Experimental Investigation and Comparison of Approaches for

Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

Chris Schöberlein

a

, André Sewohl

b

, Holger Schlegel and Martin Dix

c

Institute for Machine Tools and Production Processes, Chemnitz University of Technology,

Reichenhainer Str. 70, 09126 Chemnitz, Germany

Keywords: Electromechanical Axis, Industry 4.0, System Identification, Acceleration Correction.

Abstract: Electromechanical axes are an essential factor for productivity in almost all common production systems. In

context of Industry 4.0, using integrated sensors for machine monitoring is gaining importance in recent years.

In addition to the well-known condition monitoring of mechanical components, the internal control loop

signals are capable to estimate external load forces, e.g. caused by production process. However, this requires

the separation of all motor-related signal components from the external loads. The paper contributes to this

topic by comparing multiple approaches for detecting acceleration and braking phases during conventional

axis movements and examines the subsequent correction of associated components in motor torque signal.

All approaches exclusively use signals available in the drive and control system. Extensive experiments on a

single-axis rotary test rig show general suitability as well as limitations of the presented methods.

1 INTRODUCTION

Motion generation in production machines is mainly

realized with the aid of electromechanical axes. They

are used as auxiliary drives to generate feed motions

and hence, in case of metal-cutting machine tools,

maintain chip removal as well as all other necessary

positioning, infeed or tool change movements.

Furthermore, they are deployed as main drive of servo

screw presses. Their application area also covers a

wide range of other production systems, e.g. for

conveying, positioning and synchronization

applications, in printing and textile machines as well

as in packaging, filling and assembly systems.

Utilization of electromechanical axis for machine

monitoring is increasingly coming into focus,

especially in connection with Industry 4.0. Besides

the condition monitoring of the integrated control

loops (Quellmalz et. al., 2016) or mechanical axis

components (Schöberlein et. al., 2022), an estimation

of externally acting load forces and torques is one

major demand. Particular applications are the

a

https://orcid.org/0009-0006-3603-5012

b

https://orcid.org/0000-0003-2031-6603

c

https://orcid.org/0000-0002-2344-1656

estimation of process forces during milling, drilling,

turning or grinding (cf. Kaever 2004, Aslan and

Altintas, 2018, Aslan, 2019, Yamato et. al., 2019),

chatter suppression in milling and drilling (cf.

Yoneka et. al., 2012, Sugiyama et. al., 2017, Yamato

et. al., 2021) or the detection of collisions (cf. Rehse,

1999, Rudolf, 2014) in the working frame of machine

tools. According to Eq. (1), the sum of all load

torques T

l

is measurable as reaction in motor torque

signal T

m

.

T

m

=T

a

+T

l

(1)

According to Eq. (2), the load torque can be

further devided into several parts. Besides an external

load torque T

l,e

, it consists of friction and gravity

related torques ( T

f

and T

g

) as well as other

disturbance torques T

l,d

(e.g. cogging torques).

T

l

=T

l,e

+T

f

+T

g

+T

l,d

(2)

Hence, an estimation of external load torques

requires the knowledge of all other torque

components. While an identification of gravity and

140

Schöberlein, C., Sewohl, A., Schlegel, H. and Dix, M.

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of Electromechanical Axes.

DOI: 10.5220/0012160600003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 1, pages 140-151

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

friction induced load torques and the subsequent

correction of the measured motor torque was already

shown in (Schöberlein et. al., 2022c), an appropriate

acceleration correction is still required.

Hence, the aim of this paper is to identify and

correct acceleration phases in motor torque signal

during conventional axis movements. In chapter 2,

different approaches are researched and extended or

newly developed. A distinction is made between

methods that are based on actual or command

position signal, respectively. One main contribution

to the topic is made by chapter 3, in which all

approaches are investigated by extensive experiments

carried out on a modular drive test rig. This is

followed by a discussion of results and subsequent

derivation of recommendations for specific

applications. The paper concludes with a summary

and an outlook for further research.

2 METHODOLOGY

2.1 Acceleration Correction Based on

Actual Position Values

Acceleration torque T

a

is calculated as product of

angular acceleration φ

m

and total moment of inertia

J

tot

reduced to motor shaft.

T

a

=φ

m

⋅J

tot

(3)

Since angular acceleration is usually not available

as measurable parameter in the controller, it is

calculated from the angular position φ

m

by twofold

discrete differentiation. The resulting acceleration

torque, hereafter referred to as T

a,1

m

(motor-side

position measurement) or T

a,i1

l

(load-side position

measurement), is applied, for example, in the works

of (Aslan and Altintas, 2018) and (Aslan, 2019) as

part of an approach for drive-based reconstruction of

process forces in five-axis milling. Similar

approaches based on different variants of order-

reduced disturbance observers were already proposed

in several publications (e.g. Isshiki et. al., 2021). One

disadvantage is the assumption of a rigid or strongly

reduced order mechanical structure and hence

required low-pass filtering below the first mechanical

natural frequency. It is also mandatory to determine

the total moment of inertia based on construction data

or using an appropriate identification method (cf.

(Hofmann et. al., 2010), (Hellmich et. al., 2011) or

(Hipp et. al., 2017)).

In the following, a novel approach based on

Eq. (3) is proposed and extended for complex multi-

mass mechanics including an automatic parameter

identification routine (figure 1). Basic idea is to

model the frequency response from motor or load

angular velocity to motor torque by linking a rigid

single mass system (Eq. (4)) with several partial

oscillators (PO) according to Eq. (5) (Schöberlein et.

al., 2022b).

G

s

(s) =

1

J

tot

⋅s

(4)

G

PO

(s) =

a⋅

1

ω

f

2

⋅s

2

+

2d

f

ω

f

⋅s+1

1

ω

r

2

⋅s

2

+

2d

r

ω

r

⋅s+1

(5)

J

tot

denotes the total moment of inertia, while ω

r

and ω

f

are the resonance and antiresonance

frequencies of the partial oscillator with associated

damping values d

r

and d

f

. By assigning parameter 𝑎

with zero or one, the partial oscillator characteristic is

adjusted for direct or indirect case, respectively

(Schöberlein et. al., 2022b). Multiplying (4) with (5)

leads to

G

s

m,l

(s) =

ω

m,l

T

m

=G

s

(s)⋅G

PO,i

(s)

n

i=1

(6)

G

s

m,l

s represents the transfer function between

angular velocity measured on motor (ω

m

) or load side

(ω

l

) and motor torque T

m

. The number of partial

oscillators n depends on the order of the mechanical

system or desired modeling depth. Setting

n = 1 results in the well-known two-mass system. By

initially assuming that no internal or external load

moments are present ( T

m

= T

a

), Eq. (6) can be

rearranged as follows

T

a

m,l

=ω

m,l

⋅G

s

m,l

(s)

-1

(7)

Hence, besides an identification of transfer

functions according to (6), their subsequent inversion

is also necessary. Furthermore, all models must be

transferred into discrete-time representation to enable

an implementation on control systems with fixed

sample times. For this purpose, a five-step procedure

(figure 1) was developed, which has already been

successfully applied on a three-axis milling machine

(Schöberlein et. al., 2022b).

In a first step, the axis is excited with pseudo-

binary noise signal at level of current setpoint filter

output while recording actual values for motor torque

T

m

and angular motor velocity ω

m

. If there is an

additional load-side encoder, a second transfer

function for load-side angular velocity ω

l

can be used.

In case of linear axes, the feed rate signal is converted

considering the values for gear ratio and spindle pitch.

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

141

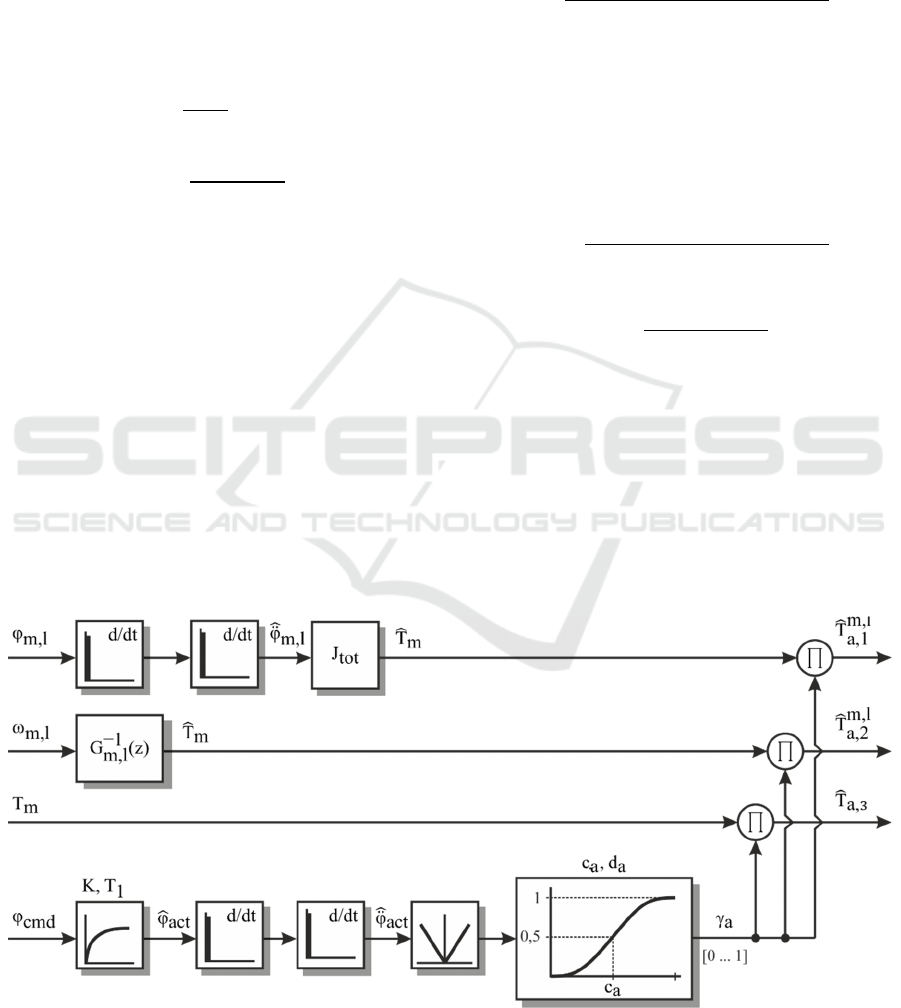

Figure 1: Methodology for identification and discrete inversion of multi-mass systems.

Subsequently, a basic system model is

determined. Therefore, a linear model for J

tot

is

approximated in low-frequency range with a slope of

-20 dB per decade. By subtracting the linear part,

values for resonance and antiresonance frequencies

(ω

r

and ω

f

) of i partial oscilators according to Eq. 4

are identified. Setting parameter a to zero or one

depends on the phase characteristic of the

corresponding partial oscillator. The value of a

becomes one when the phase angle rotates in positive

or negative direction up to a previously defined

threshold (e.g. 50 °), remains in a specified frequency

band and subsequently performs significant reverse

rotation in opposite direction. If, on the other hand, a

phase rotation of -180 ° takes place without

subsequent reversal, this indicates a partial oscillator

with a set to zero. Furthermore, aliasing effects in

upper frequency band require the definition of a

cutoff frequency ω

max,PO

up to which the phase

response is searched for partial oscillators (Siemens,

2012).

The exact determination of resonance and

antiresonance frequencies is based on subsequent

extreme value search in amplitude response in range

of the previously detected partial oscillator limits. An

extension of the frequency limits by 10 percent

ensures a reliable detection. This leads to a general

overall transfer function in product form. Damping

parameters were assigned with initial values

(d

f,i

= d

r,i

= 0.01) for each partial oscillator (cf. Eq. 5).

Subsequently, the estimation of damping values is

carried out by minimizing the squared deviation

between measured and modeled frequency response

using Nelder-Mead optimizer. Therefore, an

optimization function integrated in MATLAB

®

based

on the methodology from (Nelder and Mead, 1965)

was used. If the optimizer is also applied to the single-

mass model, the estimation accuracy of J

tot

can be

further improved.

In the next step, an inversion and discretization of

the estimated model function is required to calculate

the acceleration torque from measured rotational

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

142

speed. Regardless of the specific transfer function, the

polynomial degree of the denominator n is higher

than the degree of the numerator m. In case of a direct

inversion, this relationship is reversed, which leads to

a violation of the causality principle due to the

differential character of the resulting transfer function

(Schröder, 2007). In this paper, the proposed solution

for a stable inverted transfer function is based on an

extension by n-m high-frequency poles (Eq. 9

and 10). The time constant is set equal to control

sampling time T

S

.

G

s

s

-1

=

1

G

s

s

⋅G

Pol

s

(8)

G

Pol

s

=

1

1+T

S

⋅s

n-m

(9)

Furthermore, an implementation on fix sampled

computing systems requires a transfer of continuous-

time models into discrete-time representation. This is

carried out by applying z-transformation and thus rhe

mapping of the s-plane to the z-plane according to

Eq. (11) with control sampling time T

S

(Graf, 2012).

z=e

T

S

⋅s

(10)

Eventually, an inversion of the model equations is

carried out. Especially in case of load-side and

mechanical transfer functions, the resulting models

may have non-minimum-phase character. This means

that the transfer function shows one or more unstable

zeros, which is expressed in pole-zero diagram by

their location outside of the unit circle. By inverting

the model equation, all zeros become poles and vice

versa. Consequently, the inverted transfer function

would have the same number of unstable poles, which

results in an unstable system itself. In this case, the

transfer function is decomposed into one minimum-

phase and n all-pass components. Starting point is the

general representation of discrete transfer functions in

product form according to Eq. 12.

G

z

∏

1-z

i

z

-1

M

1

i1

⋅

∏

1-q

i

z

-1

M

2

i1

∏

1-p

i

z

-1

n

i1

(11)

Parameter p

i

denote the poles, whereas z

i

are all

zeros inside and q

i

outside of the unit circle. A

decomposition in a minimum-phase part G

MP

z

and

an allpass part G

AP

z

is carried out according to

Eq. (13) – Eq. (15) with q

i

*

as new stable zeros.

G

z

=G

MP

z

⋅G

AP

z

(12)

G

MP

z

=

∏

1-z

i

z

-1

M

1

i=1

⋅

∏

q

i

*

-z

-1

M

2

i=1

∏

1-p

i

z

-1

n

i=1

(13)

G

AP

z

=

∏

1-q

i

z

-1

M

2

i=1

∏

q

i

*

-z

-1

n

i=1

(14)

The magnitude response of the minimum-phase

model G

MP

(z) remains unchanged compared to the

original system G(z), since the magnitude of the all-

pass components G

AP

(z) is one for all frequencies.

On the other hand, the phase response shows a

significant drop in upper frequency band. For more

details on the procedure see (Schilling and Harris,

2016). For subsequent inversion, only the product of

the minimum-phase component and magnitude of the

all-pass component is used. Although this results

Figure 2: Approaches for estimating and correcting acceleration torque based on actual position values in combination with

command-value based weighting.

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

143

in a slight phase shift of the inverted transfer function,

experiments in chapter 3 show that these are

neglectable. Alternative approaches for an inversion

of mixed-phase systems based on non-recursive filters

or Kalman Filters can be found in (Aslan, 2019).

A fundamental disadvantage of both presented

approaches is the possible compensation of

unintentional acceleration phases (e.g. reaction to

external loads). Consequently, a mechanism that

solely detects acceleration phases caused by changes

in command values is required. Therefore, a

combination of the estimated motor torque T

m

and a

setpoint-based acceleration detection following the

approach presented in (Rudolf, 2014) is proposed

(figure 2, bottom).

Fundamental idea is to multiply the estimated

motor torque T

m

with an acceleration index γ

a

. Based

on thw motor command position φ

cmd

, an artificial

actual position φ

act

is calculated using a PT

1

model

(first order lag element) with gain K equal to one.

Selecting time constant T

1

inversely proportional to

position control gain factor K

v

allows adapting the

estimation to the dynamic behaviour of the axis.

T

1

=

1

K

v

(15)

After double derivation of φ

act

, theestimated

acceleration value φ

act

is weighted by a sigmoidal

function. This ensures that the acceleration index γ

a

only takes values between zero and one. Reliable

detection of deceleration movements is granted by

calculating the absolute value of φ

act

. Parameter c

a

defines for which acceleration value γ

a

reaches 0.5.

On the other hand, d

a

defines the slope at this point

(Rudolf, 2014). For the experimental setup used in

this paper, assigning c

a

= 0,001⋅φ⃛

M,max

and

d

a

= 0,0001⋅φ⃛

M,max

leads to satisfactory results.

In case of a precisely set acceleration detection, it

is also possible to use the actual value of T

m

directly.

In the following, this approach is entitled T

a,3

. This

variant corresponds to a zero setting of the torque

signal in case of detected acceleration.

2.2 Acceleration Correction Based on

Command Position Values

However, all actual value-based methods have in

common that the detection of critical load cases (e.g.

due to collision) during acceleration phases is not

readily possible. Alternatively, an exclusive

utilization of controller-generated setpoint values

combined with a more or less detailed model of the

drive control loops can be applied. However, due to

the complexity of the cascaded control including

application-specific feedforward control and setpoint

filters, a detailed modelling is not possible with

reasonable efford. On the other hand, theoretically

developed reduced-order models as described in

(Groß et. al., 2006) or (Hofmann et. al., 2010) lead to

significantly reduced estimation accuracy.

Following the methodology presented in (Kaever,

2004), which is based on an identification of PT

t

models, we propose an alternative approach for

command value-based estimation of acceleration

torque ( T

a,4

). Fundamental idea is to estimate the

transfer behavior between given setpoint acceleration

φ

cmd

and resulting actual acceleration φ

act

based on

a scalable PT

n

transfer function using least squares

method (figure 3). Acceleration torque T

a,4

is

calculated by multiplying the estimated acceleration

φ

act

with total moment of inertia J

tot

. Values for

acceleration and torque limits (φ

max

and T

m,max

) are

taken from control or drive data, respectively. By

estimating transfer functions of different order and

subsequent error measure selection (e.g. integral of

abolute error, integral of squared error, absolute

distance), the transfer behavior can be automatically

adapted to the dynamics of the respective axis. During

the experimental investigation, a combination of a

PT

1

element with time constant T

1

for dead-time

approximation (cf. Hofmann et. al., 2010) and an

oscillatory PT

2

element with gain K, damping D, and

time constant T

2

showed satisfactory results.

Applying the Padé approximation based on an all-

pass element with selectable order is also feasible for

dead time approximation (Brand, 2002).

Identification of model parameters is carried out

experimentally by applying a positioning ramp with

defined command speed and subsequent estimation

via least squares method in MATLAB

®

. For low

velocities with poor signal-to-noise ratio, the

identification results benefit from an appropriate low-

pass filtering (e.g. moving average) of the measured

acceleration signal. Note that changes in speed

Figure 3: Signal flow chart of acceleration correction with PT

2

substitute model (T

a,4

).

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

144

command also result in minor differences for the

identified parameter values. To quantify this effect, a

speed-individual parameterization is compared with a

fixed setting based on an identification in medium

speed band in chapter 3. In contrast to actual-value-

based approaches, changes in drive dynamics (e.g.

when adjusting parameters of drive control loops)

require a further parameter identification.

3 RESULTS

3.1 Test Setup

Experimental investigation of all presented

approaches is carried out on a modular drive test rig

with rotational mechanics. Its overall mechanical

structure is illustrated in the left part of figure 4. The

test rig is equipped with a SIMOTION D445 motion

control system and a subordinate SINAMICS drive

system. It provides all required basic functions (noise

generator, signal recording) for determining transfer

functions and signal measurement. The mechanical

system consists of a position-controlled servomotor

for converting motion setpoints (1) specified by the

control system and an identical synchronous motor on

load side for impressing dynamic load torques (9),

measurable with an additional torque sensor (8). A

toothed belt drive (2) with transmission ratio i

G

= 1

connects drive and load side. Besides the motor-

integrated position sensors (2048 increments),

another incremental rotary encoder (3) with 4096

increments enables modeling of partial transfer

functions. All position sensors are incremental sine-

cosine encoders. Based on the right part of figure 4,

the theoretically calculated total moment of inertia of

the experimental setup is J

tot

= 0,0055763 kg⋅m

2

.

Toothed belt and bearings are assumed to be

massless.

All approaches are evaluated in terms of their

estimation quality by investigating several

positioning sequences with varying speed

specification. The nomenclature for the acceleration

torque estimation is defined as follows:

Variant V

1

: weighted product of total moment of

inertia and actual acceleration according to

equation (1) (T

a,1

m,l

),

Variant V

2

: inverse filtering of actual angular

velocity and weighting via sigmoidal function

(T

a,2

m,l

),

Variant V

3

: weighting of actual motor torque

value (T

a,3

),

Variante V

4a,b

: calculation based on command

position with identified PT

2

model (T

a,4

).

Additionally, the influence of the measurement

system for calculating angular acceleration or angular

velocity is investigated. Besides the internal motor

sensor, the external encoder with higher resolution is

used. In case of V

1

and V

4

, total moment of inertia is

set to theoretically determined value

J

tot

= 0,0055763 kg⋅m

2

. Acceleration and torque

limits for variant V

4

are set equal to control internal

values. Additionally, the parameters for the PT

2

model are either calculated individually for each

motion profile (V

4a

) or averaged for the whole test

series and (V

4b

). The transfer functions for inverse

filtering according to variant V

2

result from identified

parameters (cf. Table 2).

The selected positioning profiles in table 1

distinguish whether acceleration torque result from

Figure 4: Structure of drive test rig (left) and moments of inertia (all data in kg⋅mm², taken from data sheets).

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

145

standstill or from a given speed setpoint.

Furthermore, the direction of movement as well as

acceleration and deceleration phases are varied. All

drive controller parameters are set according to an

automatic commissioning routine and remain

unchanged during the experiments. Only acceleration

and jerk limits are increased by a factor of ten

compared to the preset value. This deliberately

dynamically chosen parameterization serves to show

limits of the individual approaches. All combinations

and the associated parameter specifications are listed

in table 1.

Table 1: Parameters for rotary axis test stand.

Paramete

r

Value

Am

p

litude

A

1

±10 min

-1

A

2

±50 min

-1

A

3

±100 min

-1

A

±200 min

-1

A

5

±400 min

-1

Offset

O

1

(Acceleration)

0 min

-1

O

2

(Acceleration) 0.5⋅A

i

O

1

(Braking) 1⋅A

i

O

2

(Braking) 2⋅A

i

Acceleration and

j

erk limit

φ

max

,

1

100 s

-2

φ

max

,

2

1000 s

-2

φ

⃛

max

,

1

2000 s

-3

φ

⃛

max

,

2

20000 s

-3

3.2 Parameter Identification and

Setting

Table 2 lists all identified model parameters for

variant V

2

according to the described procedure in

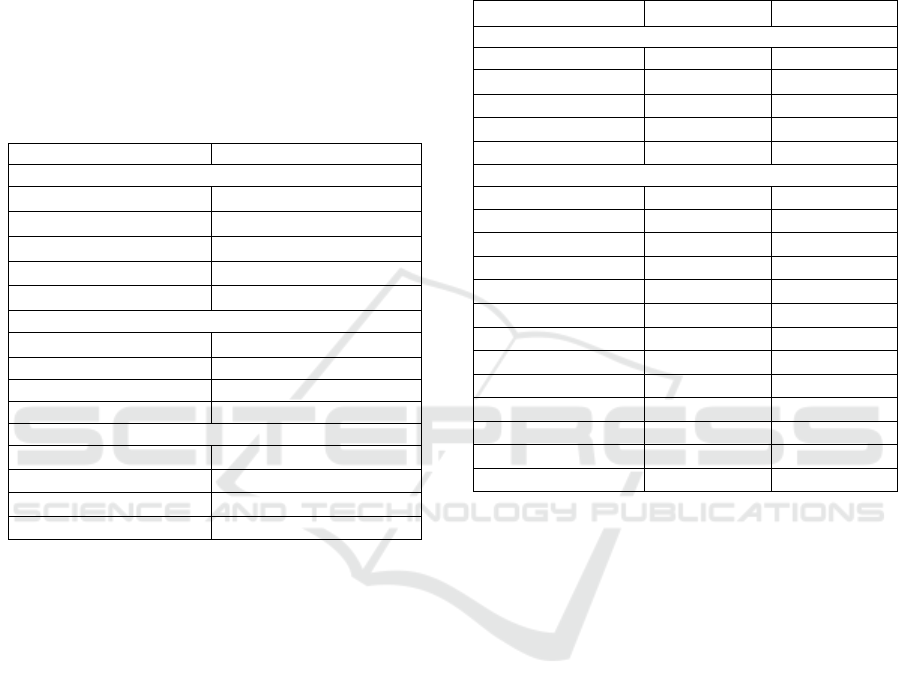

figure 1. In addition, figure 5 shows the Bode plot of

measured (gray), discrete-time (blue) and inverted

(orange) frequency responses for motor (left) and

external encoder (right). Regardless of encoder

configuration, both identified models show high

agreement with the measurement, especially in

amplitude response.

However, due to discretization of continous-time

models, a phase drop in upper frequency band arises.

In addition, the load side transfer function G

s

l

z

has

one unstable zero. However, by subtracting the all-

pass part (purple) according to Eq. (13) to Eq. (15)

and subsequent inversion of remaining minimum-

phase part (green dashed), a stable inverse transfer

function is obtained. Considering the compensated

signal (yellow), it becomes clear that the inverse

transfer function for both encoder configurations

leads to appropriate results over a wide frequency

band. Nevertheless, a significant phase drop is

noticeable depending on the transfer function.

Table 2: Set and identified Parameters depending on

encoder used for actual vaue-based acceleration torque

correction.

Parameter

G

s

m

z

G

s

l

z

Settin

g

Parameters

ω

min

in Hz

10

30

ω

max,

J

in Hz

80

60

ω

max

,

PO

in Hz

530

600

φ

min

,

m

in °

50

50

φ

min

,

l

in °

120

120

Identified Parameters

J

to

t

in kg⋅m

2

0.005357

0.004834

ω

f

,

1

in Hz

116.37

134.55

d

f

,

1

0.05

0.04

ω

r

,

1

in Hz

146.47

149.11

d

r

,

1

0.03

0.04

ω

f

,

2

in Hz

304.05

32.41

d

f

,

2

0.05

0.30

ω

r

,

2

in Hz

364.47

372.41

d

r

,

2

0.06

0.05

ω

f

,

3

in Hz

425.38

407.12

d

f

,

3

0.01

0.02

ω

r

,

3

in Hz

432.94

448.22

d

r

,

3

0.05

0.05

3.3 Experimental Investigation and

Comparison

In the following, all discussed approaches are

investigated by applying the positioning profiles

listed in table 1. Note that friction torque was

subtracted beforehand using a static model approach

(cf. Schöberlein et. al., 2022c). Hence, smaller

deviations naturally occur in the resulting motor

torque. However, since this applies to all approaches

to the same extent, it does not affect the comparison

results. Figure 6 depicts the results for estimation and

correction in case of one exemplary position profile

(A

1

-O

1

- φ

max,1

- φ

⃛

max,1

). Besides measured motor

torque (black), estimated acceleration torques

(dashed) and associated deviations for V

1

(a), V

2

(b),

V

3

(c) and V

4

(d) are shown. In addition, areas with

acceleration index γ

a

greater than zero are

highlighted. Note that for variant V

4

, model

parameters were calculated individually for this

specific motion profile.

Comparing approaches V

1

(blue and orange) and

V

2

(yellow and green), a significant reduction in

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

146

Figure 5: Comparison of measured, discretely modeled and inverted frequency responses for G

s

m

z

(left) and G

s

l

z

(right).

Figure 6: Exemplary signals for measured motor torque and estimated acceleration torque as well as modelling error for

approaches V

1

(a), V

2

(b), V

3

(c) and V

4

(d).

signal noise in case of the inverse filtering is

achieved. Due to lower amplitude gain in upper

frequency band, the motor-based approach offers

marginal advantages over a load-based model.

Furthermore, the underestimated value for total

moment of inertia compared to theoretically

calculated value leads to recognizable deviations in

case of T

a,2

l

. As mentioned in chapter 2, an additional

frequency response measurement with reduced

bandwidth may further increase the model accuracy.

Naturally, ideal correction behavior for the area

covered by weighting factor γ

a

is obtained by

approach V

3

(purple). The estimation quality of V

4

(light blue and red) is comparable to V

2

in terms of

average deviation, but without any signal noise.

Identification of model parameters using load-side

acceleration signal (red) results in only minor

differences for the estimated acceleration torque.

If one compares the individual approaches based

on all motion profiles specified in table 1, the results

of the exemplary measurement are confirmed. For

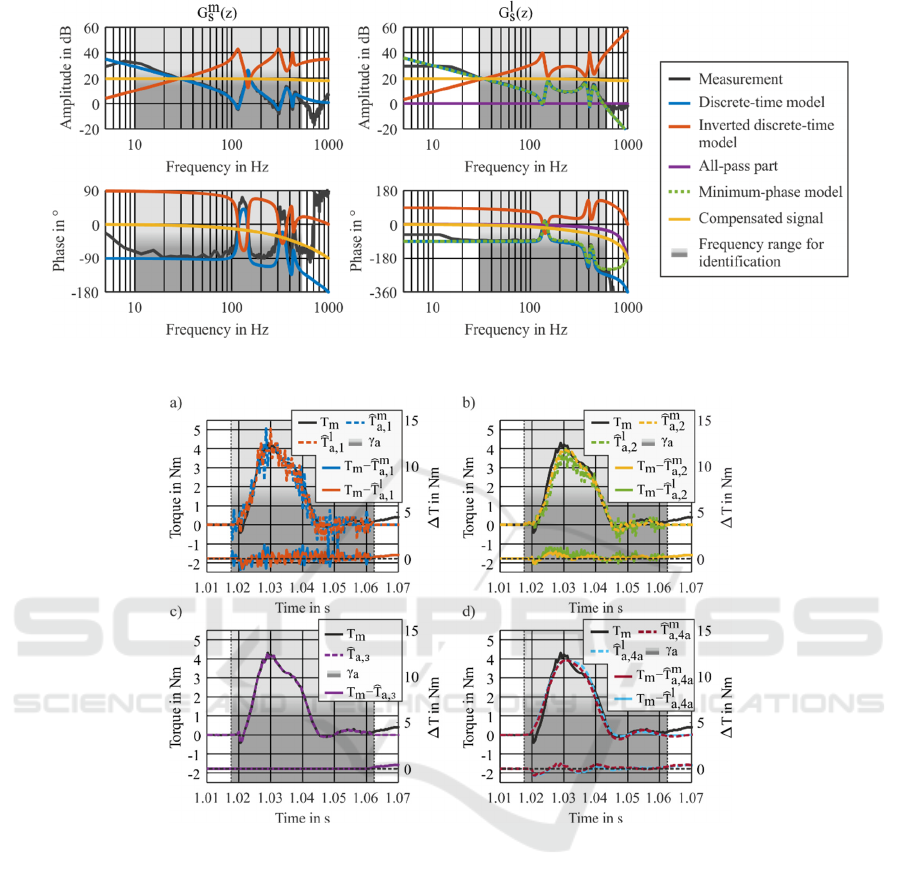

clarity, figure 7 only depicts the integral of absolute

error A

IAE

according to Eq. 17 over the weighting

area.

A

IAE

= T

m

t

-T

a

(t)⋅dt

t

2

t

1

(16)

Since the width of the weighting area is not

constant for all motion profiles, A

IAE

is normalized

taking into account the number of included sampling

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

147

Figure 7: A

IAE

of acceleration correction approaches for all motion profiles with preset (left) and increased values for

acceleration and jerk limitation (right).

points. Due to deviations in friction correction as well

as not yet included standstill torque compensation,

minor differences in A

IAE

for acceleration and

deceleration may occur for identical approaches. This

is particularly noticeable for deceleration movements

to standstill. However, these phenomena are not

significant for a comparison of the concepts in the

respective positioning sequence.

On the other hand, the load-side encoder leads

only in exceptional cases to a significant

improvement of estimation accuracy. Hence, only

results using motor internal encoder are considered in

the following. This can also be justified by the fact

that not every electromechanical axis is equipped

with an additional load-side position sensor. For the

command value-based approach, V

4a

indicates an

individual parameter identification for the

corresponding motion sequence while V

4b

determines

an overall parametrization.

The left part of figure 7 shows the A

IAE

for all

motion sequences with preset values for acceleration

and jerk limits (

φ

max,1

and φ⃛

max,1

). As expected,

variant V

3

leads to an ideal correction independent of

the given motion profile. This is followed by

command value-based approaches V

4a

and V

4b

. A

general parameter set of the PT

2

model based on mean

values over all motion sequences leads to an

equivalent or even better correction. Considering

actual-value-based approaches V

1

and V

2

, a more

complex model of the mechanical system leads to

smaller deviations between measured and modeled

acceleration torque for all sequences. This is

primarily due to a significant improvement in signal-

to-noise ratio, which is more noticeable for smaller

torque amplitudes. Overall, motion profiles with

speed offset lead to an improved correction behavior

for all approaches. This is due to additional stick-slip

effects for acceleration movements and not yet

included correction of motor torques when

decelerating until standstill. In combination with

smaller deviations in modeled friction torque, this

effect is more significant for low torque amplitudes

(e.g. A

1

-O

1

).

The right part of figure 7 shows the results for

increased acceleration and jerk limits

φ

max,2

and

φ⃛

max,2

. This deliberately dynamically chosen

parameterization serves to show limits of the

respective correction approaches. In case of A

4

and

A

5

, the torque limit is reached when moving from or

to standstill as well as when decelerating with offset

O

2

. As expected, this is no limitation for all actual

value-based approachs (V

1

, V

2

and V

3

). In case of V

4a

and V4

b

, consideration of nonlinear torque limitation

during parameter identification is not provided due to

the structure of the underlying system model.

Consequently, significantly higher deviations occur

compared to actual value-based methods. For all

other motion sequences, command value-based

approaches show good agreement between modeled

and measured acceleration torques, regardless of the

specific parameterization (individual or averaged).

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

148

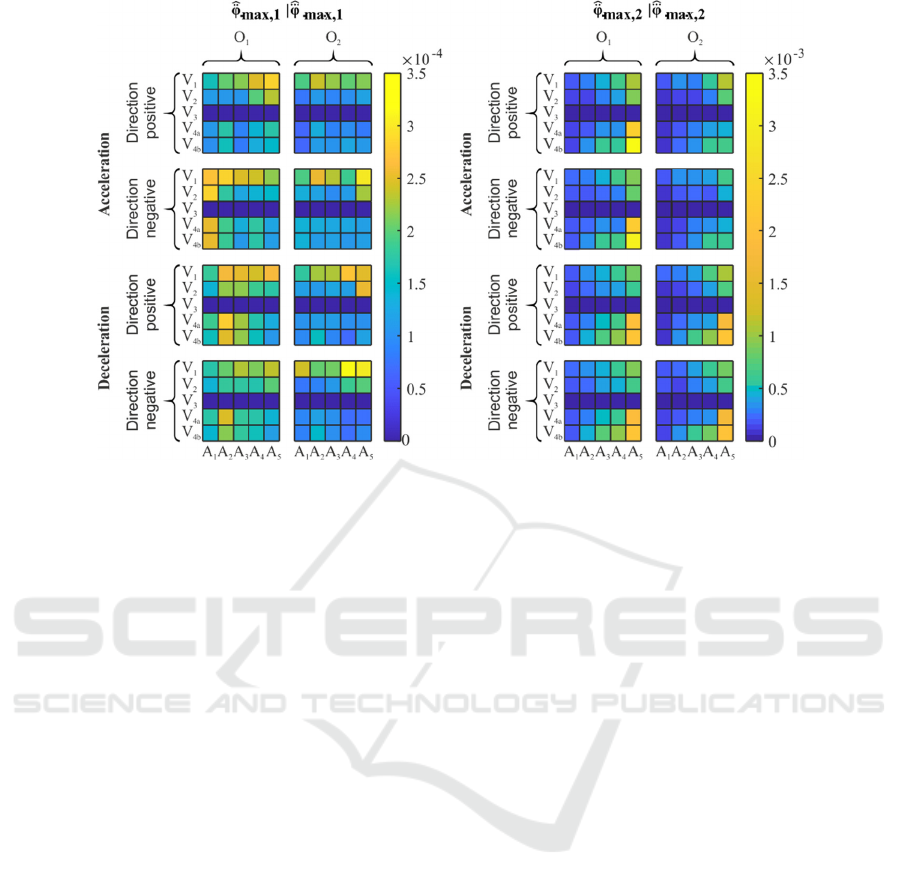

Figure 8: A

IAE

of acceleration correction approaches for direction reversal with preset (left) and increased values for

acceleration and jerk limitation (right).

In addition, several experiments were conducted

to evaluate the approaches in case of direction

reversal. These are considered separately due to their

increased requirements for acceleration correction.

The axis is first accelerated to a constant velocity

according to table 1. Subsequently, the speed setpoint

value changes its sign. Due to higher accelerations,

acceleration and torque limits are reached more

frequently. Furthermore, stick-slip effects as well as

additional slack in the reversal range are challenges

for an exact acceleration torque estimation. All

magnitudes and limitations for jerk and acceleration

correspond to the values from table 1. Again, figure 8

summarizes the results based on A

IAE

over the

weighting area γ

a

.

The left part of figure 8 represents the remaining

deviations with preset values for acceleration and jerk

limits when accelerating in positive and negative

direction, respectively. Regardless of the speed

amplitude, it becomes clear that besides an ideal

acceleration correction according to approach V

3

,

setpoint-based methods V

4a

and V

4b

again achieve

highest accuracy. This also applies in case of

acceleration-limited motion profile, as it occurs for

A

3

to A

5

. A parameterization based on averaged

setting values leads to better or equivalent results

compared to an individual setting.

However, a more dynamic setting for acceleration

and jerk limits (

φ

max,2

and φ⃛

max,2

) shows that

command value-based approaches cannot achieve

appropriate estimation results, especially for higher

magnitudes (A

5

). Once more, the main reason is that

the torque limit is reached. Furthermore, it should be

noted that the detection of the weighting area is no

longer fully successful due to high overshoot in actual

torque value. Regarding actual value-based methods

V

1

and V

2

, an increased estimation quality in case of

inverse filtering is confirmed again. This can be

observed independent of applied motion profile or

parameterized limits for acceleration or jerk.

4 DISCUSSION

Overall, approach V

3

leads to an ideal correction of

acceleration torques for all investigated positioning

sequences. Hence, it represents the preferred solution.

However, if external load torques act during

acceleration phases (e.g. in event of collision), a

command value-based approach (V

4

) offers a

valuable option. Parameterization based on several

averaged parameter sets does not compulsorily lead

to reduced accuracy compared to a speed-related

setting. Hence, this approach is much more robust

than the method presented in (Kaever, 2004), which

requires an additional variation of gain factors

depending on actual motor speed. Merely in case of

dynamic motion profiles with reversal of direction or

while reaching torque limit, a command value-based

approach is not recommended. If no position

command signal is available, approach V

2

achieves a

sufficient acceleration correction in combination with

parallel weighting of acceleration phases. Although

the commissioning procedure is more complex

compared to approach V

1

, V

2

leads to a significantly

better approximation for all examined motion

sequences.

5 CONCLUSION

Within the scope of the paper, four approaches for a

correction of acceleration phases in motor torque

signal of electromechanical axes were developed and

experimentally investigated. It has been shown that

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

149

an increased modeling depth equally leads to an

improvement of the estimation quality. In addition,

the described weighting function enables a detection

of acceleration and braking phases. This allows an

ideal correction by subtracting the actual motor

torque in the detected range. Main advantage of the

presented command value-based approach is

asignificantly lower noise of the artificial acceleration

signal. Furthermore, the approach operates

independently of any additional external loads that

may act during acceleration phases (e.g. process

forces). By comparing all variants for a wide range of

acceleration and braking situations using extensive

experimental tests, a performance evaluation of all

approaches is carried out. Hence, the results of the

paper may be used to select suitable approaches for

specific application scenarios.

Future work should examine the influence of

superimposed external load torques on the

acceleration correction. Additionally, an adequate

reconstruction of external load forces requires the

estimation of further operation-related effects in the

motor torque signal. Besides already corrected

frictional torques, periodic disturbances caused by

motor poles and notches should be compensated.

Furthermore, conducted experiments have shown that

motor torque does not drop to zero in case of axis

standstill. Main cause are effects in the current control

loop. However, these sections in the motor torque

signal must be detected and corrected. Eventually, an

inverse transfer function between the initiation point

of an external load torque at the end of the mechanical

chain and the measured motor torque must be

modeled. Therefore, it should be examined to what

extent the discrete method presented needs to be

adapted.

ACKNOWLEDGEMENTS

Funded by the Federal German Ministry for

Economic Affairs and Climate Action.

REFERENCES

Quellmalz, J. et. al. (2016). Performance Index for Servo

Drives under PI Speed Control. In: Solid State

Phenomena 251, pp. 152 – 157.

Schöberlein, C. et. al. (2022a). Sensorless Condition

Monitoring of Feed Axis Components in Production

Systems by Applying Prony Analysis. In: Proceedings

of the 19th International Conference on Informatics in

Control, Automation and Robotics - ICINCO,

pp. 214 – 221.

Kaever, M. (2004). Steuerungsintegrierte

Fertigungsprozeßüberwachung bei spanender

Bearbeitung. Dissertation, Rheinisch-Westfälische

Technische Hochschule Aachen.

Aslan, D., Altintas, Y. (2018). Prediction of Cutting Forces

in Five-Axis Milling Using Feed Drive Current

Measurements. In: IEEE/ASME Transactions on

Mechatronics 23(2), 2, pp. 833 – 844.

Aslan, D. (2019). Integration of Virtual and On-line

Machining Process Control and Monitoring using CNC

Drive Measurements. Dissertation, University of

British Columbia.

Yamato, S. et. al. (2019). Enhancement of Sensor-less

Cutting Force Estimation by Tuning of Observer

Parameters from Cutting Test. In: Procedia

Manufacturing 41, pp. 272 – 279

Yoneka et. al. (2012). Disturbance Observer–Based In-

process Detection and Sup-pression of Chatter

Vibration. In: Procedia CIRP 1, pp. 44 – 49

Sugiyama et. al. (2017). Development of sensorless chatter

detection method in ball screw drive system applying

mode decoupling. In: Proceed-ings IECON 2017 - 43rd

Annual Conference of the IEEE Industrial Electronics

Society, pp. 3185 – 3190

Yamato et. al. (2021). Development of Automatic Chatter

Suppression System in Parallel Milling by Real-Time

Spindle Speed Control with Observer-Based Chatter

Monitoring. In: International Journal of Precision

Engineering and Manufacturing 22(2), pp. 227 – 240

Rehse, M. (1999). Flexible Prozessüberwachung bei der

Bohr- und Fräsbear-beitung in einer Autonomen

Produktionszelle. Dissertation, Rheinisch-Westfälische

Technische Universität Aachen

Rudolf, T. (2014). Adaptierbare Parametrierung von

Diagnosesystemen durch Verwendung digitaler

Antriebssignale in der Prozessüberwachung.

Dissertation, Rheinisch-Westfälische Technische

Hochschule Aachen.

Schöberlein, C. et. al. (2022c). Modeling and Identification

of Friction and Weight Forces on Linear Feed Axes as

Part of a Disturbance Observer. In: International

Journal of Mechanical Engineering and Robotics

Research 11(4), pp. 198 – 206.

Isshiki, K. et. al. (2021). Enhancement of Accuracy in

Sensorless Cutting-Force Estimation by Mutual

Compensation of Multi-integrated Cutting-Force

Observers. In: Proceedings of the Machining

Innovations Conference for Aerospace Industry (MIC),

pp. 33 – 40.

Hellmich, A. et. al. (2011). Non-Invasive Parameter

Identification by using the Least Squares Method. In:

The Archive of Mechanical Engineering 8 (2), pp. 185 –

194.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

150

Hofmann, S. et. al. (2010). Identification of Parametric

Models for Commissioning Servo Drives. In. Brezina,

T., Jablonski, R. (eds) Recent Advances in

Mechatronics. Springer, Berlin, Heidelberg.

Hipp, K. et. al. (2017): Simulation based optimization for

controller parameterization of machine tool axes –

advanced application. In: Journal of Machine

Engineering 17(1), pp. 57 – 68.

Schöberlein, C. et. al. (2022b). Identification and Discrete

Inversion of Multi-Mass Systems as Part of a

Disturbance Observer. In: Proceedings of the 2nd

Winter IFSA Conference on Automation, Robotics and

Communications for Industry 4.0, pp. 13 – 18

Siemens AG (2012): Servo Drive Optimization Guide

SINAMICS S120 / SIMOTION D. Technical

Specification.

Nelder, J., Mead, R. (1965). A Simplex Method for

Function Minimization. In: The Computer Journal

Advance 7, pp. 308 – 313.

Schröder, Th. (2007). Entwicklung und Evaluation von

Algorithmen zur zeitoptimierten Bewegungszerlegung

bei kinematisch redundanten Werkzeugmaschinen.

Dissertation, Technische Universität Chemnitz.

Graf, U. (2012). Applied Laplace Transforms and Z-

Transforms for Scientists and Engineers: A

Computational Approach Using a Mathematica

Package. Switzerland, Birkhäuser Basel.

Schilling, R. J., Harris, S. L. (2016). Digital Signal

Processing Using MATLAB. USA, Cengage Learning.

Groß, H.; Hamann, J.; Wiegärtner, G. (2006). Technik

elektrischer Vorschubantriebe in der Fertigungs- und

Automatisierungstechnik. Mechanische Komponenten,

Servomotoren, Messergebnisse. Erlangen: Publicis

Corporate Publishing.

Brand, C. (2002). Neuronale Identifikation von Totzeiten.

Dissertation, Technische Universität München.

Experimental Investigation and Comparison of Approaches for Correcting Acceleration Phases in Motor Torque Signal of

Electromechanical Axes

151