Design of Modular and Distributable Automation Software for PLCs

Oscar Miguel-Escrig

a

, Isabel Rosell

´

o-Gonz

´

alez and Julio-Ariel Romero-P

´

erez

b

Departament d’Enginyeria de Sistemes Industrials i Disseny, Universitat Jaume I,

av. de Vicent Sos Baynat, Castell

´

o de la Plana, Spain

Keywords:

Distributed Control System, Grafcet, IEC 60848, IEC 61131, PLCs.

Abstract:

Design and maintainability of modular automation software are common concerns nowadays. Common prac-

tice in industry usually overlooks the design phase of software, jumping directly into the coding phase, which

typically results in poorly readable and maintainable code. In this work, it is shown how modular and hier-

archically structured design of discrete event control systems, which is supported by Grafcet models, can be

subsequently implemented in several devices distributed across the fieldbus. Besides, the resulting software

is more readable and maintainable due to its similarities with the proposed Grafcet model. An example is

provided showing how a distributed application can be tested in a centralized fashion.

1 INTRODUCTION

Automation software in industry is mainly imple-

mented in devices called Programmable Logic Con-

trollers (PLC). Their usage is extended across indus-

try due to their degree of standardization, their accep-

tance and accumulated know-how among practition-

ers and the support provided from institutions and re-

lated companies.

Different aspects surrounding PLCs are standard-

ized in the norm IEC 61131 (IEC, 2013), which is

widely adopted among the control community. PLCs

from different suppliers are programmed using Inte-

grated Development Environments (IDEs) based on

the standard IEC 61131, which interpret and incorpo-

rate in their programming environment the principles

of the standard, enabling portability to different ex-

tents.

It is worth mentioning that, in the context of dis-

tributed control systems, standard IEC 61499 (Zoitl

and Lewis, 2014) has been proposed to implement au-

tomation software. Despite the fact that its software

components are based on IEC 61131’s, IEC 61499 is

not as spread across industry as IEC 61131. However,

remarkable efforts are being made from the industry

domain and the academia to develop and integrate au-

tomation software according to IEC 61499, (Lyu and

Brennan, 2021).

The standard IEC 61131 defines in its third

a

https://orcid.org/0000-0002-2472-2038

b

https://orcid.org/0000-0003-3397-2239

part (IEC 61131-3) the programming languages that

can be used to implement the automation software.

Namely, these languages are Sequential Function

Chart (SFC), Function Block Diagram (FBD), Lad-

der Diagram (LD), Structured Text (ST) and Instruc-

tion List (IL). The first three languages are graphical,

and the remaining two textual. A project according to

IEC 61131 can be composed of several Program Or-

ganization Units (POU) each of them programmed in

the language of preference. Each of the languages de-

fined in the standard has its own strengths, which can

be exploited in the coding process. Despite the flex-

ibility and variety of languages, LD and ST are the

most used nowadays, (PLCopen, 2019).

Before starting coding, it is advisable to properly

define the system’s functionality with an appropriate

model. This step is generally overlooked in industry

because it is perceived as an unnecessary step that de-

lays code development. Some studies like (Johnson,

2007; Ljungkrantz et al., 2011) point out that this un-

deruse of models is due to strong time constraints and

to a lack of tools for automatically obtain control soft-

ware from models. However, coding directly from

the textual definition of the system’s behavior leads to

possible delays and results in harder to maintain code

since no formal definition of the behavior using mod-

els has been made.

There exist several tools for modeling the behav-

ior of automation systems which have been proved

in practice. Some examples of these tools are Con-

trol Interpreted Petri Nets, Grafcet diagrams or UML

Miguel-Escrig, O., Roselló-González, I. and Romero-Pérez, J.

Design of Modular and Distributable Automation Software for PLCs.

DOI: 10.5220/0012183700003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 2, pages 135-141

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

135

state diagrams. The obtained models allow a formal

description of the behavior, thus avoiding the ambi-

guities that a textual description can induce. In this

work, Grafcet diagrams, defined in the IEC 60848

(IEC, 2002), which are state-transition diagrams well-

known in the automation field, will be used to model

the behavior of discrete event control systems.

Grafcet diagrams and SFC language of standard

IEC 61131 are similar since both have the step-

transition concepts at its base. This makes the imple-

mentation of discrete event controller in SFC easier

to read and understand compared with implementa-

tions of controllers in other languages of the standard.

Thus, the usage of SFC results in a more maintain-

able code. Furthermore, due to the similarities be-

tween Gafcets and SFC, the formal description of the

controller behavior in Grafcet models can be easily

obtained from the SFC code, even if it is modified.

The aim of this work is to show that modular de-

sign enables for a modular implementation, enhanc-

ing the capability of the software to be distributed

across fieldbus devices, maintaining the structural hi-

erarchy of the Grafcet model. The translation step

from the model to the implementation is out of the

scope of the work since it has been detailed in the

literature (Julius et al., 2017; Schumacher and Fay,

2014). However, the usage of SFC for implementing

structuring mechanisms will be also explored. Be-

sides, aspects like readability and maintainability will

be shown to be enhanced through SFC implementa-

tion from GRAFCET diagram.

The structure of the work is as follows. In Sec-

tion 2 some preliminary discussion is made with

regard to the modeling and implementation of dis-

tributed automation software. In Section 3 the pro-

cedure for the design and implementation of the soft-

ware is explained. Section 4 presents the platform

used for validating the results, together with the mod-

eling and implementation details. Finally, in Section 5

de conclusions about this work are drawn.

2 PRELIMINARY NOTES

2.1 Modeling

Among the different modeling techniques available,

Grafcet diagrams, defined in the standard IEC 60848,

are a well-known tool in the field of control engi-

neering since this kind of diagrams form part of the

contents studied in higher education and technical

schools of the automation branch.

This modeling language allows the designer to de-

fine the general behavior of an automation system

regardless of the particular implementation details,

leaving their definition for subsequent and more de-

tailed design rounds or directly for the implementa-

tion.

Grafcet diagrams allow defining the detailed be-

havior of discrete event systems through a modular

and hierarchical design. This is accomplished, in part,

because of the language elements, which cover most

of the possible situations that can be found in actual

applications. Besides, the user has the possibility of

modeling the functioning of a whole system through

different partial Grafcet diagrams, enabling a modular

design.

To coordinate the different partial Grafcets that

can result from the design process, the norm provides

some mechanisms for hierarchically structuring the

functioning. In particular, the modeling mechanisms

are enclosures, macro-steps and forcing orders. The

particularities and rules concerning these mechanisms

are defined in the norm, and will not be further dis-

cussed. In this work, forcing orders will be used as

structuring mechanism since they enable for a hierar-

chical design.

It is worth noticing that these principles of mod-

ular design, hierarchy and abstraction in the behavior

definition, are not tied to a given physical device. In

this sense, there is not any hindrance to use Grafcet

diagrams for modeling distributed automation appli-

cations.

2.2 Implementation

The standard IEC 61131 in its third part offers five

programming language for implementing automation

software, each of them with their own properties

which make them more suitable than another lan-

guage for a given task.

In (Bonfatti et al., 1997), a discussion about the

roles of the language in IEC 61131 was provided.

SFC was highlighted as the most suitable to sup-

port the initial phases of PLC software development.

Several characteristics that endorsed SFC were men-

tioned: 1) High expressive power, 2) Graphic formal-

ism, 3) Support to preliminary design, 4) Support to

detailed design, 5) Natural connection with other lan-

guages and 6) Support to software fragmentation.

Due to these characteristics, SFC is recommended

for early design and to structure any application, leav-

ing the remaining languages to auxiliary tasks as

further specifying or implementing specific parts of

code. According to this, a hierarchy was defined in

(Bonfatti et al., 1997) between the IEC 61131 lan-

guages, regarding to their capabilities in different cod-

ing phases and to their level, which is presented in

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

136

SFC

ST

FBD IL

Level

high

low

Phases

codingdesignanalysis

LD

Figure 1: Hierarchy of IEC 61131 languages according to

(Bonfatti et al., 1997).

Figure 1. This recommendation for the implementa-

tion will be kept in this work since it allows main-

taining the structure and hierarchy defined in Grafcet

models.

Since SFC language is very close to Grafcet mod-

eling, being both of them state diagrams, the com-

ments made regarding the applicability of Grafcet

models to design of distributed automation software,

also apply for SFC’s implementation. However, it

is important to notice that, while Grafcet models

can theoretically split steps across devices, (Miguel-

Escrig et al., 2020; Wiesmayr et al., 2021), SFC’s im-

plementation is tied to a single device. This aspect

will have to be considered in the modeling process.

Regarding the distribution of programs developed

under the IEC 61131 standard, it should be noted that,

unlike the IEC 61499, the IEC 61131 is highly tied

to the device where the code is implemented. This

standard, however, supports communication between

devices. The information exchange is supported in

the standard by access paths mechanisms. Alterna-

tively, other communication approaches can be used,

like Modbus or OPC.

3 FOLLOWED PROCEDURE

The procedure followed for the development of dis-

tributable automation software consists of a design

phase using Grafcet and an implementation phase us-

ing SFC as the main language, using the rest of lan-

guages of the IEC 61131 for further code developing

or adding some specific feature.

In the design phase, the process starts by identify-

ing the independent “tasks” that compose the whole

system behavior. The tasks are delimited according

to three principles, namely, interaction between tasks,

virtual modularity and physical modularity.

Reducing the interaction between tasks allows

lowering the communication network traffic, there-

fore, problems associated with the communication

such as packet losses or delays have a lesser impact

on the systems’ performance.

A differentiation has been made with regard to

the principle of modularity, which has been split be-

tween virtual and physical. Both aspects are equally

important and they take into account different char-

acteristics of the system. Under the physical modu-

larity, there are gathered aspects as plant layout or re-

usability of components (e.g. conveyors) in other pro-

cesses. Whereas by virtual modularity, all the aspects

regarding the software design and implementation are

gathered such as PLCs used, programs re-usability,

fieldbus constraints, etc.

With the different tasks identified following as

much as possible these principles, a Grafcet model

is designed for each of them. If needed, several par-

tial Grafcets are designed to correctly characterize

the behavior of the task. Afterward, a main Grafcet

model functioning as a coordinator between the pre-

vious partial Grafcets is designed. This main Grafcet

is in a hierarchically higher position with regard to

the partial Grafcets modeling the tasks and contains

structuring mechanisms like forcing orders or enclo-

sures. In this main Grafcet are included the coordina-

tion tasks for the normal operation of the process and

also stoppage or maintenance procedures.

Once the behavior of the system has been mod-

eled, with the desired degree of precision, through

different Grafcets, the implementation in IEC 61131

languages can begin. The language of choice for this

work is SFC due to its similarities with the developed

Grafcet models. The methodology for implementing

most of Grafcet model elements in SFC has been pre-

sented in (Schumacher and Fay, 2014). Following

the procedure explained in that paper the functioning

of each partial Grafcet is implemented in a different

POU, being the forcing orders the remaining aspect to

implement since an implementation guideline has not

been provided for the structuring mechanism.

For the scope of this work, it has only been con-

sidered forcing orders that empty the marking of a

Grafcet and forcing orders that initialize the function-

ing of a partial Grafcet to a given step.

According to the IEC 61131 standard, each SFC

network must always have at least one step active.

Therefore, to implement the aforementioned forcing

orders in a SFC that implements a forced Grafcet, we

propose to include an additional step symbolizing the

empty marking state. This new step, not included in

the developed partial Grafcet, will be implemented as

the initial step for the SFC network and will be placed

before the expected initial step for the functioning.

Design of Modular and Distributable Automation Software for PLCs

137

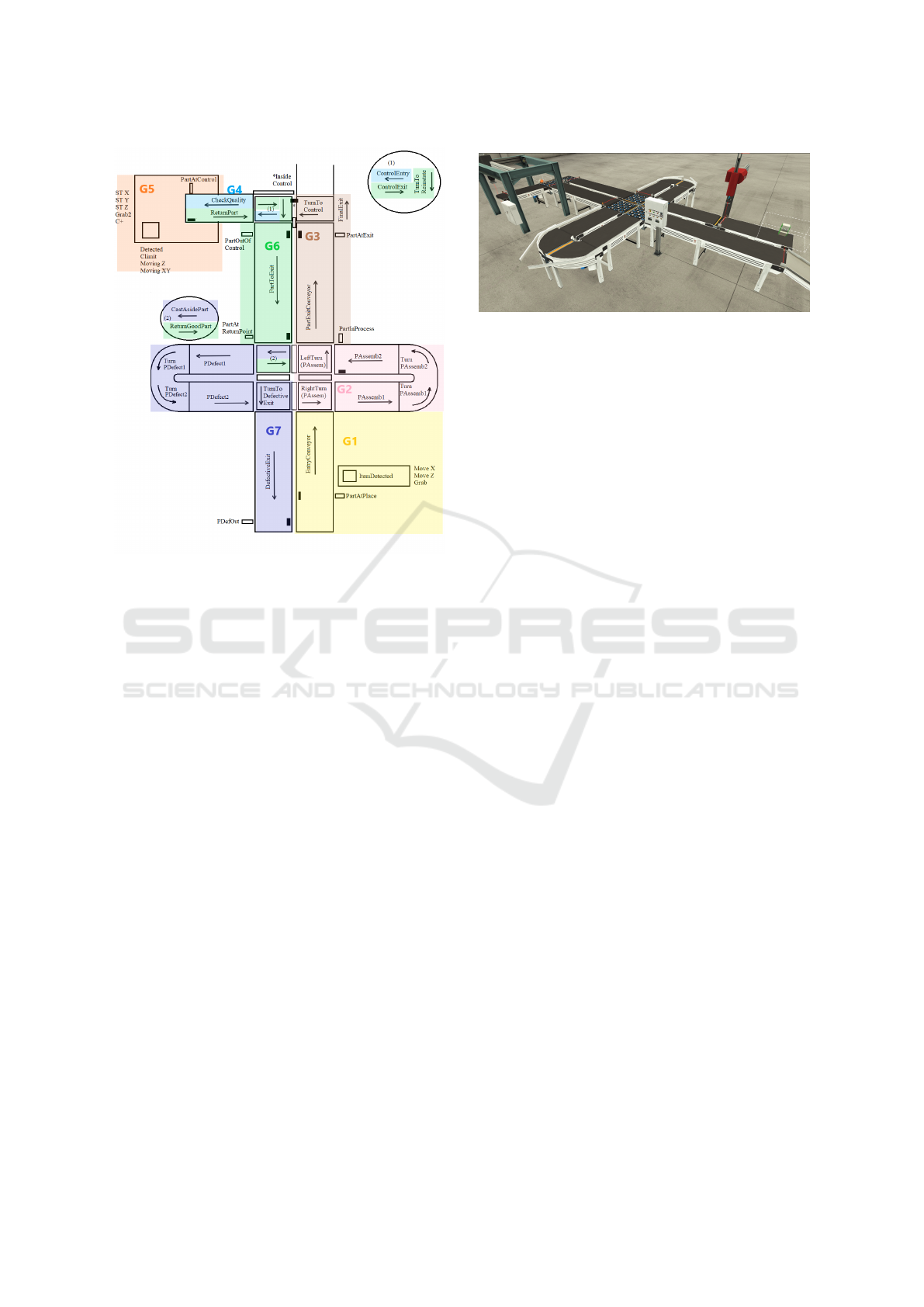

Figure 2: Diagram of the system with modeled Grafcets.

An additional always true transition will be included

after the new step. Besides, some mechanism to ini-

tialize and pause the execution of SFC networks must

be used. In Codesys, for instance, the flags SFCInit

and SFCPause play this role (Codesys, 2022).

To implement the forcing order in the SFC that

implements the functioning of a Grafcet that forces

another Grafcet, it is only required to modify the state

of the flags of the forced SFC accordingly. If the SFC

must return to its initial step, SFCInit is activated and

it will transition to the initial functioning step through

the always true transition included. If the SFC must

simulate an empty behavior, SFCInit and SFCPause

must be activated.

4 EXPERIMENTAL VALIDATION

4.1 Platform Presentation

The system under study is formed by a combination

of different conveyors, robots and sensors. The aim of

this system is to hold an assembling process in which

a lid is put onto a base. In addition, a quality control

is stochastically realized upon some of the assembled

pieces. The depiction of the system is presented in

Figure 2.

The normal operation of the system starts when

the Start Button is activated. Then, lids and bases

arrive alternatively through the entry conveyor. The

Figure 3: Digital model of the physical system in Fac-

tory IO.

robot in charge of the assembly takes one lid and puts

it on top of the base that comes after. Once the assem-

bly process is done, the part goes through a group of

perpendicular and round conveyors. Here, a series of

manual operations are conducted on the part to obtain

the final product. Then the final product is taken out

of the system by another set of conveyors.

The final products selected to pass the quality con-

trol are deviated towards the robot where it is carried

out. This is done once the manual operation has been

realized and before the piece leaves the system. Once

the product has passed the quality control an operator

establishes whether it has to be cast aside or not. If the

product has good quality, it is returned to the normal

exit. If the product has to be cast aside, it goes out of

the system though another set of conveyors, where an

operator examines the part to make most of the mate-

rial if it can be used again. Then the part leaves the

system to the defective part storage.

To stop the system, the Stop Button has to be

pressed. Once this button is activated, no more parts

arrive and the parts that are already into the system are

processed. When all the pieces have abandoned the

system, the conveyors stop and the system waits to be

activated again. There is also an Emergency Button

that immediately stops all the elements in the system

when pressed. When the emergency is repaired and an

operator releases the Emergency Button, all the pro-

cesses in the system restart.

A digital model of the physical system is built us-

ing Factory IO which is shown in Figure 3. This envi-

ronment allows testing the final automation software

in a realistic manner, since the communication with

the PLC code is performed via standardized protocols

like Modubs or OPC. Besides, Factory IO already im-

plements the physics of the components (like convey-

ors or robot arms), which provides a realistic feedback

of the behavior. For more details the reader is referred

to their website, (Factory IO, 2022).

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

138

Figure 4: Identified tasks and their hierarchical relationship.

Figure 5: Mode Coordination Grafcet G0.

4.2 Modeling Details

With the goal of reducing the communication traffic

and producing modular software components, several

tasks have been identified. It has been attempted that

each task corresponds to a given physical module,

however, with the aim of reducing the communica-

tion traffic some parts have been mixed into a single

task. The resulting tasks and their hierarchical rela-

tionship are presented in Figure 4. The modularity of

the tasks can be appreciated in Figure 2, where the

distribution of the developed Grafcets in the physical

layout is presented.

In the communications aspect, the data shared be-

tween Grafcets are the forcing orders and some flags

indicating the usage of actuators in the points where

bidirectional movement can happen to avoid activat-

ing both actuators at the same time.

With regard to the structure, a general Mode Coor-

dination Grafcet (G0) has been included in the highest

hierarchical position, which is presented in Figure 5.

The remaining tasks are placed on the same hierarchy

level, but Grafcet G8 has been developed to facilitate

Figure 6: Partial Grafcet of task G2: Transport.

Figure 7: SFC implementation of Mode Coordination

Grafcet G0 in Figure 5.

the coordination between the different tasks related

with the quality control. As an example, the partial

Grafcet G2:Transport is included in Figure 6.

4.3 Implementation Details

The implementation of the previously presented

Grafcets has been done in separate POUs in Codesys.

Concretely, these POUs are of type PROGRAM, in this

way, the code developer can chose to distribute them

across different devices.

Since modular software has been developed, there

is a great flexibility in how to distribute the applica-

tion. The level of flexibility is such that each POU

could be executed by a different PLC, although other

more reasonable and practical choices are possible.

Each of these POUs has been programmed using

SFC language following the procedure explained in

the previous section. Examples of the implementation

are provided in Figures 7 and 8 for Grafcets G0 and

G2, respectively.

It is worth noticing the remarkable similarities be-

tween the SFC implementations and the Grafcet mod-

els. This feature enhances the readability and main-

Design of Modular and Distributable Automation Software for PLCs

139

Figure 8: SFC implementation of task G2: Transport from

Grafcet in Figure 6.

tainability of the developed software because, if dif-

ferences in the code structure are spotted, they can

be easily translated to the model documentation and

vice-versa.

The communication has been established between

the different POUs through an OPC UA server, where

the variables referring to the state of actuators and the

forcing orders are shared.

4.4 Validation

The functioning of the application can be tested in a

centralized fashion, execution all the developed POUs

in the same PLC. It has to be taken into account

that each POU will have Local and Shared variables,

which will be used by its SFC. To perform the testing,

Shared variables must be declared in the OPC Server,

which will provide the communication link between

POUs. Feedback from the state of the system is ob-

tained from the Factory IO model, which is also con-

nected through OPC UA.

The described structure for testing distributed ap-

plications with Codesys and Factory IO via OPC UA

is presented in Figure 9.

5 CONCLUSIONS

In this work the importance of a proper design phase

for modular automation software is highlighted. This

step, generally overlooked in industry practice, if

OPC UA

POU-G0

Factory IO

Shared variables

SFC

POU-Gn

Shared variables

PLC

Local variables

SFC

Local variables

Figure 9: Communication structure for testing distributed

applications.

done properly facilitates the implementation of mod-

ular and distributable automation software.

To model the behavior of an application with these

characteristics of modularity and distributability, it is

proposed to use Grafcet models, which allow the de-

sign of software components with different degrees of

abstraction.

The functionality that these Grafcet models de-

scribe is implemented in PLC controllers, which

constitute the hegemonic device in industry and

are typically programmed according to the standard

IEC 61131. It has been chosen to use mainly SFC

language due to its similarities with Grafcet models,

resulting in an easy to read and maintain code.

Grafcet standard provides a series of mechanisms

for hierarchically structuring applications. Guidelines

to implement part of these mechanisms in IEC 61131

are provided.

Finally, an example is provided in which the de-

scribed design and implementation procedure is ap-

plied. In that example, it is shown how the testing of

the resulting distributed application can be done in a

centralized fashion.

ACKNOWLEDGEMENTS

This work is supported by the project number UJI-

B2021-45/21I596 from Universitat Jaume I.

REFERENCES

Bonfatti, F., Monari, P. D., and Sampieri, U. (1997). IEC

61131-3 programming methodology: software engi-

neering methods for industrial automated systems.

ICS Triplex.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

140

Codesys (2022). Codesys online help - SFC flags.

https://content.helpme-codesys.com/en/CODESYS

Accessed: 2023-06-10.

Factory IO (2022). Factory IO - Manual.

https://docs.factoryio.com/manual/. Accessed:

2023-06-10.

IEC (2002). IEC 60848: GRAFCET specification language

for sequential function charts.

IEC (2013). IEC 61131 - programmable controllers, part 3:

Programming languages.

Johnson, T. L. (2007). Improving automation software de-

pendability: A role for formal methods? Control en-

gineering practice, 15(11):1403–1415.

Julius, R., Sch

¨

urenberg, M., Schumacher, F., and Fay, A.

(2017). Transformation of grafcet to plc code includ-

ing hierarchical structures. Control Engineering Prac-

tice, 64:173–194.

Ljungkrantz, O., Akesson, K., Yuan, C., and Fabian, M.

(2011). Towards industrial formal specification of pro-

grammable safety systems. IEEE transactions on con-

trol systems technology, 20(6):1567–1574.

Lyu, G. and Brennan, R. W. (2021). Towards iec 61499-

based distributed intelligent automation: A literature

review. IEEE Transactions on Industrial Informatics,

17(4):2295–2306.

Miguel-Escrig, O., Romero-P

´

erez, J.-A., Wiesmayr, B.,

and Zoitl, A. (2020). Distributed implementation of

grafcets through iec 61499. In 2020 25th IEEE Inter-

national Conference on Emerging Technologies and

Factory Automation (ETFA), volume 1, pages 402–

409.

PLCopen (2019). PLC Programming Prefer-

ence Survey - Insights and User Comments.

https://www.automation.com/en-us/articles/2019/plc-

programming-preference-survey-insights-user-co.

Accessed: 2023-06-10.

Schumacher, F. and Fay, A. (2014). Formal representa-

tion of grafcet to automatically generate control code.

Control Engineering Practice, 33:84–93.

Wiesmayr, B., Zoitl, A., Miguel-Escrig, O., and Romero-

P

´

erez, J.-A. (2021). Distributed implementation of hi-

erarchical grafcets through iec 61499. In 2021 26th

IEEE International Conference on Emerging Tech-

nologies and Factory Automation (ETFA ), pages 1–8.

Zoitl, A. and Lewis, R. W. (2014). Modelling control sys-

tems using IEC 61499, volume 95 of IET Control en-

gineering series. IET, London, 2. ed. edition.

Design of Modular and Distributable Automation Software for PLCs

141