Modelling of a 6DoF Robot with Integration of a Controller Structure

for Investigating Trajectories and Kinematic Parameters

Armin Schleinitz, Chris Schöberlein

a

, Andre Sewohl

b

, Holger Schlegel and Martin Dix

c

Institute for Machine Tools and Production Processes, Chemnitz University of Technology,

Reichenhainer Str. 70, 09126 Chemnitz, Germany

Keywords: Robotic, Simulation, Kinematic Analyse, Inverse Transformation, Multi-Body Modelling, Feedback Control

System.

Abstract: Knowledge of robot joint position as a function of TCP-position and pose is of outstanding importance, since

position and pose are specified by the process. However, there is no generally applicable method for the

inverse transformation. In addition to a kinematic analysis and the inverse transformation of a 6DoF robot,

this work also presents the development of a multi-body model based on it. All components are linked in a

drive-specific controller structure. To validate the overall model, the simulation-based drive torques are

compared with the values of a real robot. Likewise, target and actual Tool Center Point (TCP) positions of a

given trajectory are examined in the simulation model and compared with a real system. It was shown that in

the simulation model, the realized trajectory exhibits only very slight deviations compared to the previous

trajectory, but greater deviations compared to the real system. The overall model forms the basis for further

analyses regarding kinematic joint parameters as a function of a given trajectory.

1 INTRODUCTION

Robots are conquering more and more areas of

application in industrial production. They are not only

used in component handling, in joining and assembly

operations. For some time, the possibilities of using

robots in cutting machining have also been

investigated (Abele et al. 2008). However, numerous

challenges still need to be overcome in this area in

order to further expand the range of applications. In

this context, a wide range of work and investigations

have already been carried out, which aim to increase

the rigidity (Lin et al. 2017) and the movement

speeds, but also to increase the positioning,

repeatability and path accuracy (Hu et al. 2023). The

optimization approaches pursued for this essentially

concentrate on the following subject areas:

- Stiffness modelling and pose planning

- Identification of dymanic parameters and

trajectory planning

- Compensation of structural deformation

a

https://orcid.org/0009-0006-3603-5012

b

https://orcid.org/0000-0003-2031-6603

c

https://orcid.org/0000-0002-2344-1656

- Analysis of vibration characteristics and chatter

suppression (Zhu et al. 2022).

One common feature of all approaches are

suitable simulation models for replicating the system

and process behaviour (Metzner et al. 2019). In this

paper, an approach is presented in which a multi-body

simulation model is developed based on the kinematic

analysis and the inverse transformation. Knowledge

of robot joint position as a function of TCP-position

and pose is of outstanding importance, since position

and orientation are specified by the process.

Compared to the forward transformation, however,

the inverse or backward transformation for an open

kinematic chain is much more complicated. However,

there is no generally applicable method that can be

applied to all types of robots. This paper presents the

application of a geometric approach for the inverse

transformation in the simulation model. This is

subdivided in two problems: the special backward

calculation for determining joint angles one to three

as well as the explicit backward calculation for joint

Schleinitz, A., Schöberlein, C., Sewohl, A., Schlegel, H. and Dix, M.

Modelling of a 6DoF Robot with Integration of a Controller Structure for Investigating Trajectories and Kinematic Parameters.

DOI: 10.5220/0012203700003543

In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023) - Volume 1, pages 697-703

ISBN: 978-989-758-670-5; ISSN: 2184-2809

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

697

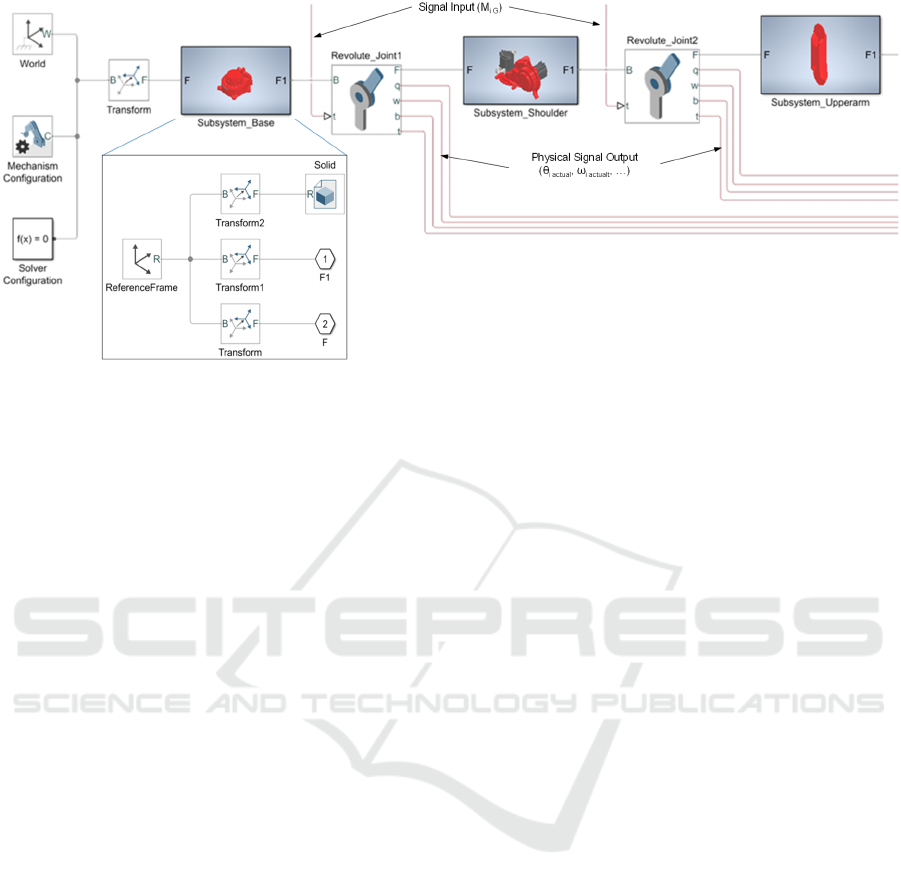

Figure 1: Structure of the Multi-Body model designed in MatLab-Simulink

®

.

angles four to six (Siegert, 1996). In Addition, the

model is connected to a drive-specific controller

structure in MatLab-Simulink

®

. This combination

enables the investigation of robot behaviour and

kinematic joint parameters depending on a given

trajectory and the overall model forms the basis for

further analyses in future.

2 MODEL DEVELOPMENT

2.1 Multi-Body Model

Initially, it is necessary to create the physical robot

structure in MatLab. The model is based on a Comau

NJ130 2.05 robot created with aid of MatLab-

Simcape

®

. The overall structure is shown in Fig. 1.

First of all, the global coordinate system (World

Frame) to which the model is aligned has to be

defined. For this purpose, a function block is

generated which, among other things, reflects the

value and the direction of the prevailing gravity

(Mechanism Configurator). In addition, a solver

(Solver Configuration) must be specified. These three

function blocks are connected with a Rigid Transform

function block, which enables a manipulation of the

alignment of the connected structures.

The Rigid Transform function block is followed

by a subsystem that contains the structure for the first

link (robot foot). Each subsystem has two ports that

form the physical connection to the neighbouring

elements. In each subsystem, a Rigid Transform

function block is set after or before each port. This

allows the geometric robot structure to be taken into

account. The translational and rotational

specifications define the connection points for

neighbouring elements. These are aligned in such a

way that they correspond to the Denavit &

Hartenberg nomenclature (DH nomenclature) (cf.

table 1). Likewise, at least one solid (File Solid) is

modeled in a subsystem and connected to the existing

structure with a Rigid Transform function block. With

the File Solid function block, geometry, material and

visual properties can loaded an external file into the

model. Masses and centers of gravity of the solids can

also be defined and included in the model. It is also

possible to insert a Reverence Frame in each

subsystem.

In the robot’s kinematic chain, the Robot base

subsystem is followed by a revolute joint. For

modelling, a Revolute Joint function block is used

whose axis of rotation is always oriented in the z-

direction as a consequence of the arrangement of the

Rigid Transform function block at the ports of the

subsystems. Likewise, the upper and lower limits are

specified in the rotary joint according to the robot data

sheet (Comau, 2023). However, further properties

can be added to the revolute joint. They serve as

actuators to which a torque can be applied. At the

same time, Revolute Joint function blocks can serve

as sensors and provide angular position and velocity

via physical signal ports. For further modelling of the

robot, another subsystem (robot shoulder) is

connected to the second port of the revolute joint (F).

According to this procedure, the entire kinematic

chain of the robot is built up.

2.2 Controller Structure

In order to move the created robot structure in a

targeted manner, it is necessary as a further step to

model a corresponding controller structure for the six

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

698

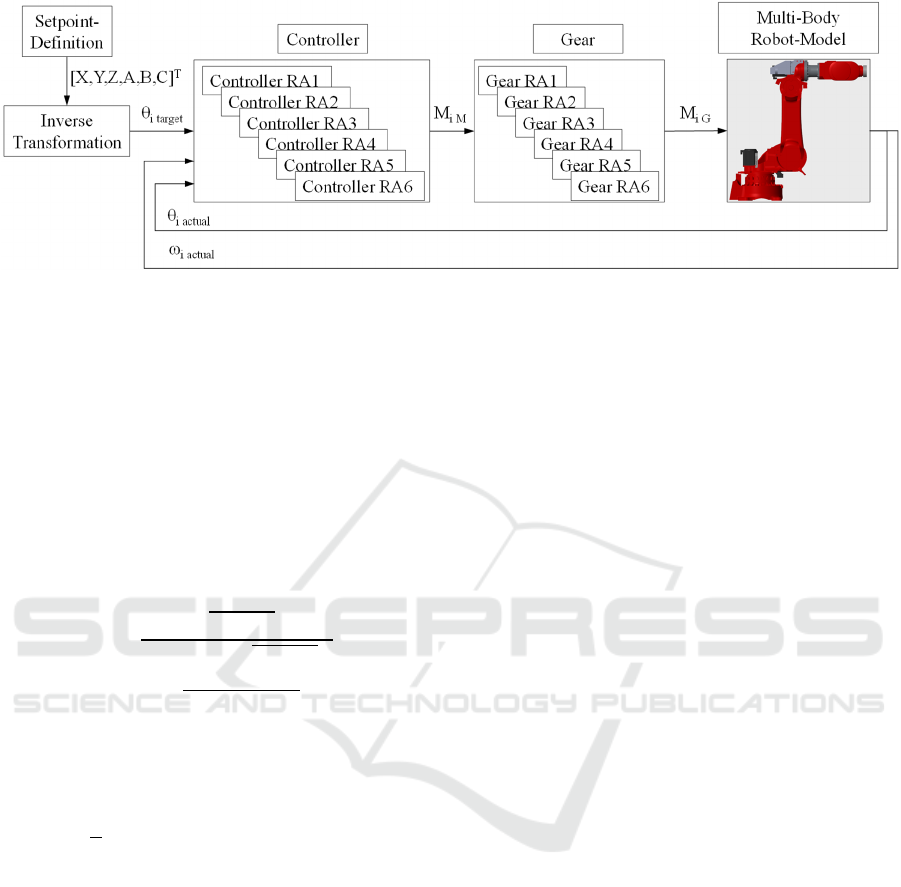

Figure 2: Signal diagram of the position control with

simplified speed control loop.

axes. For this purpose, a controller structure is created

in MatLab-Simulink

®

. The design required for the

simulation follows the explanations of GROß,

HAMANN, WIEGÄRTNER (cf. Groß, 2006). The

authors describe the creation of a simplified speed

control loop in which the current control loop is

included in the sum of the small delay times of the

speed control loop (T

σn

) For this purpose, the

substitute structure and its setting variables are

determined for the speed control loop. In the further

course, the controller structure is extended by a

superimposed position control loop. The model thus

follows a cascade structure (cf. figure 2).

For the calculation of suitable controller

parameters, specific variables of the drives and the

servo inverters must be included. Drive RA1 is used

as an example to describe the parameterization (cf.

table 1).

Table 1: Controller Parameters (RA1).

Parameter Name Sign Value

Sample time current

loo

p

T

Ai

125e-6 s

Sample time speed

control loo

p

T

An

125e-6 s

Sampling time

p

osition control loop

T

Ax

4000e-6 s

Motor constant

K

m

1.23 Nm/A

As already mentioned, the calculation of the

controller parameters follows the explanations of

GROß, HAMANN AND WIEGÄRTNER (cf. Groß,

2006) and takes into account the optimization rule of

the symmetrical optimum. A high damping (0.707)

was assumed for the determination of the equivalent

time constant in the speed control loop system (

T

En

).

This means that there is a sufficiently large phase

reserve, which represents a criterion for controller

stability. Likewise, for the calculation of the gain

factor in the position controller (K

v

), a significantly

higher damping has been assumed, taking into

account formula 1. This leads to a lower K

V

value and

consequently to a reduced overshoot. All determined

controller parameters for drive 1 are listed in table 2.

This procedure is carried out analogously for all

six drives. Equal sampling times are used while motor

constants are adjusted according to data sheets.

𝐾

1

2∗𝑇

(1)

Table 2: Controller Parameters (RA1).

Controller parameter Sign Value

Equivalent time constant of

current control loop

T

Ei

3.6e-04 s

Equivalent time constant speed

control loop

T

En

0.0012 s

Sum of the small time constants of

the s

p

eed control loo

p

T

N

6.1e-04 s

Gain factor speed controller K

P

6.3934

Nms/ra

d

Equivalent delay time of the speed

control loop

T

n

0.0024 s

Speed setpoint delay time T

Gn

0.0024 s

Sum of the small time constants of

the

p

osition control loop

T

x

0.0096 s

Gain factor position controller K

v

0.5210 s

-1

3 TRANSFORMATIONS

3.1 Forward Transformation

The Comau NJ130 2.05 is a 6-DoF robot whose

structure as well as position and orientation of the

coordinate systems of the axes are shown in figure 3

(Comau, 2023). In order to describe the robot

kinematics unambiguously in mathematical terms,

the DH convention has been established (Denavit and

Hartenberg, 1955). The parameters for the robot used

are listed in table 3.

Figure 3: Comau NJ130 2.05.

Modelling of a 6DoF Robot with Integration of a Controller Structure for Investigating Trajectories and Kinematic Parameters

699

Table 3: DH-Parameters for Comau NJ130 2.05.

Link θ

i

a

i

[m] d

i

[m] α

i

[°]

1 var 0.40 0.55 -1.570796

2 var 0.86 0 0

3 var 0.21 0 -1.570796

4 var 0 0.7615773 1.570796

5 var 0 0 -1.570796

6 var 0 0.21 0

The six linked axes are described by four DH

parameters joint angle (θ

i

), arm lengh (a

i

), joint offset

(d

i

) and torsion angle (α

i

) (Mareczek, 2020a).

Furthermore, axis-specific rotational and

translational transformation matrices leads to form

the general A-matrix according to formula 2.

A

cos𝜃

sin𝜃

cos𝛼

sin𝜃

sin𝛼

𝑎

cos𝜃

sin𝜃

cos𝜃

cos𝛼

cos𝜃

sin𝛼

𝑎

sin𝜃

0sin𝛼

cos𝛼

𝑑

00 01

(2)

Knowing all joint positions and DH parameters as

well as the calculation by means of the A-matrix, the

position of the TCP with respect to the robot base,

which at the same time represents the base coordinate

system, can be calculated according to formula 3.

T

A

A

∗

A

∗

A

∗

A

∗

A

∗

A

(3)

3.2 Inverse Transformation

For practical use, however, knowledge of robot joint

position as a function of TCP-position and pose is of

outstanding importance, since position and pose are

specified by the process. Compared to the forward

transformation, however, the inverse or backward

transformation for an open kinematic chain is much

more complicated. There is no generally applicable

method for this. The basic solution approaches are

divided into algebraic, numerical and geometric

methods (Goldenberg et al. 1985). In the present

model, the inverse transformation is solved using a

geometric approach, which assumes that joint axes

four to six intersect at the wrist root (S4) (Siegert,

1996). The overall approach is subdivided of two

subproblems: the special backward calculation for

determining joint angles one to three as well as the

explicit backward calculation for joint angles four to

six. The wrist position of the robot is defined by the

first partial solution and orientation of the end

effector by the second partial solution. In addition, to

obtain a unique solution, three configuration

parameters (ARM, ELBOW, FLIP) were selected

depending on the existing configuration (cf. Siegert,

1996).

For the special inverse calculation, knowledge of

carpus position (S4) is decisive which is calculated

from:

𝑆4

𝑝

𝑝

𝑝

𝑝

𝑝

𝑝

𝑑

∗

𝑎

𝑎

𝑎

(4)

From knowledge of S4, its projection on the x

0

- y

0

surface results as S4’. With this relationship, joint

angle θ

1

can now be determined as function of the

present robot configuration:

𝜃

𝑎𝑟𝑐𝑡𝑎𝑛2

𝐴

𝑅𝑀 ∗𝑝

;

𝐴

𝑅𝑀 ∗𝑝

(5)

Now, to determine the joint angle θ

2

, a

1

and d

1

must be taken into account, so that only the position

between S1 to S4 is considered:

𝑞

𝑝

𝑝

𝑝

𝑝

𝑝

𝑝

𝑎

𝑎

𝑑

∗

𝑐𝑜𝑠

𝜃

𝑠𝑖𝑛𝜃

1

(6)

Knowing q' and R', relationships for the auxiliary

angles sin(α) and cos(α) as well as for sin(β) and

cos(α) can be derived (cf. figure 4). Taking into

account the robot configuration parameters ARM and

ELBOW as well as the addition theorem for angular

functions, one obtains the following equations:

Figure 4: Comau NJ130 2.05 with angular relations.

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

700

Figure 5: Simulation model.

𝑠𝑖𝑛

𝜃

𝑠𝑖𝑛

𝛼

∗𝑐𝑜𝑠

𝛽

𝐸𝐿𝐵𝑂𝑊∗

𝑐𝑜𝑠

𝛼

∗𝑠𝑖𝑛

𝛽

(7)

cos

𝜃

𝐴

𝑅𝑀∗ 𝑐𝑜𝑠

𝛼

∗ cos

𝛽

𝐴

𝑅𝑀∗

𝐸𝐿𝐵𝑂𝑊∗ 𝑠𝑖𝑛

𝛼

∗sin

𝛽

(8)

Using the arctangent-2 function, this determines

the joint angle θ

2

.

𝜃

𝑎𝑟𝑐𝑡𝑎𝑛2𝑠𝑖𝑛

𝜃

;cos

𝜃

(9)

To calculate joint angle θ

3

, the auxiliary angle ψ

is initially determined from:

𝑐𝑜𝑠

𝜓

𝑎

𝑎

𝑑

𝑞

2 ∗ 𝑎

∗𝑎

𝑑

(10)

sin

𝜓

1

cos

𝜓

(11)

Applying the arctangent-2 function again, the

auxiliary angle ψ is obtained. This is inserted into the

following formula, which calculates joint angle θ

3

.

𝜃

𝜋

2

𝐴

𝑅𝑀∗𝐸𝐿𝐵𝑂𝑊∗𝜓𝜋

(12)

The Explicit-Backward-Calculation is described

in (Siegert, 1996) and can be applied to this robot

considering the present DH parameters.

3.3 Overall Model

Eventually an overall model is created from the

modeled components (cf. figure 5). It contains the

multi-body robot model, which is connected to the

control structure. Thus, the actual joint angle position

(θ

i actual

) and the actual joint angle velocity (ω

i actual

) are

fed back into the control structure. In addition, a

setpoint generator and gear stages between controller

and robot complete the model. Hence, it is possible to

specify the setpoint position (X,Y,Z) as well as the

pose (A,B,C) as angle information in the global

coordinate system continuously in time. The target

values are converted into corresponding joint angles

(θ

i target

) by means of inverse transformation and

transferred to the controller. The axis-specific

controllers determine the joint angle deviation and

balance them out.

4 RESULTS

To verify the Simscape multi-body model, it is

possible to specify the corresponding joint angles

directly. If these joint angles are all set equal to "0",

the robot position from figure 3 is obtained. This

position is described in the manual (Comau, 2023)

and leads to a TCP of

P0 = [1.37158 0 1.62 0 1.5708 0]

T

considering the

described DH parameters. The model leads to the

identical TCP.

To check the inverse transformation, P0 is used as

a setpoint specification. Inverse transformation

should determine the corresponding joint angles. The

TCP-resulting from the simulation model is identical

to the specified point P0.

To derive meaningful conclusions, it is necessary

to compare the model with the real system. For this

purpose, a real Comau NJ130 2.05 robot is available

for comparative tests. The aim is to keep the

deviations between the model and the real system as

small as possible with regard to the subsequent

focused points of the investigation.

First, a static consideration of joint-specific

torques (M

i M

) at input of the transmission using TCP

position P0 is carried out. Table 4 compares the joint-

specific holding torques for the TCP position. All

deviations are neglectable small and can be explained

by simplifications of the model. For example, friction

and damping in the gears and joints have not been

considered.

Modelling of a 6DoF Robot with Integration of a Controller Structure for Investigating Trajectories and Kinematic Parameters

701

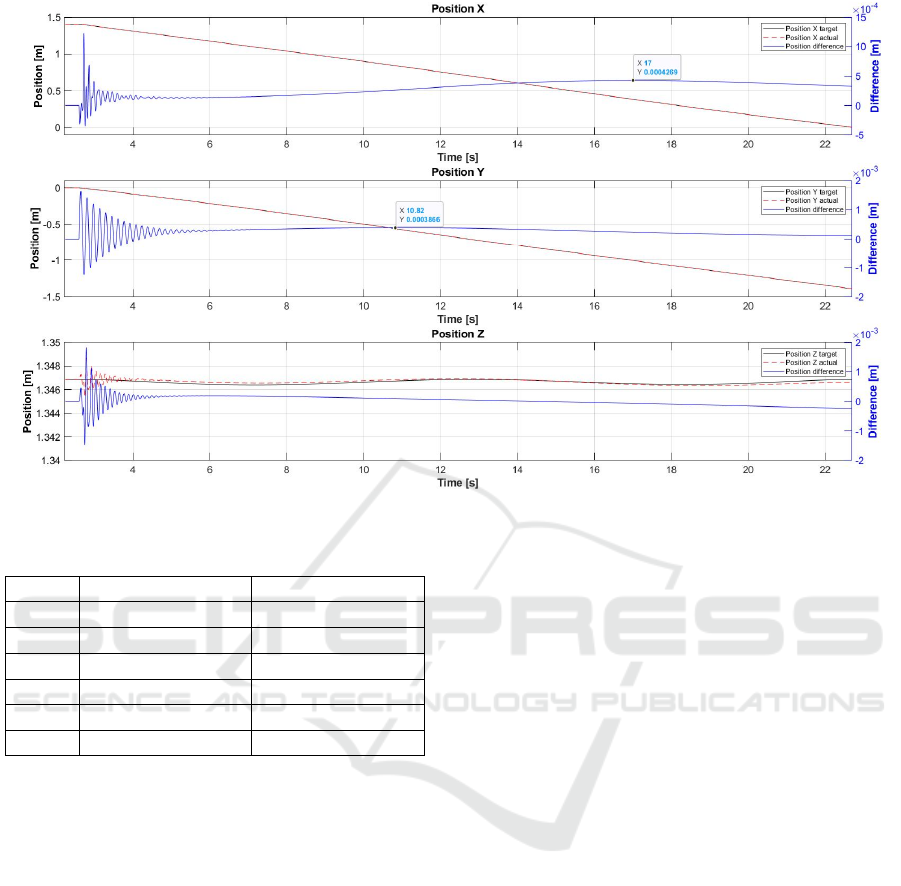

Figure 6: TCP-Position of the simulation-model (P1 to P2).

Table 4: Motor Torque [Nm] on P0.

Jerk Simulation Comau NJ130 2.05

1 0 0.1

2 -6 -5.89

3 -5.741 -5.94

4 0 0

5 -1.572 -1.52

6 0 0.02

By means of setpoint specification and inverse

transformation, a motion execution is possible. The

simulation model was given a trajectory which leads

directly from P1 = [1.3975 0 1.3469 0 1.5708 0]

T

to

P2 = [0 1.3975 1.346 0 1.5708 1.5708]

T

. The TCP-

curves of the setpoint specification and the realized

trajectory are shown in figure 6. Only small

deviations of the two curves can be seen. In

X-direction as well as in Y-direction 0.3 mm each.

However, the oscillations at the beginning of the

movement are particularly noticeable. These

originate from the actual curve and should be quickly

compensated by the corresponding controllers. It

must be taken into account that overshooting is

problematic in robotics, since it can lead to collisions

of the robot with the environment (Mareczek, J.,

2020b). Regardless of this, the occurrence of this

transient behavior is an indication of insufficient

regulation of the system.

Figure 7 shows the comparison of the TCP-

position of the trajectories between the simulation

model and the real system. Only the actual trajectories

are considered, which again lead on a direct path from

P1 to P2. During this movement, θ

1

must rotate by

-90°. First of all, it can be stated that deviations of the

given trajectory between simulation model and real

system are recognizable, the maximum of which is

amount to 19.61 mm for position X, 15.68 mm for

position Y and 1 mm for position Z. It is striking that

the largest deviations between the two trajectories

occur between 0° and -45° and between -45° and

-90°. Taking into account the small deviations

between target and actual positions from the

simulation model (cf. figure 6), only the desired value

generation or the inverse transformation can be

considered as the cause and therefore should be

optimized for further investigations.

5 SUMMARY AND OUTLOOK

For a 6-DoF robot (Comau NJ130 2.05), the DH

convention was used to show the forward

transformation. The inverse transformation was

solved with a geometric approach. Hence, the inverse

transformation is devided into two subproblems, the

special and the explicit inverse. A simulation model

was created in which both transformations were

linked with a multi-body model and supplemented by

an axis-specific controller structure. With this

approach for the inverse transformation, a suitable

ICINCO 2023 - 20th International Conference on Informatics in Control, Automation and Robotics

702

Figure 7: TCP-Position simulation model vs. real system (P1 to P2).

overall model was developed, which can form the

basis for further analysis regarding controller

parameters together with kinematic joint parameters

as a function of a given trajectory.

It was shown that the static holding torques at the

input to the gearbox are comparable between

simulation model and real system. It was also shown

that the realized trajectory in the simulation model

exhibited only very slight deviations compared to the

predefined trajectory. In comparison with a real

system, however, larger deviations were found.

At the start of the movement of the simulation

model, there are rigid oscillations which are only

slowly eliminated. Thus, the control system appears

to be insufficient. For this purpose, the controller

structure should be adapted by a more precise

modelling of the current, speed and position control

loop, resulting in a more complex controller cascade.

After optimizing the controller structure of the

individual joints, the overall model is ready for

further analysis. In particular, analyses with reference

to specific, predetermined trajectories and their

resulting kinematic parameters at the TCP and in the

joints become possible.

REFERENCES

Abele, E., Bauer, J., Rothenbücher, S. Stelzer, M., von Stryk,

O. (2008), Prediction of the Tool Displacement by

Coupled Models of the Compliant Industrial Robot and

the Milling Process, Proceedings of the International

Conference on Process Machine Interactions, pp. 223-

230.

Lin, Y., Zhao, H., Ding, H. (2017), Posture optimization

methodology of 6R industrial robots for machining using

performance evaluation indexes. Robotics and

Computer-Integrated Manufacturing, Volume 48,

pp. 59-72.

Hu, Y., Zhang, S., Chen, Y. (2023), Trajectory Planning

Method of 6-DOF Modular Manipulator Based on

Polynomial Interpolation, Journal of Computational

Methods in Sciences and Engineering, pp. 1-12.

Zhu, Z., Tang, X., Chen, C., Peng, F., Yan, R., Zhou, L., Li,

Z., Wu, J. (2022). High precision and efficiency robotic

milling of complex parts: Challenges, approaches and

trends. Chinese Journal of Aeronautics, Volume 35,

Issue 2.

Metzner, M., Weissert, S., Karlidag, E., Albrecht, F., Blank,

A., Mayr, A., Franke, J. (2019), Virtual Commissioning

of 6 DoF Pose Estimation and Robotic Bin Picking

Systems for Industrial Parts, IFAC-PapersOnLine,

pp. 160-164.

Groß, H., Hamann, J., Wiegärtner, G. (2006). Elektrische

Vorschubantriebe, Publicis Kommunikations Agentur

GmbH, GWA, Erlangen.

Denavit, J., Hartenberg, R.S. (1955). A Kinematic Notation

for Lower-Pair Mechanisms Based on Matrices. ASME

Journal of Applied Mechanics, 22, pp. 215-221.

Comau (2023), Comau_Nj13020_Workingareas, Comau

S.p.A., Grugliasco.

Mareczek, J. (2020a). Grundlagen der Roboter-

Manipulatoren – Band 1: Modellbildung von Kinematik

und Dynamik. Berlin: Springer Vieweg.

Goldenberg, A., Benhabib, B., Fenton, R. (1985). A complete

generalized solution to the inverse kinematics of robots,

IEEE Journal on Robotics and Automation, vol. 1, no. 1,

pp. 14-20.

Siegert, H. (1996). Robotik: Programmierung intelligenter

Roboter. Berlin: Springer.

Mareczek, J. (2020b). Grundlagen der Roboter-

Manipulatoren – Band 2: Pfad- und Bahnplanung,

Antriebsauslegung, Regelung. Berlin: Springer Vieweg.

Modelling of a 6DoF Robot with Integration of a Controller Structure for Investigating Trajectories and Kinematic Parameters

703