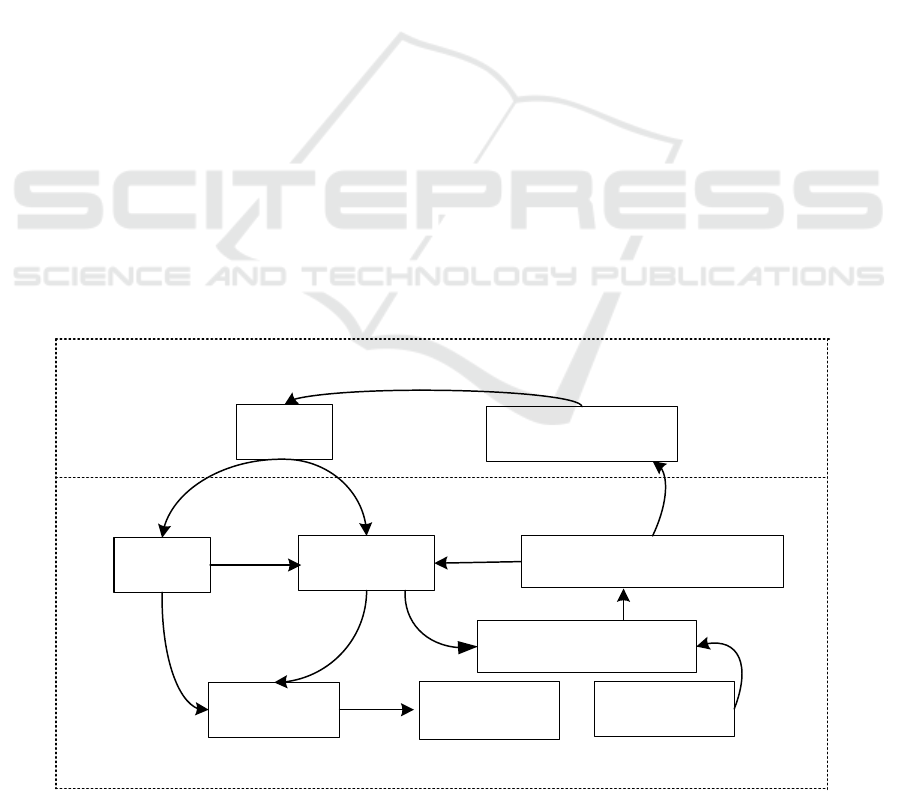

Figure 4: Power comparisons between normal working condition, stall state and that after optimized control.

Figure 4 shows the comparison between the power

under normal working conditions, the power under

stall state and the power after optimized control.

The black line represents the actual power (Actual

power/NWC) under normal operating conditions,

because the wind speed under normal operating

conditions on land generally does not exceed 10ms

-1

,

so at the end of the normal operating curve, when

the wind speed exceeds 10ms

-1

, is the Theoretical

power/ NWC, which is the blue dotted line of the

theoretical derivation. The wind speed

corresponding to the light-yellow area in the figure

is the wind speed fluctuation area with mild and

moderate stall state, and the approximate range is

between 5.5-7.9ms

-1

. The purple curve represents

the power fluctuation (Power / MMSS) in the state

of mild and moderate stall without control. The

light green curve is the power (Optimised power /

MMSS) after the dynamic optimization control is

turned on when the blade has mild and moderate

stall, its numerical fluctuation is between the normal

working condition and the stall state, and the

fluctuation is stable, which reflects the effectiveness

of the dynamic optimization control algorithm.

Although it cannot reach the maximum power under

the normal working condition, it is higher than the

power under the stall state. More importantly, it

avoids the harm of mild and moderate stall to the

blade and the generation of blade hidden faults. At

this time, the active control from the big data

monitoring platform only drives the flap action to

avoid mild and moderate stall. When the wind speed

is greater than 9.6 ms

-1

, the blade is in a severe stall

condition. The red curve represents the power

generation (Power /SSS) under the heavy stall state.

The dark green curve represents the power

(Optimised power /SSS) after the dynamic

optimization control is turned on in case of severe

stall of the blade.

After the stall state is controlled, the power is

lost, at this time the big data monitoring platform

simultaneously adjusts the matching of energy

consumption and storage, completes the scheduling

of relevant supporting links, so as to make the

power grid in a stable output power supply state.

4 CONCLUSION

The design is based on reinforced deep learning to

build a big data monitoring cloud platform for the

new energy industry chain. Its big data business

architecture communicates with the

decision-making level, the big data research

institute and the front-line industry companies,

including production process monitoring, operation

management, operation of relevant supporting

business centers, prediction and promotion of

sustainable business, to the wind power industry,

photovoltaic industry, and all aspects of operation

1

2

34567

8

9

10 11

0

1

2

3

0.5

1.5

2.5

Wind speed/(ms

-1

)

Power/(MW)

12 13

Actual power/NWC

Power /MMSS

Theoretical power/NWC

Power /SSS

Optimised power /MMSS

Optimised power /SSS

Wind speeds /

MMSS

Wind speeds /SSS

ICDPCS 2023 - The International Conference on Data Processing, Control and Simulation

100

and maintenance management of relevant front-line

supporting industries. Its advantages are reflected in

the following aspects:

1) The big data center platform is based on

RDLA and the elastic cloud platform of

multi-source data fusion. It fully combines the

cutting-edge RDLA optimization technology, the

characteristics of multi-source transmission of

industrial 4.0 Internet of things and the advantages

of elastic cloud platform, so that the real-time

transmission, elastic optimization storage,

synchronous processing and dynamic optimization

of massive data can be realized.

2) RDLA technology makes the comprehensive

combination of reinforcement technology, deep

learning and ANN, which is no longer limited to a

single data mining process, but also successfully

applied in cloud platform computing, dynamic

optimization and active control.

3) The elastic cloud platform is no longer

limited to a single cloud storage and cloud

computing function. It can be seamlessly integrated

with the industrial 4.0 platform of the Internet of

things. At the same time, it has built-in rich

engineering application software interfaces, making

it possible to realize the real-time dynamic control

and remote field regulation.

4) The specific case implementation of this

paper only reflects a strategy of big data monitoring

cloud platform to deal with extreme working

conditions, and the function of big data monitoring

cloud platform is not limited to this. It can also be

used in consumption and energy storage

optimization, fault prediction and diagnosis, power

optimization and double carbon target control,

coordination of real-time production and supporting

industrial chain, sales management and scheduling

coordination, and many other optimization

processes.

ACKNOWLEDGEMENT

The authors gratefully acknowledge the support of

the National Natural Science Foundation of China

(no. 51675315).

REFERENCES

Wang L, Zhang X, Feng Q, et al. 2021 Distributed

Energy 6(1) 44−50.

Wang K, Liu H. Key 2022 Journal of Global Energy

Interconnection 5(2) 157−166.

Yang X, Yang Y 2019 Southern Energy Construction

2019 22(1) 48−54.

Shi R, Ma F 2017 Journal of Jilin Engineering Normal

University 33(12) 108−110.

Liu W 2021 Automation and Instrumentation 12 49−52.

Sun F 2021 Intelligent Connected Vehicles 1 73−74.

Zhang Q, Yang L, Guo W, et al. 2022 Energy 241

ID:122716.

Zhang W 2021 Wireless Internet Technology 19 110−111.

Huawei Technology Co., Ltd 2022 Figure elastic cloud

server. https://support.huaweicloud.com/productdesc

-ecs/ecs_01_0073.html. Obtained on March 30, 2022.

Li M. 2020 Information & Communications 4 52−53.

Liu T, Gong A, Song C, et al. 2020 Energies 13 1−21.

Construction of Big Data Monitoring Cloud Platform for New Energy Industry Chain

101